Cup sleeve taking-out and stacking tool

A cup sleeve and tooling technology, which is applied in the field of cup sleeve removal and stacking tooling, can solve problems such as excessive sweating, cup sleeve surface adhesion, etc., and achieve the effects of multiple benefits, short molding cycle, and enlarged anti-vibration effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

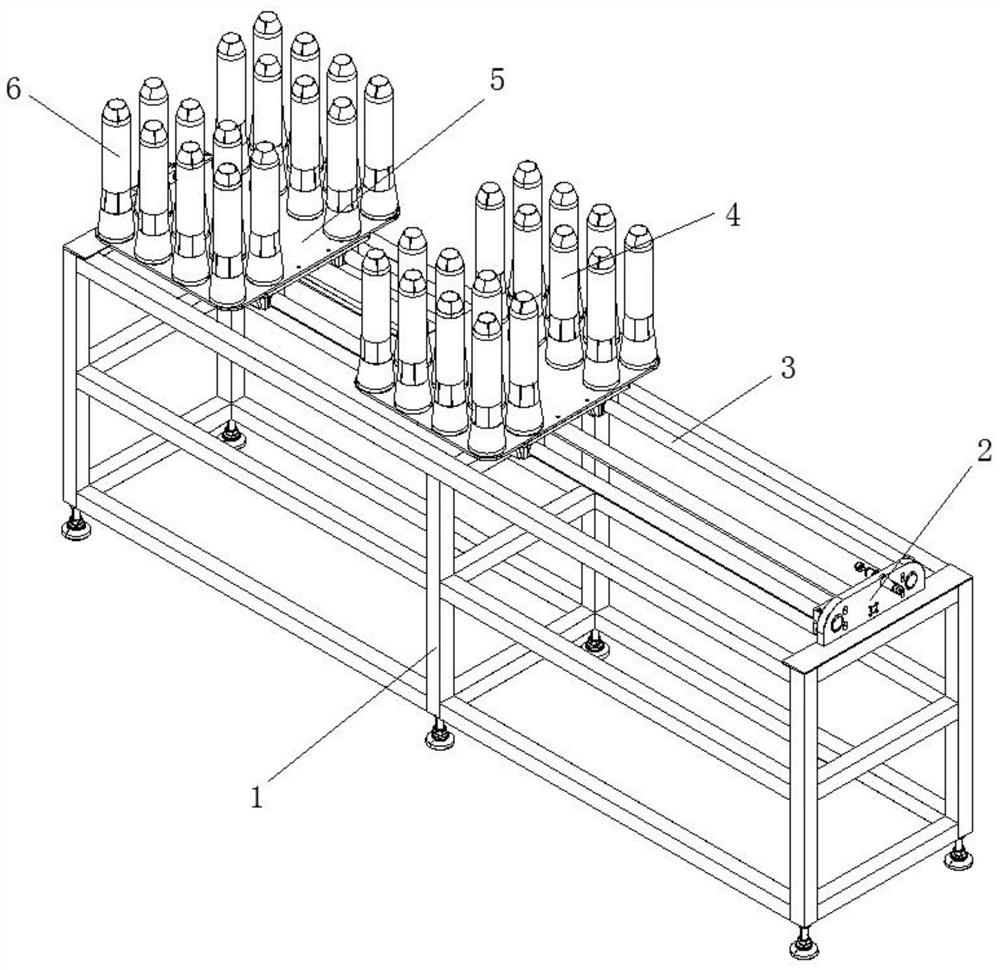

[0033] Such as Figure 1-3 As shown, the present invention provides a technical solution: a cup sleeve removal and stacking tool, including a frame 1, the top of the frame 1 is fixedly connected with a station exchange device 2, and the station exchange device 2 The interior is fixedly connected with a solenoid valve driving cylinder mechanism 3, and the top of the solenoid valve driving cylinder mechanism 3 is slidably connected with a backing plate device 5, and the top of the backing plate device 5 is fixedly connected with A station 6 and B station 4 respectively. ;

