Patents

Literature

44results about How to "Guaranteed Grinding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

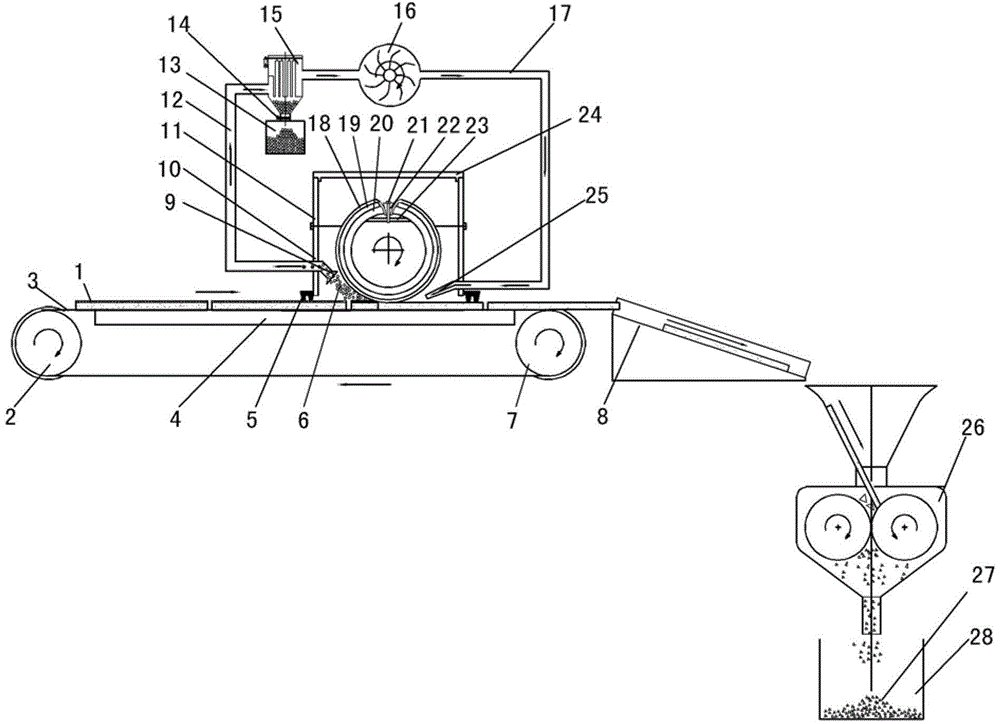

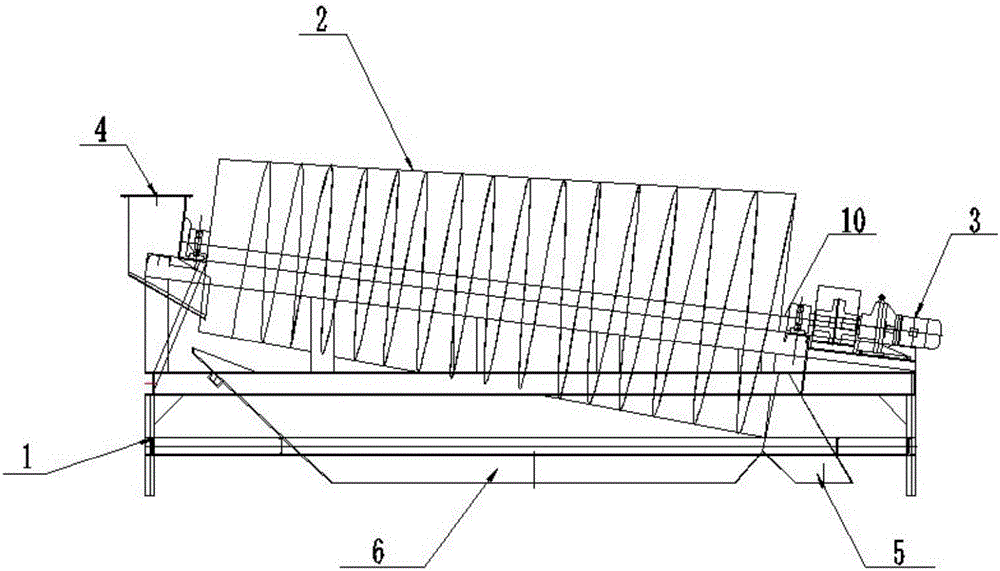

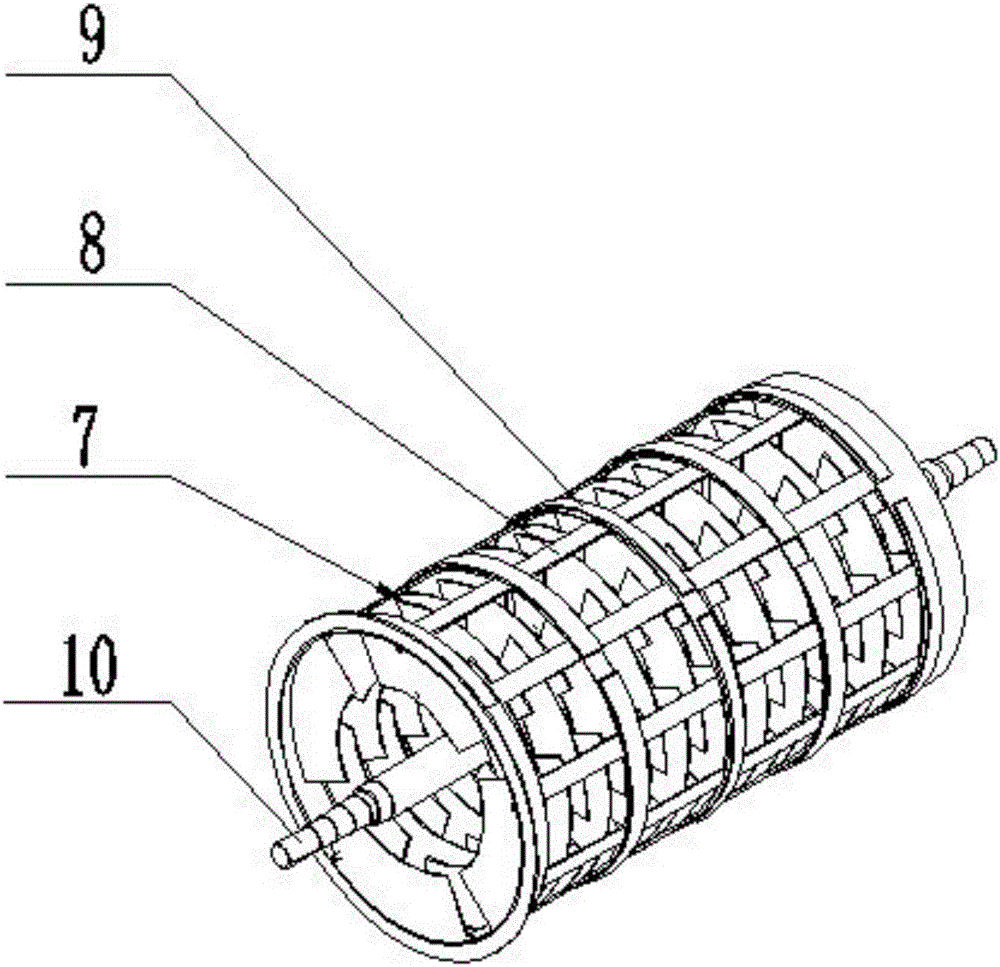

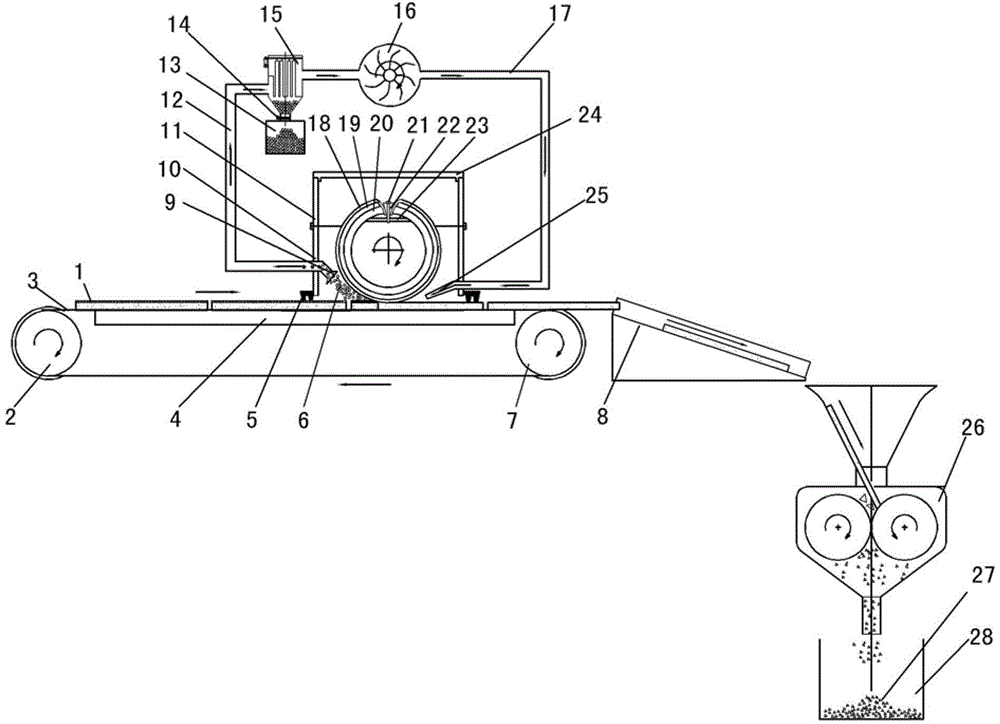

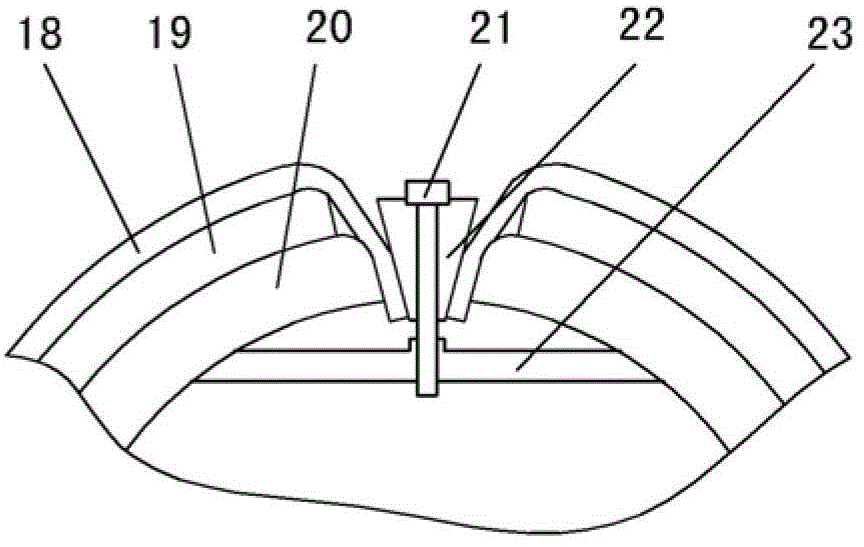

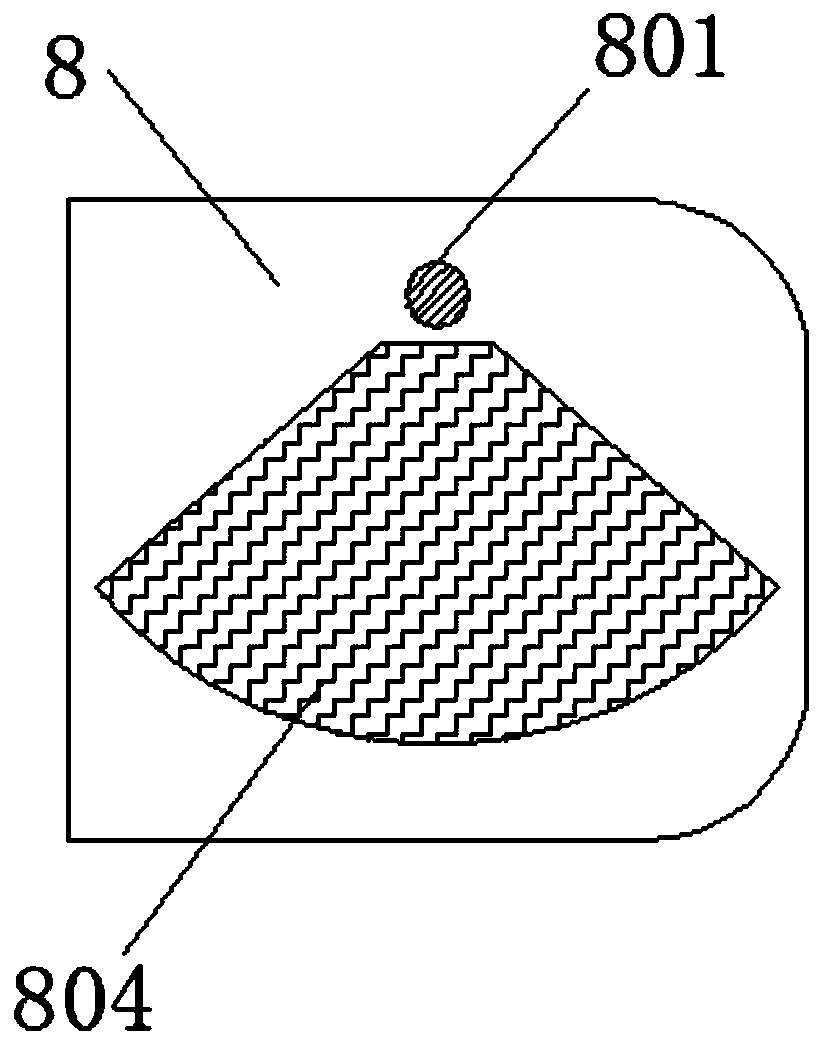

Industrialized recovery method and apparatus of waste liquid crystal display glass panel

InactiveCN103331295AImprove recycling efficiencyImprove environmental benefitsSolid waste disposalRecovery methodIndium

The invention discloses an industrialized recovery method and an apparatus of a waste liquid crystal display (LCD) glass panel. The recovery method comprises following steps: a glass substrate is placed on a conveyor belt, with the surface where a membrane is arranged being upward, and self-locking and positioning of the glass substrate are realized by the static friction force between the glass substrate and the conveyor belt; the LCD glass substrate and the membrane are separated from each other by grinding, grinding dust is collected to obtain indium metallurgy raw materials; and at last the grinded glass substrate is crushed, immersed in an organic solvent and centrifuged successively, so that classification collection of glass and a polaroid is realized. The recovery method is simple and practical, can be industrialized, is high in efficiency, and can be used for classification collection of waste liquid crystal display glass panel with high quality.

