Bearing centrifugal testbed

A centrifugal test and bearing technology, which is used in mechanical bearing testing, mechanical component testing, and machine/structural component testing, etc. It can solve the problem that the operation is not convenient enough to use, the testing and testing equipment cannot provide good vibration effects, and the structure of the test bench complex issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

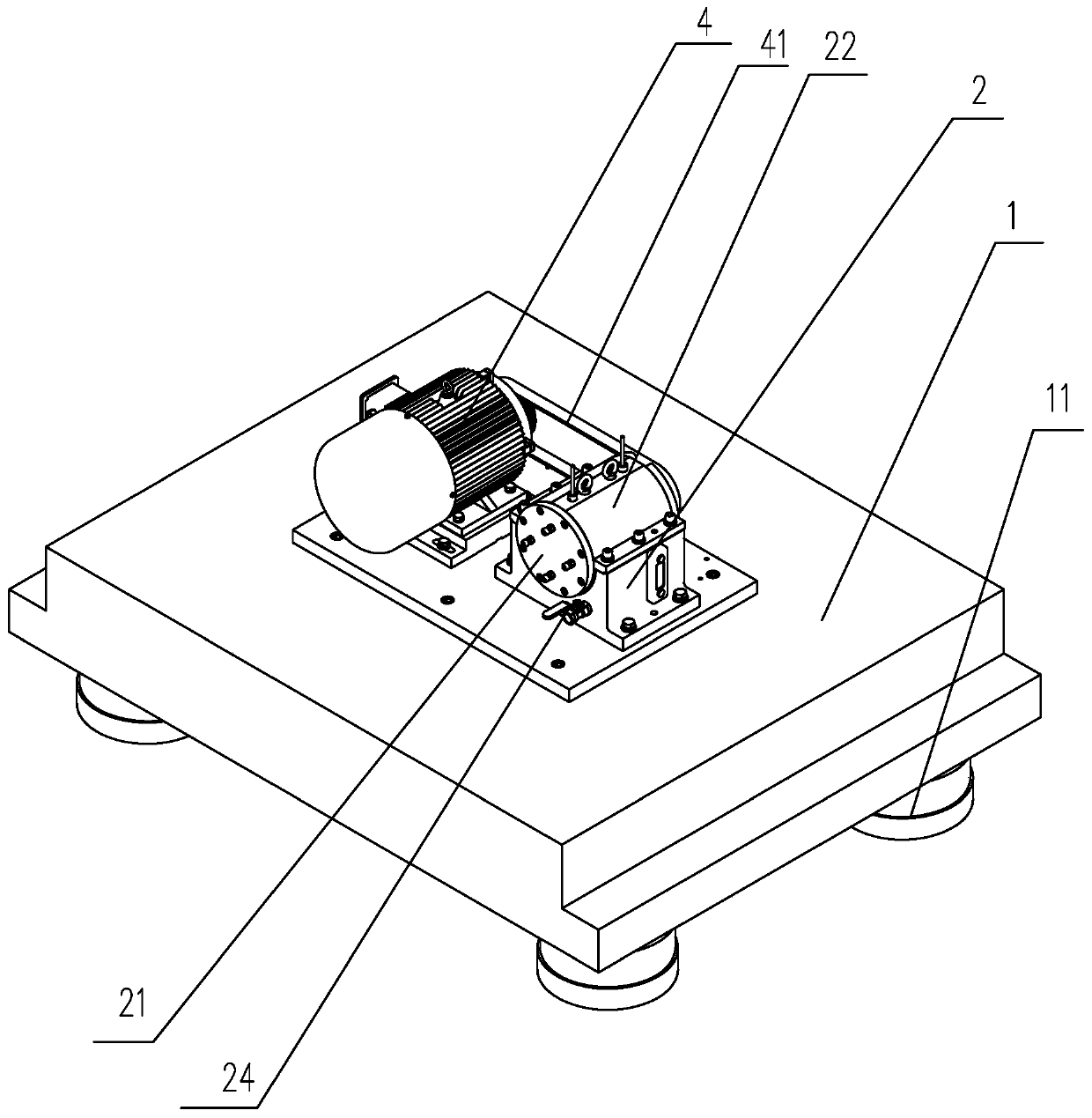

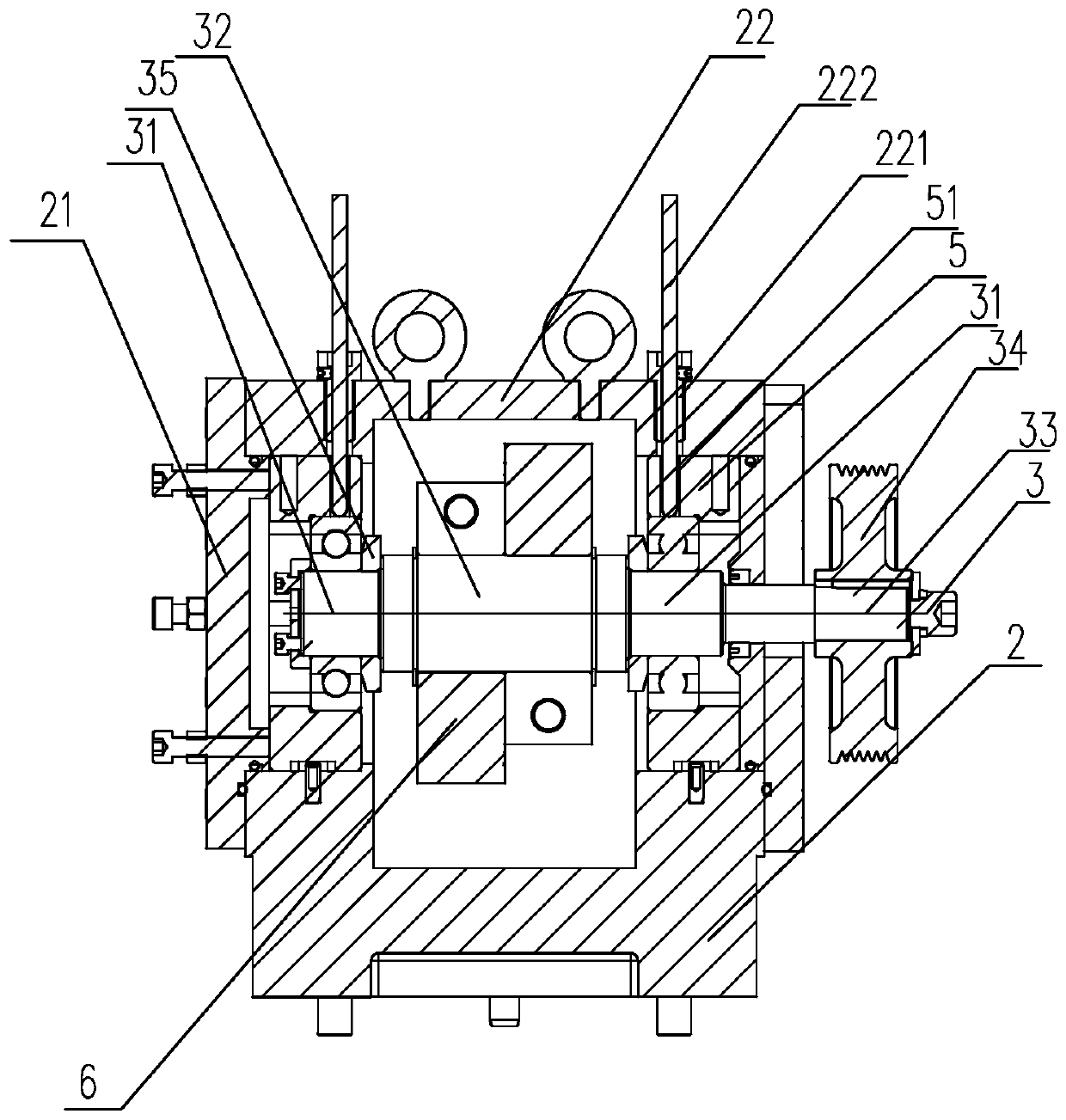

