Waste plastic barrel cutting and recycling equipment

A technology for recycling equipment and waste plastics, which is applied in the field of cutting and recycling equipment for waste plastic barrels, which can solve the problems of hidden safety hazards, dangers, and inconvenient collection on the ground

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

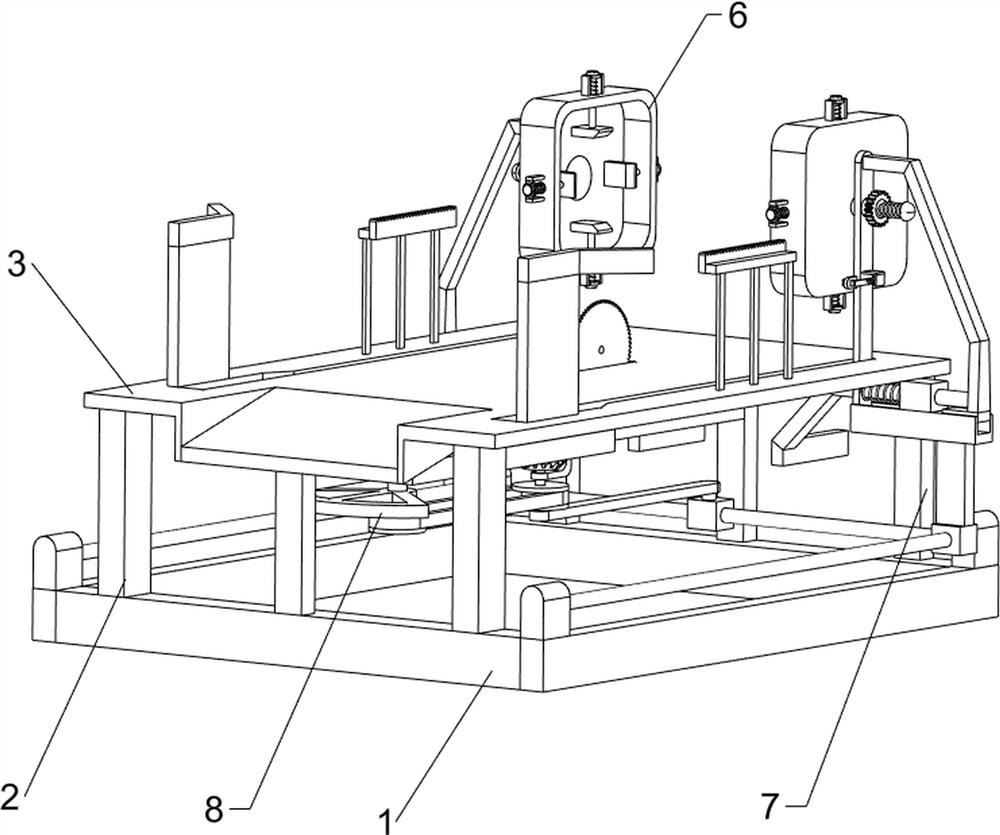

[0051] A waste of plastic bucket cutting recovery equipment, such as figure 1 with figure 2 As shown, including the base 1, the holder 2, the table 3, the high speed response motor 4, the cut saw blade 5, the cutting mechanism 6, and the moving mechanism 7, and the top of the base 1 is uniformly disposed with 4 brackets 2, and the top of the bracket 2 is connected. There is a table 3, and there is a high-speed response motor 4 at the top of the table 3. The right end of the output axis of the high-speed response motor 4 is connected to the cut saw blade 5, and the cut saw blade 5 is located in the table 3, and the top of the table 3 is opened. The guide groove, the guide groove is slidably equipped with a moving rod 30, and a moving mechanism 7 is connected to the base 1, and the inside of the moving rod 30 is connected to the cutting mechanism 6.

[0052] When the staff needs to cut recovery of the discarded plastic bucket, the collector can be placed below the inclination of t...