Owner:HEFEI UNIV OF TECH

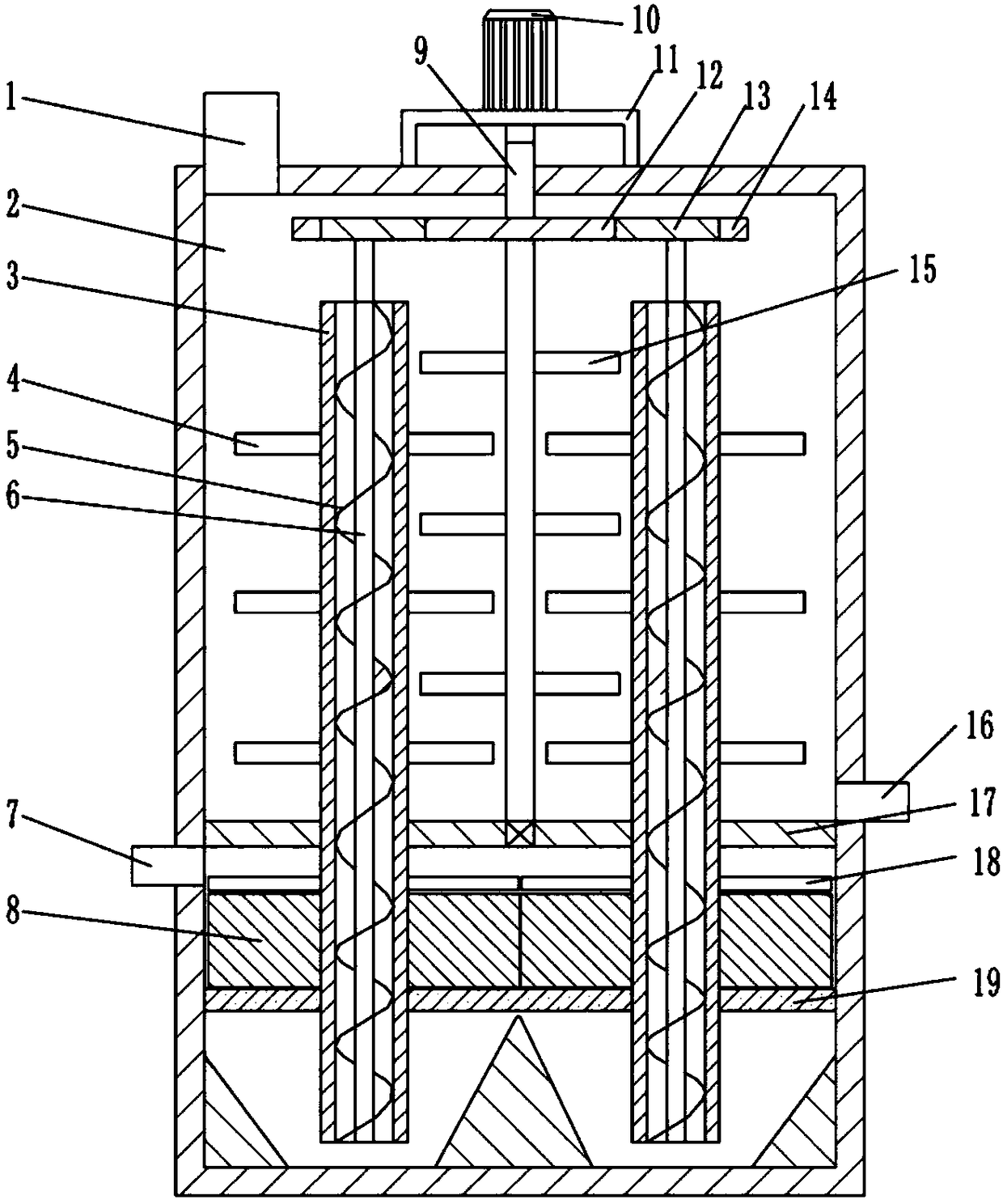

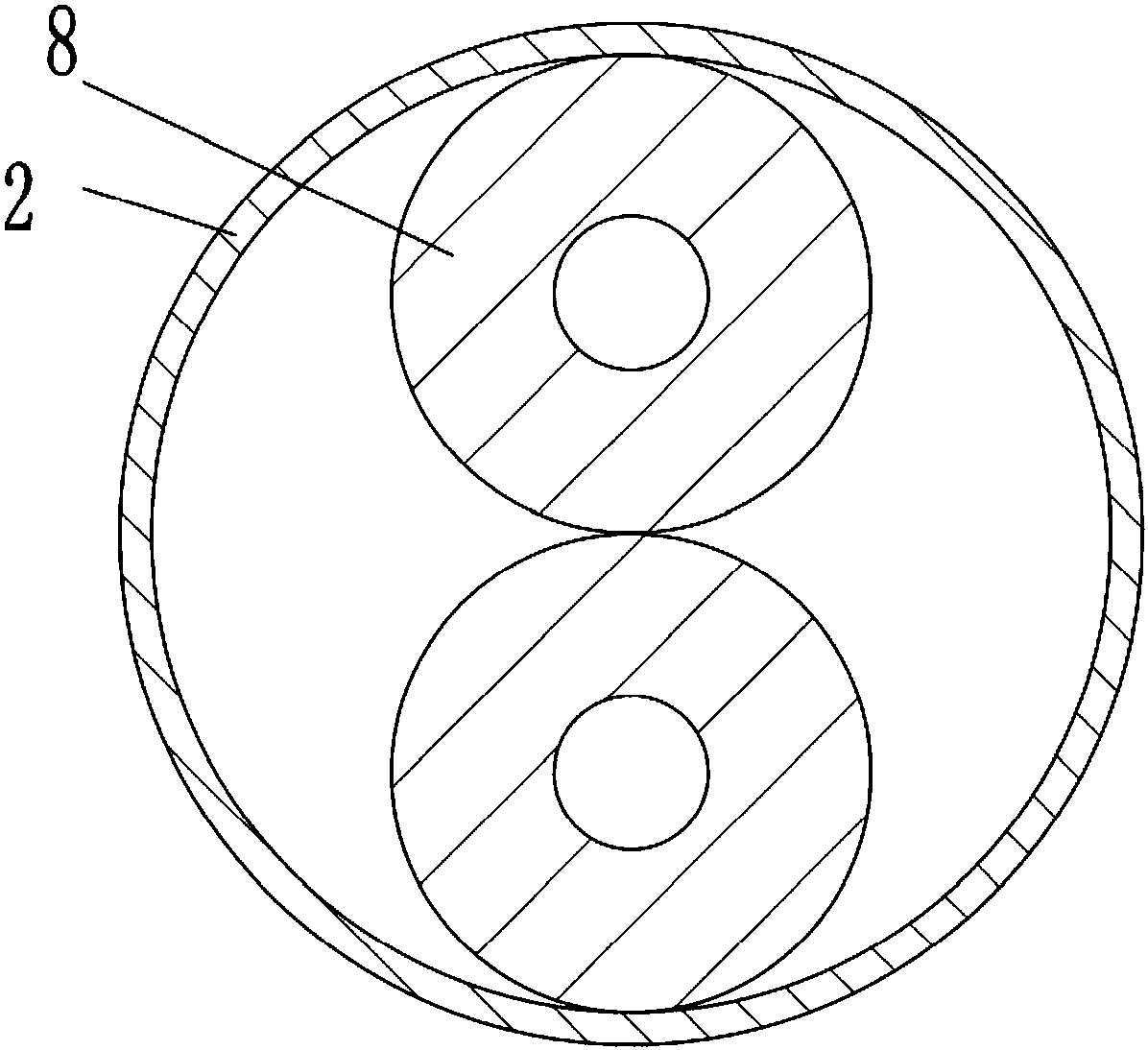

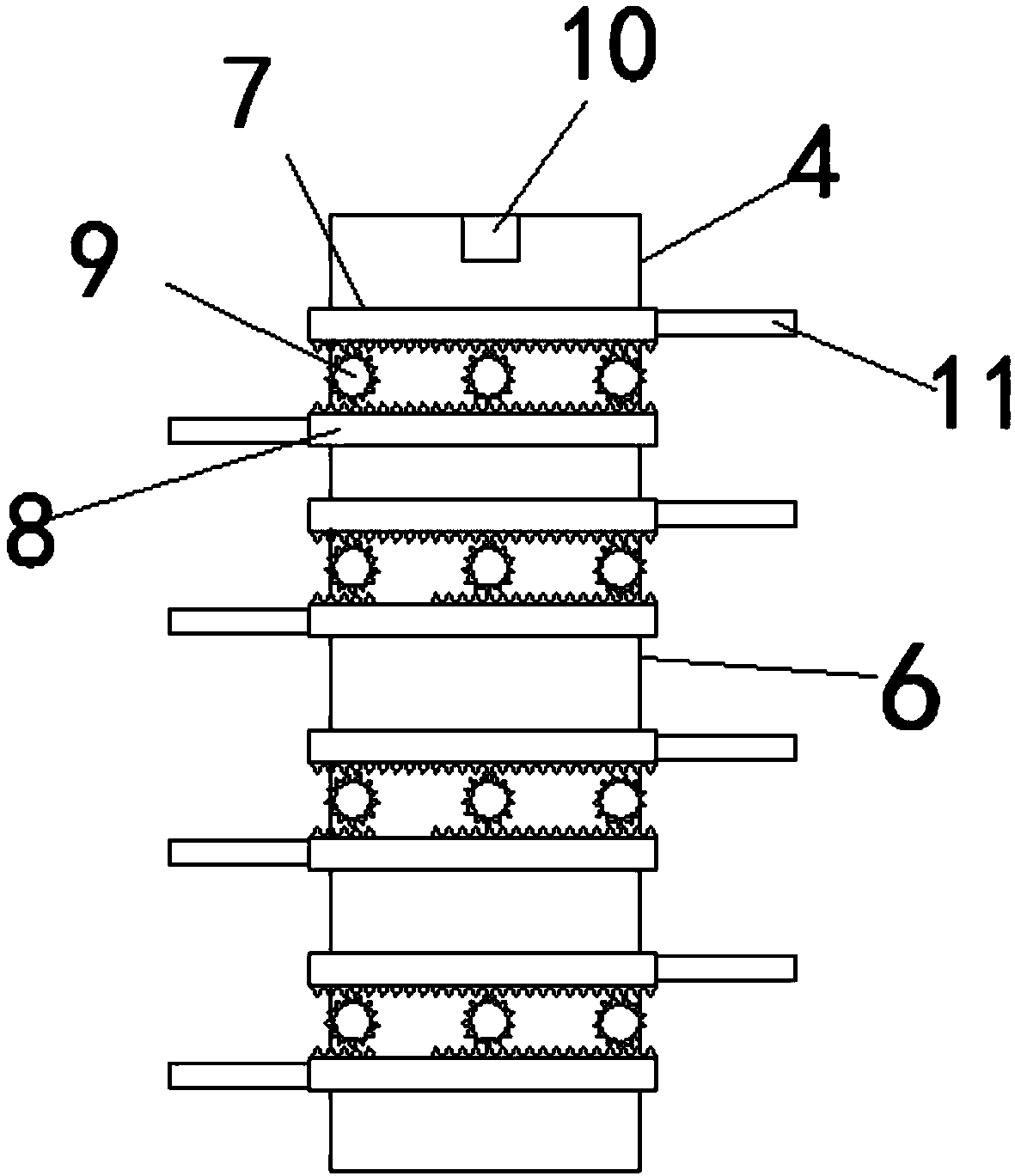

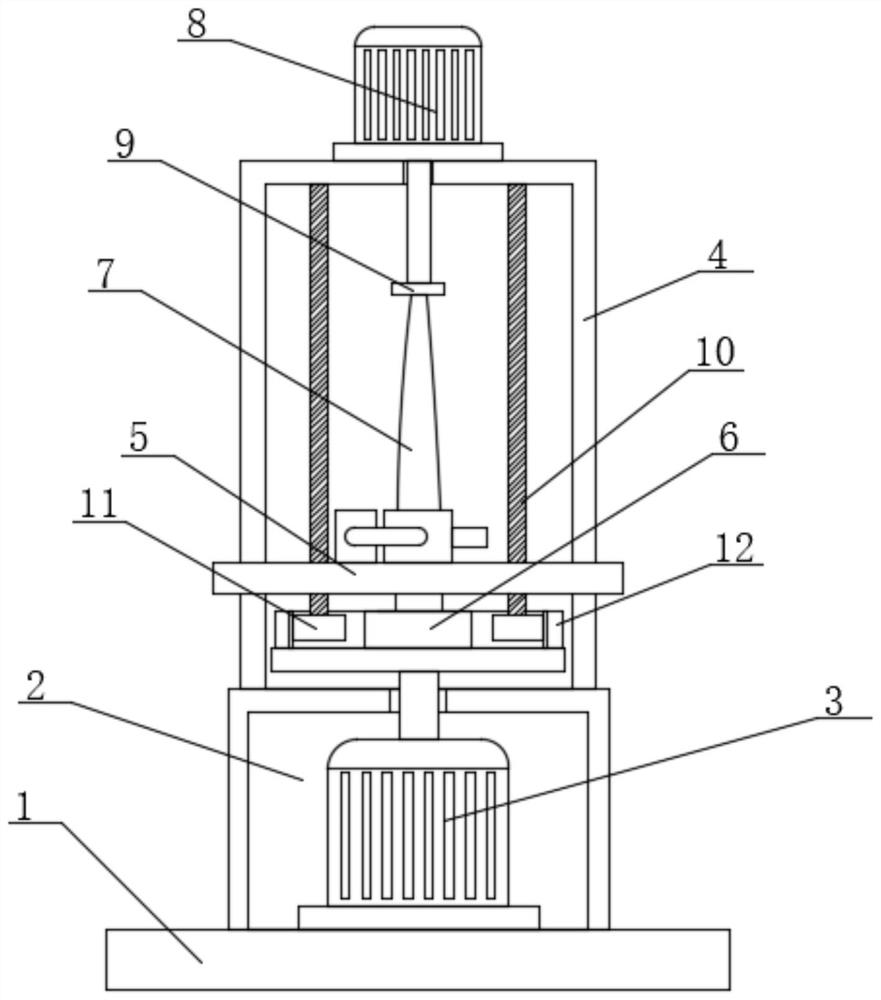

Sound-absorbing decoration material stirring device

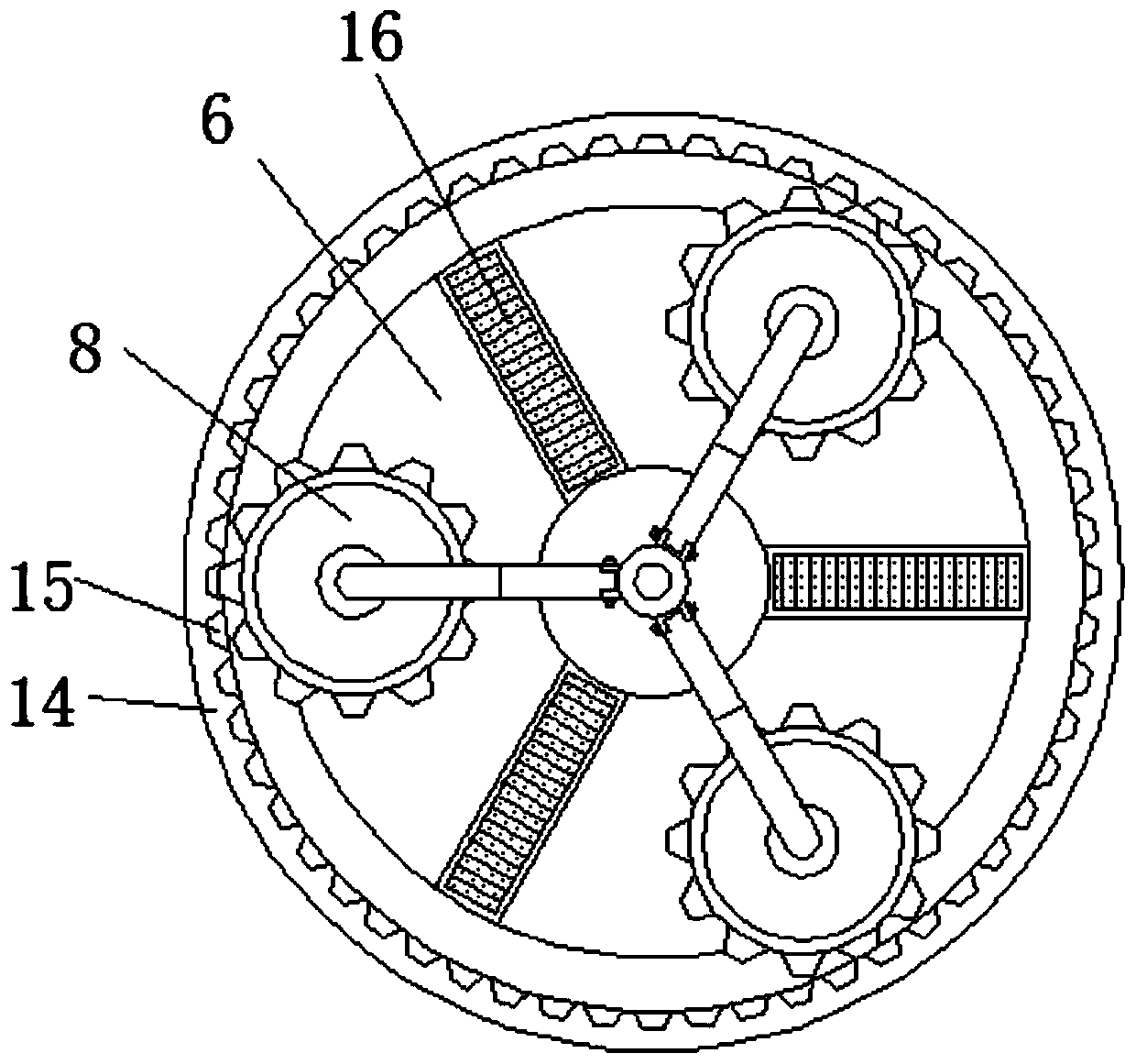

ActiveCN108079885AStir wellAchieve cycleTransportation and packagingRotary stirring mixersSpiral bladeEngineering

The invention belongs to the technical field of processing of sound-absorbing decoration materials, and in particular, discloses a sound-absorbing decoration material stirring device which includes astirring barrel; a separation plate and a filter screen are arranged in the stirring barrel. The top wall of the stirring barrel is equipped with a motor, an output shaft of the motor is connected with a center shaft, the center shaft is equipped with a planetary gear structure, and the planetary gear structure includes a sun wheel and two planetary wheels. The center shaft is equipped with a plurality of stirring paddles, and the center of each of the two planetary wheels is fixedly connected with a rotating shaft. The separation plate and the filter screen are each rotatingly connected withan annular plate. Each rotating shaft is provided with a spiral blade, and the two rotating shafts are each sleeved with a feeding tube with two ends opening. The feeding tubes are fixedly connected on the annular plates, the outer walls, above the separation plate, of the feeding tubes are provided with a plurality of stirring blades, and the outer walls, between the filter screen and the separation plate, of the two feeding tubes are each rotatingly connected with a grinding roller. While raw materials are stirred, the raw materials are ground.