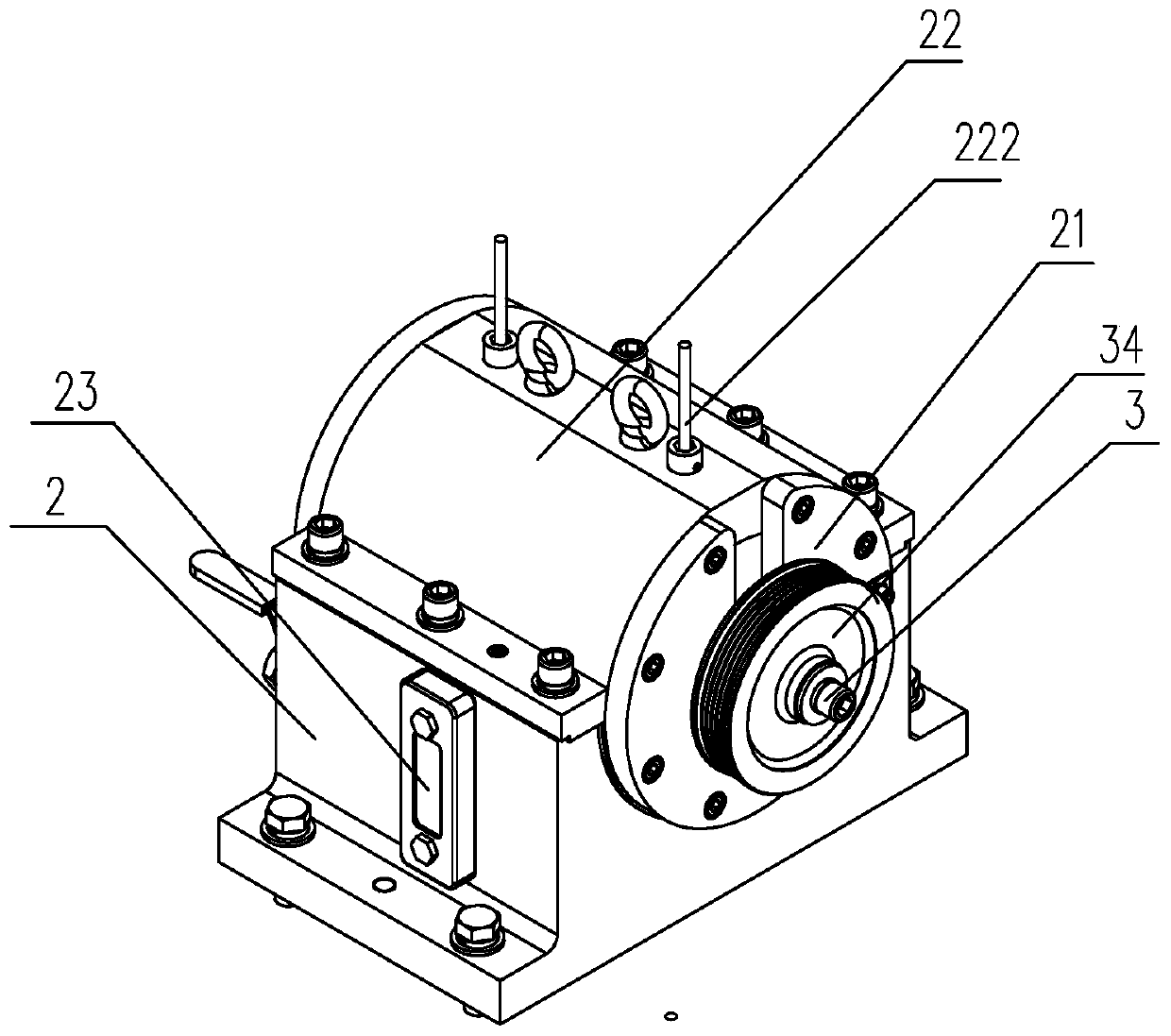

[0023] Depend on Figure 1 to Figure 5 It can be seen that a bearing centrifugal test bench is disclosed, including a bearing seat 1, a drive motor 4 and a test bench 2 for installing the bearing to be tested, the test bench 2 is set on the bearing seat 1, and the drive motor 4 is set On the bearing and arranged on one side of the test bench 2, a mounting groove is formed on the test bench 2, and a mandrel 3 is arranged in the mounting groove, and the mandrel 3 is installed in the mounting groove through a bushing 5, The bush 5 is provided with a positioning groove for installing the bearing to be tested. The mandrel 3 includes a test part 31, a counterweight part 32 and a transmission part 33. The test part 31 is arranged at the corresponding position of the bush 5, so The test part 31 is provided with a backing plate 35 for positioning the bearing to be tested, and the combination of the positioning groove and the backing plate 35 forms the locking of the bearing to be teste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com