Membrane paving method for lignin phenol and formed lignin phenol membrane

A lignin phenol and film-laying technology, which is applied in the fields of chemical instruments and methods, alkali metal oxides/hydroxides, inorganic chemistry, etc., can solve problems such as damage to the gold sheet substrate and cumbersome film-laying process, and achieve recycling The effect of increasing the number of times of use, good repeatability, and even surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

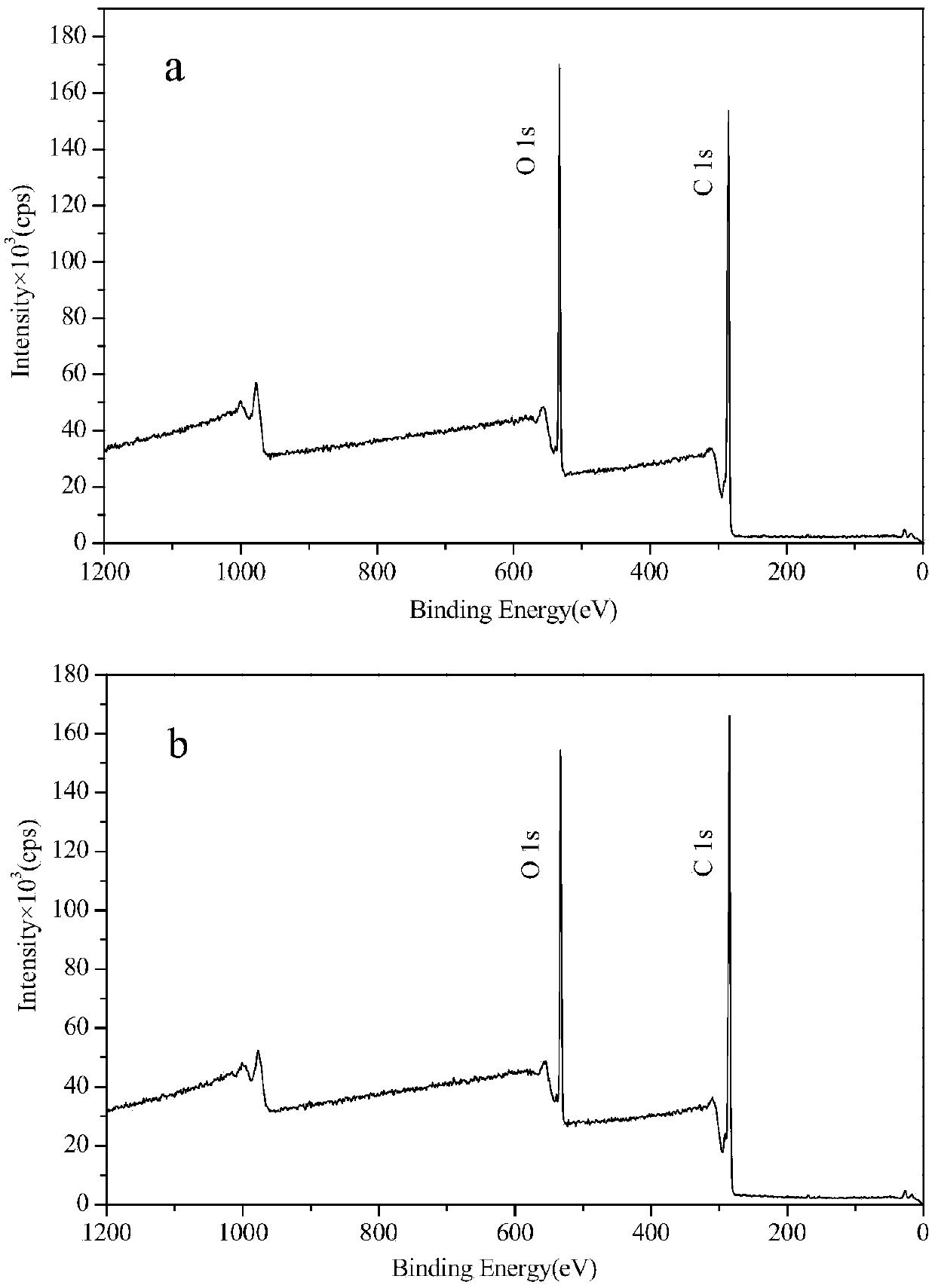

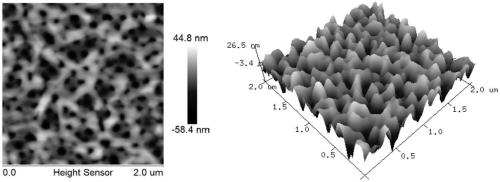

[0045] The coating method for lignin phenol of the present embodiment comprises the following steps:

[0046] (1) Prepare a 10 mg / mL acetone solution of poplar lignin phenol, centrifuge at 3500 rpm for 10 min at 5° C., collect the supernatant, and obtain the treated poplar lignin phenol acetone solution;

[0047] (2) After soaking and cleaning the QCM-D gold flakes with ethanol first, rinse them with distilled water, dry them with nitrogen, and then perform UV cleaning; On the spin coater, centrifuge at 3000rpm for 30s to obtain pretreated QCM-D gold flakes;

[0048] (3) Draw the acetone solution of poplar lignin phenol prepared in 0.15mL step (1) with a pipette, and add it dropwise to the pretreated QCM-D gold sheet obtained in step (2), 1.5 Turn on the spin coater after 1 min, set the spin coating program, the initial spin coating speed is 500r / min, after spinning for 5s, adjust the spin coating speed to 4000r / min, spin coating for 55s;

[0049] (4) After the spin coater i...

Embodiment 2

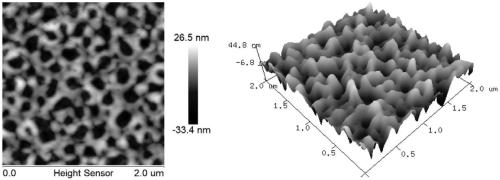

[0055] The coating method for lignin phenol of the present embodiment comprises the following steps:

[0056] (1) Prepare a 10 mg / mL acetone solution of masson pine ligninphenol, centrifuge at 3500 rpm for 10 minutes at 5°C, remove a very small amount of insoluble matter to obtain a supernatant, and use it as the acetone solution of masson pine ligninphenol after treatment;

[0057] (2) After soaking and cleaning the QCM-D gold flakes with ethanol first, rinse them with distilled water, dry them with nitrogen, and then perform UV cleaning; On the spin coater, centrifuge at 3000rpm for 30s to obtain pretreated QCM-D gold flakes;

[0058] (3) Draw the acetone solution of the processed masson pine ligninol prepared in 0.15mL step (1) with a pipette gun, add dropwise to the pretreated QCM-D gold sheet obtained in step (2), 1.5 Turn on the spin coater after 1 min, set the spin coating program, the initial spin coating speed is 500r / min, after spinning for 5s, adjust the spin coati...

Embodiment 3

[0063] The coating method for lignin phenol of the present embodiment comprises the following steps:

[0064] (1) Prepare an acetone solution of 8 mg / mL poplar lignin phenol, centrifuge at 3500 rpm for 10 min at 5° C., collect the supernatant, and obtain the treated poplar lignin phenol acetone solution;

[0065] (2) After soaking and cleaning the QCM-D gold flakes with ethanol first, rinse them with distilled water, dry them with nitrogen, and then perform UV cleaning; On the spin coater, centrifuge at 3000rpm for 30s to obtain pretreated QCM-D gold flakes;

[0066] (3) Draw the acetone solution of poplar lignin phenol prepared in 0.15mL step (1) with a pipette, and add it dropwise to the pretreated QCM-D gold sheet obtained in step (2), 1.5 Turn on the spin coater after 1 min, set the spin coating program, the initial spin coating speed is 500r / min, after spinning for 5s, adjust the spin coating speed to 4000r / min, spin coating for 55s;

[0067] (4) After the spin coater i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com