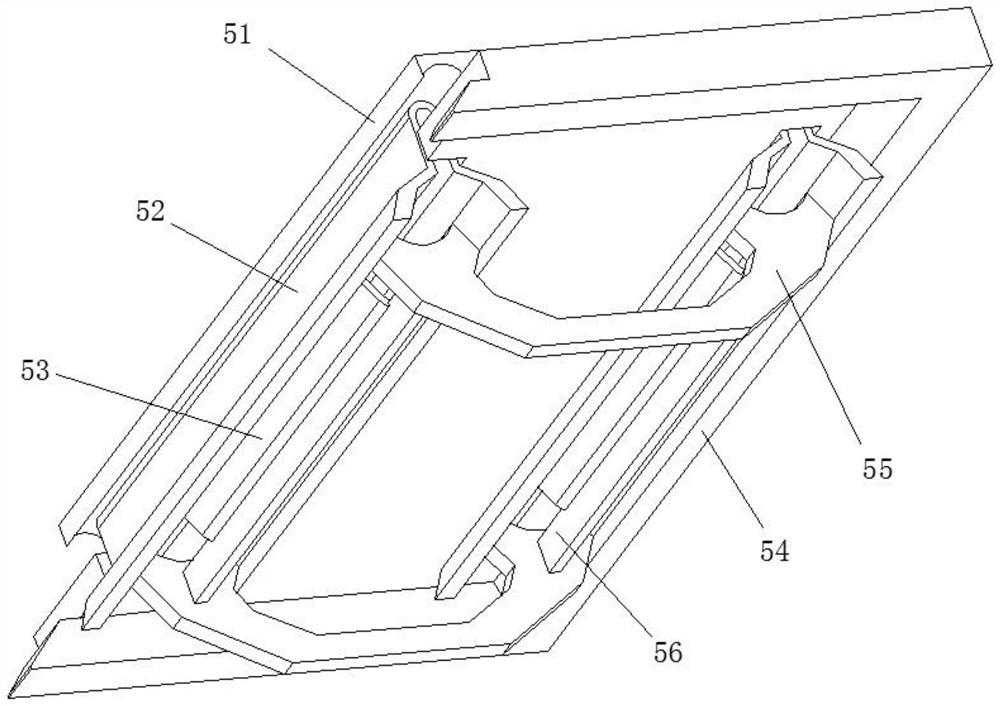

[0034] The backing plate device 5 includes a socket pressing plate 54, an outer supporting folded plate 52 is sleeved inside the sleeve pressing plate 54, and an upper load-bearing backing plate 51 is sleeved on the top of the outer supporting folded plate 52. The upper load-bearing backing plate 51 is fixedly connected under the A station 6 and the B station 4 . The number of times the manipulator complete...

Embodiment 2

[0043] Such as Figure 4-5 As shown, on the basis of Embodiment 1, the present invention provides a technical solution: the B station 4 includes a cup collar bar 401, and the outer surface of the cup collar bar 401 is fixedly connected with a sleeve orifice plate 405 , the outer surface of the sleeve hole plate 405 is provided with an outer cooling hole 403 , and the depression on the outer surface of the cup collar rod 401 is provided with an elastic rubber plate 402 .

[0044] The outer surface of the bottom of the cup collar bar 401 is fixedly connected with a collar 404, the collar 404 is arranged on the outer surface of the elastic rubber plate 402, and the inner surface of the cup collar bar 401 is fixedly connected with a vibration device 410 A rotating shaft 406 is sheathed in the inner cavity of the cup sleeve ring rod 401 .

[0045] The end of the rotating shaft 406 is fixedly connected with a rotating plate 407, the outer surface of the rotating plate 407 is fixedl...

Embodiment 3

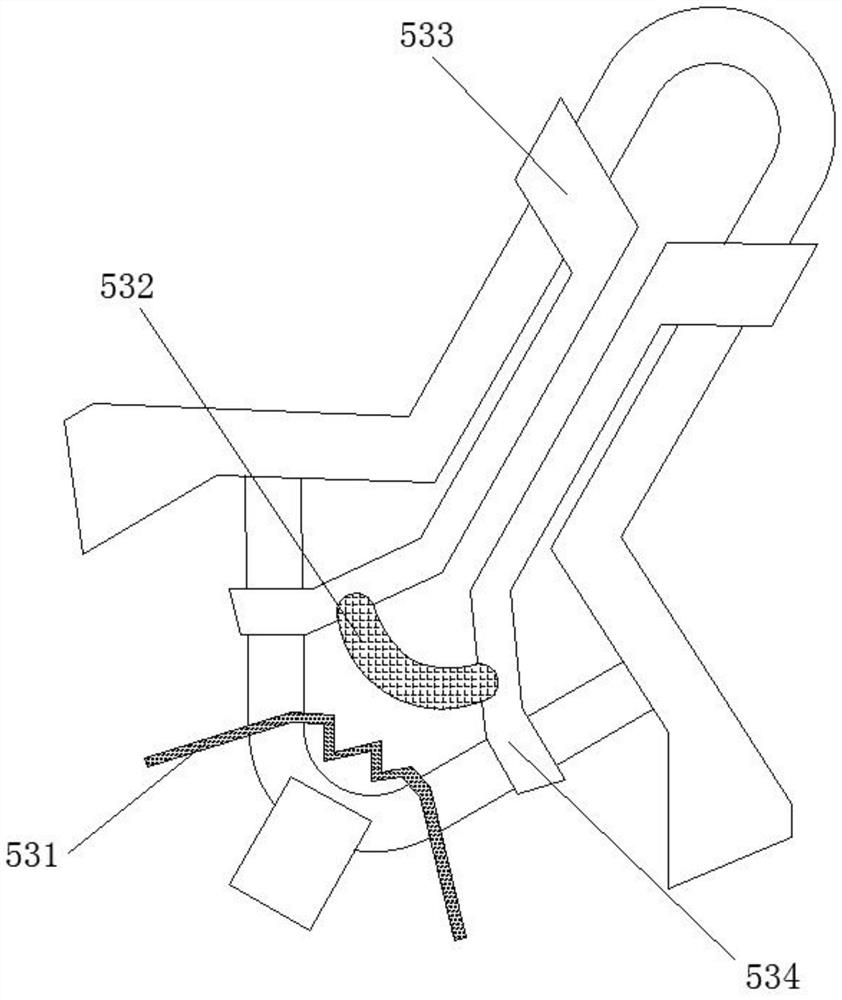

[0049] Such as Image 6 As shown, on the basis of Embodiment 1 and Embodiment 2, the present invention provides a technical solution: the vibration device 410 includes a vibration bending piece 4101 and an outer bonding plate 4103, and the vibration bending piece 4101 and the outer bonding plate 4103 An internal pressure air bag 4102 is provided between the opposite surfaces, and an elastic strut 4106 is fixedly connected to the inside of the outer lamination plate 4103 .

[0050] The outer surface of the outer bonding plate 4103 is sleeved with a sliding sleeve shaft 4104 , and the bottom of the sliding sleeve shaft 4104 is fixedly connected with a friction brush 4105 , and the elastic strut 4106 is extruded and fitted with the vibrating bending piece 4101 . The friction brush 4105 can fit and scrape the inner surface of the cup cover when the vibration bending piece 4101 vibrates, and the contact area between the cup cover and the outer bonding plate 4103 can be reduced by t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com