Continuous measuring moisture content meter by underground low-frequency dielectric method

A technology of water cut and low frequency, which is applied in wellbore/well parts, earthwork drilling and production, etc. It can solve the problem that the water cut meter cannot be matched with the current collector, so as to improve the accuracy and logging efficiency and ensure the accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

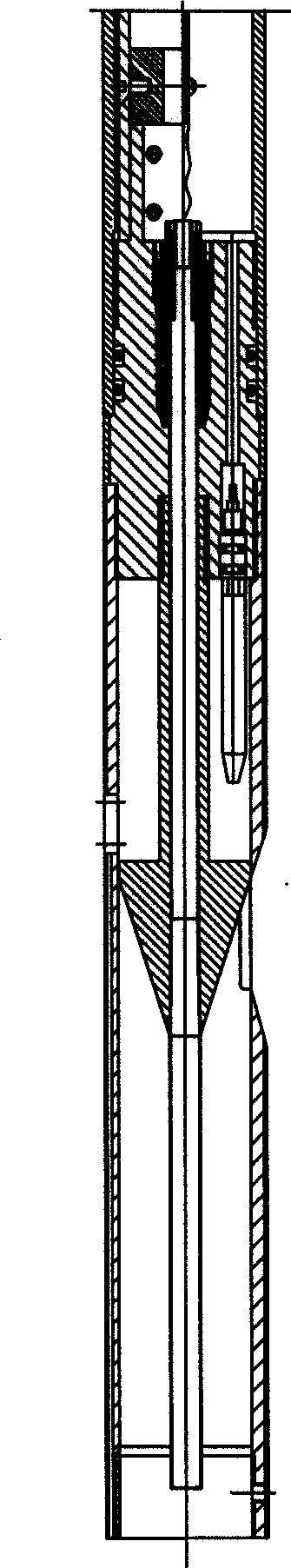

[0014] attached figure 1 The structural representation of the moisture content meter in the background technology;

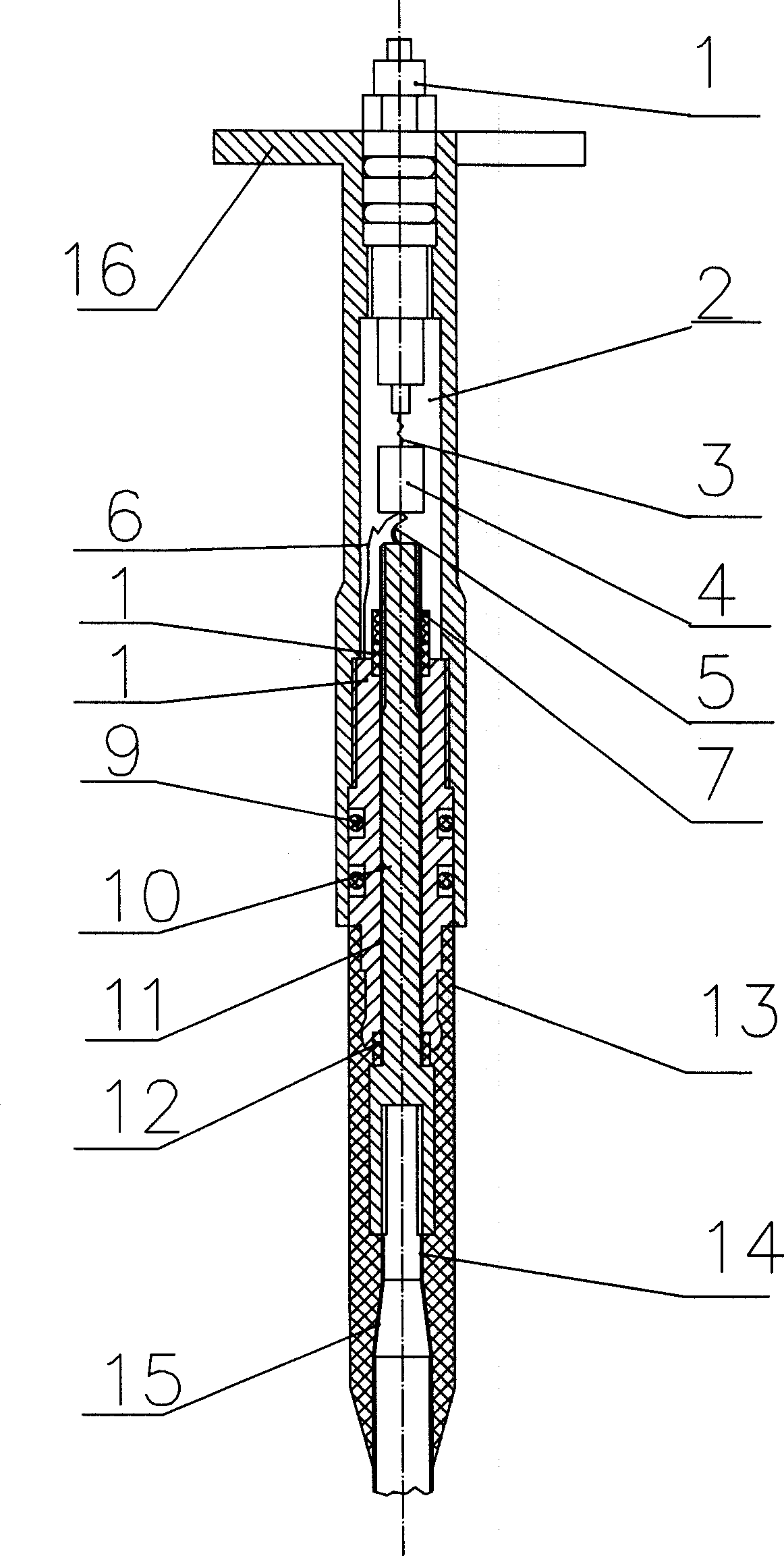

[0015] attached by figure 2 As shown, the downhole low-frequency dielectric method continuous measurement water content meter includes a terminal 1 and an integrated measurement circuit module 4, a connecting arm 16, an electrode 14 and its sealing sleeve (8, 13), and the terminal 1 is fixed on the upper end of the installation arm 16 , the lower end of the mounting arm 16 is sequentially connected to the metal sealing sleeve 8 and the rubber sealing sleeve 13; the inner surface of the rubber sealing sleeve 13 has a measuring electrode 14 with an electrode insulating sleeve 15, and the upper section of the measuring electrode 14 is connected to the outer diameter with a sealing core insulating sleeve 11 The upper part of the sealing core 10 is matched with the inner hole of the metal sealing sleeve 8, and the electrode lead wire 5 passing through the top end i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com