End-bend blade for improving working stability of gas compressor

A technology of stability and compressor, which is applied to components, mechanical equipment, machines/engines, etc. of pumping devices used for elastic fluids, and can solve problems such as poor working stability of compressors, so as to improve working stability and inhibit flow separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

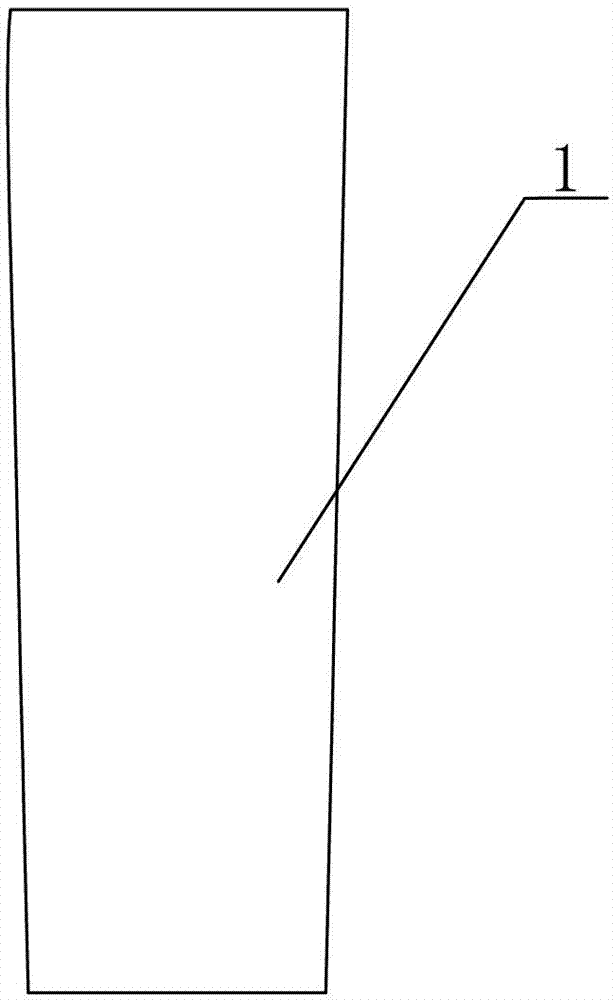

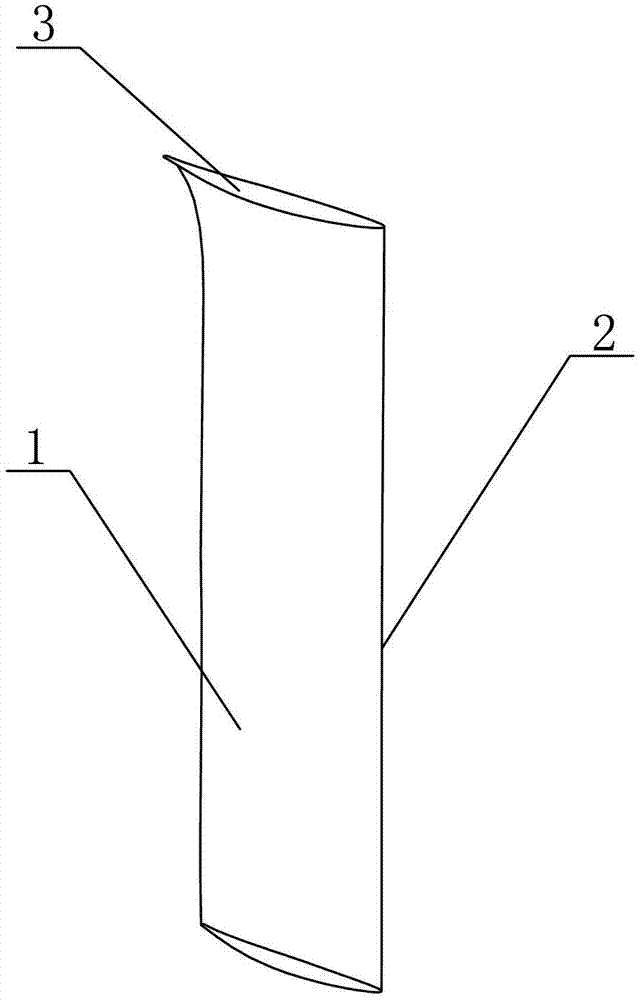

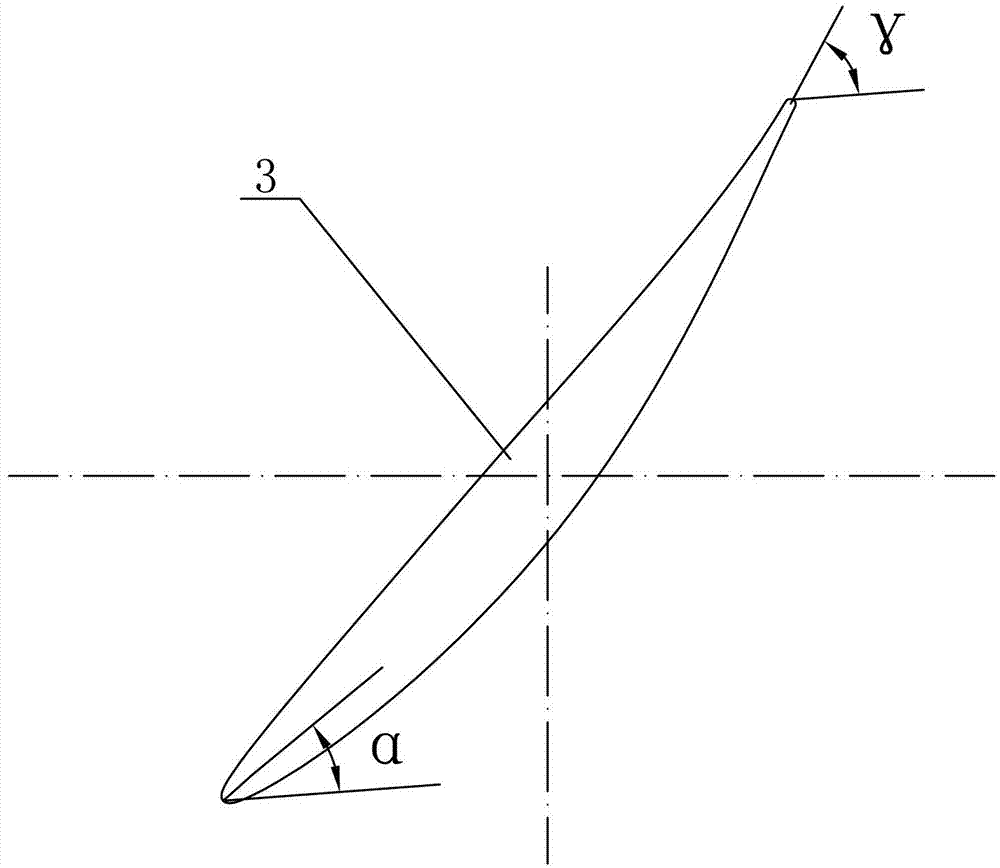

[0007] Specific implementation mode one: combine Figure 1-Figure 3 Describe this embodiment. An end-curved blade used to improve the working stability of a compressor in this embodiment includes a guide vane 1. The upper part of the guide vane 1 is an end-curved area 3, and the end-curved area 3 follows the track of the stacking line 2. Carry out end bending, the end bending height of the end bending area 3 is 7% of the overall height of the guide vane 1, in the end bending height area, the inlet geometric angle of the guide vane 1 increases linearly along the blade height by 0°-10°, the guide vane The end-curved vane at the upper end of 1 is offset from the middle of guide vane 1 to the side of the suction surface by 0mm-7.53mm.

[0008] The outlet geometric angle of this embodiment is γ, γ=57.65°, the chord length is 51.94mm, and the maximum thickness is 6.98mm.

specific Embodiment approach 2

[0009] Specific implementation mode two: combination image 3 To illustrate this embodiment, the end curvature height of the upper part of the guide vane 1 in this embodiment is 11.94 mm, the inlet geometric angle of the guide vane 1 is α, α=45.3°, and the end curve shape of the upper end of the guide vane 1 is relative to the guide vane 1 The offset of the middle part to the side of the suction side is 7.53mm. With this setting, the pressure ratio of the single-stage compressor is increased by 1%, and the isentropic efficiency of the single-stage compressor is increased by 3% compared with that before the modification. It can also effectively suppress the flow separation in the end zone, making the inflow and outflow of the airflow more efficient. Fit the blade curve of the blade, match the angle of the mainstream area of the compressor, and improve the working stability of the compressor. Other components and connections are the same as those in the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Chord length | aaaaa | aaaaa |

| Maximum thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com