Owner:重庆李不凡商贸有限公司

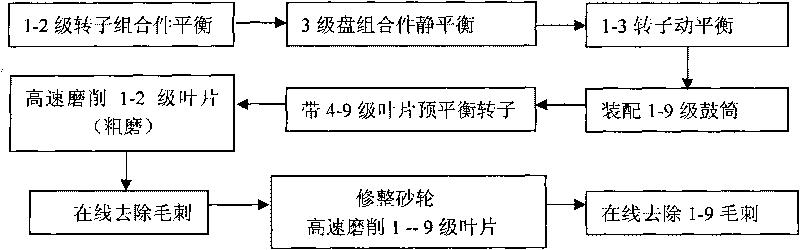

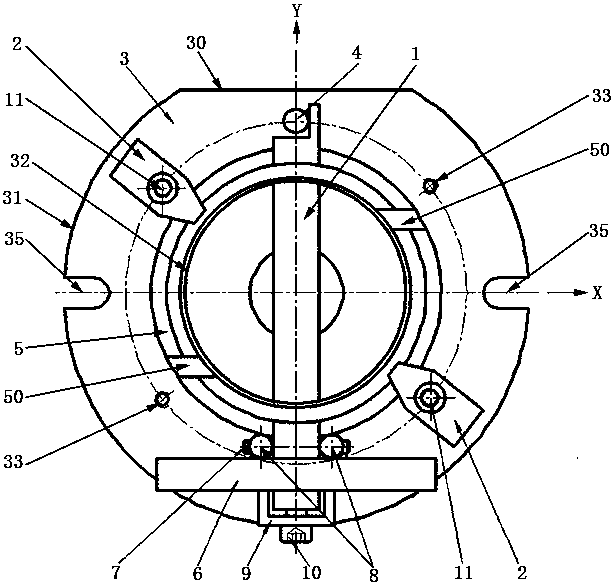

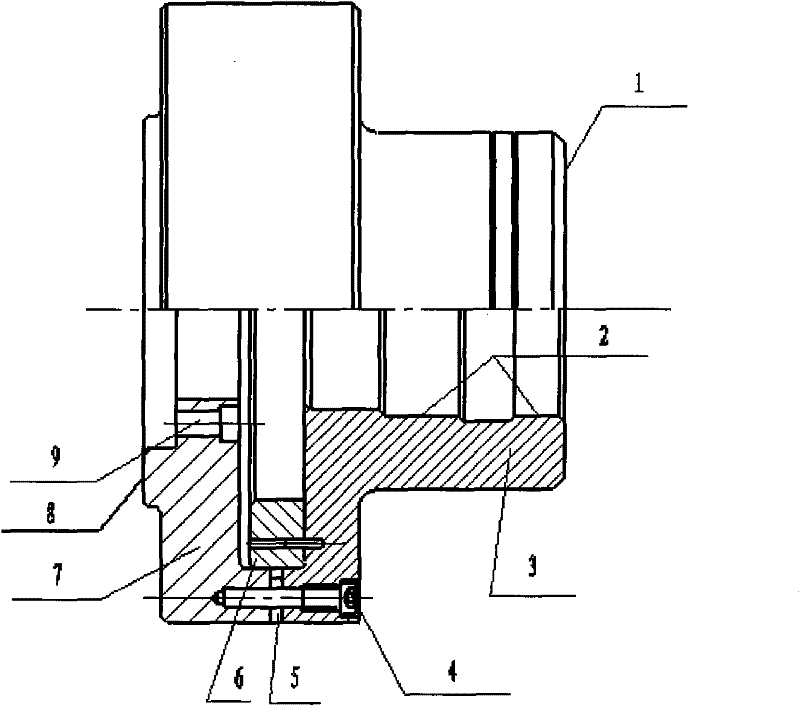

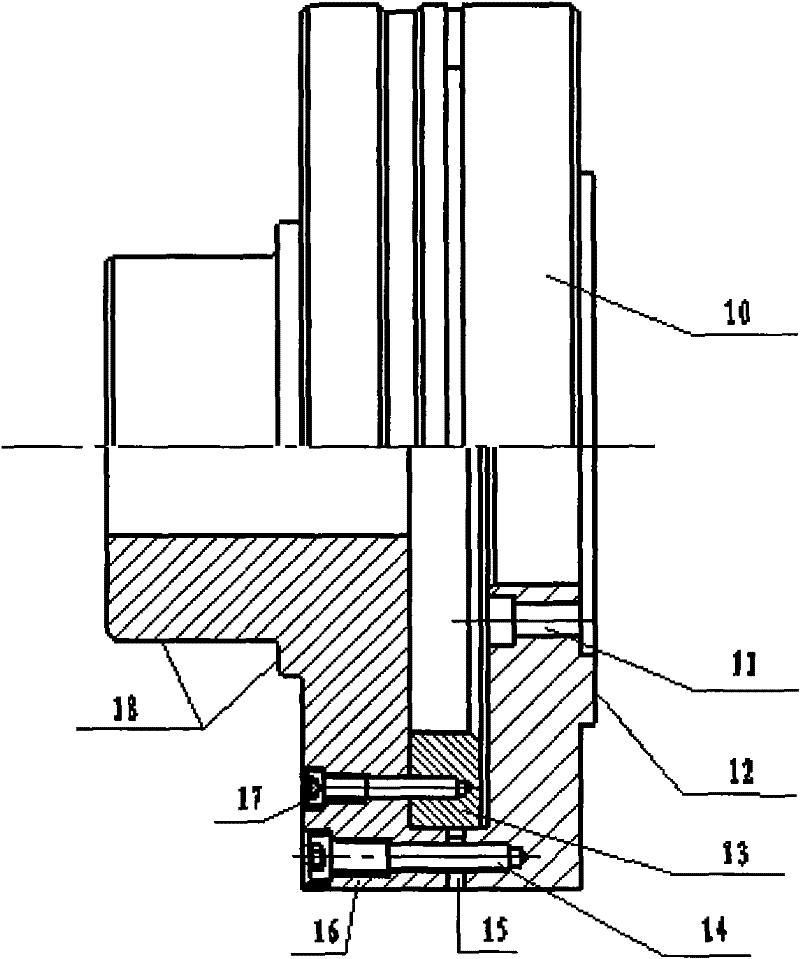

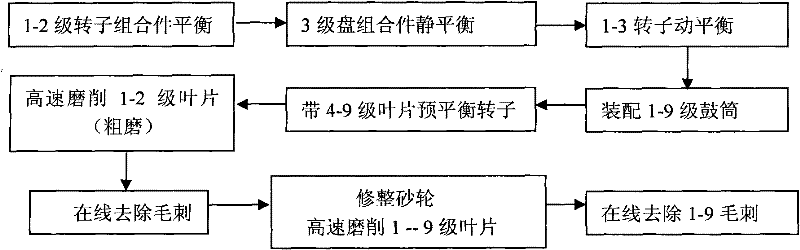

Composite processing method for grinding vane apex of rotor vane of aeroengine at high speed

ActiveCN101722459AGuaranteed GrindingMeet the design requirementsGrinding machinesAviationEngineering

The invention relates to a composite processing method for grinding the vane apex of a rotor vane of an aeroengine at a high speed, which comprises the following steps of: firstly, balancing a rotor in advance, controlling unbalance quantity which is permitted to be used for balancing the rotor in advance to be within 254g.mm, then installing the rotor on a fixture, enabling the rotor to be in a stretching state and grinding at a high speed. In the grinding process, the rotational speed of a processing part is 1600-2000r / min, the linear speed of a grinding wheel is 33-36m / s, the rotational speed of a scrubbing brush is 1500-1900r / min, and the control temperature during grinding is 20+ / -5 DEG C.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

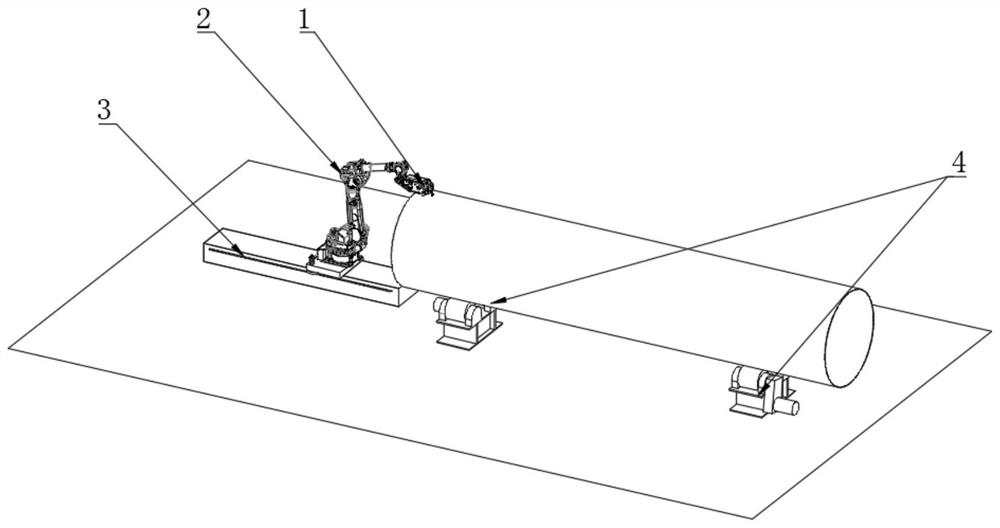

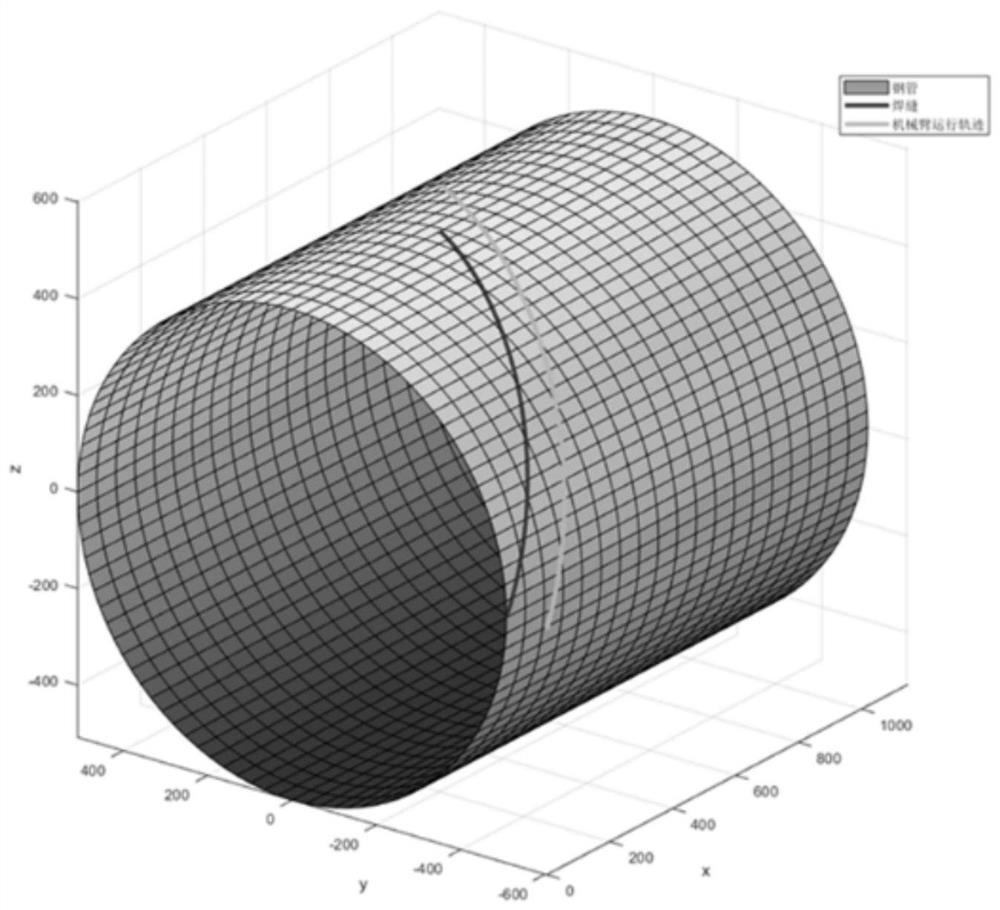

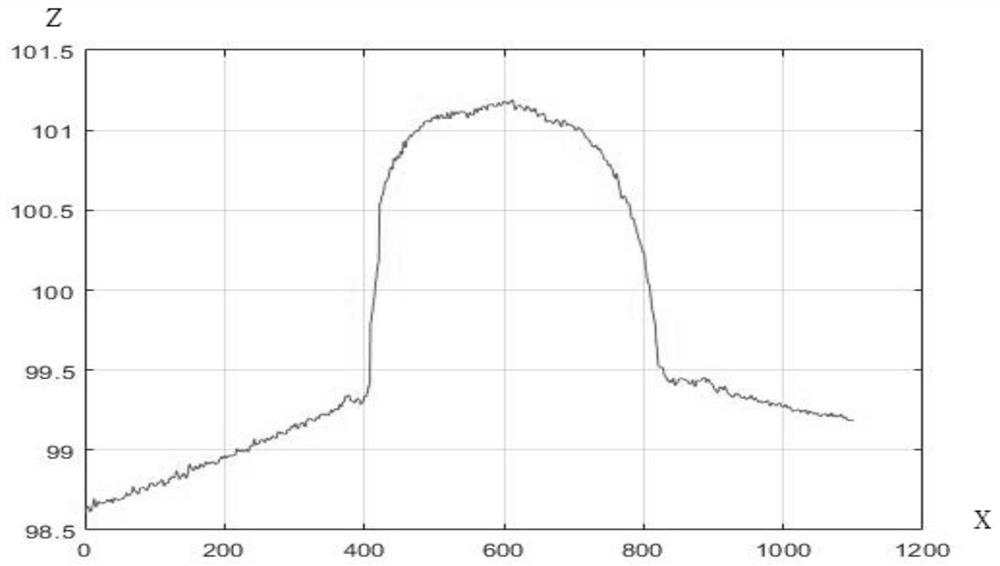

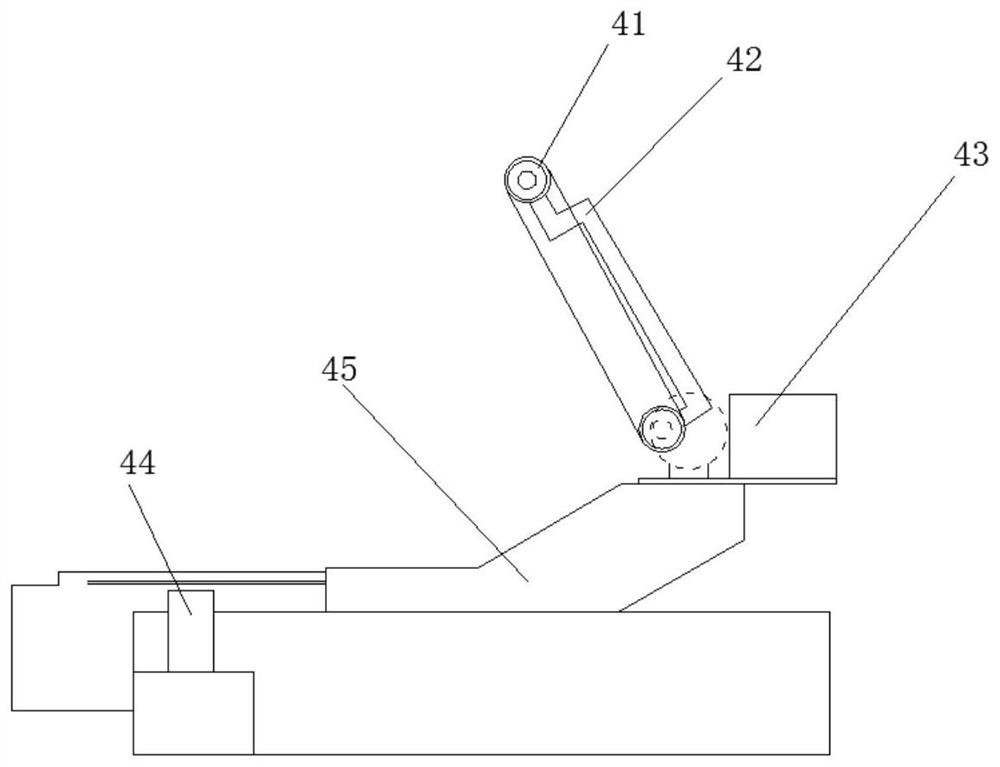

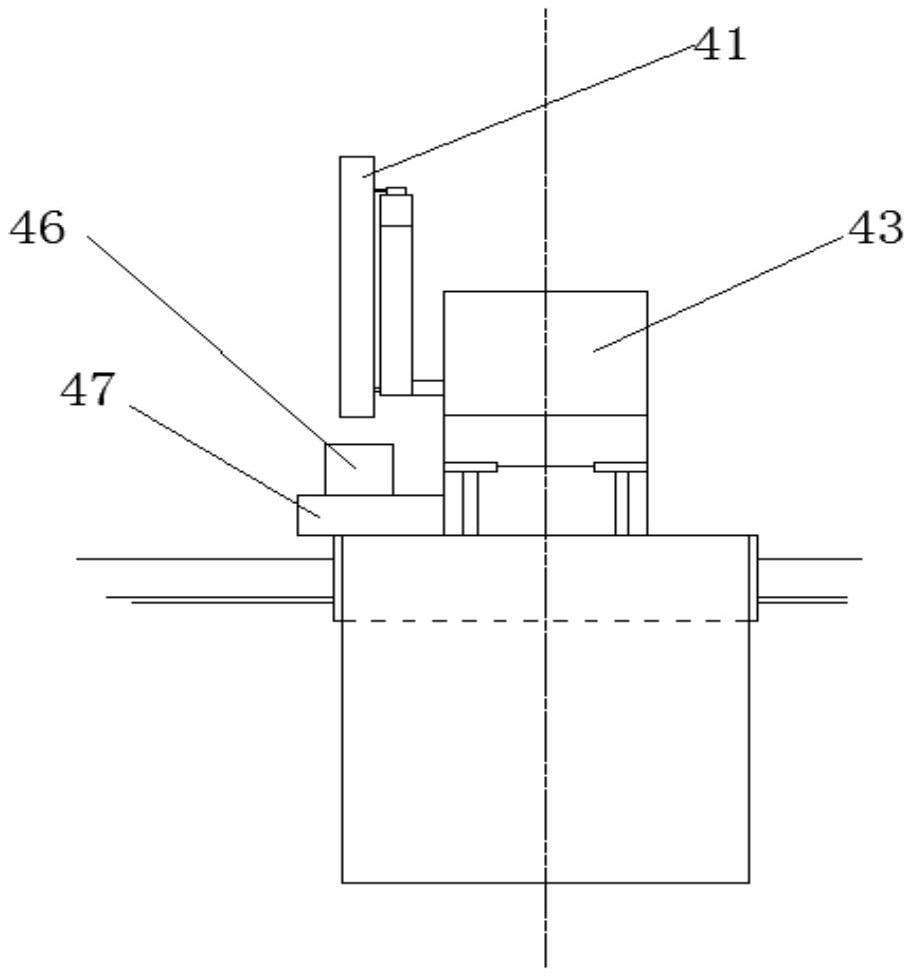

Grinding method of steel pipe end spiral weld grinding robot

ActiveCN112296822AIncrease productivityNo need for manual secondary grindingGrinding drivesBelt grinding machinesPipeIndustrial engineering

The invention provides a grinding method of a steel pipe end spiral weld grinding robot. A grinding device is carried on a mechanical arm, a contourgraph is used in cooperation to detect and scan a steel pipe, an upper computer is adopted to establish a coordinate system to plan a path, and then the grinding device is controlled to conduct grinding along the path, so that high-precision grinding is achieved, manual secondary grinding is not needed, and the production efficiency is high. When a triangular area of a weld is ground, a piecewise linear fitting method is adopted to grind the triangular area of the weld, so that grinding of the triangular area of the weld is guaranteed under the condition that the steel pipe is not abraded; and the toe point of the weld is found through the upper computer according to a weld scanning processing algorithm based on a difference method, and the distance between the grinding device and the steel pipe is controlled through the toe point of the weld, so that the APISPEC5L standard and the GBT97111-1997 standard regulation are met.

