A mems substrate, a display unit comprising a mems substrate, and an intelligent display mirror

A display unit and substrate technology, applied in optical components, instruments, optics, etc., can solve the problems of high cost, small operating temperature range, thick panel, etc., and achieve the effect of cost reduction and simplified structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

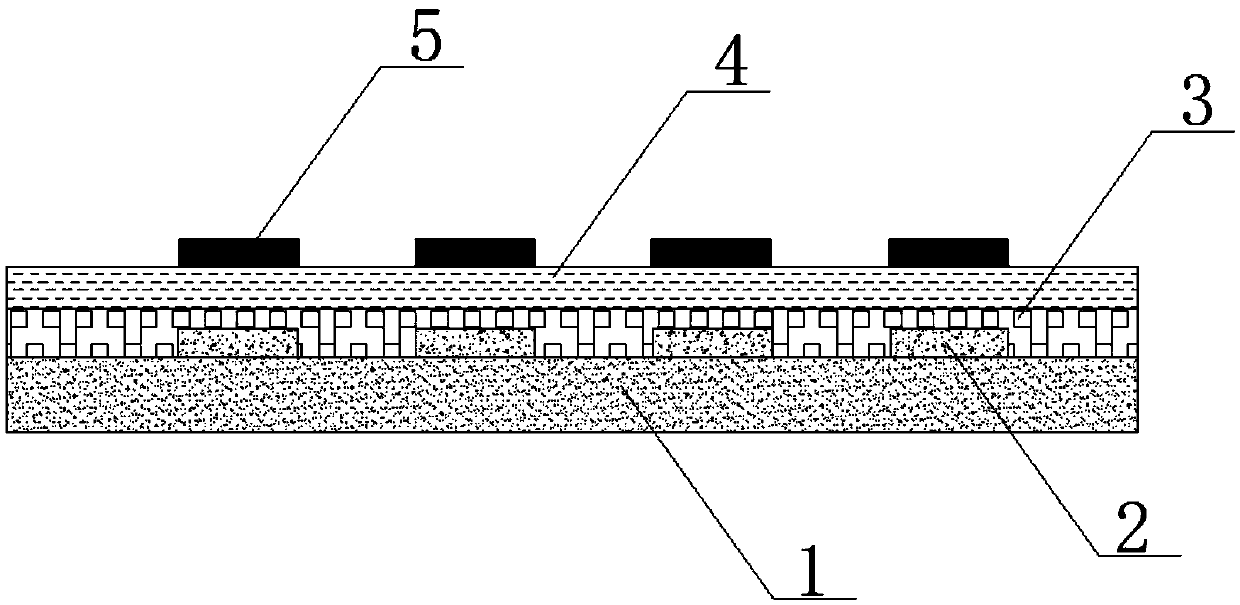

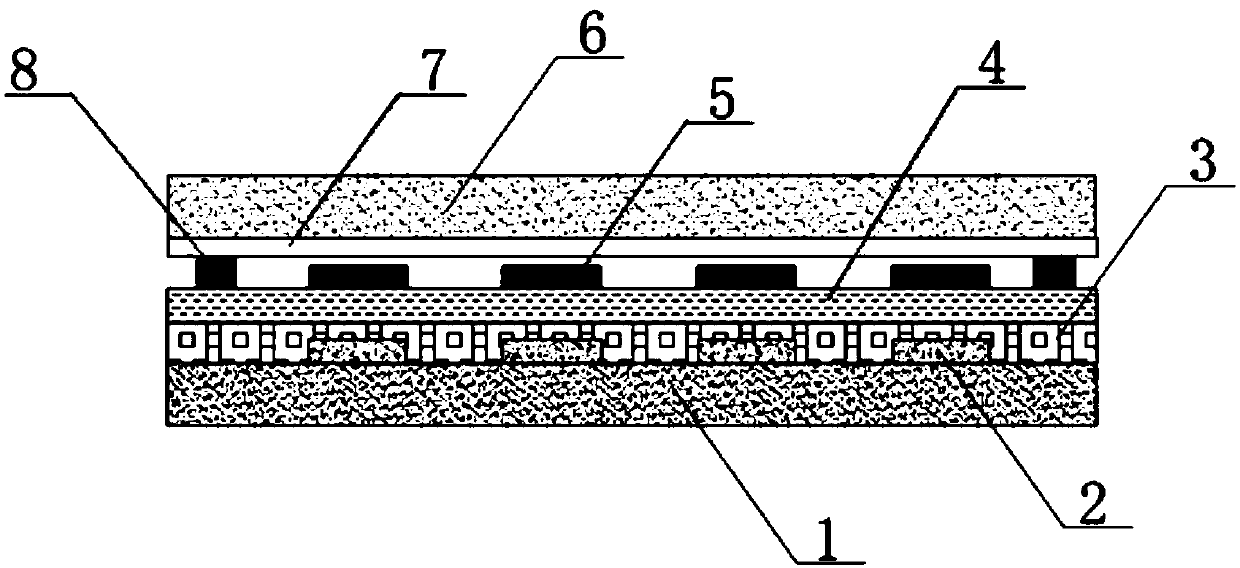

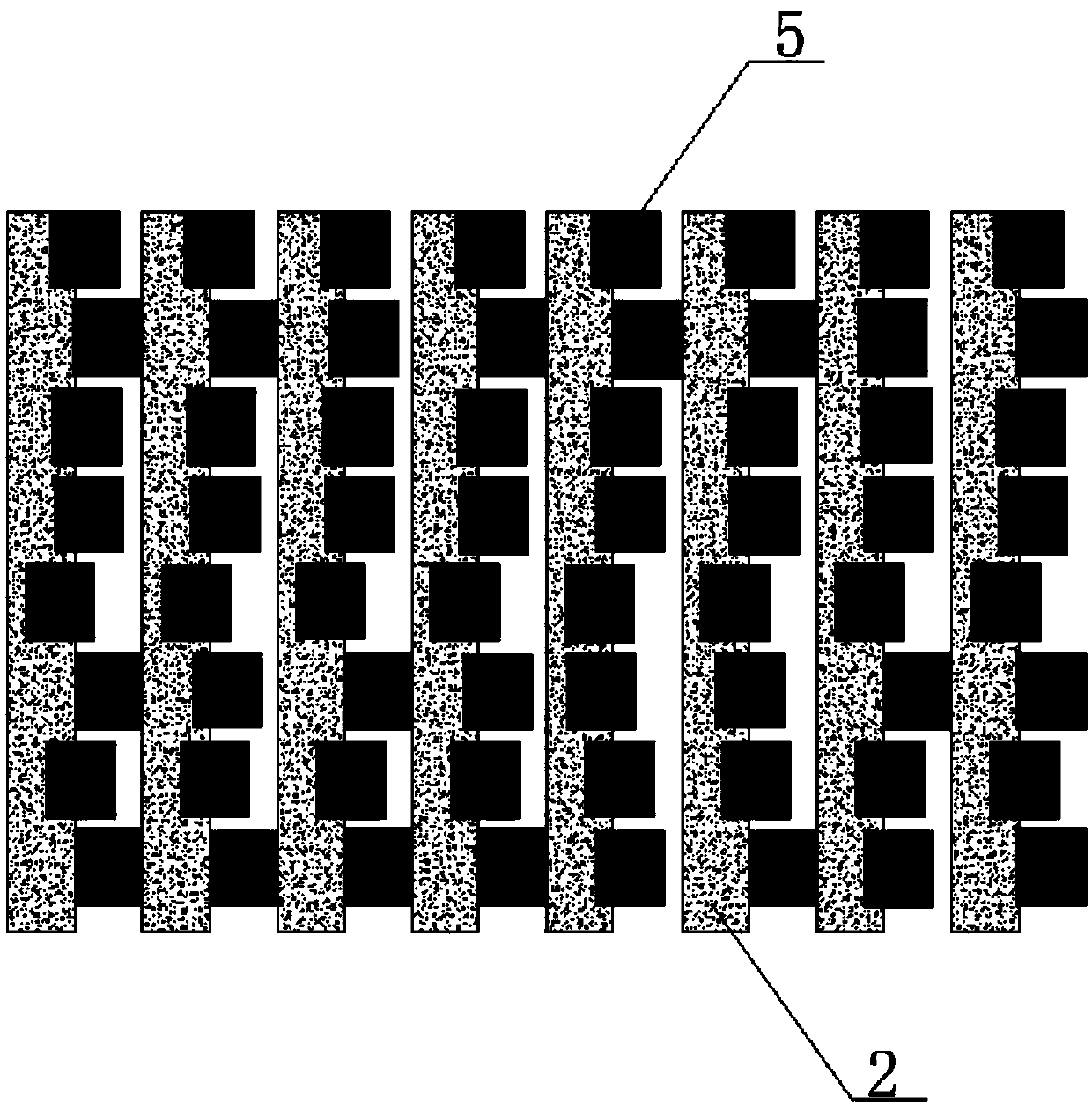

[0028] Embodiment 1: In this embodiment, the adjusting grating is made of a black light-absorbing material, which has better light-absorbing properties, so in this embodiment, the adjusting grating is called a light-absorbing grating. Such as figure 1 As shown, the MEMS substrate includes an array substrate 1, a reflective ambient light grating 2, an insulating layer 3, a color filter photoresist 4, and a light absorption grating 5. The reflective ambient light grating 2 is arranged on the array substrate 1, and the array substrate 1 provides reflective ambient light. The grating driving circuit of the grating 2 and the light-absorbing grating 5, the light-absorbing grating 5 is located above the reflective ambient light grating 2 and has a gap with the reflective ambient light grating 2, and the color film photoresist 4 is sandwiched between the reflective ambient light grating 2 and the light-absorbing grating 5 to make the MEMS substrate display a color screen.

[0029] Wh...

Embodiment 2

[0041] Embodiment 2: In this embodiment, the adjusting grating is made of highly reflective material, which has better reflected light characteristics. Therefore, in this embodiment, the adjusting grating is called a high reflective grating.

[0042] Figure 5 It is a structural diagram of a MEMS substrate containing a highly reflective grating, including an array substrate 1, a reflective ambient light grating 2, a color filter photoresist 4, and a high reflective grating 9. The reflective ambient light grating 2 is mounted on the array substrate 1, and the array substrate 1 provides reflection The grating driving circuit of the ambient light grating 2 and the highly reflective grating 9, the high reflective grating 9 is located above the reflective ambient light grating 2 and has a gap with the reflective ambient light grating 2, and the color film photoresist 4 is sandwiched between the reflective ambient light grating 2 and the gap between the high reflection grating 9 to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com