Grouting sleeve and prefabricated member

A technology of grouting sleeves and sleeves, which is applied in the direction of building components, building reinforcements, structural elements, etc., can solve problems such as the inability of steel bars to penetrate, increase the ability to resist shear force and tensile strength, and have good integrity , Improve the effect of grouting density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention will be described in detail below in conjunction with the accompanying drawings. The description in this part is only exemplary and explanatory, and should not have any limiting effect on the protection scope of the present invention. In addition, those skilled in the art can make corresponding combinations of features in the embodiments in this document and in different embodiments according to the descriptions in this document.

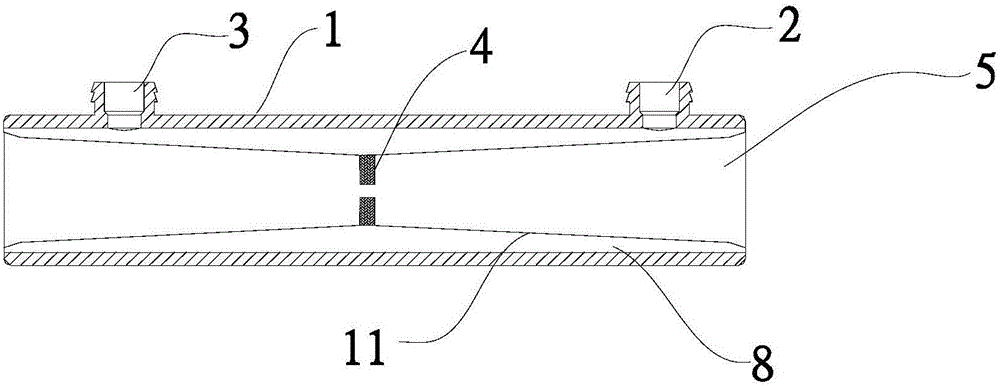

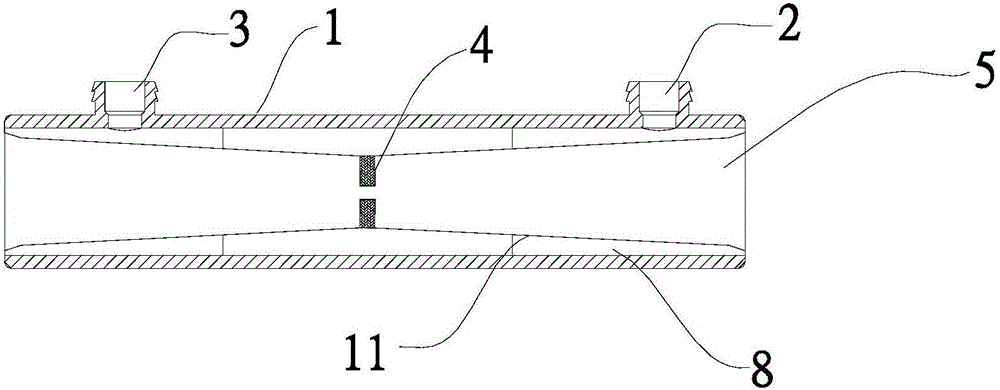

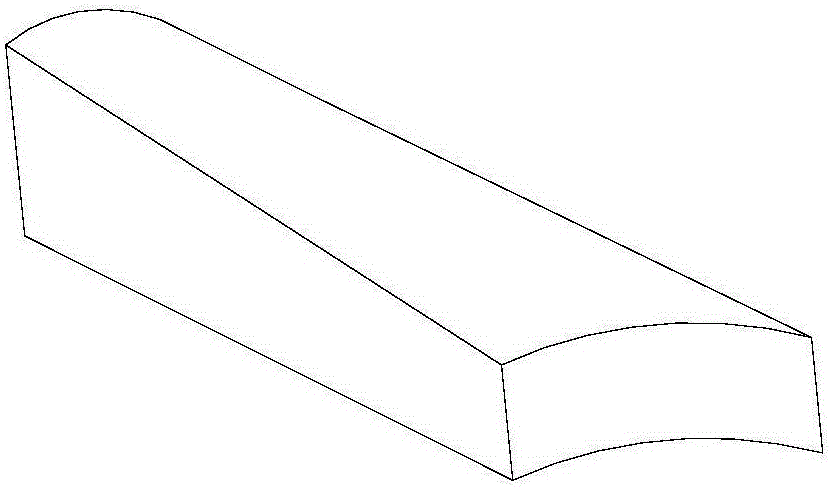

[0049] Embodiments of the present invention are as follows, with reference to Figure 1~6 , a grouting sleeve, including a sleeve body 1, the sleeve body 1 is provided with a grouting port 2 and an exhaust port 3, the two ends of the sleeve body 1 are open, and the inner cavity of the sleeve body 1 is 5 The middle part is provided with a fixing part 4, the inner wall of the sleeve body 1 is provided with a steel petal 8, the thickness of the steel petal 8 gradually increases from both ends of the sleeve body 1 to the mid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com