Teaching laser carving cutter

A laser engraving and cutting machine technology, applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of being unable to intuitively and truly watch the operation of laser engraving and cutting machines, reducing students' learning enthusiasm, and unable to show physical objects in teaching, etc. , to achieve the effect of ensuring high-precision engraving and cutting, controlling manufacturing costs, and good practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

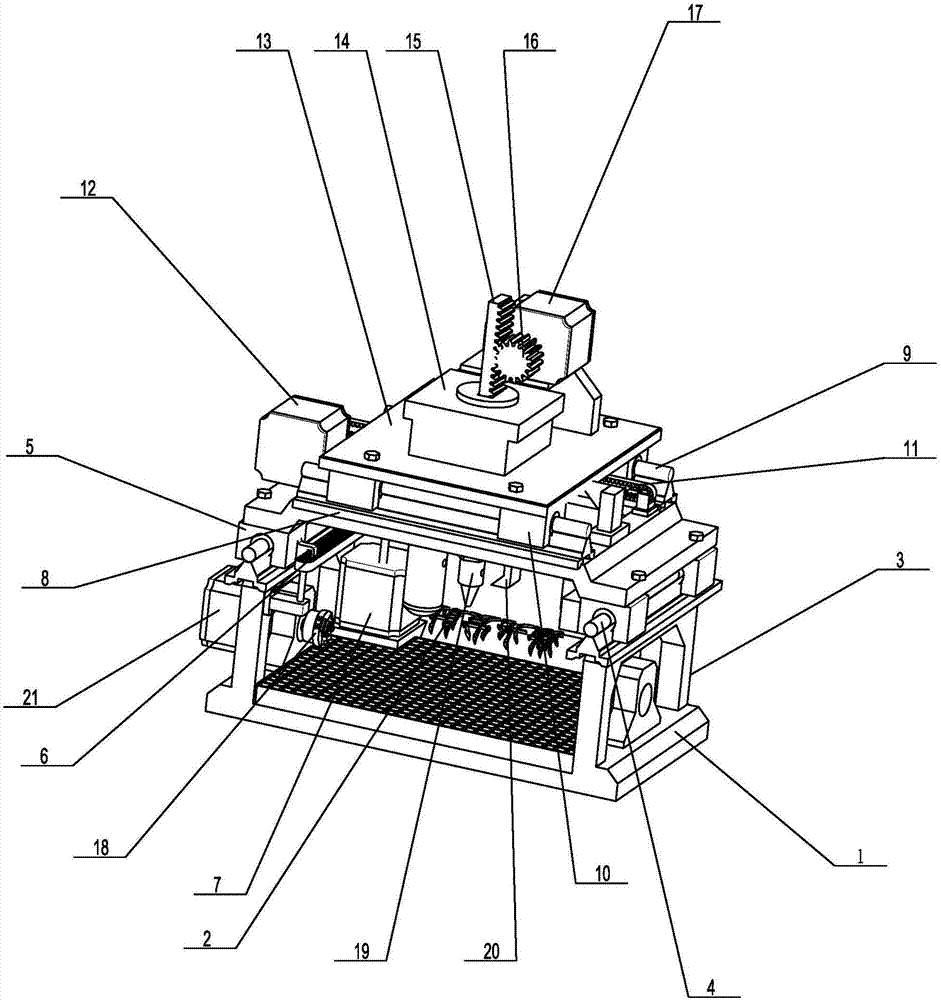

[0016] Such as figure 1 A specific embodiment of the present invention is proposed as shown, the teaching laser engraving and cutting machine, including a square base 1, a laser emitter 2 is provided at the rear of the base 1, and a vertical For the support rods 3 arranged in this embodiment, four support rods 3 are integrally formed with the base 1, and a Y-axis round rod 4 is connected between the tops of the two support rods 3 on the same side. There is a Y-axis linear guide rail 5 that can slide along the straight line, the Y-axis linear guide rail 5 is connected with the Y-axis timing belt 6, and the Y-axis timing belt 6 is connected with the Y-axis motor 7 on the base 1; The Y-axis linear guide rail 5 is provided with an X-axis support plate 8 arranged horizontally, and an X-axis round rod 9 is arranged on both sides of the X-axis support plate 8, two X-axis round rods 9 and two Y-axis round rods 4 are perpendicular to each other, and the two X-axis round rods 9 are equ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com