A manufacturing method of a rotor, a repairing method of the rotor, the rotor and a motor

A manufacturing method and rotor technology, applied in the field of rotors and motors, can solve the problems of generator failure, resin paste failure, stator and rotor wear, etc., to achieve high mechanical strength, avoid jumping out, and ensure reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Hereinafter, exemplary embodiments will be described in detail with reference to the accompanying drawings. In the drawings, the shapes, dimensions, etc. of components may be exaggerated for clarity.

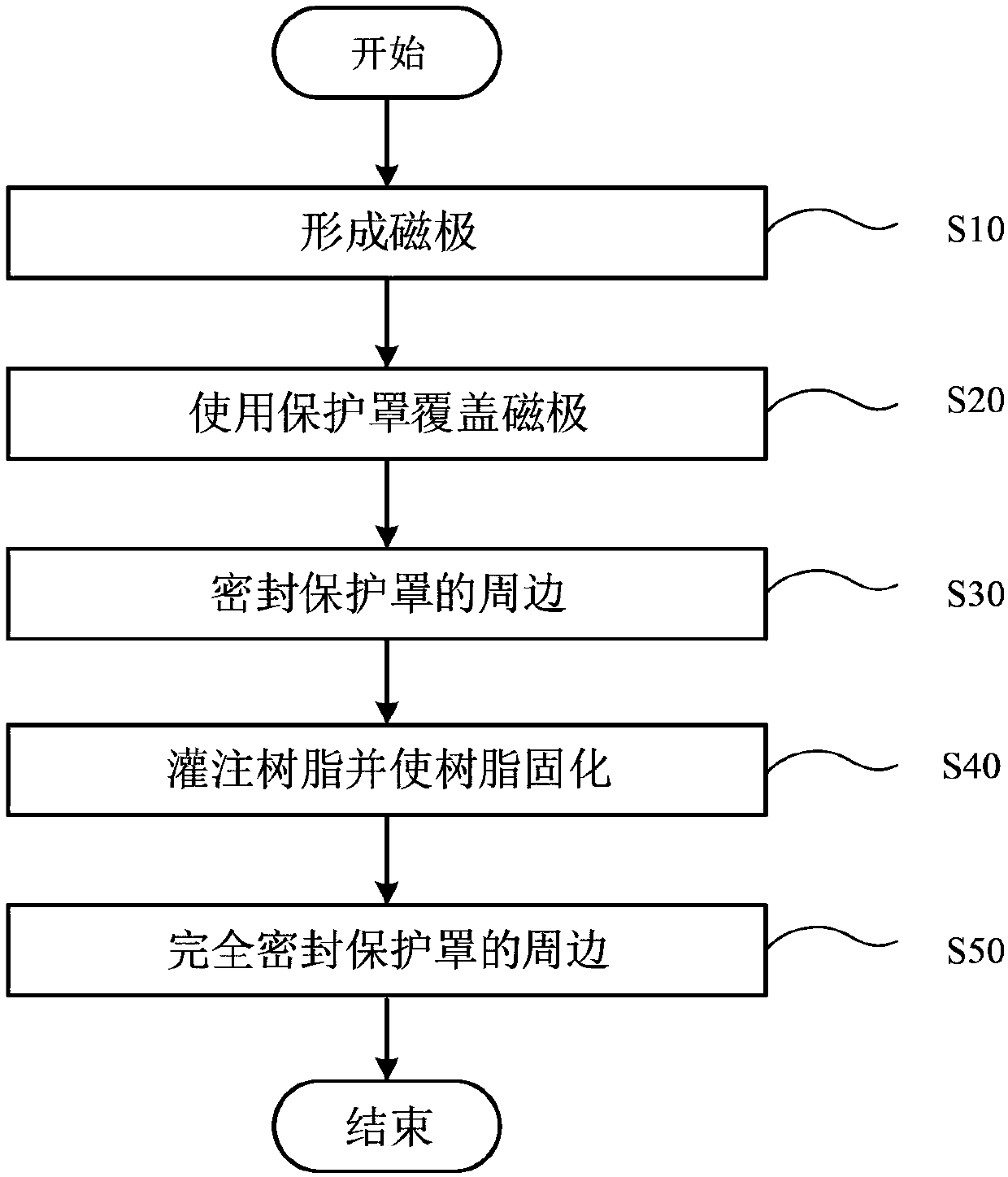

[0035] Below, will refer to Figure 1 to Figure 9 A method of manufacturing a rotor according to an embodiment of the present invention will be described in detail.

