Using method of cutting machine tool capable of achieving recovering of metal chippings

A technology for metal chips and cutting machine tools, applied in metal processing machinery parts, metal processing equipment, maintenance and safety accessories, etc. The effect of reducing the difficulty of collection and manual work, improving accuracy and reducing the difficulty of collection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

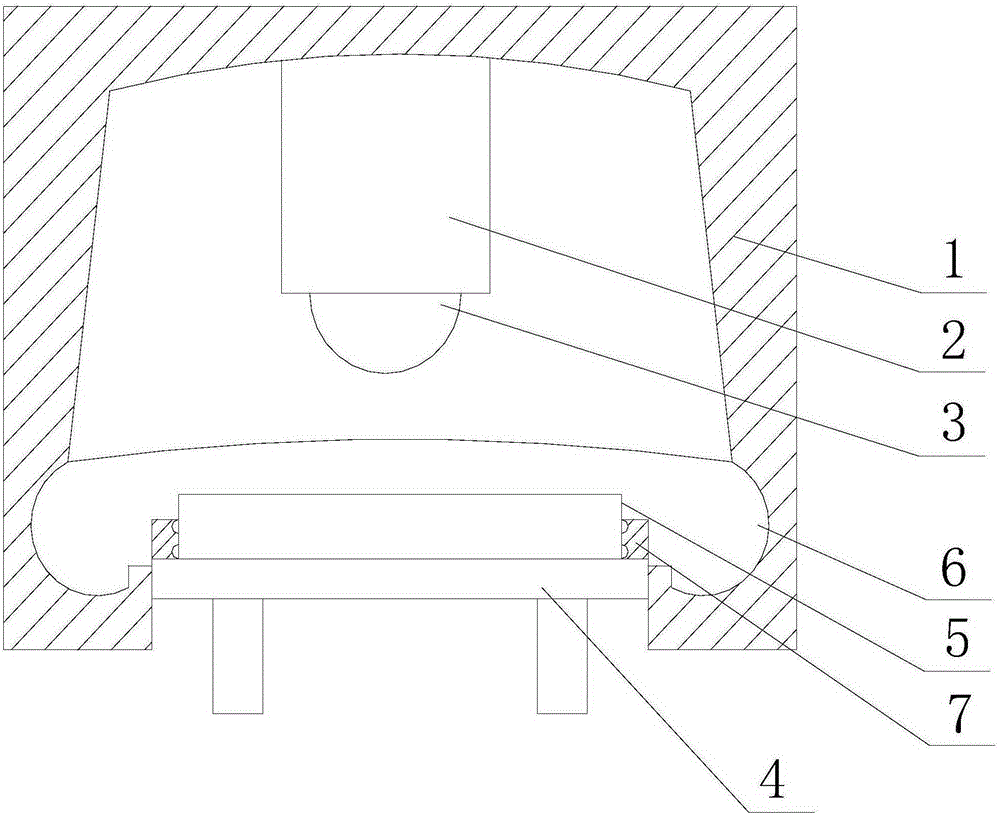

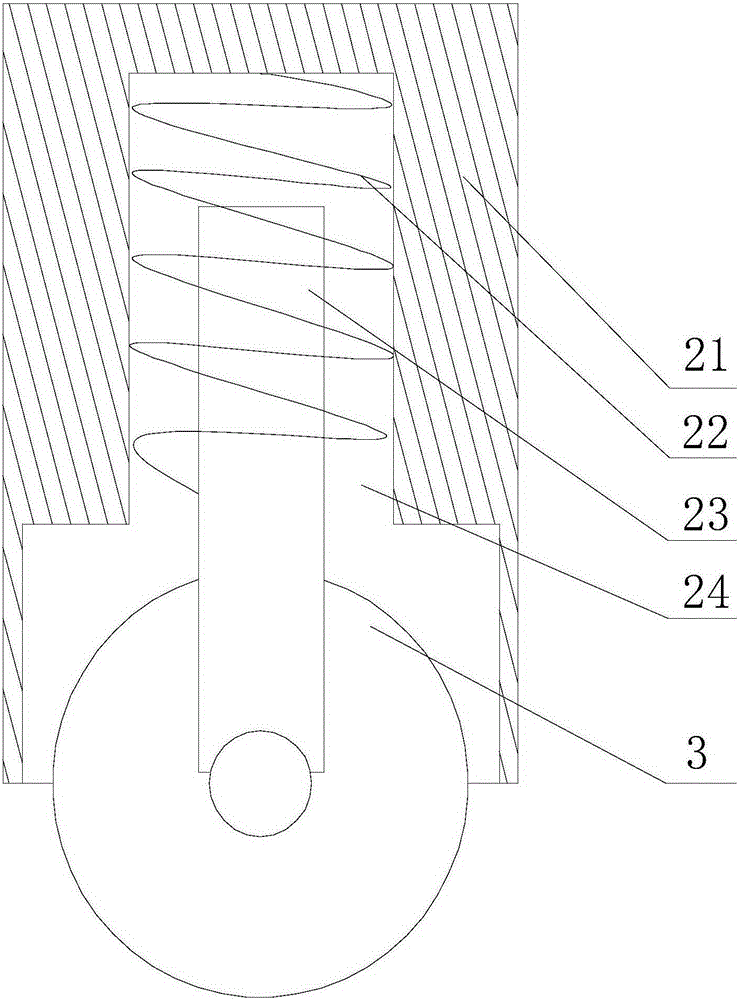

[0025] like figure 1 and figure 2 As shown, this embodiment includes the following steps:

[0026] A. Slide and push the workpiece into the clamping area formed by two oppositely arranged limit blocks directly on the workbench, adjust the telescopic arm so that the cutting wheel at the bottom end of the telescopic arm contacts the upper surface of the workpiece;

[0027] B and then close the opening of the mask, start the driving equipment so that the cutting wheel starts to cut the workpiece;

[0028] C When cutting, the generated metal debris begins to slide down along the inner wall of the cavity until it falls into the ring-shaped collection groove. When the workpiece vibrates during cutting, the protrusion is always in contact with the side wall of the workpiece, through its own deformation And restore the deformation to eliminate the vibration generated by the workpiece. When the radial runout of the rotating shaft occurs, the rotating shaft will transmit the acting s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com