Owner:宝鸡宇喆工业科技有限公司

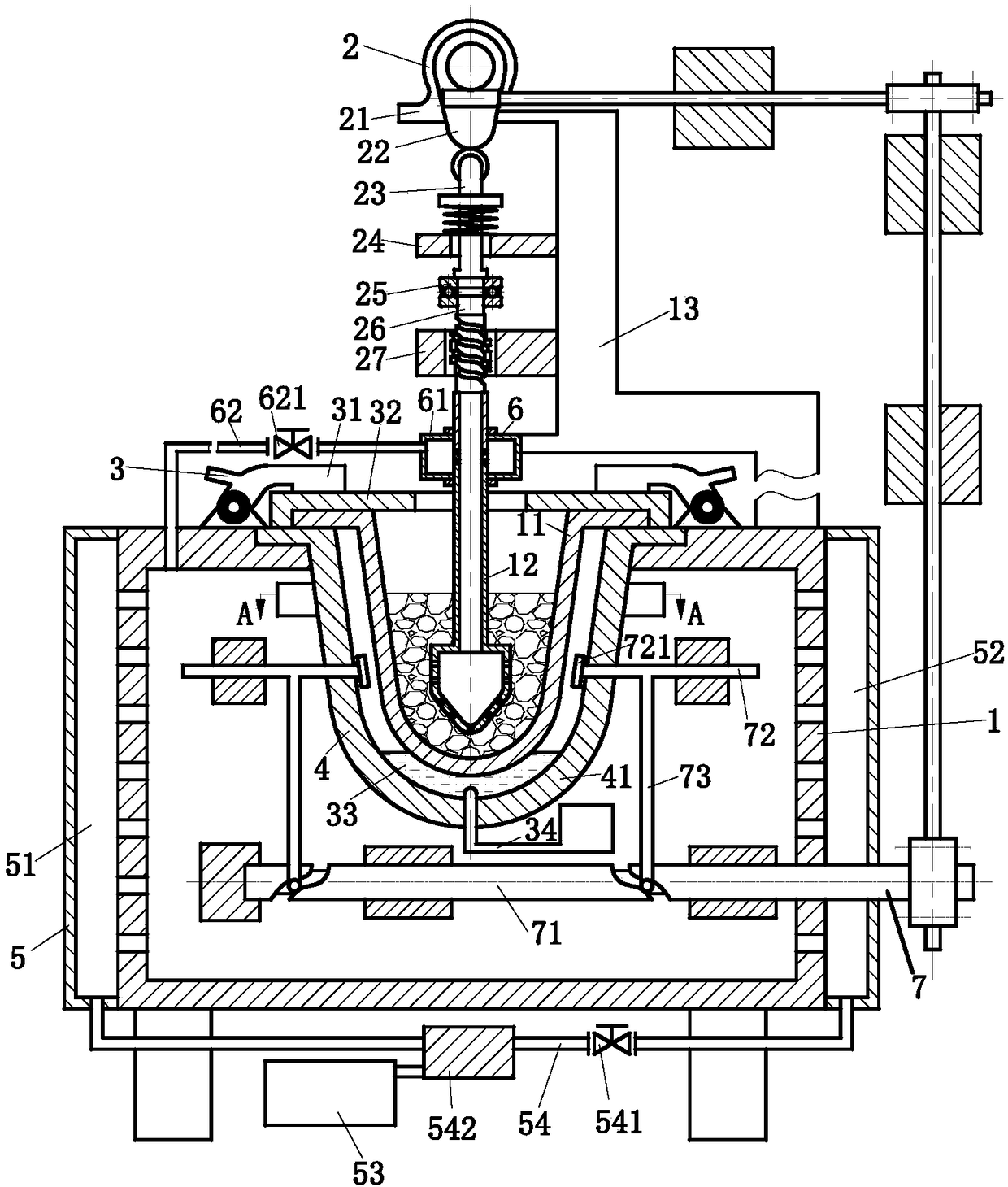

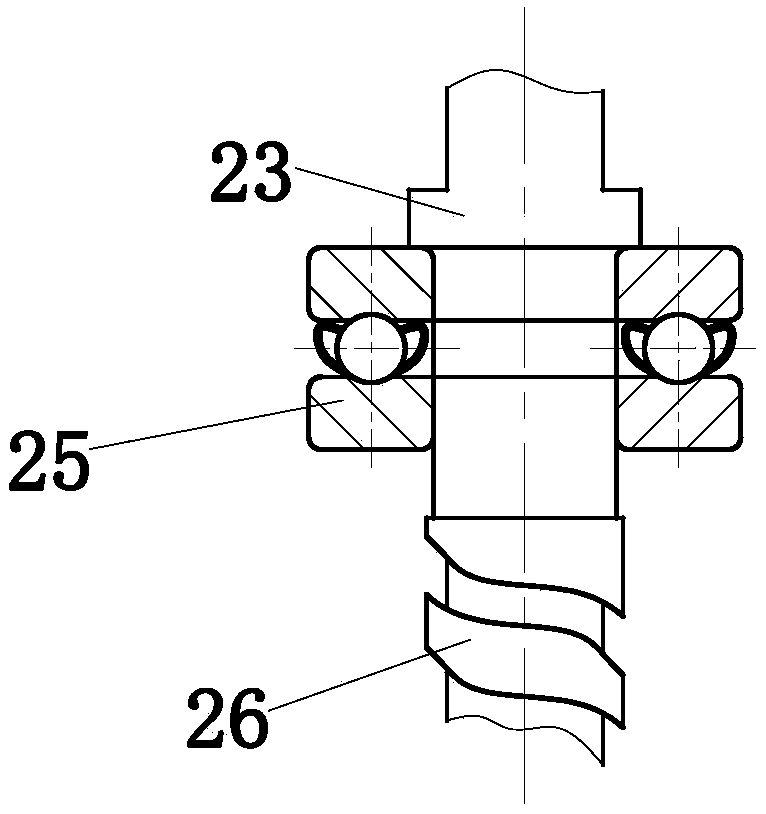

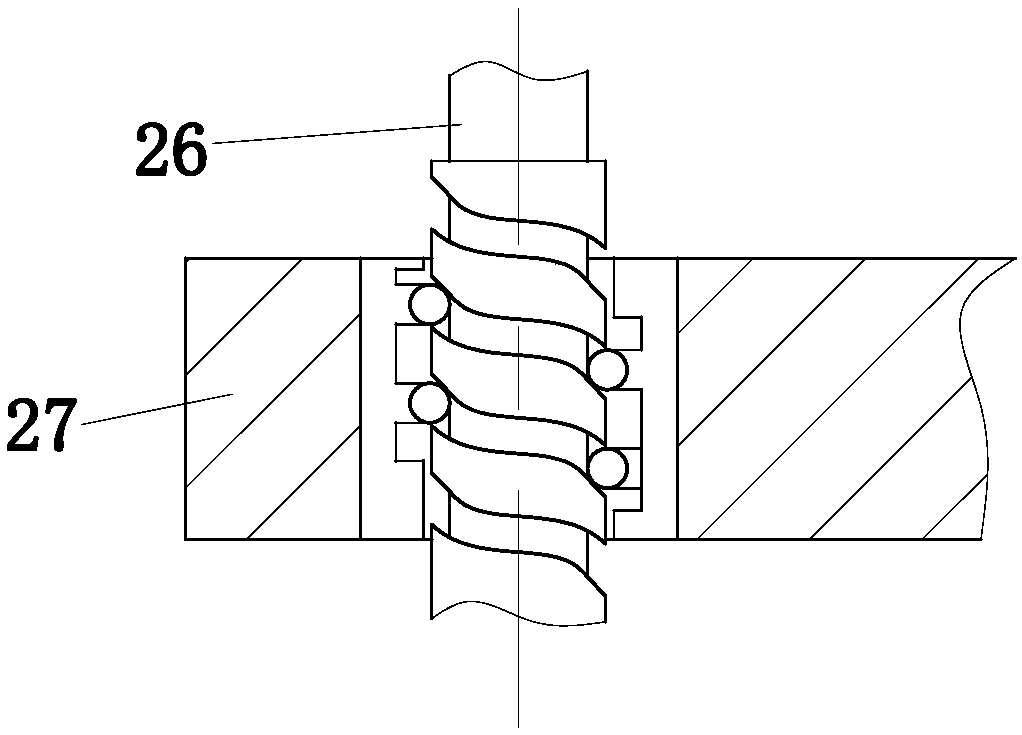

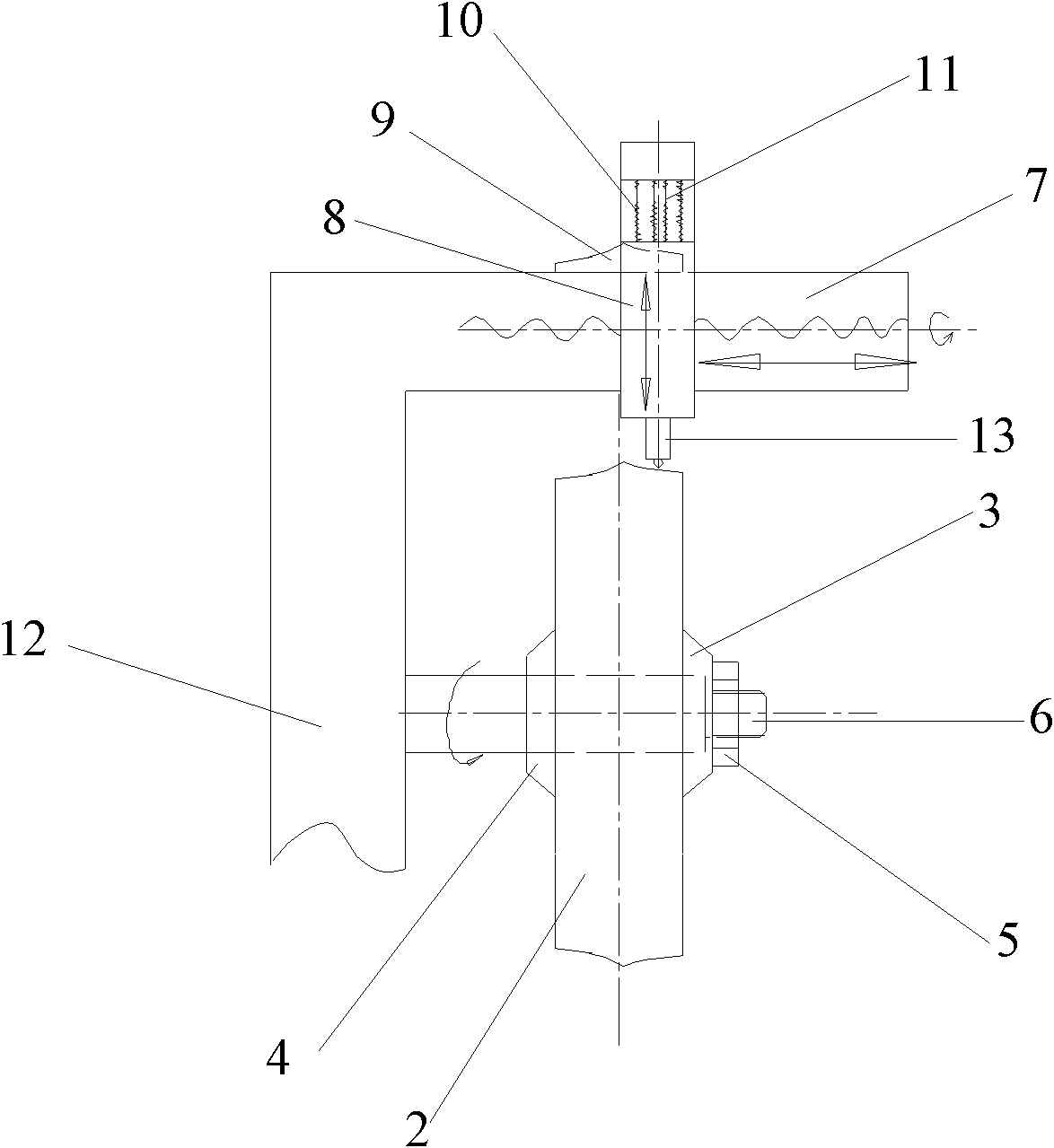

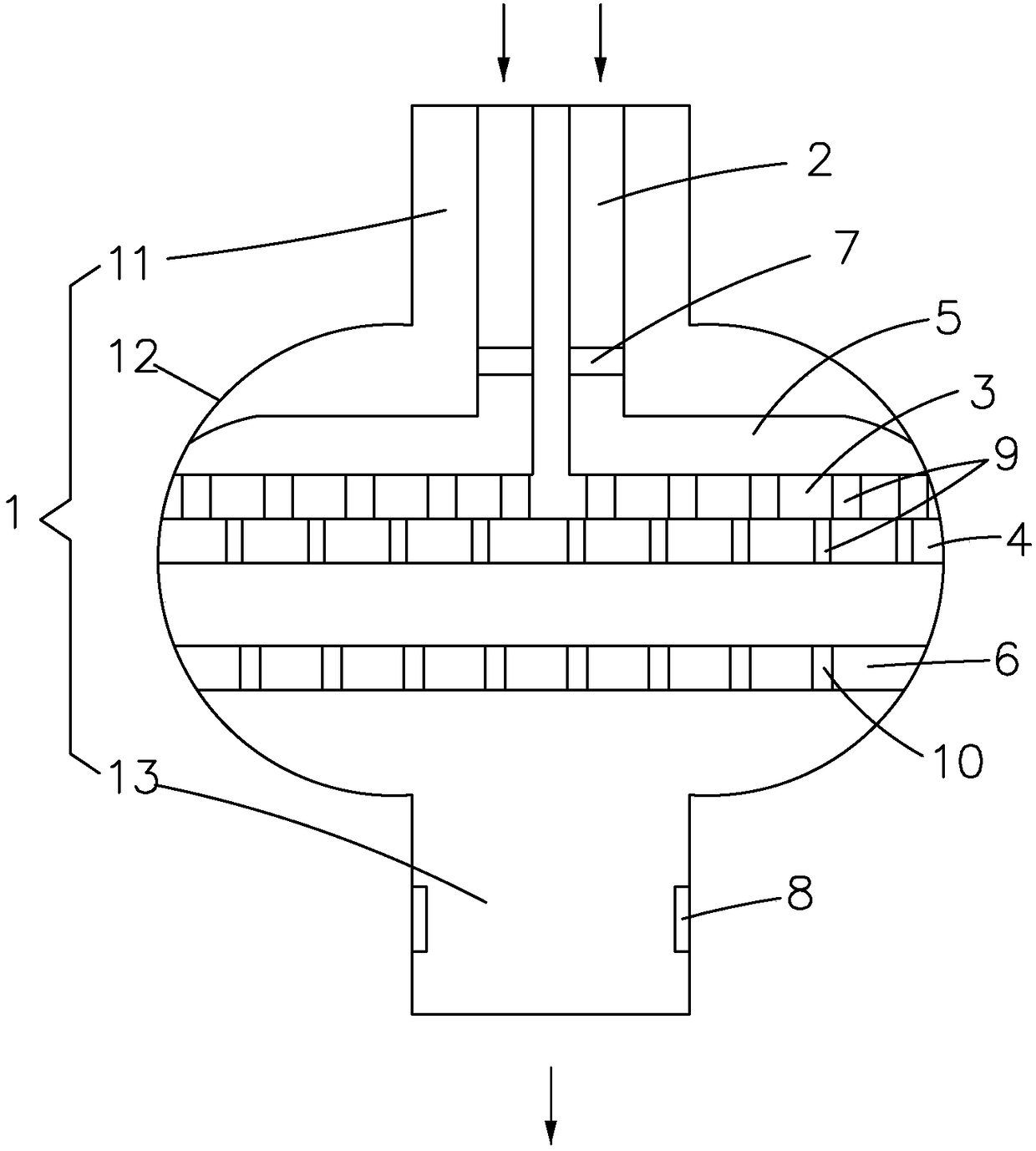

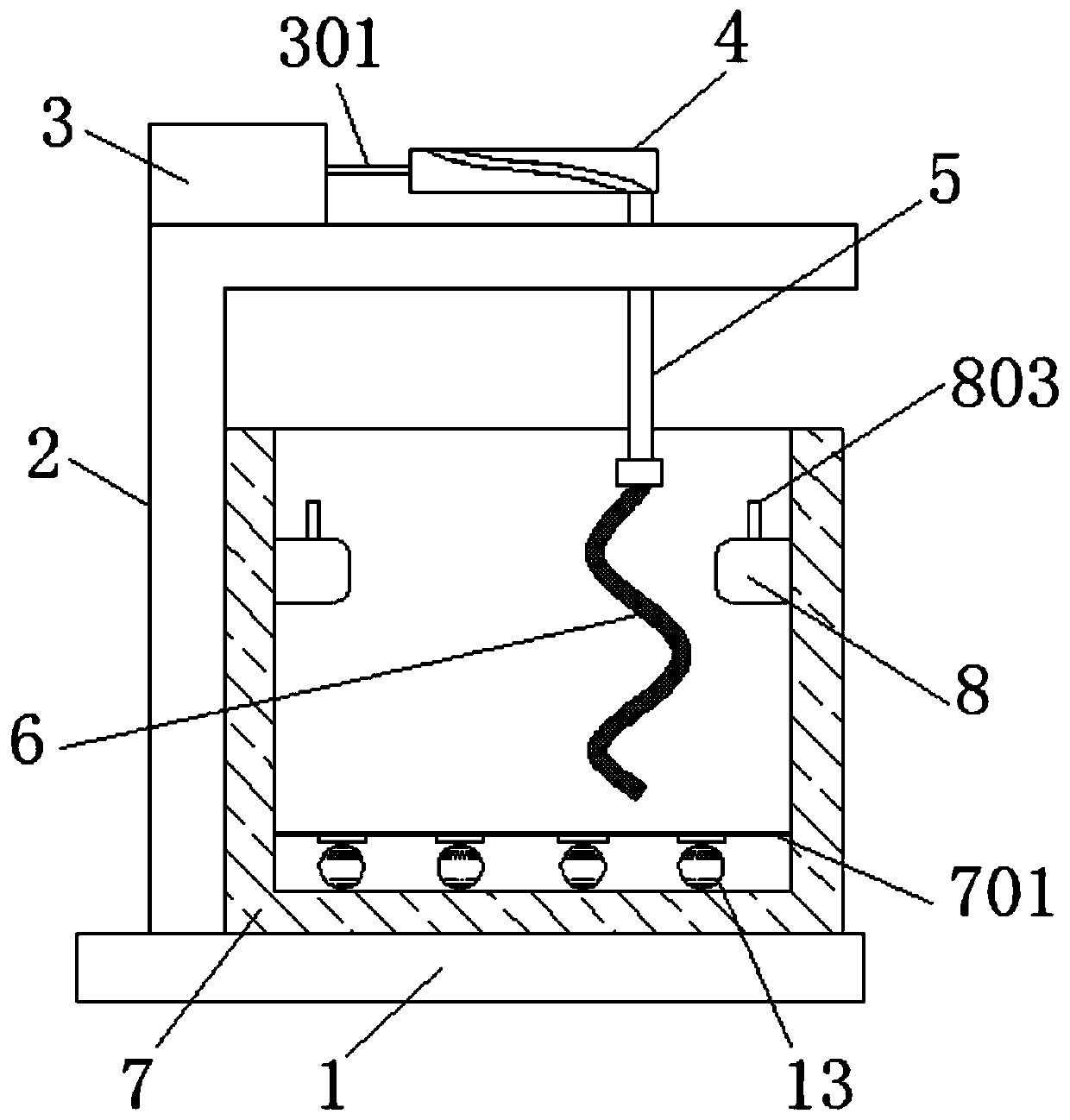

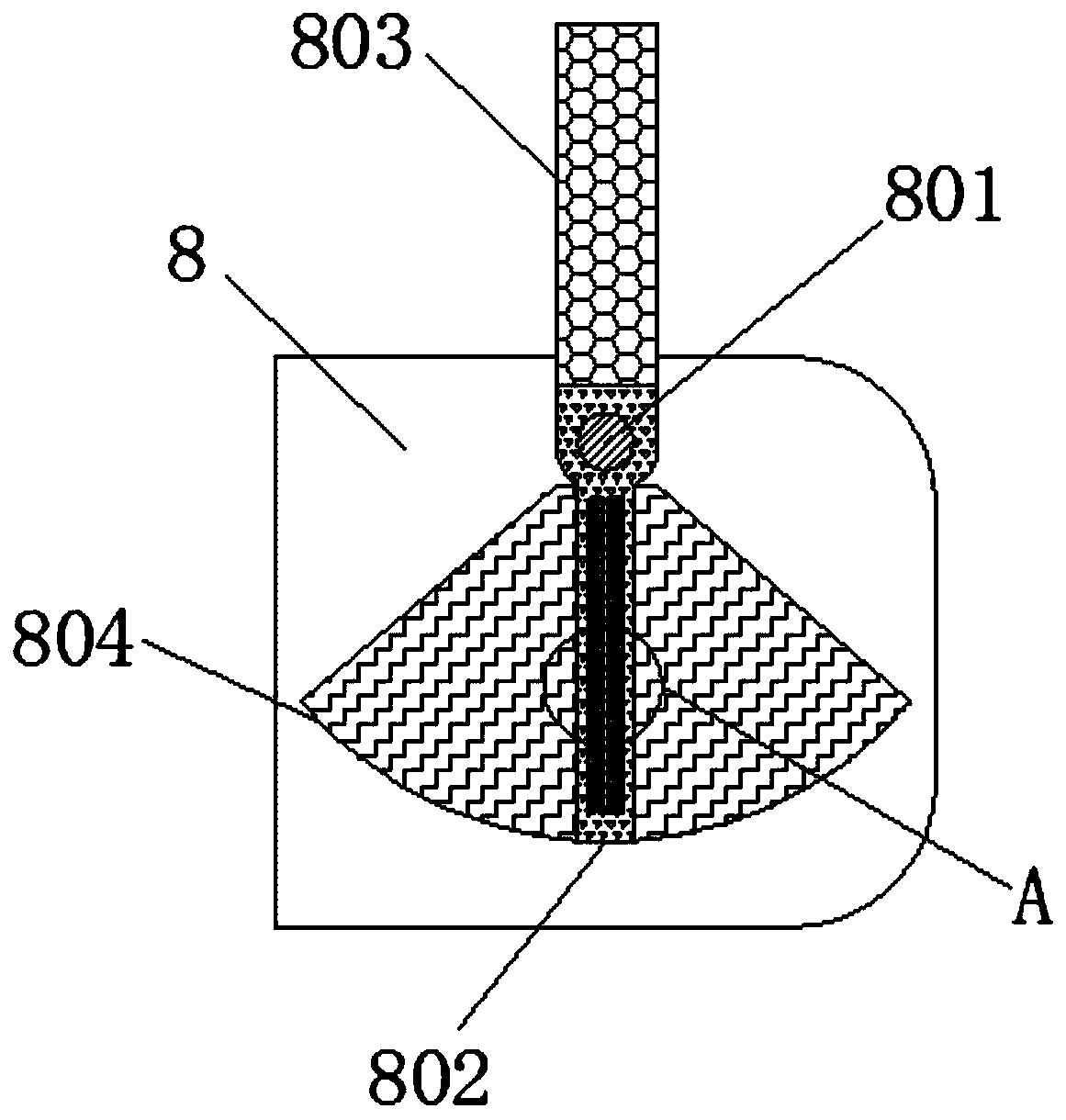

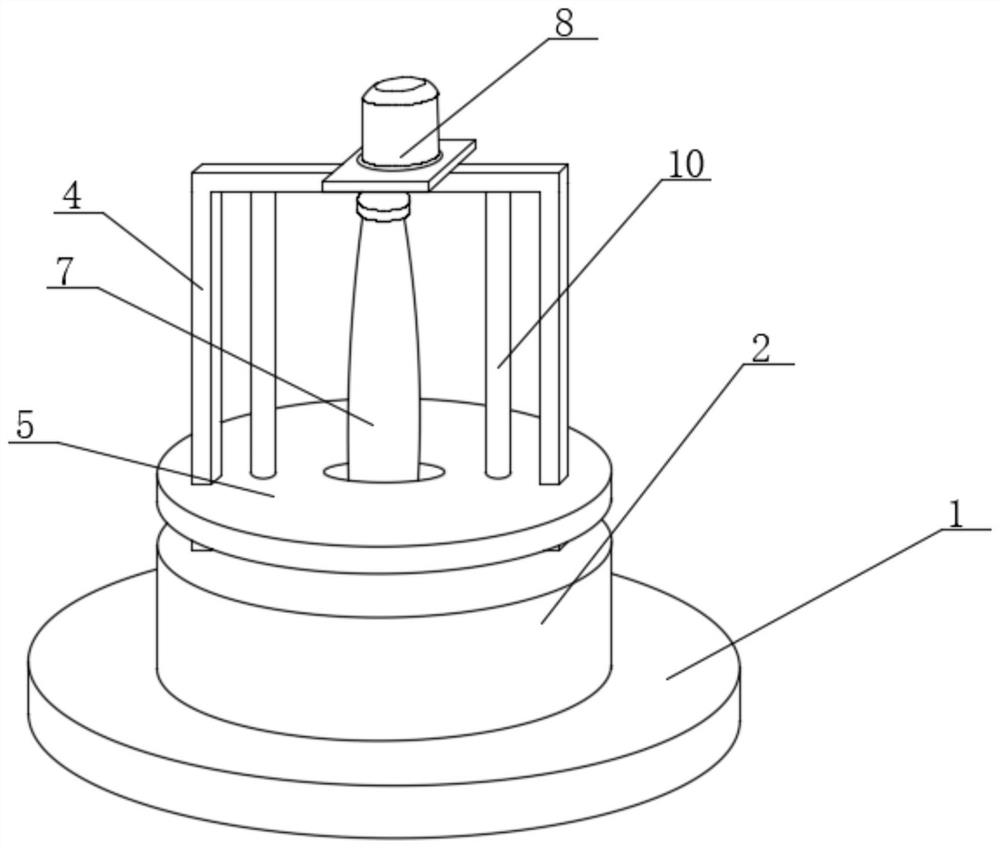

RNA (Ribonucleic Acid) grinding and extracting system

ActiveCN108435379AIncrease collection rateGuaranteed GrindingPreparing sample for investigationGrain treatmentsRNA extractionNitrogen gas

The invention belongs to the technical field of RNA extraction, and particularly relates to a RNA grinding and extracting system. The RNA grinding and extracting system adopts RNA grinding equipment which comprises a box, a centrifugal tube, a grinding head, a power module, a clamping fixed module, a heat preservation module, a nitrogen circulating pressure maintaining module, a nitrogen guiding module and a pressing module, wherein a cantilever is arranged on the box; the power module is fixed on the cantilever; the grinding head is connected to the power module; the power module is used fordriving the grinding head to rotate positively and negatively and move upwards and downwards linearly; the clamping fixed module is located on the box and is used for clamping and fixing the centrifugal tube on the box; the heat preservation module is used for heat preservation of the centrifugal tube; the nitrogen circulating pressure maintaining module is used for feeding nitrogen into the box and maintaining the stability of the pressure of nitrogen in the box; and the nitrogen guiding module is communicated with the box and is used for guiding nitrogen into the grinding head. The RNA grinding and extracting system has the beneficial effects that RNA is extracted and ground mechanically, can be fully refined and ground and facilitates extraction of RNA.