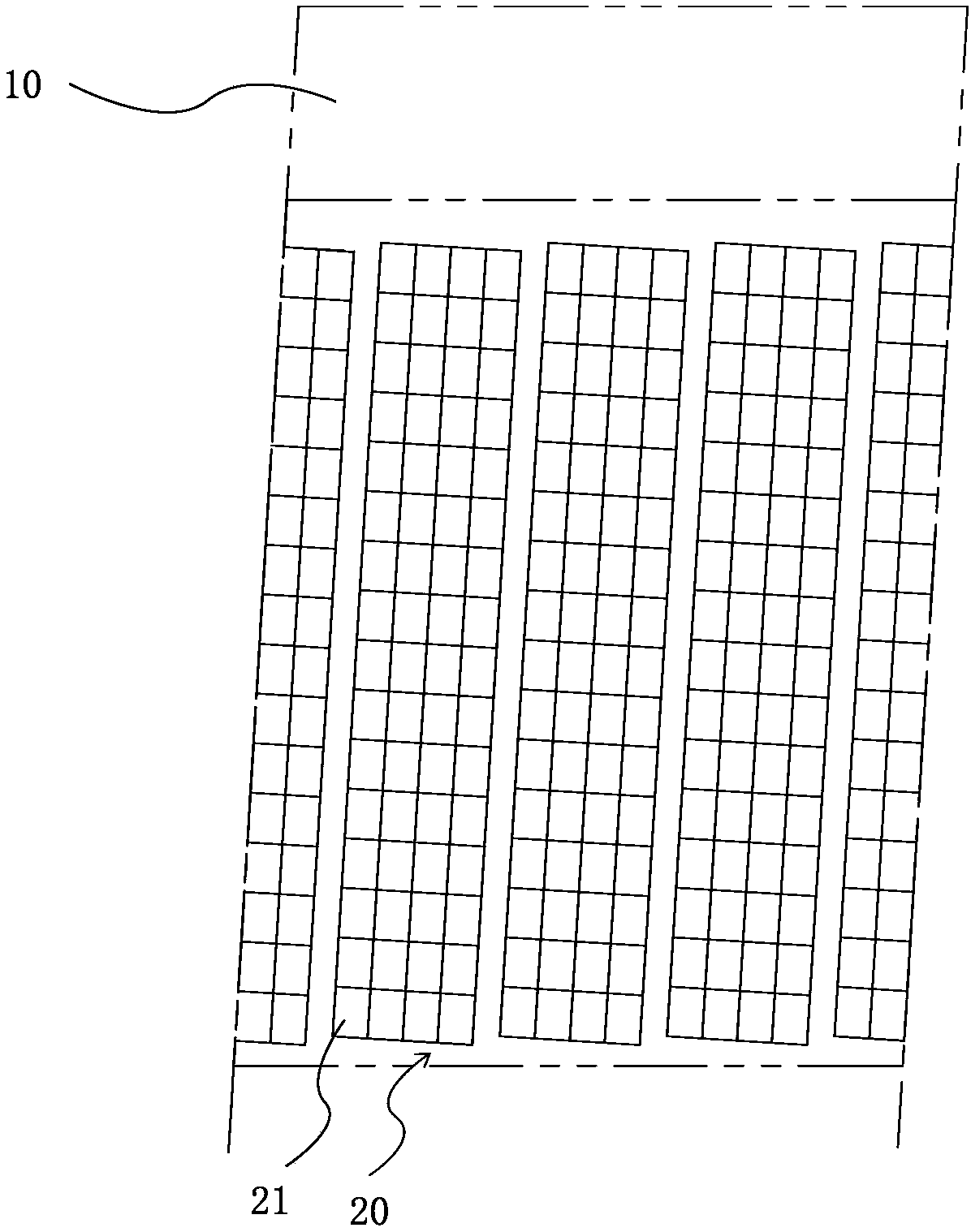

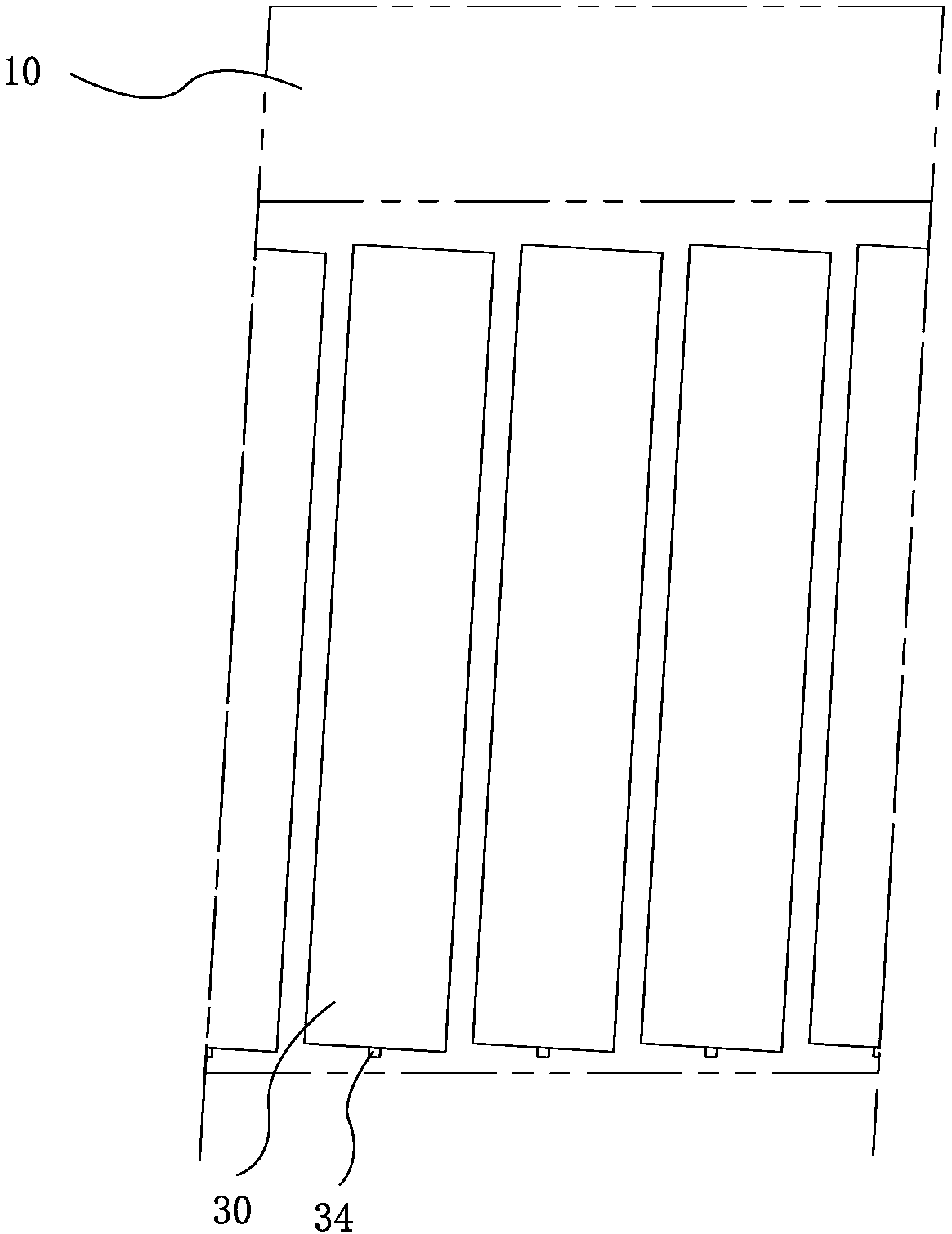

[0036] According to an embodiment of the present invention, the manufacturing method of the rotor may include: pasting the magnet 21 on the rotor yoke 10 to form the magnetic pole 20 (S10); The height of the cover 30 in the radial direction of the rotor is smaller than the height of the magnetic pole 20 in the radial direction of the rotor, so that a radial gap (S20) is formed between the protective cover 30 and the rotor yoke 10; A gap is reserved between the part of the cover 30 away from the pouring port 34 and the rotor yoke 10 as an air outlet (S30); pouring resin into the protective cover 30 through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com