Mold cavity adjustment device of injection machine and adjustment method thereof

An adjustment device and injection molding machine technology, applied in the field of injection molding machines, can solve the problems of time-consuming, time-consuming manufacturing, and long time for temperature adjustment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

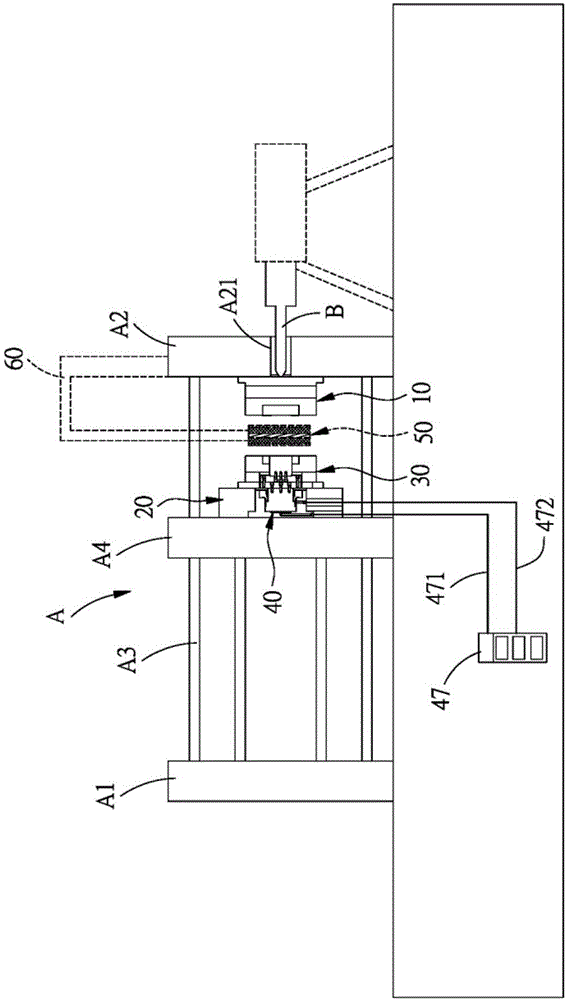

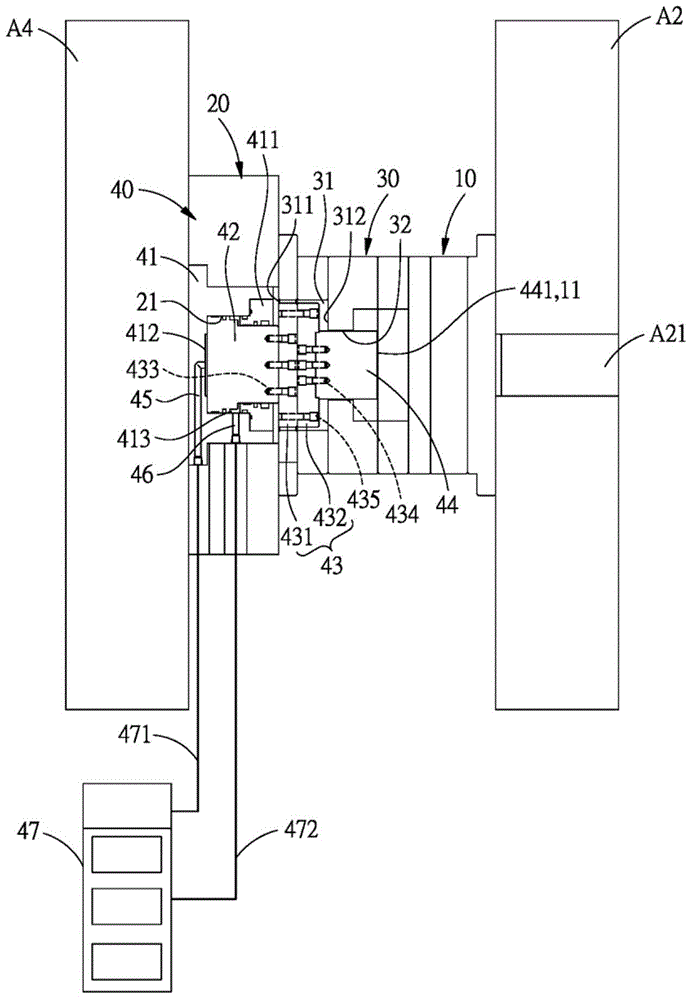

[0047] Please refer to Figure 1 to Figure 5 As shown, the specific implementation of the mold cavity adjustment device of the injection molding machine of the present invention is described.

[0048] The present invention achieves the purpose of adjusting the cavity of the injection mold by providing an oil cylinder adjustment mechanism 40 in the injection molding machine A. like figure 1 As shown, the injection molding machine A of the present invention has a base A1 and a fixed template A2 arranged oppositely, and a track mechanism A3 extending from the base A1 is arranged between the base A1 and the fixed template A2, and a movable template A4 It is arranged between the base A1 and the fixed formwork A2 and is displaced along the track mechanism A3.

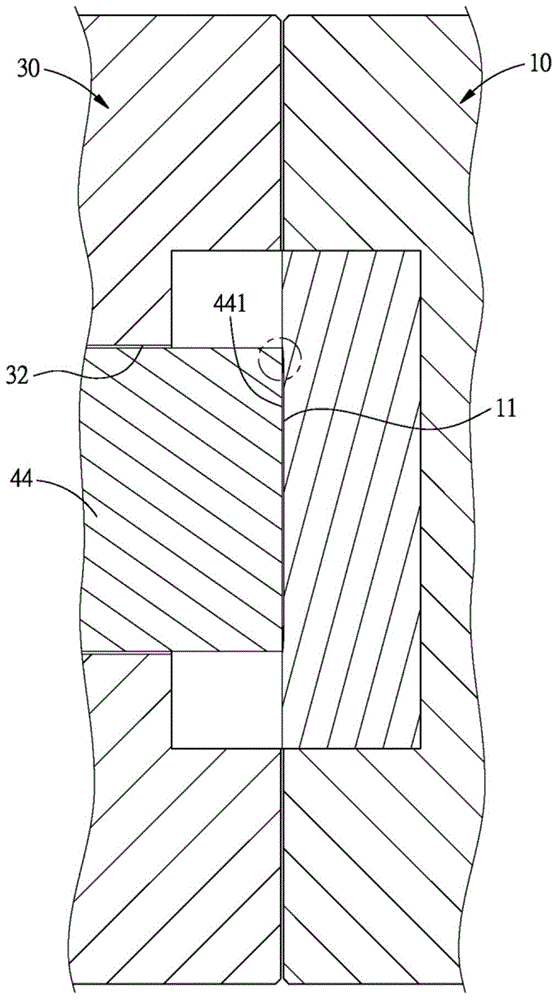

[0049] like figure 1 , figure 2 As shown, the fixed formwork A2 is provided with a first module 10, which is formed with a mold cavity 11 towards the side of the fixed formwork A2, and the fixed formwork A2 is provided w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com