Owner:JILIN UNIV

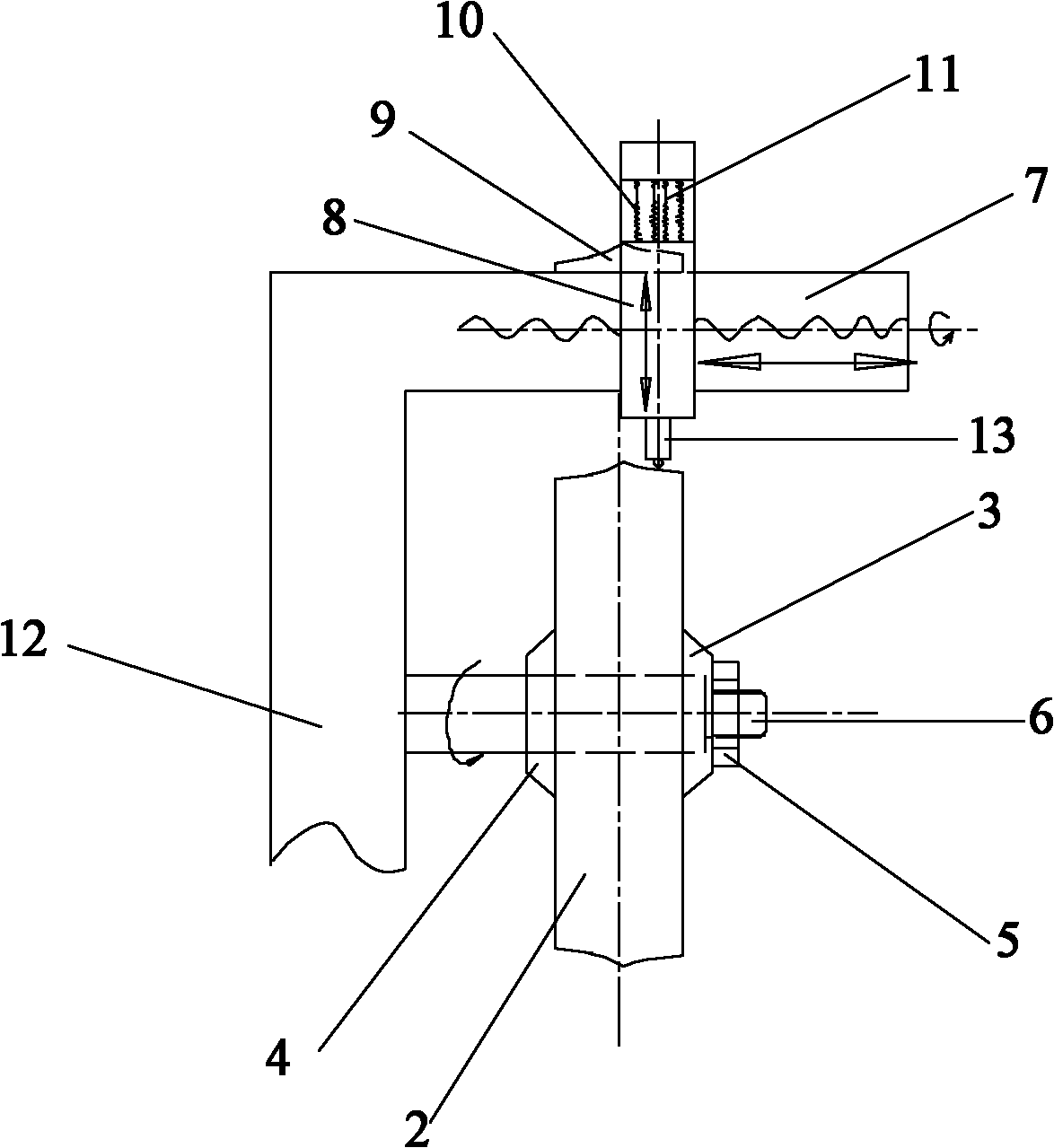

Processing method of molding curve part and device used in same

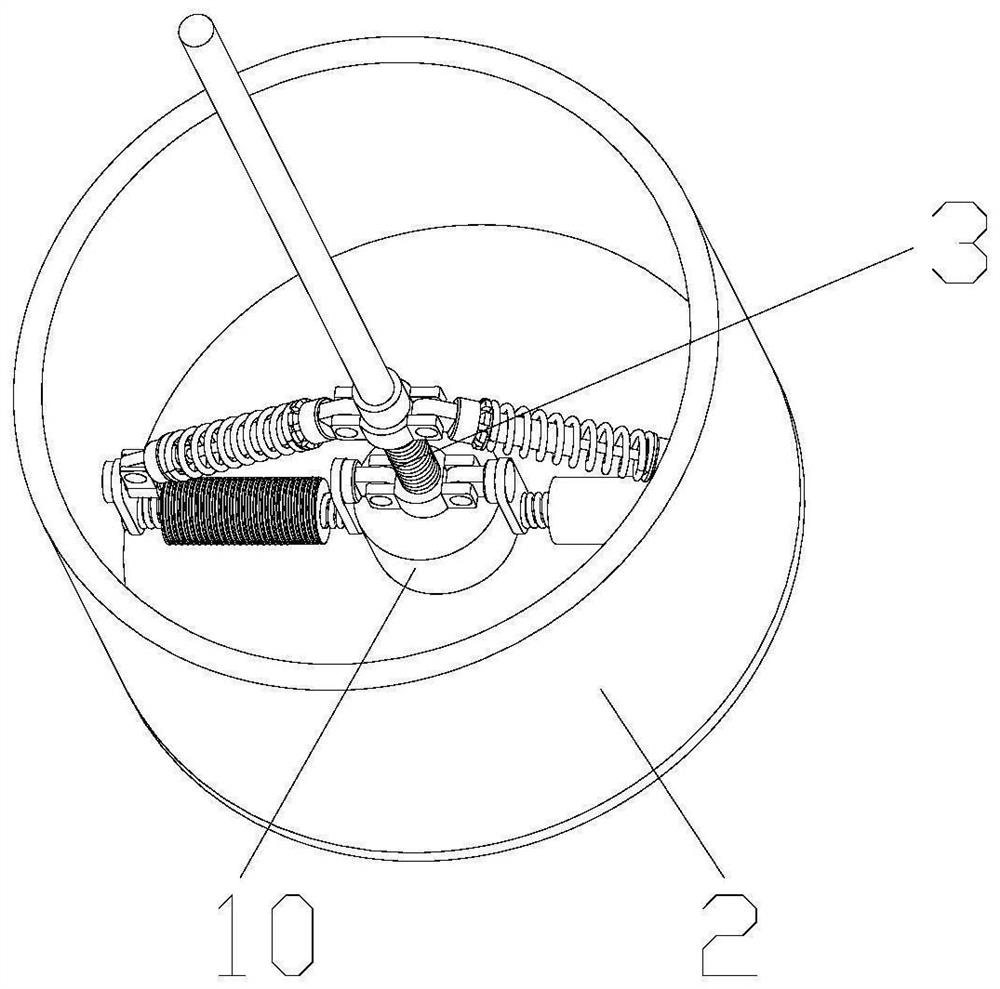

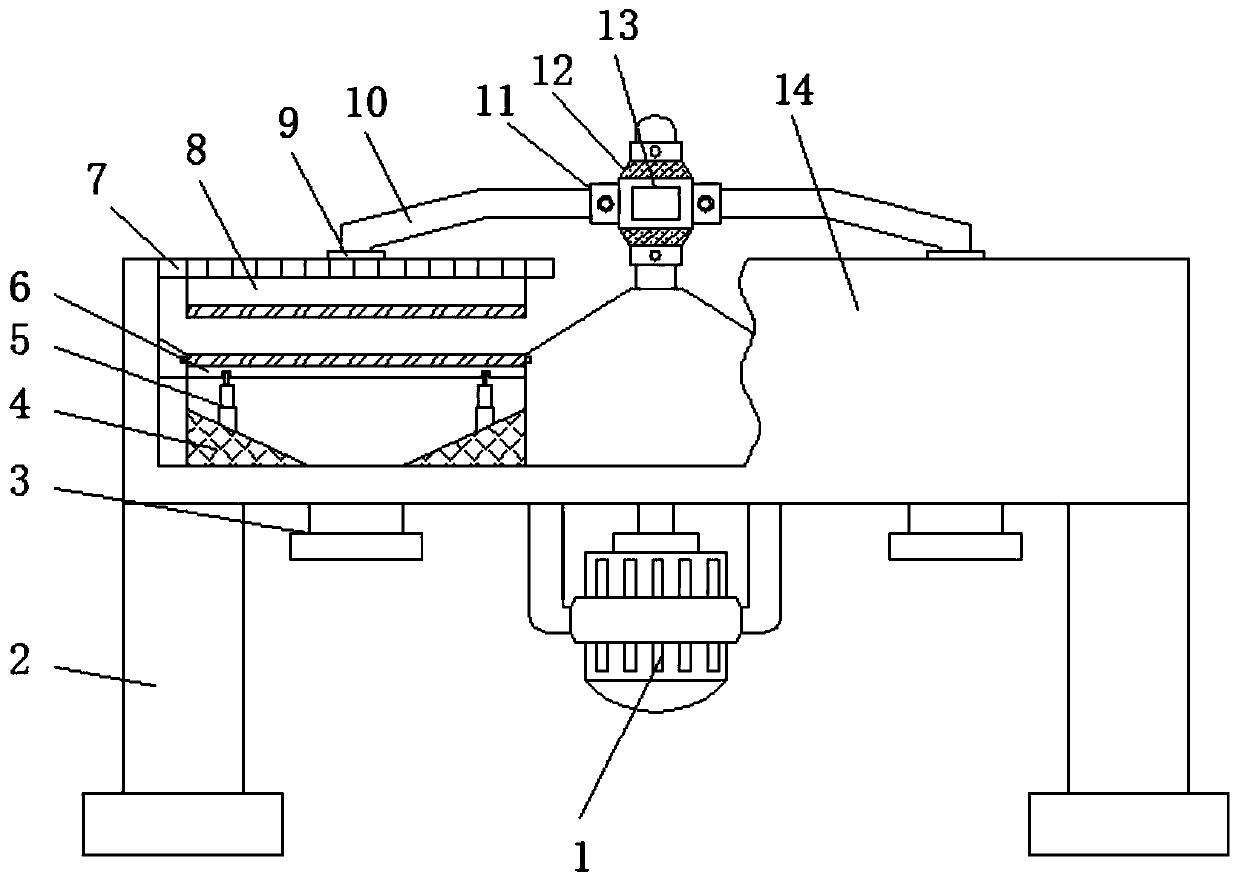

The invention relates to a processing method of a molding curve part and a device used in the same. The method comprises the following steps of: customizing a rough milling cutter according to the curve shape of a curve part to be processed; roughly milling the curve part to be processed by using the customized rough milling cutter, and forming a rough molding curve on the surface of the part to be processed; quenching the roughly milled part; polishing a grinding wheel by using the device provided by the invention, forming a shape consistent with the molding curve of the part on the surface of the grinding wheel; and accurately grinding the quenched part by using the ground grinding wheel to obtain a part with an accurate molding curve. The device provided by the invention comprises a grinding machine with a machine body, a grinding wheel corrector, a main shaft and a grinding wheel, wherein the main shaft is arranged on the machine body and is capable of rotating around the axis per se, the grinding wheel is coaxially arranged on the main shaft and rotates under the drive of the main shaft, a horizontal support plate and an explorator which are capable of moving along the X axis direction and the Y axis direction are arranged on the machine body, and the grinding wheel corrector is used for grinding the grinding wheel according to the outline of the upper surface of the explorator under the action of the horizontal support plate and a pressure spring.

