Infrared technology based wafer cutting online detecting system

A detection system, infrared technology, applied in the direction of working accessories, stone processing equipment, manufacturing tools, etc., can solve the problems of air cutting, blade wear, incomplete cutting, etc., to improve stability, ensure no damage, structure compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with specific drawings and embodiments.

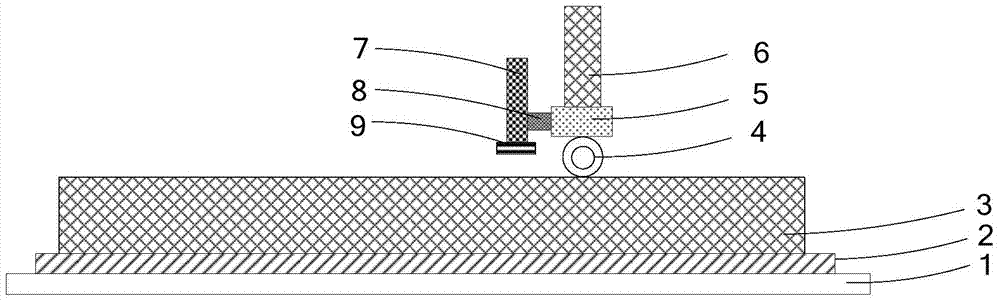

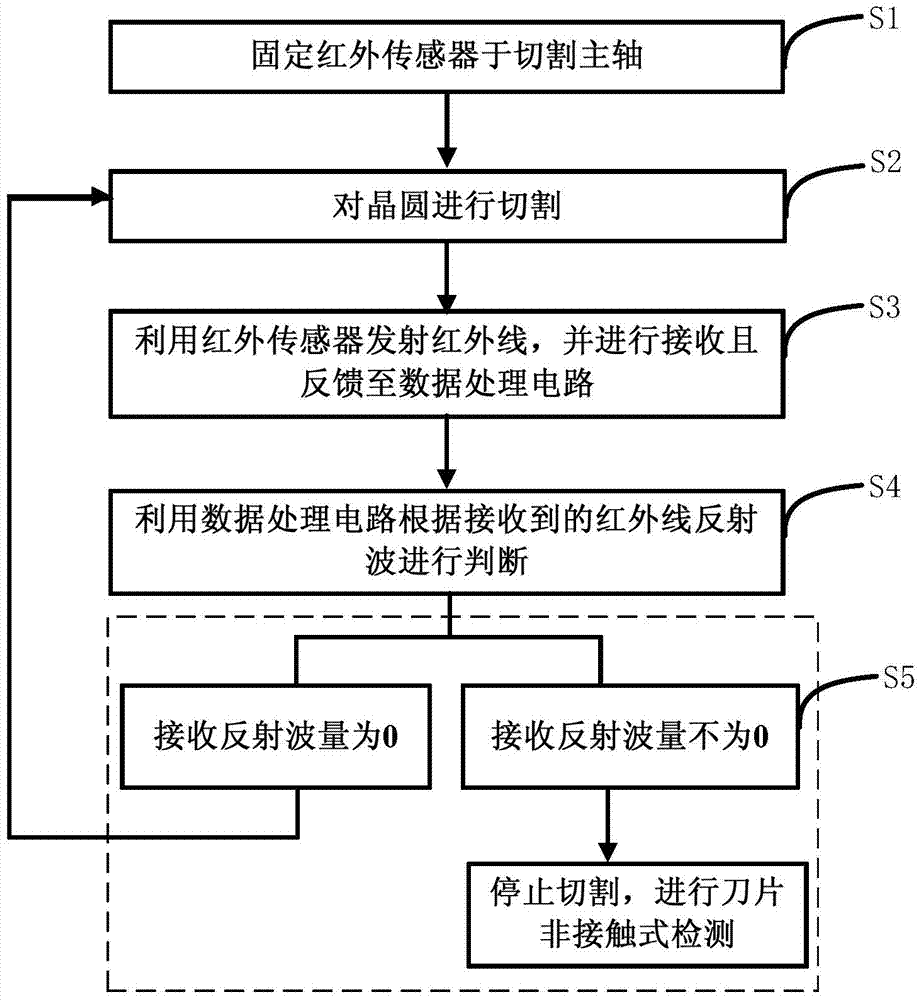

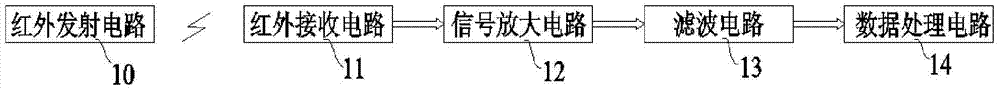

[0014] Such as figure 1 , figure 2 and image 3 As shown: in order to be able to detect the wafer cutting process in real time, to ensure that the wafer cutting is carried out normally and the cutting knife 4 is not damaged, the present invention includes a transmission shaft 6 and a flange 5 located at the end of the transmission shaft 6; An infrared sensor 7 for detecting the cutting line is also fixedly installed on the flange 5 .

[0015] Specifically, a cutting knife 4 is installed on the flange 5 , and a detection window 9 is provided at the emitting end of the infrared sensor 7 , and an air blowing device is provided in the detection window 9 . A wafer 3 is disposed below the dicing knife 4 , and the wafer 3 is disposed on the carrier plate 1 through the protective film 2 . The infrared sensor 7 can detect the dicing line when the dicing knife 4 cut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com