Shielding device for machine tool cutting

A technology of machine tools and shields, applied in metal processing machinery parts, maintenance and safety accessories, metal processing equipment, etc., can solve the problems of affecting the service life of the cutting machine, increasing the wear and tear of the cutting machine, and being easy to enter the cutting machine, so as to reduce the collection Difficulty and manual work intensity, provide cutting efficiency, and reduce the effect of collection difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

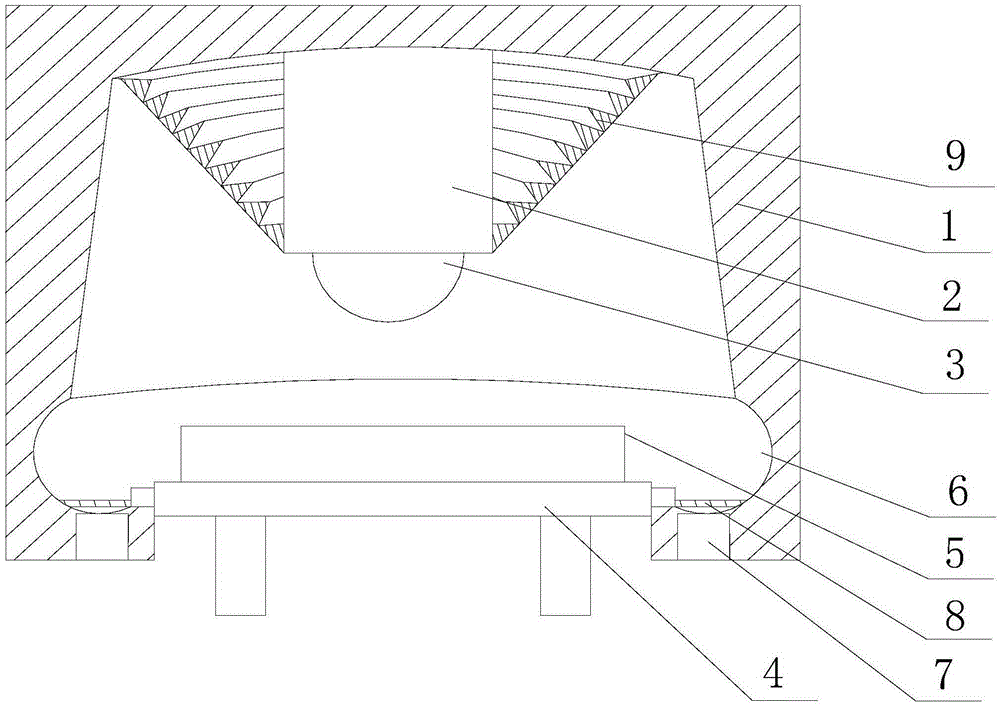

[0021] Such as figure 1 As shown, the present embodiment includes a circular workbench 4, on which a shield cover 1 is installed, the side of the shield cover 1 is provided with an opening for the workpiece 5 to enter and exit, and there is an opening in the shield cover 1 cavity, and an annular collecting tank 6 is arranged at the bottom of the cavity, and the side of the collecting tank 6 is connected to the side wall of the workbench 4, and the telescopic arm 2 moves through the top of the shielding cover 1 and is placed Directly above the workbench 4, a cutting wheel 3 is rotated at the end of the telescopic arm 2; it also includes a fan 7 installed at the bottom of the collection tank 6, the suction end of the fan 7 is connected to the collection tank 6, and A filter screen 8 is installed on the collecting tank 6, and there is a gap between the filter screen 8 and the bottom of the collecting tank 6, and a frustum-shaped sealing organ cover 9 is arranged on the inner wall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com