Unattended liquefied gas transmission station

A technology of liquefied gas and conveying station, which is applied in gas/liquid distribution and storage, pipeline system, mechanical equipment, etc., can solve the problems of high frequency of maintenance and replacement of parts, high cost of human resources and high cost, and achieves compact structure, The effect of low labor cost and high pressure capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

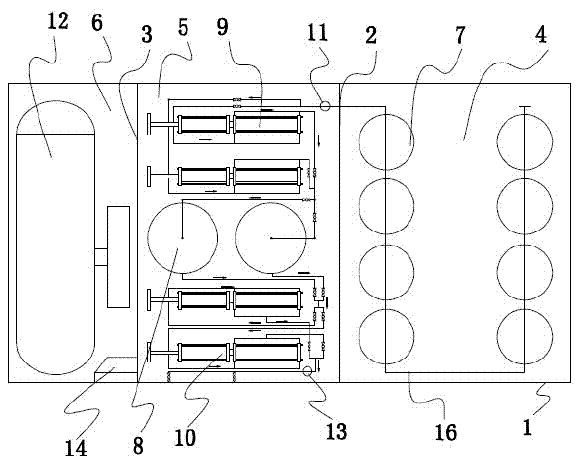

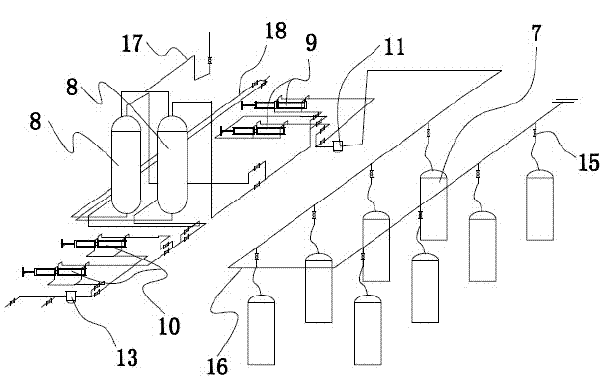

[0019] In order to further understand the features, technical means, specific objectives and functions achieved by the present invention, and to analyze the advantages and spirit of the present invention, a further understanding of the present invention can be obtained through the following detailed description of the present invention in conjunction with the accompanying drawings and specific embodiments.

[0020] As shown in the drawings of the description, the present invention includes a casing 1, on which a ventilation grid is arranged, and the ventilation grid is beneficial to the circulation of air in the casing 1 . The housing 1 is provided with a first partition 2 and a second partition 3, and the first partition 2 and the second partition 3 divide the housing 1 into a first unit 4, a second unit 5 and a second unit 5. Three units 6, the first unit 4 is provided with a steel cylinder group 7; the steel cylinder group 7 is provided with a plurality of special joints 15 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com