Intra-cavity mounting rack of inside deviation rectifying device

A technology of rectifying device and mounting frame, which is applied in water conservancy projects, artificial islands, underwater structures, etc., to achieve the effect of reducing operation risks, improving work efficiency, and simplifying installation steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

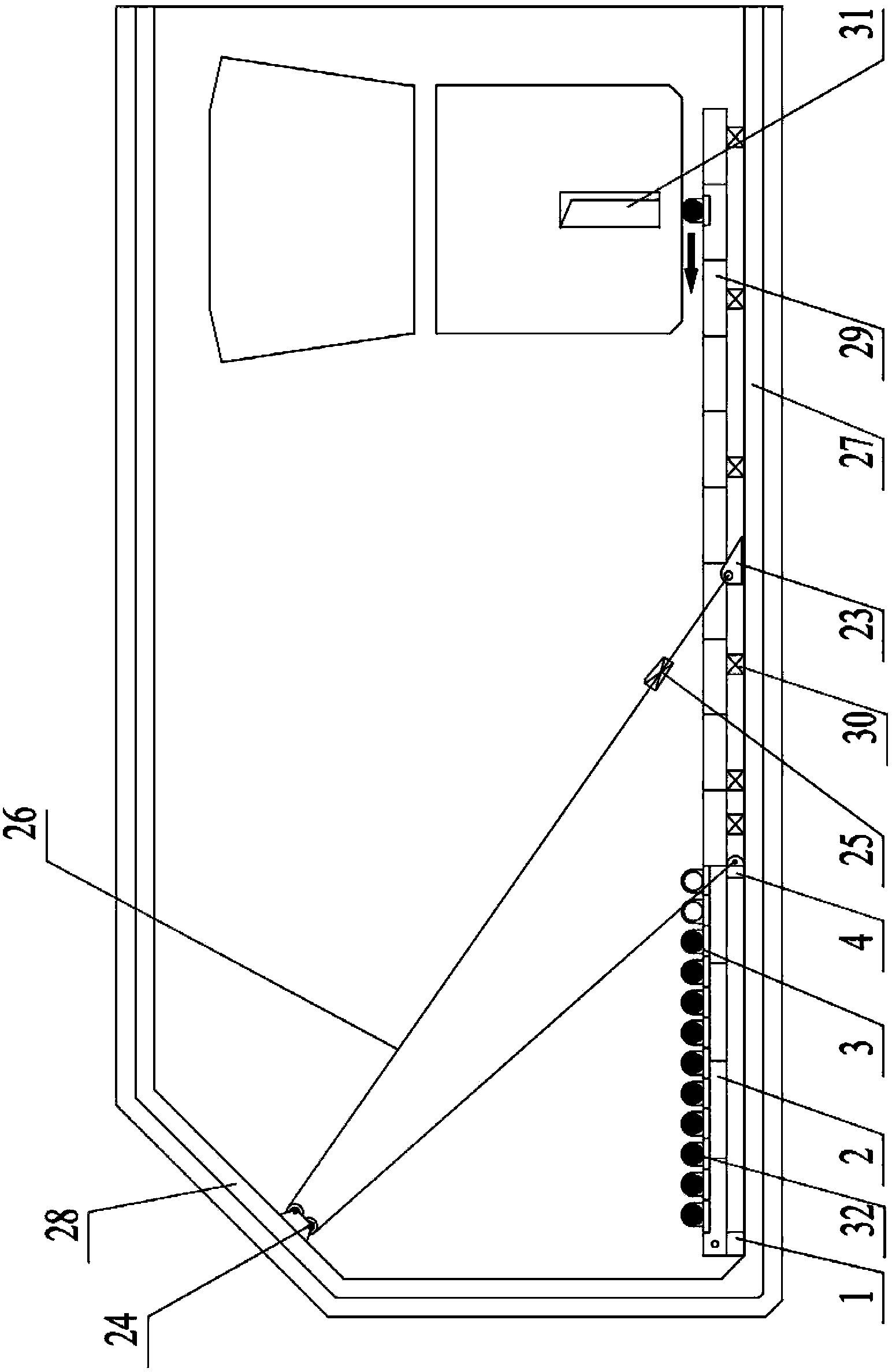

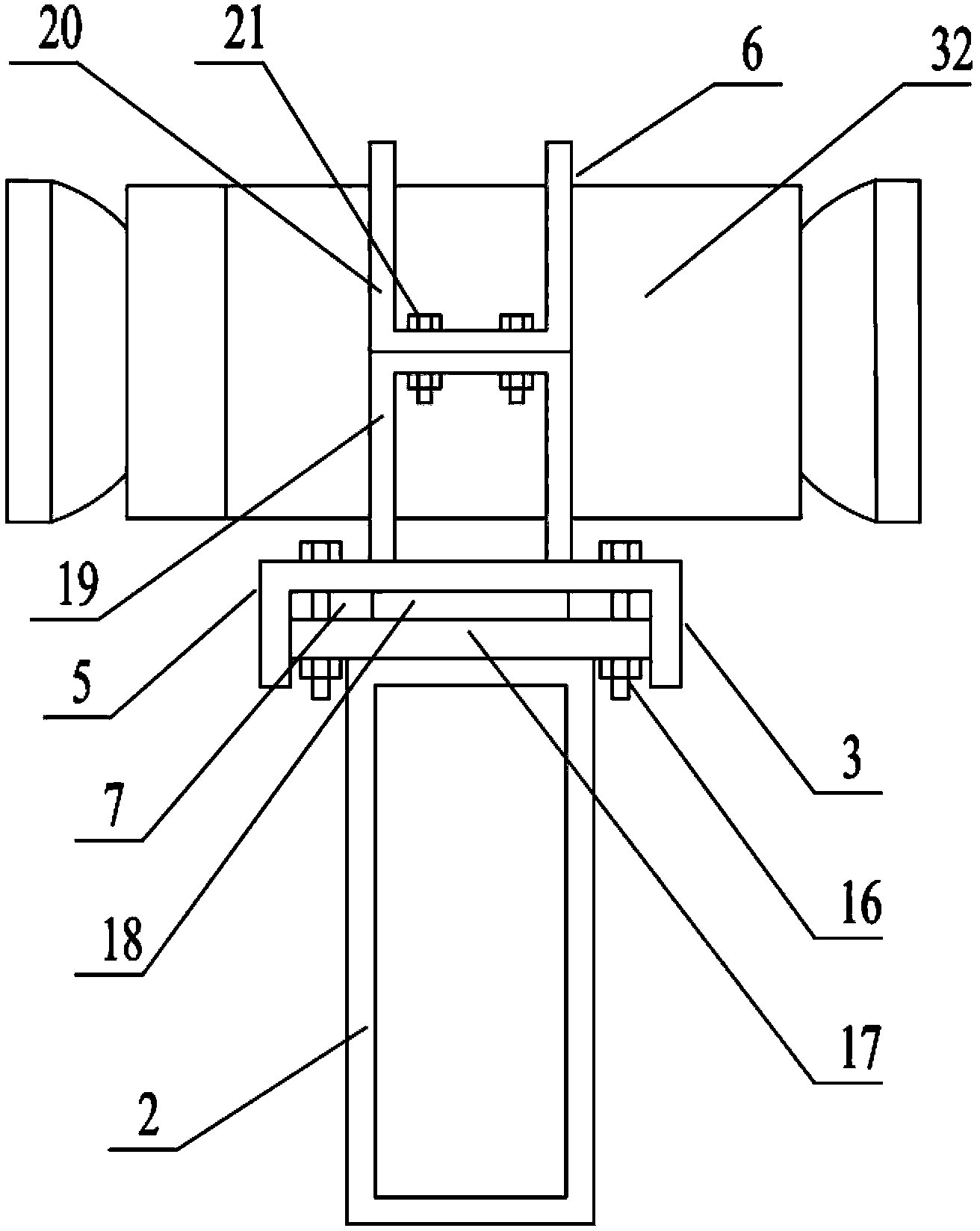

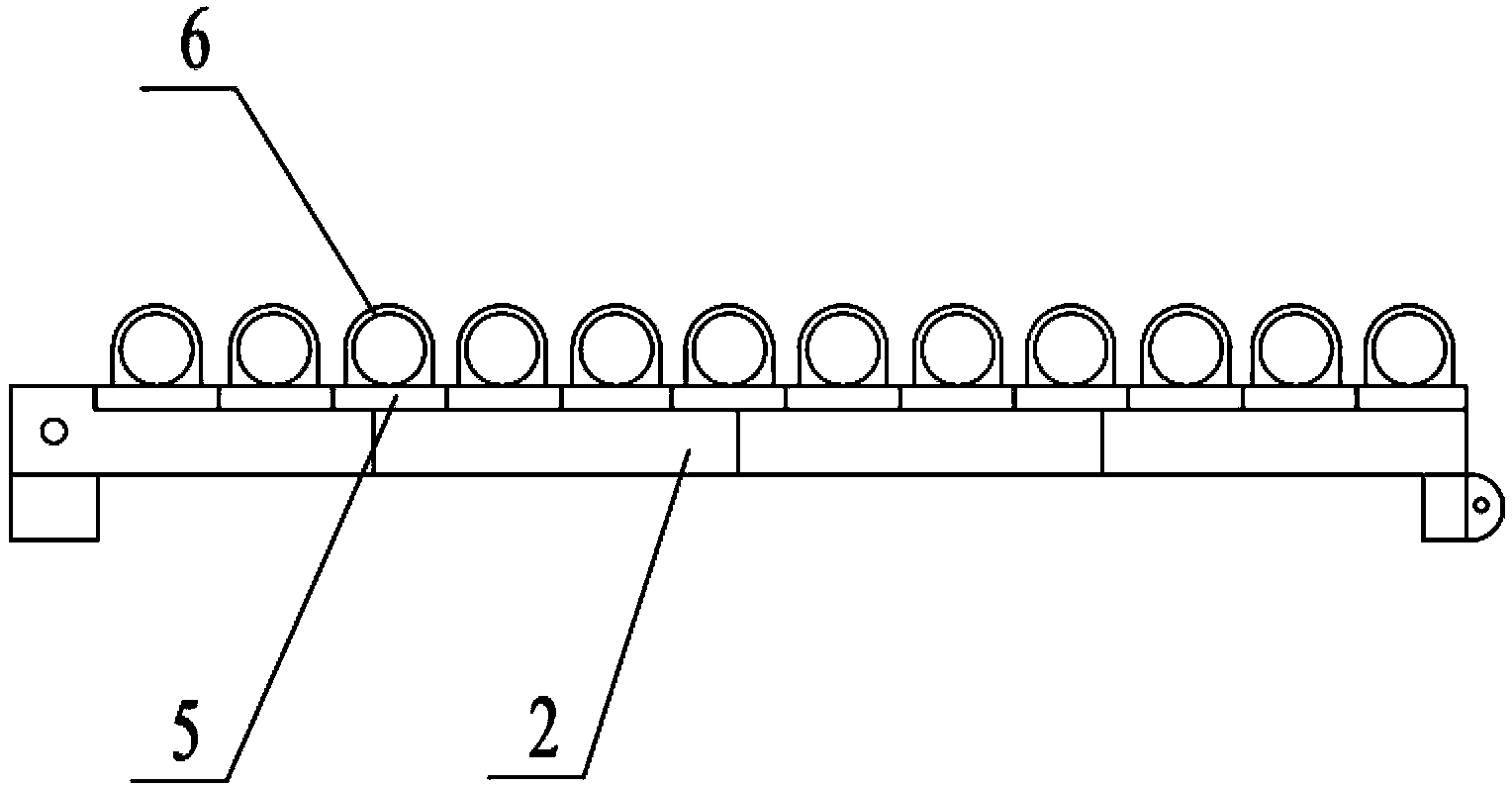

[0029] see figure 1 (The direction of the arrow is the sliding direction of the sliding mount), figure 2 , Figure 6 , Figure 7 As shown, the present invention is an intracavity installation frame of an internal deviation correction device. The intracavity installation frame includes a rotating base 1 installed with the bottom plate of the joint cavity and a rotating beam 2 installed on the upper part of the rotating base. On the rotating beam There is a sliding mounting seat 3 that can be used to install the internal deviation correction device. The left end of the rotating beam is hinged to the rotating base, and the right end of the rotating beam is connected to a lifting mechanism; Leg 4. The invention adopts the hinged design of the rotating beam and the rotating base; it can realize the rotating connection between the rotating beam and the rotating base; the internal deviation correcting device can be quickly installed in the joint cavity; when hoisted into the join...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com