Six-dimensional force sensor dynamic calibration device and calibration method thereof

A six-dimensional force sensor and dynamic calibration technology, which is applied in the direction of measuring devices, instruments, force/torque/power measuring instrument calibration/testing, etc. It is difficult to control the magnitude, direction and action point of the force, poor repeatability and accuracy, etc., to achieve the effect of stable and continuously adjustable loading force value, good dynamic performance and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

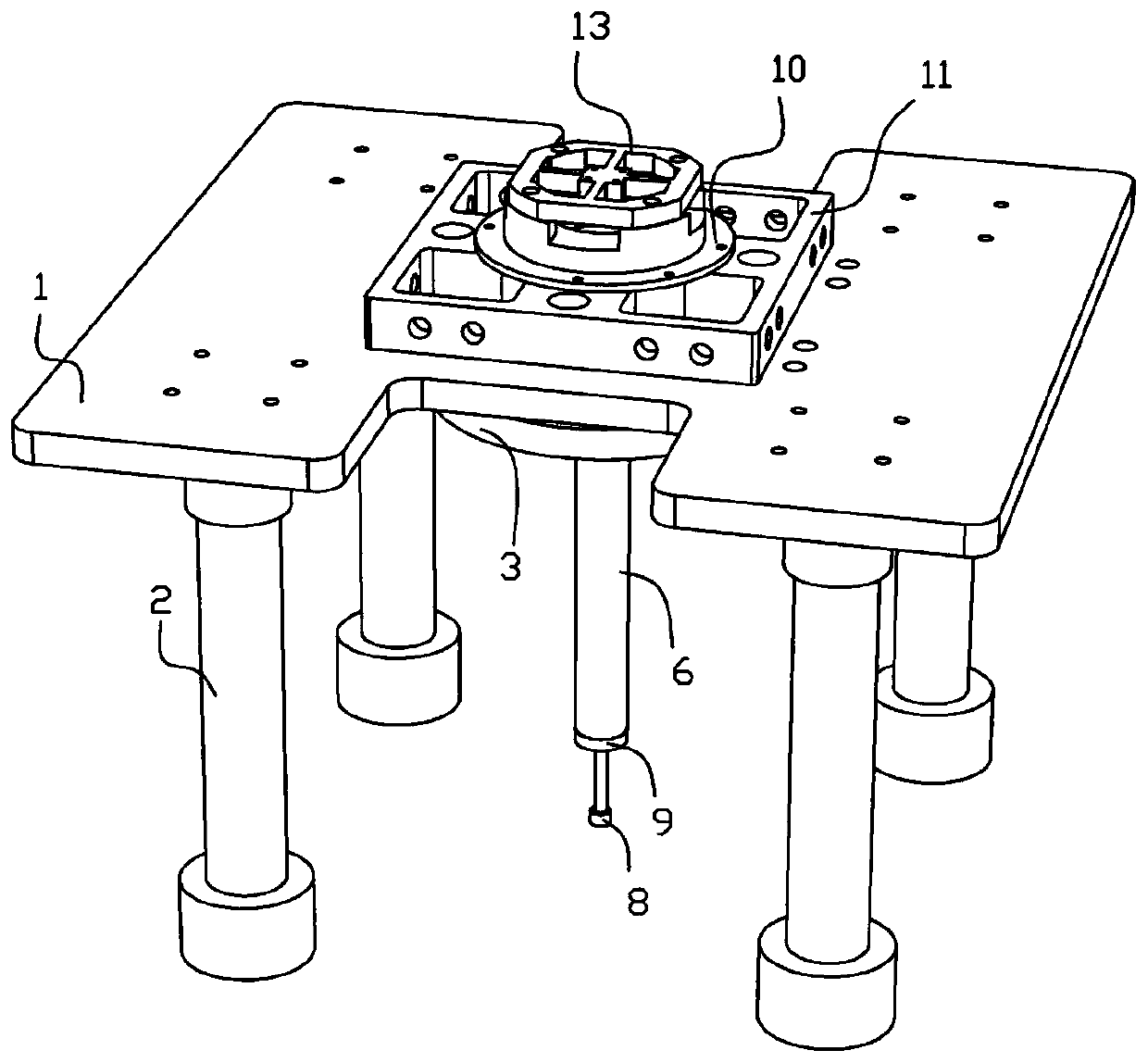

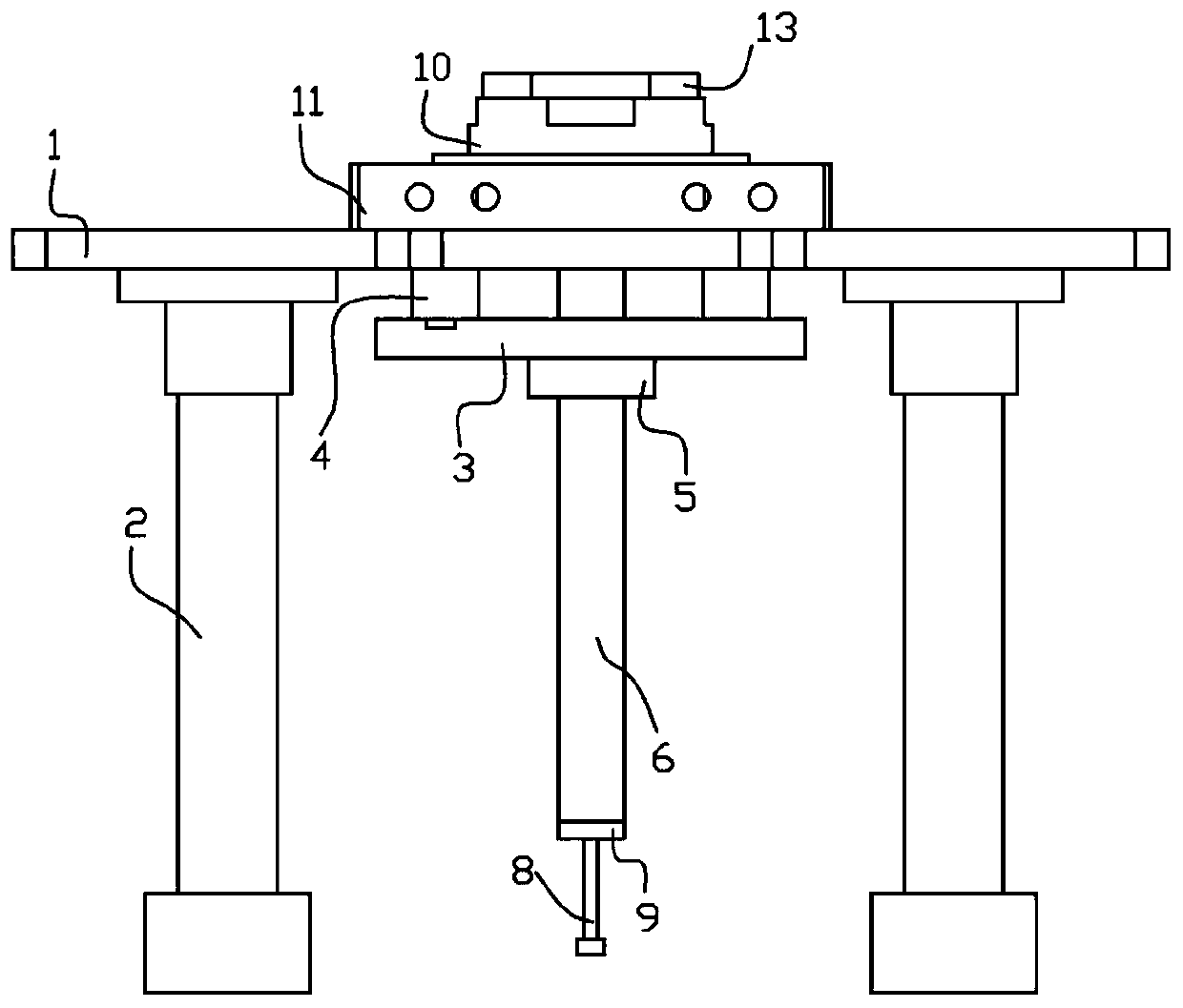

[0043] Embodiment 1, the six-dimensional force sensor dynamic calibration device of this embodiment includes a calibration platform 1, a pulse force loading device and a fixing device for fixing the force sensor to be measured. There are multiple sets of positioning holes on the surface of the calibration table for installing fixtures in different orientations.

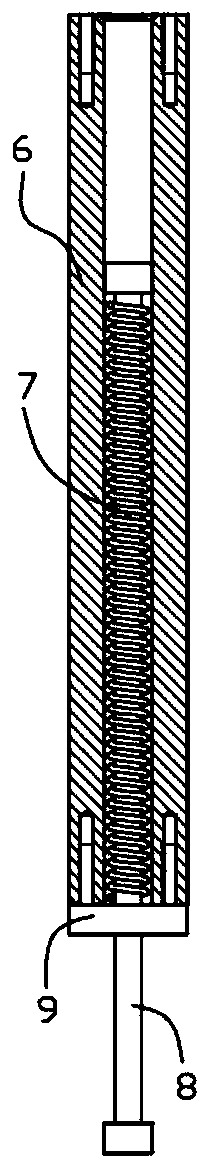

[0044] The specific structure is that a through hole is provided in the middle of the calibration platform for the passage of the small ball that exerts force on the sensor. The aforementioned pulse force loading device includes a sleeve 6 fixedly installed on the bottom surface of the calibration platform, and a spring coaxially arranged in the sleeve. Pull rod 8 and the spring 7 that is sleeved on the spring pull rod 8, the two ends of spring 7 are respectively with the upper end of spring pull rod and the spring that is installed on the sleeve bottom. end cap 9 is a spring seat; figure 1 , 2 As shown, the sleev...

Embodiment 2

[0047] Embodiment 2, adopting above-mentioned calibration device to carry out the dynamic calibration method of six-dimensional force sensor, it comprises the following steps:

[0048] S1. For force calibration, first adjust the calibration platform to a horizontal state through the adjustable outriggers;

[0049] S1-1. Install the mounting base horizontally on the calibration platform, install the six-dimensional force sensor to be tested on the base, fix the base on the mounting base, and adjust the position of the mounting base through different mounting holes so that the six-dimensional force The z-axis of the sensor coincides with the axis of the pulse force loading device; put the ball into the sleeve, pull down the spring rod to the set position, and then release it, the ball hits the six-dimensional force sensor to generate a z-direction pulse excitation force, through The displacement sensor, laser vibrometer, acceleration sensor and other instruments measure and reco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com