Owner:SUZHOU ZHOUYANG PRECISION MACHINERY TECH CO LTD

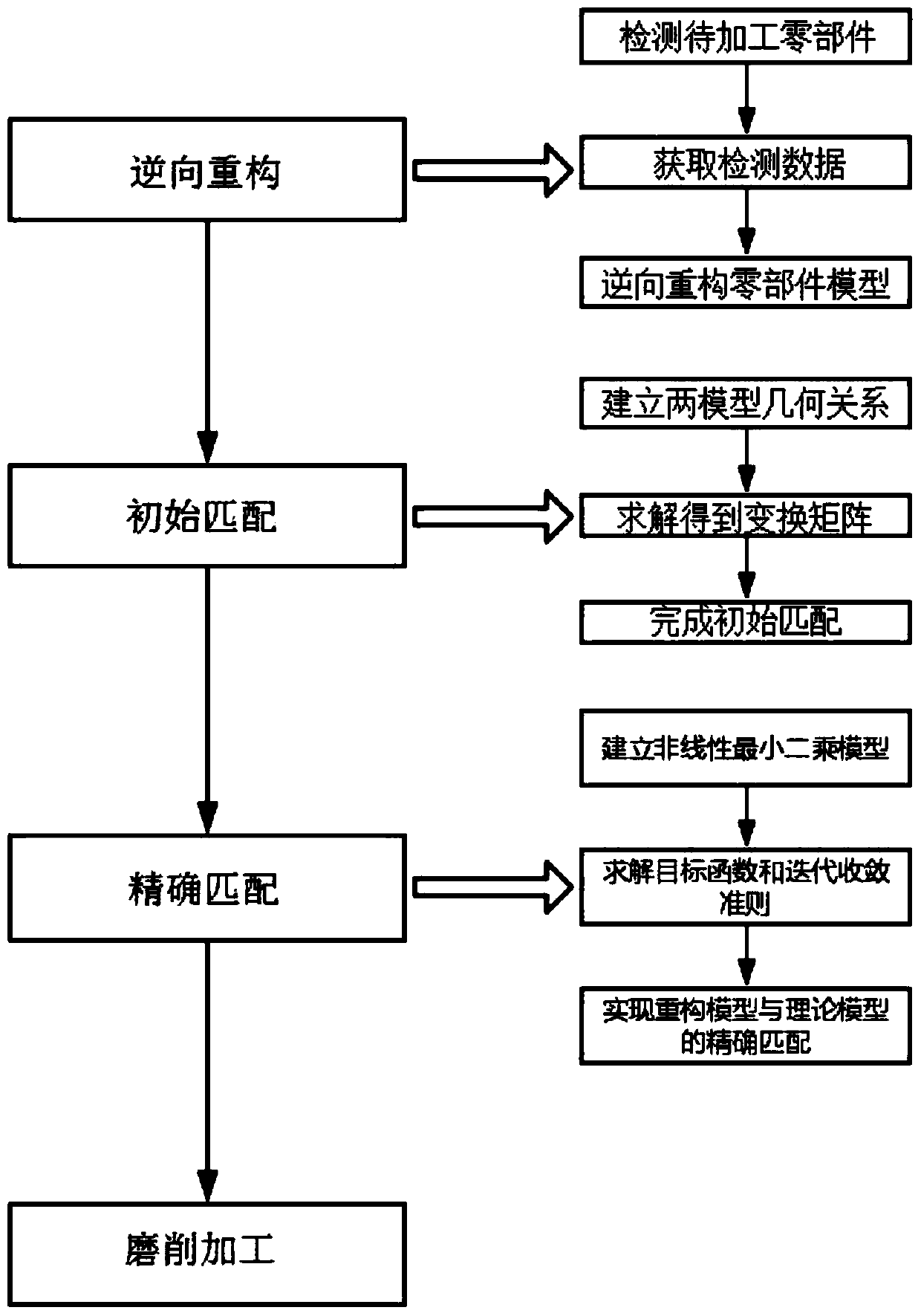

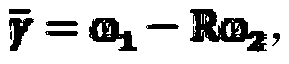

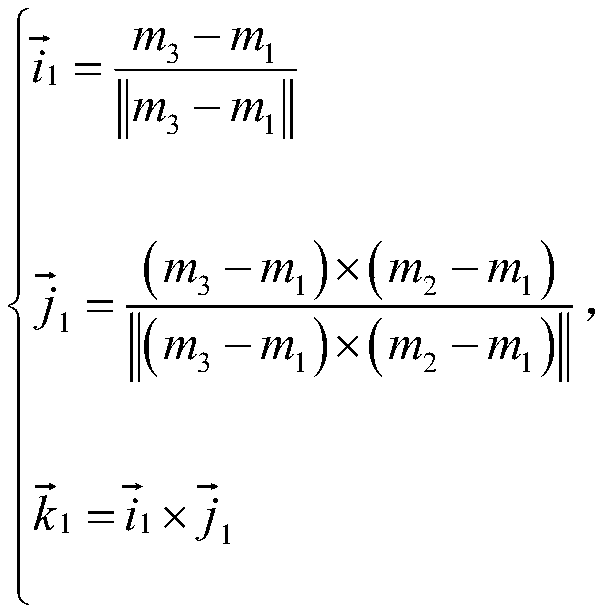

Grinding method based on margin constraint condition

The invention discloses a grinding method based on a margin constraint condition. The method comprises following steps: step one, acquiring three-dimensional measurement data of a part, and reverselyreconstructing a reconstruction model of the part according to the three-dimensional measurement data; step two, performing initial matching to obtain an initial transformation matrix from the reconstruction model to a theoretical model; step three, performing accurate matching, completing accurate matching of the reconstruction model and the theoretical model through iterative operation, and obtaining machining reference and machining allowance of the part; step four, setting grinding parameters according to the machining reference and machining allowance which are obtained in step three, andgrinding the part. According to the method, the machining reference and the machining allowance of the part can be effectively determined, and the problem of difficulty in a numerical control abrasive belt self-adaptive grinding technology of reference-free blade parts is effectively solved.

Owner:CHONGQING UNIV OF TECH

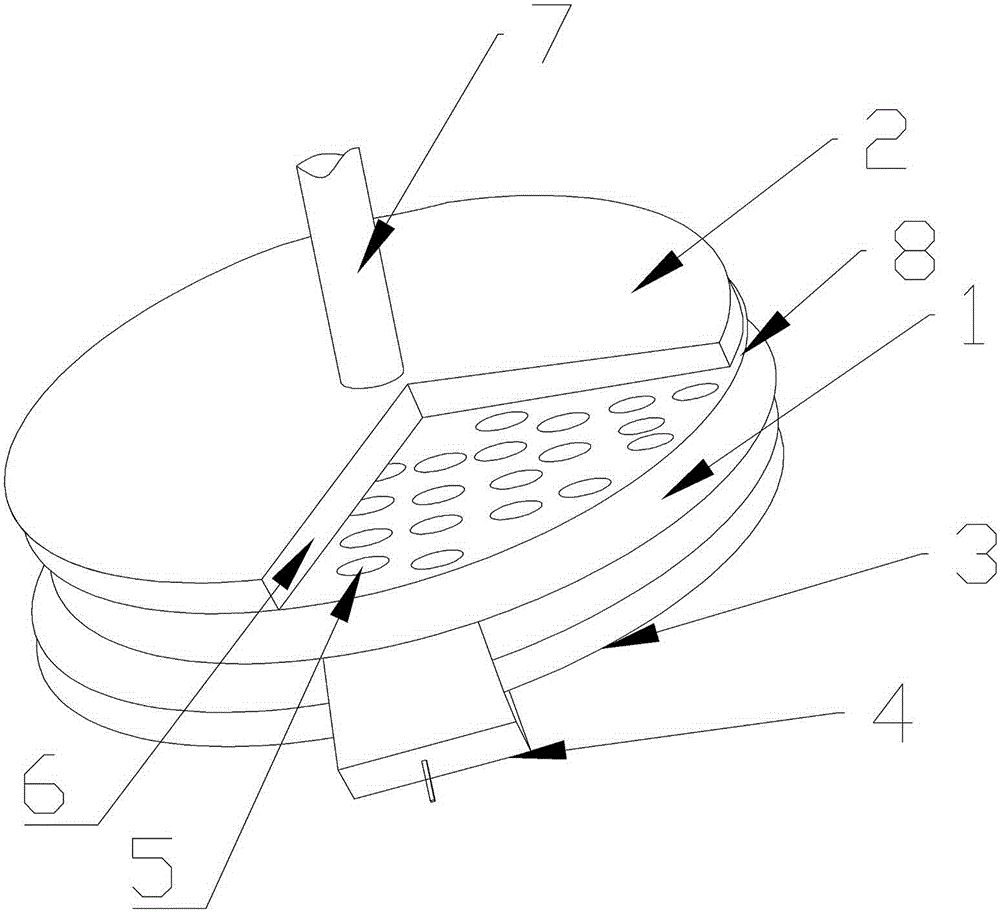

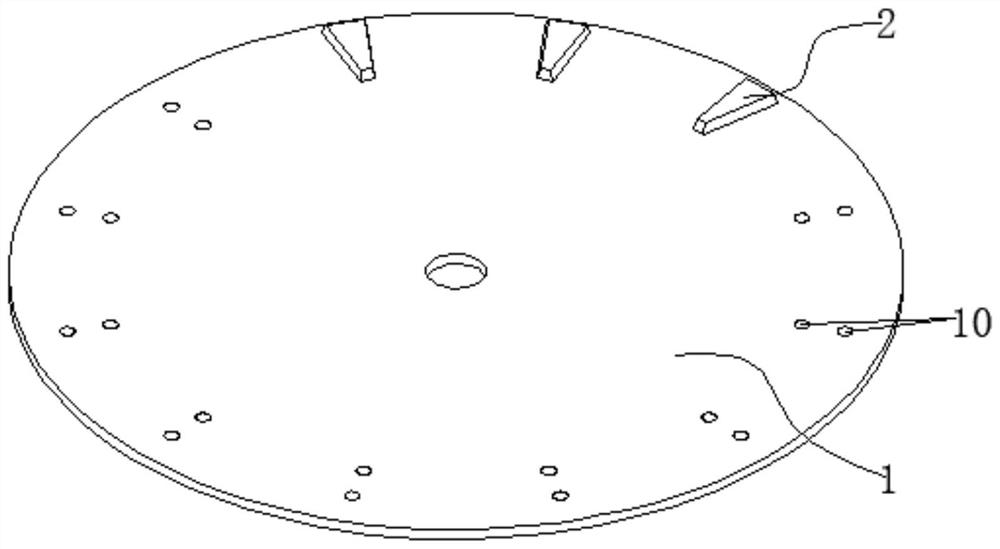

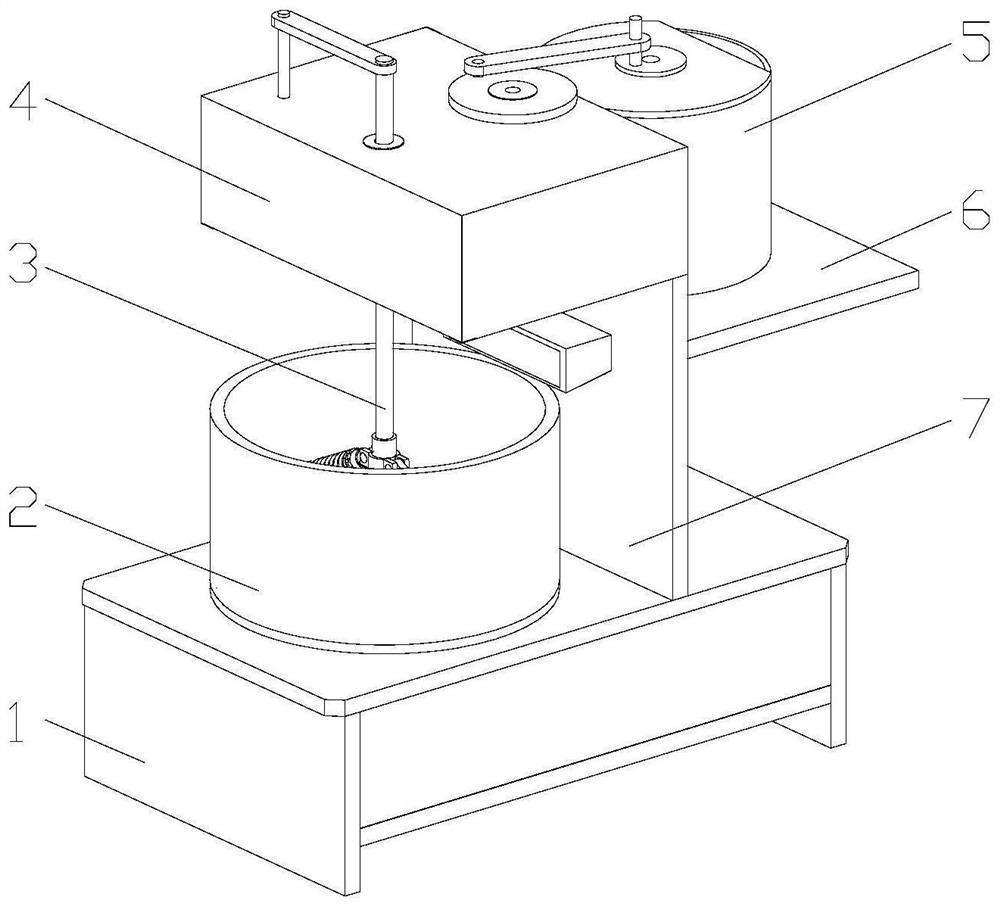

Spring grinding equipment

The invention relates to the field of spring machining machinery equipment and particularly relates to spring grinding equipment. The spring grinding equipment comprises a top tray and a chassis, wherein grinding wheels are arranged at the lower bottom surface and the upper bottom surface of the top tray, a grinding disc is arranged between the top tray and the chassis, spring holes for containing springs are formed in the grinding disc, and a spring door is further arranged on the chassis; a gap is formed in the top tray, and the spring door is located right below the gap; and the lower bottom surface of the top tray is obliquely arranged, an inclined seam is formed between one end of the gap and the grinding disc, and the other end of the gap fits with the grinding disc. The spring grinding equipment has the beneficial effects that the structure is relatively simple, the design is reasonable, and energy sources are saved; and the spring grinding equipment is capable of continuously working and is used for grinding and machining the springs, so that the machining efficiency is improved.

Owner:CHONGQING ANTAI SPRING IND

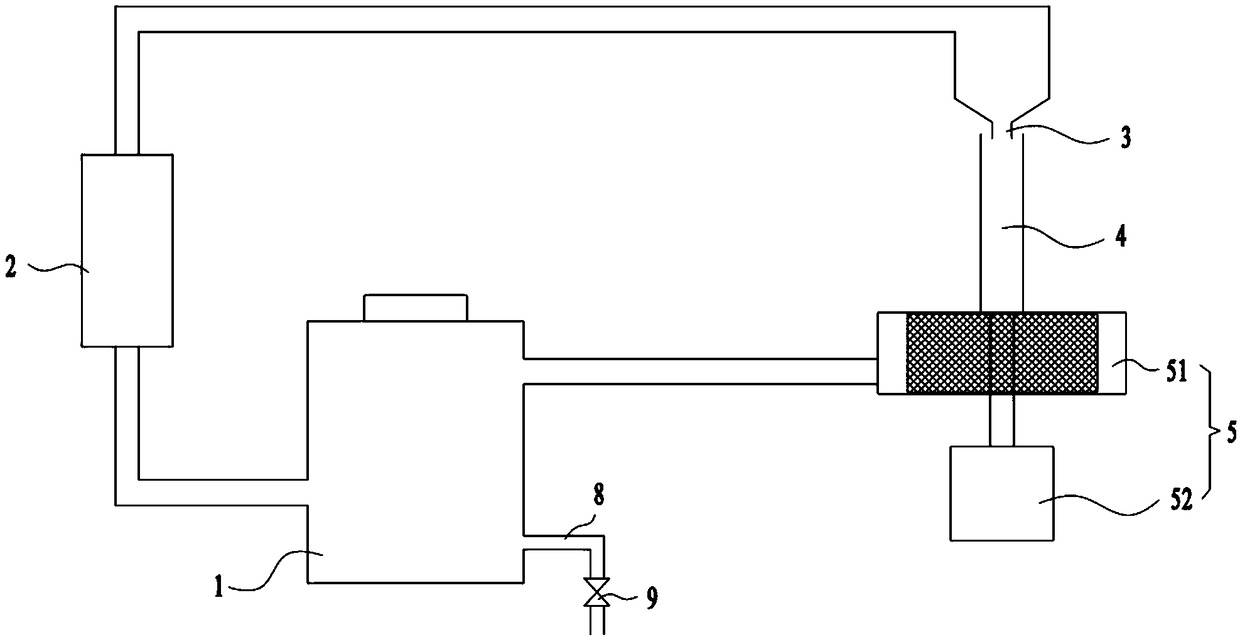

Solid-liquid mixing equipment and solid-liquid mixing method

InactiveCN108786509AUniform treatmentAvoid over crushingFlow mixersTransportation and packagingSpray nozzleEngineering

The invention discloses solid-liquid mixing equipment. The solid-liquid mixing equipment comprises a storage tank, a pump body, a spray nozzle, a material receiving pipe and a shearing device, whereina material inlet of the pump body is connected with the storage tank; the tail part of the spray nozzle is connected with a material outlet of the pump body; one end of the material receiving pipe islocated in a feed liquid spraying direction of the spray nozzle; a material inlet of the shearing device is connected to the other end of the material receiving pipe, and a material outlet of the shearing device is connected to the storage tank. The invention also discloses a solid-liquid mixing method. The solid-liquid mixing method comprises the following steps: adding to-be-mixed feed liquid in the storage tank; spraying the feed liquid from the spray nozzle under the driving of the pump body; enabling the feed liquid to enter the shearing device through the material receiving pipe, and enabling the feed liquid to flow into the storage tank after shearing and mixing. According to the solid-liquid mixing equipment disclosed by the invention, the storage tank is separated from the shearing device, solid-liquid mixed materials can be uniformly treated, a phenomenon of doping of large particles cannot occur, and particles can also be prevented from being excessively smashed; through the arrangement of the spray nozzle, ejected fluid is enabled to quickly enter the material receiving pipe, so that negative pressure is formed at the periphery of a pipe opening of the material receiving pipe, and materials can be sucked into the material receiving pipe.