Embodiment 2

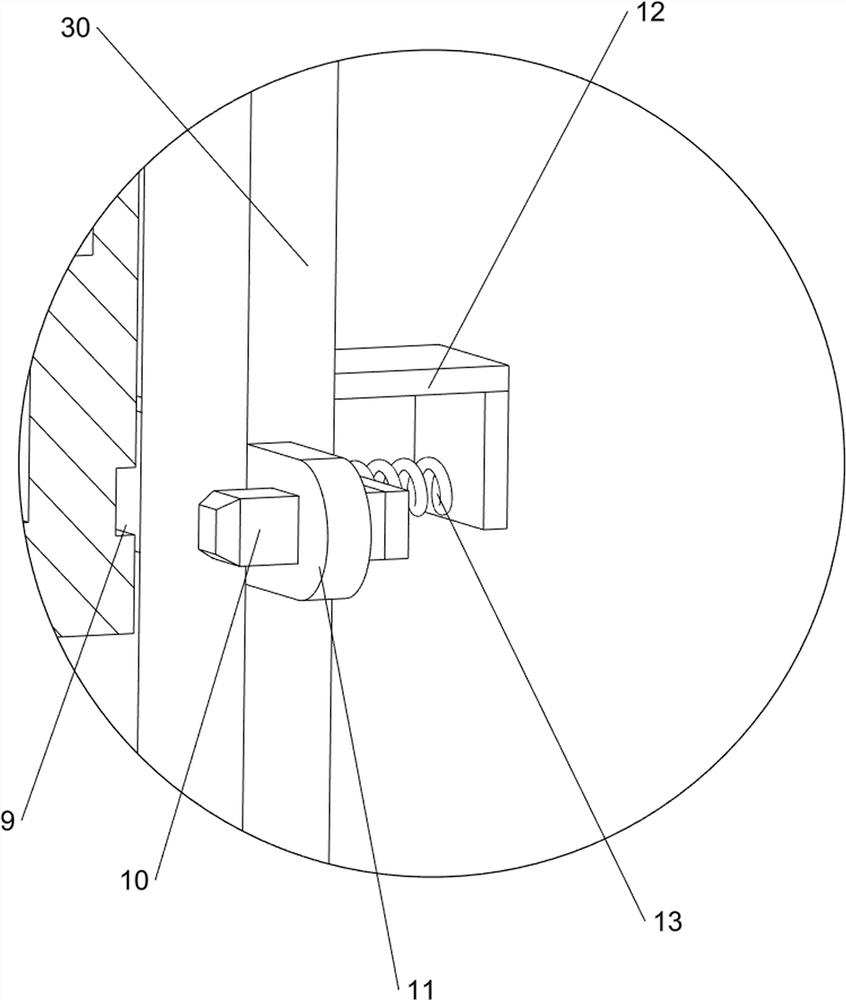

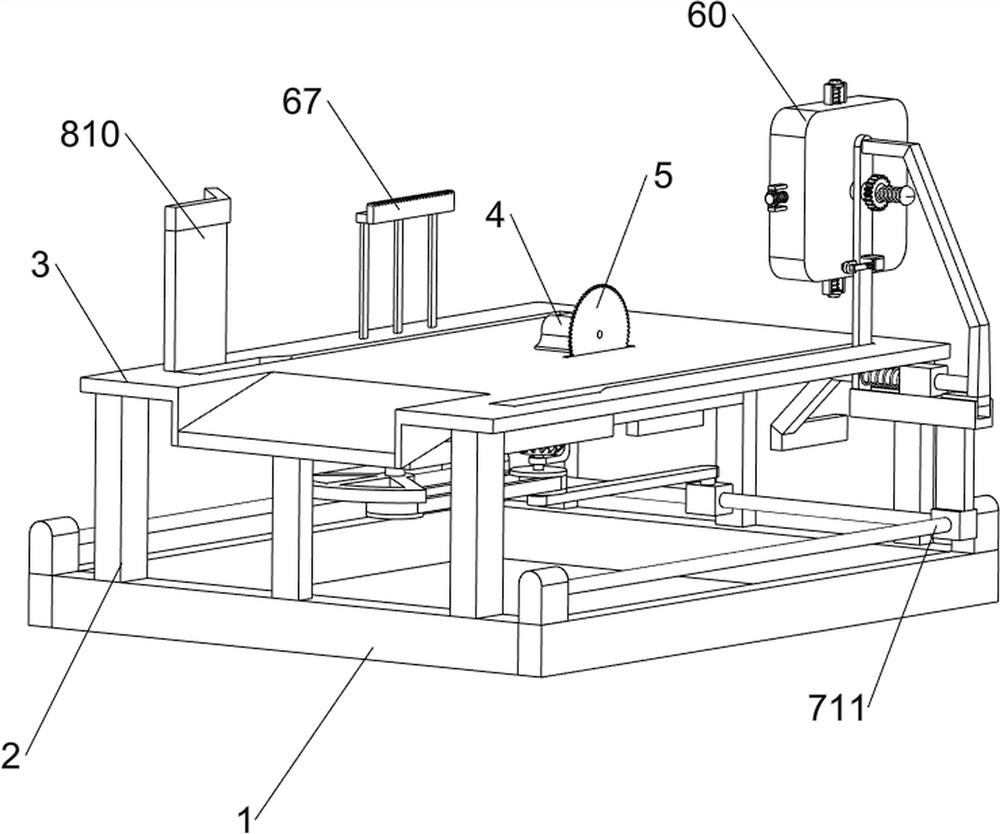

[0054] On the basis of Example 1, such as figure 2 with image 3 As shown, the cutting mechanism 6 includes a placing frame 60, a clamping block 61, a top rod 62, a first spring 63, a fixing frame 64, a sleeve 65, a whole gear 66, and a rack 67, and the upper spinning of the moving rod 30 There is a sleeve 65, and the inner side of the sleeve 65 is connected by a connecting shaft, the sleeve 65 is slidable with the connecting shaft, and the placing frame 60 is slidably equipped with a top rod 62, and the inner end portion of the top rod 62 is provided. The clamping block 61, the outer side of the top rod 62 is provided with a first spring 63, and the outer wall of the placing frame 60 is symmetrically configured with a fixing frame 64, and the mounting frame 64 is slidably fitted, and the outer end of the sleeve 65 is provided. There is a full gear 66, and the rack 67 is connected to the left and right sides of the top of the table 3, and the rack 67 is fitted with the same side a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com