Owner:哈尔滨万鑫石墨谷科技有限公司

High-efficient Chinese medicine grinding machine

InactiveCN108355785AGuaranteed normal cuttingGuaranteed GrindingHollow article cleaningElectrostatic cleaningEngineeringMechanical engineering

The invention discloses a high-efficient Chinese medicine grinding machine. The high-efficient Chinese medicine grinding machine comprises a grinding chamber and a collecting chamber, wherein the collecting chamber is positioned at the bottom end of the grinding chamber, and a feed inlet is formed in the middle part of the top end of the grinding chamber; a fixed shaft is arranged at the top end of the grinding chamber, and a plurality of groups of cutting devices are arranged on the fixed shaft; the cutting devices comprise first gears, second gears and third gears, wherein the fixed shaft issleeved with the first gears and the second gears, and the third gears matched with the first gears and the second gears are arranged on the middle parts of the first gears and the second gears; a first motor is arranged in the fixed shaft, and a rotating shaft of the first motor is rotatably connected with the third gears; and cutters are symmetrically arranged on both sides of the first gears and the second gears, a conveying belt is arranged at the bottom end of the grinding chamber, and a plurality of filtering holes are uniformly formed in the conveying belt. The high-efficient Chinese medicine grinding machine has the beneficial effects that Chinese medicinal materials are cut and grinded in the grinding chamber from various directions, so that the grinding accuracy can be greatly ensured, and a dust collecting plate and a cleaning brush can thoroughly clean and collect the residual Chinese medicinal materials in a storage box and simultaneously reduce residual impurities.

Owner:钱进

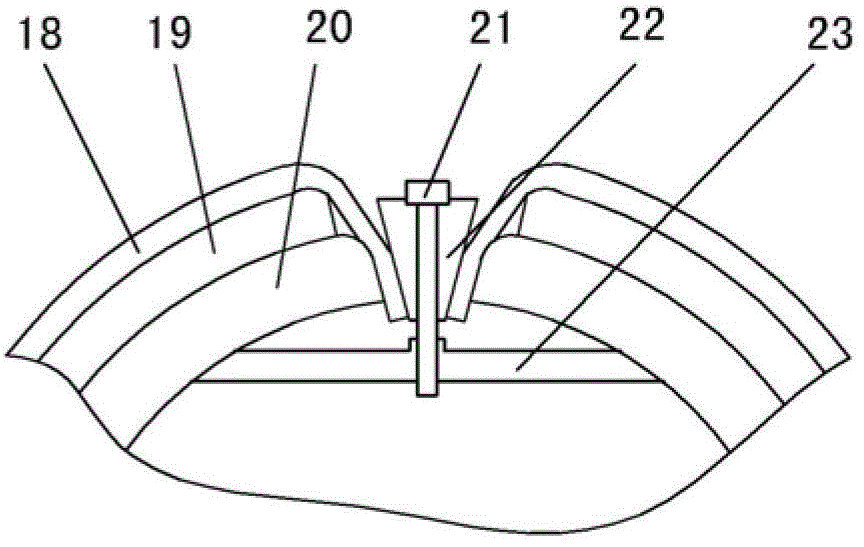

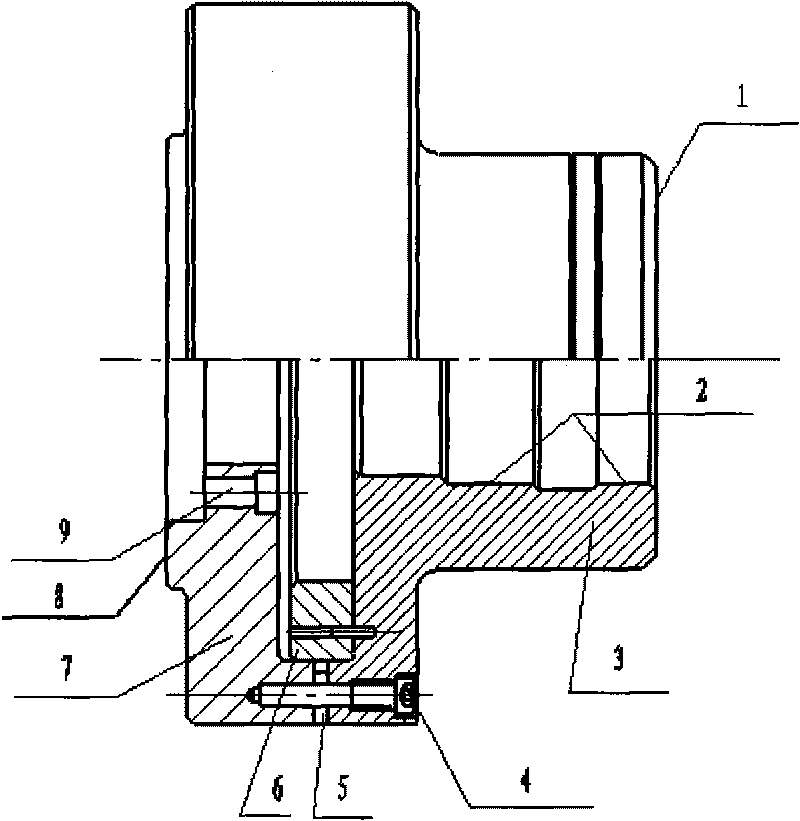

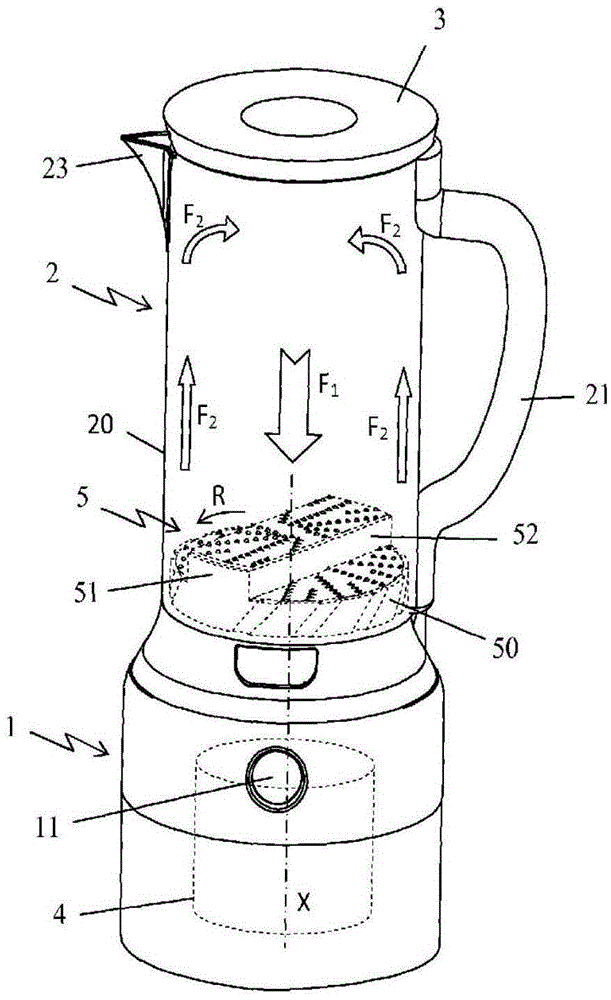

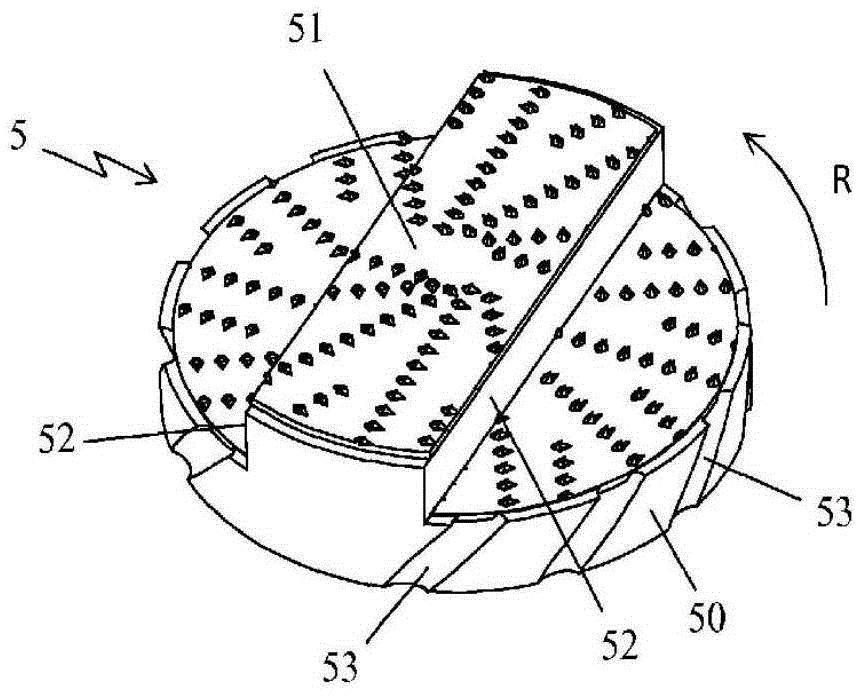

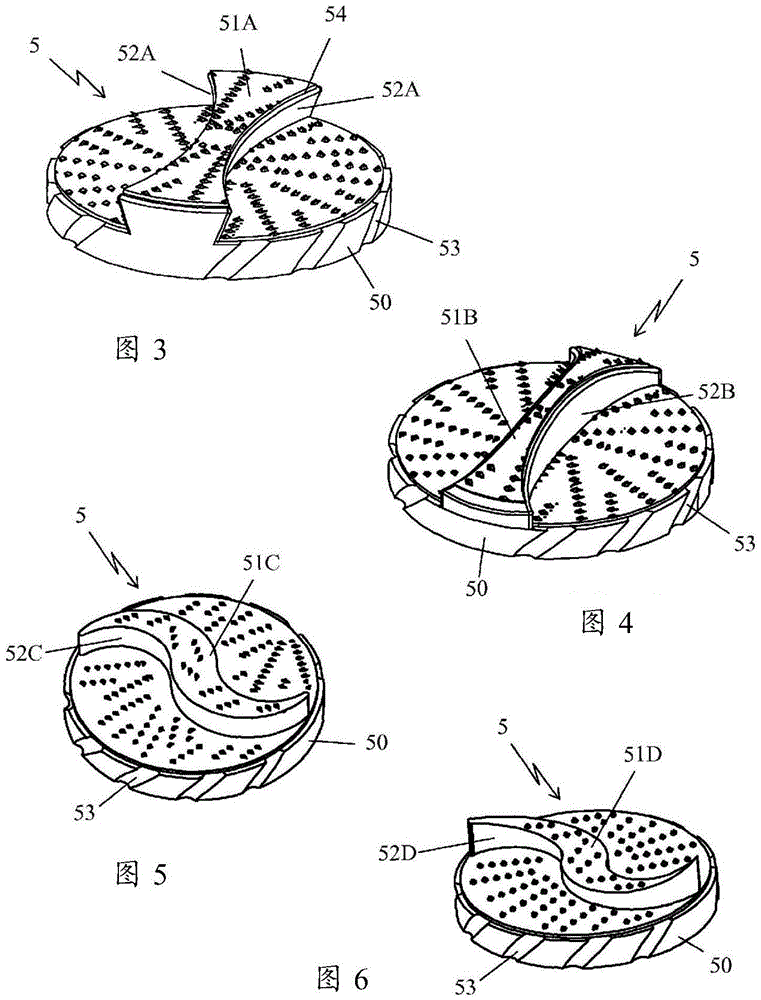

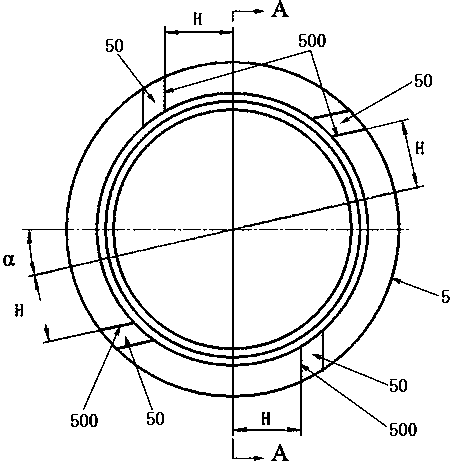

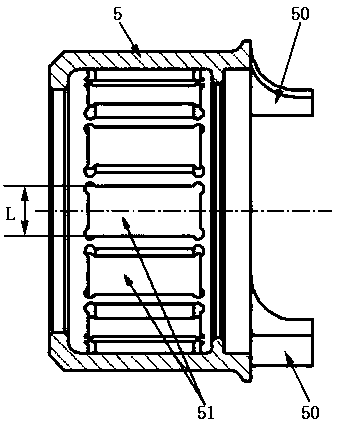

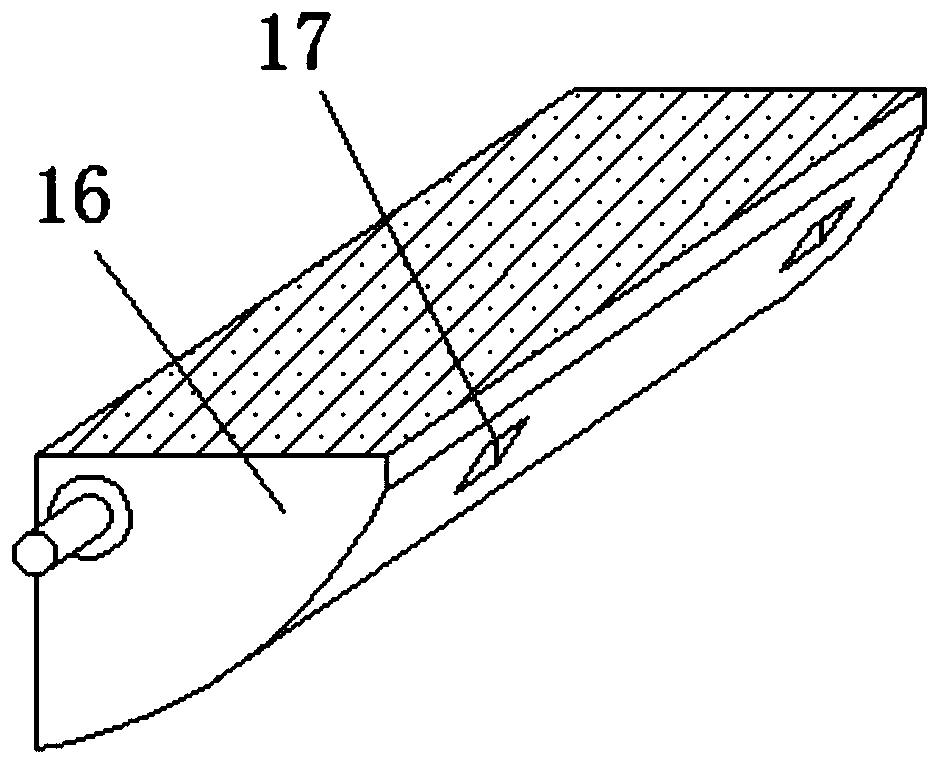

Household food preparation apparatus comprising work receptacle containing grinding tool

The invention relates to a household food preparation apparatus comprising a work receptacle (2) that receives food to be ground in order to extract the juice thereof, said work receptacle (2) comprising a bottom including a grinding tool (5) rotated about an axis X, said grinding tool (5) comprising an upper abrasive surface engaging with the food, characterised in that said upper surface of the grinding tool (5) includes a projecting transverse obstacle (51; 51A; 51B; 51C; 51D) lying at least partially near the periphery of the grinding tool (5), said transverse obstacle (51; 51A; 51B; 51C; 1D) including a side surface (52; 52A; 52B; 52C; 52D) that does not have a shape for rotating about the axis X, colliding with the food during the rotation of the grinding tool (5) about the axis X.

Owner:SEB SA

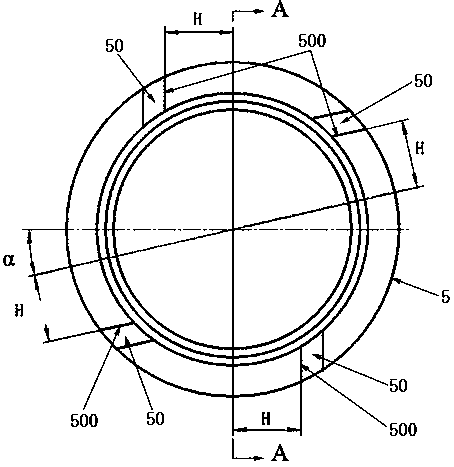

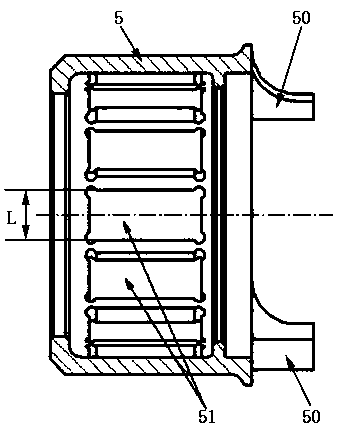

Online measuring device and measuring method for cage end flanges

ActiveCN108286926AGuaranteed GrindingFast and convenient online measurement requirementsMechanical thickness measurementsEngineeringFlange

An online measuring device and a measuring method for cage end flanges are provided. The device comprises a clamping tool and a measuring tool. The clamping tool comprises a base plate, a positioningplate, a long cylindrical pin and pressing plates. The pressing plates are installed on the base plate. The positioning plate is arranged in a window hole of a cage in a penetrating manner. The long cylindrical pin is fixed on the base plate, and abuts against the wall of the positioning plate. The measuring tool comprises a pressing ring, a measuring plate, short cylindrical pins and two cylindrical rollers. The short cylindrical pins are vertically connected with one end of the positioning plate. The two cylindrical rollers are arranged on the short cylindrical pins in a penetrating manner.The measuring plate vertically sleeves the positioning plate. The length of the measuring plate is the same with the maximum outer diameter of the cage. The pressing ring abuts against the outer sideof the measuring plate, and is tightly pressed on the outer side of the measuring plate by a screw I connected with one end of the positioning plate. The problem that online grinding and measuring cannot be realized by a surface grinder is solved. The purpose of fast and convenient online measurement is achieved. The production efficiency is improved.

Owner:LUOYANG BEARING RES INST CO LTD

Composite processing method for grinding vane apex of rotor vane of aeroengine at high speed

ActiveCN101722459BGuaranteed GrindingMeet the design requirementsGrinding machinesHigh-speed grindingControl theory

The invention relates to a composite processing method for grinding the vane apex of a rotor vane of an aeroengine at a high speed, which comprises the following steps of: firstly, balancing a rotor in advance, controlling unbalance quantity which is permitted to be used for balancing the rotor in advance to be within 254g.mm, then installing the rotor on a fixture, enabling the rotor to be in a stretching state and grinding at a high speed. In the grinding process, the rotational speed of a processing part is 1600-2000r / min, the linear speed of a grinding wheel is 33-36m / s, the rotational speed of a scrubbing brush is 1500-1900r / min, and the control temperature during grinding is 20+ / -5 DEG C.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

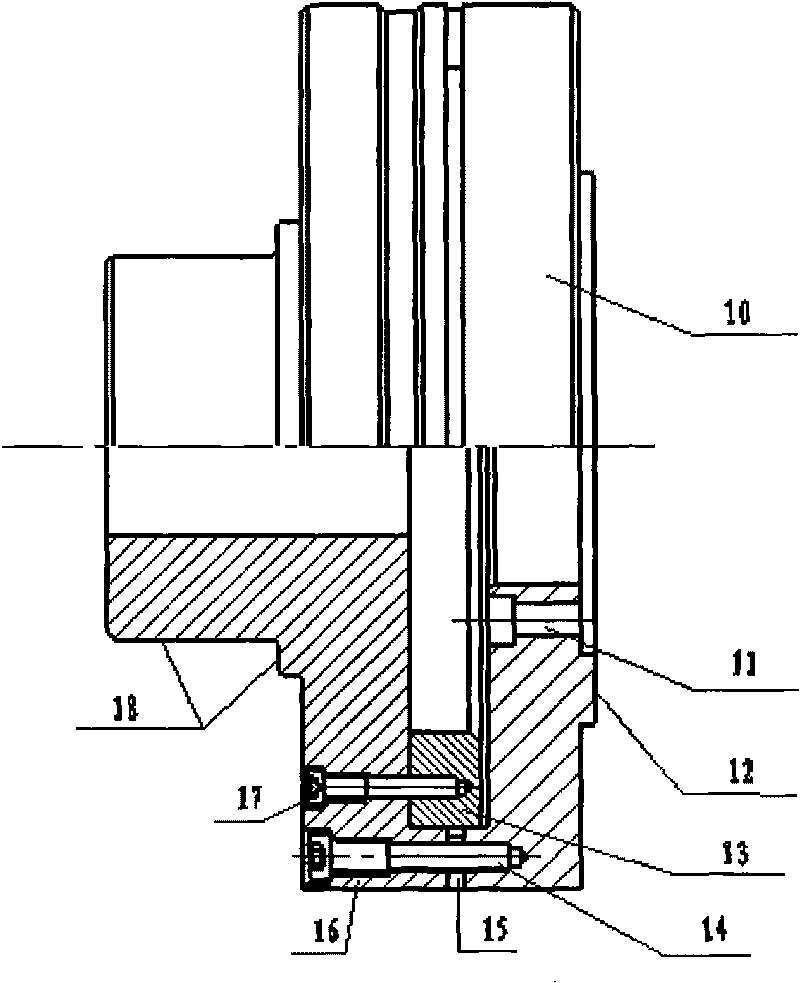

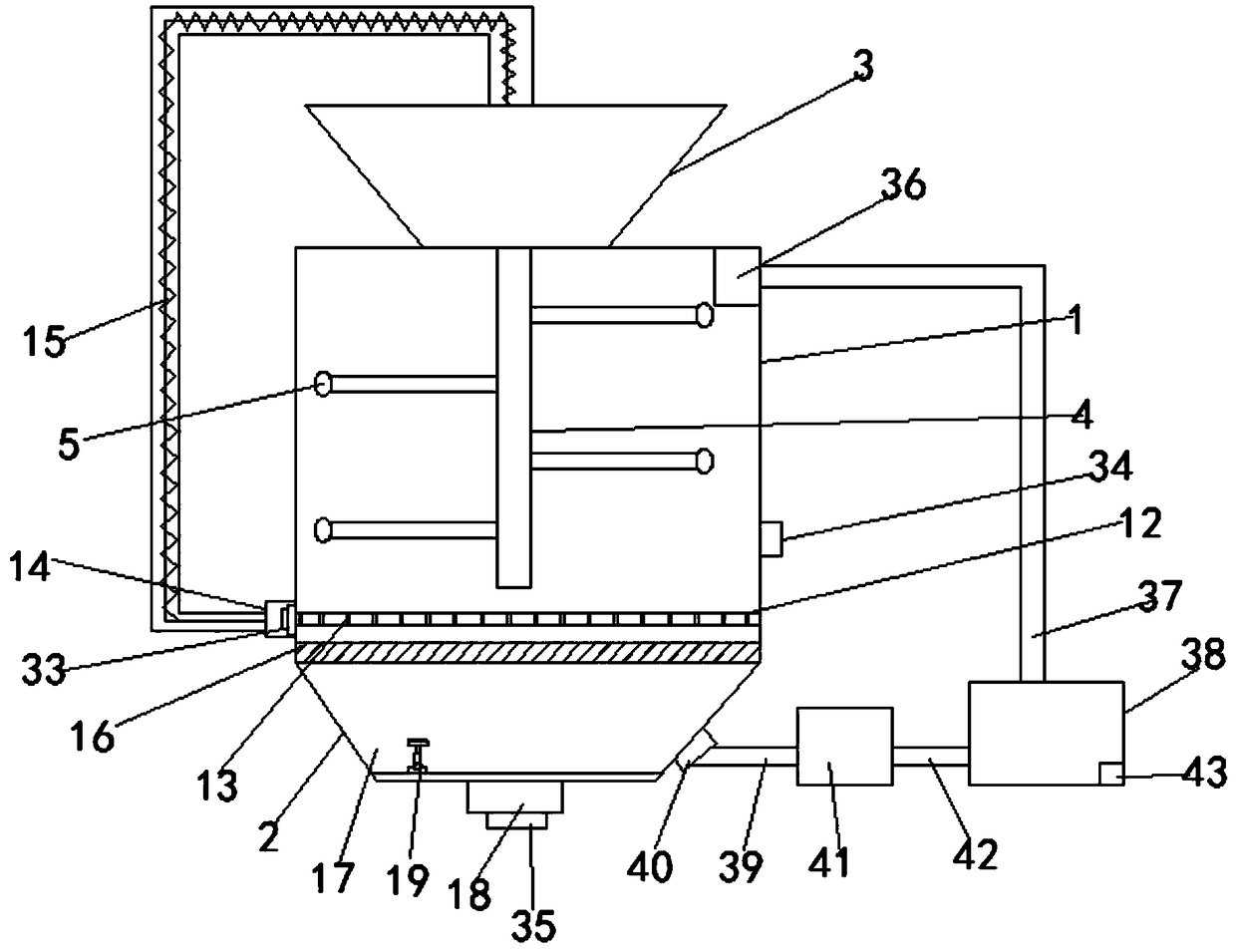

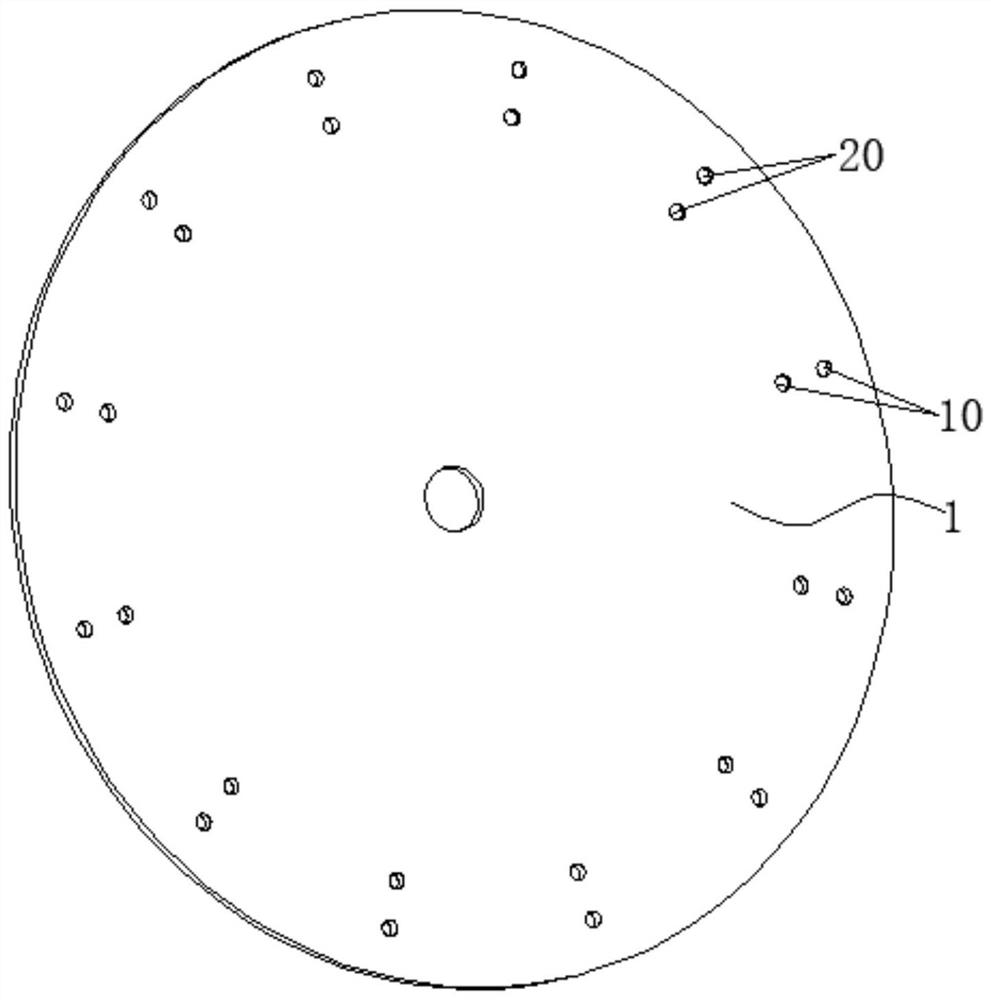

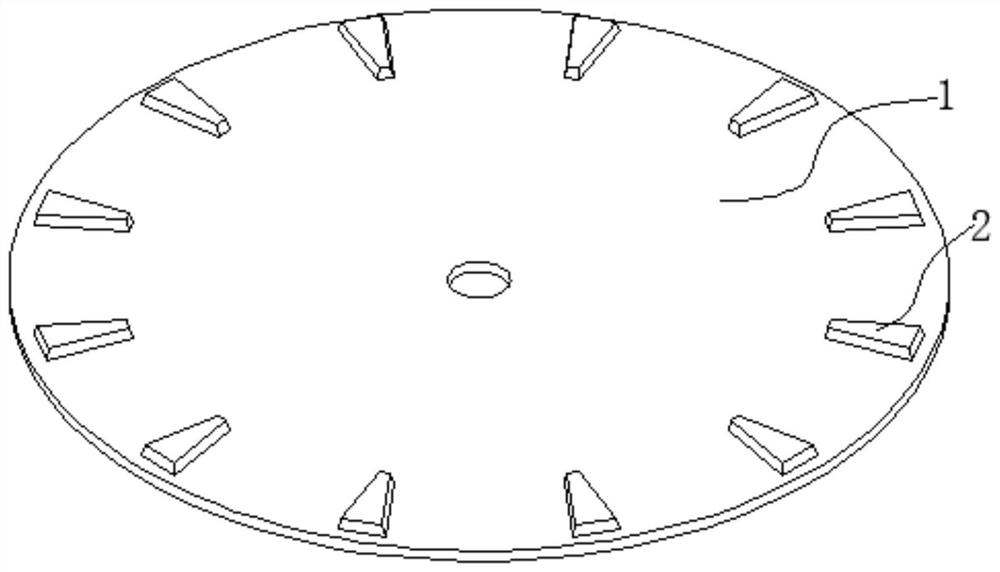

Grinding-assisted laser cladding powder feeder

InactiveCN108359980AKeep drySolve the problem of clumpingMetallic material coating processesMetallurgyLaser

The invention provides a grinding-assisted laser cladding powder feeder. The powder feeder comprises a box, a powder feeding pipe, an upper rotary disc and a lower grinding disc. The box is provided with an upper opening, a middle section and a lower opening. The powder feeding pipe is arranged inside the upper opening and the upper portion of the middle section. The upper rotary disc and the lower grinding disc are arranged in the middle section, and the lower grinding disc is fixedly connected with the inner wall of the middle section. The upper rotary disc acts on the lower grinding disc. Aplurality of through holes are formed in each of the upper rotary disc and the lower grinding disc. The powder feeder has the advantages that firstly, by grinding composite powder, the problems thatthe composite powder is not uniformly mixed and cakes are solved; secondly, an induction heating coil is additionally arranged, the dryness of the mixed powder is improved, and the problem of powder caking can be solved easily; and thirdly, an oscillator is additionally arranged, the ground mixed powder is subjected to oscillation mixing and screening again, and meanwhile, the ground powder is more uniform when being discharged.

Owner:FUJIAN UNIV OF TECH

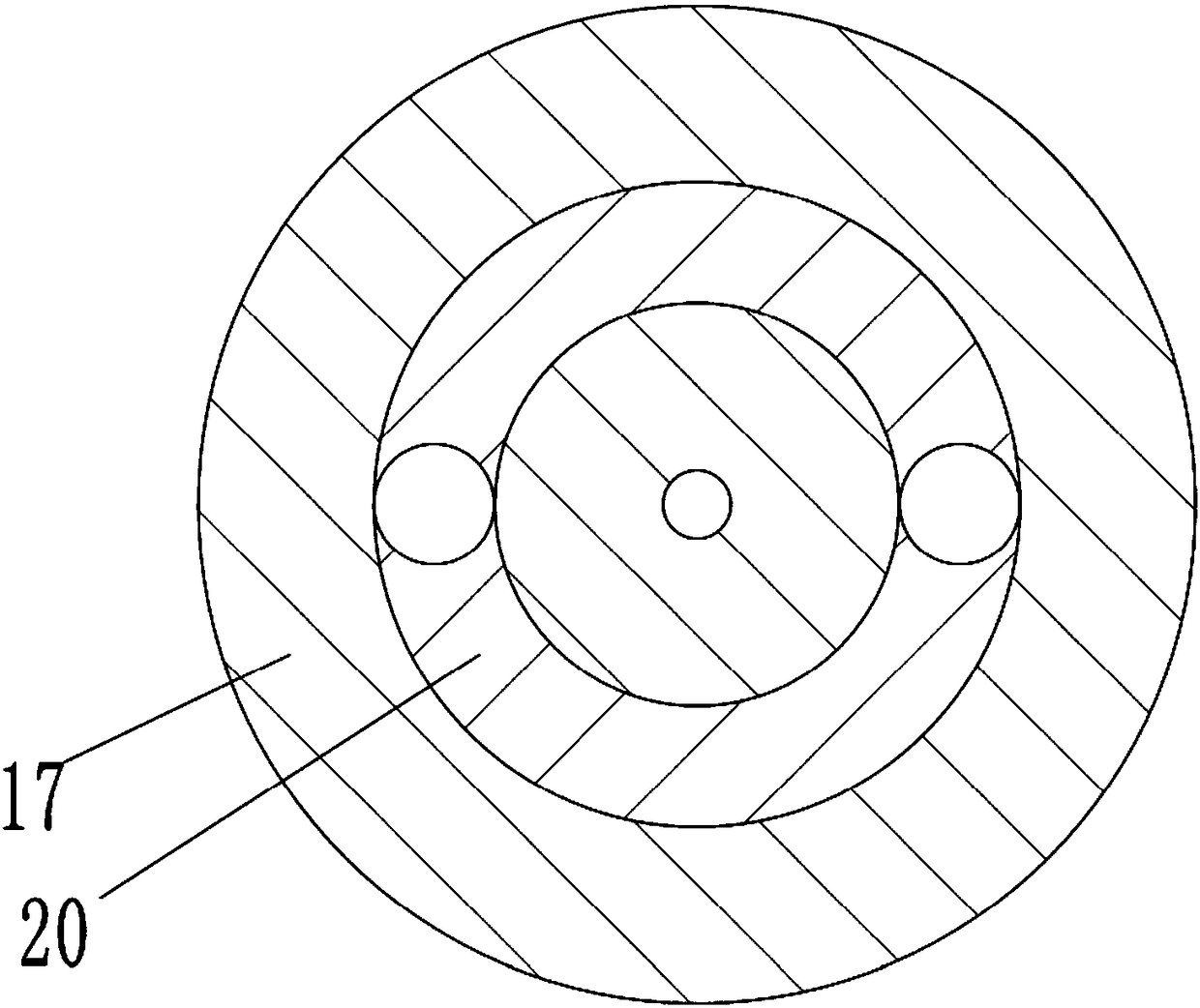

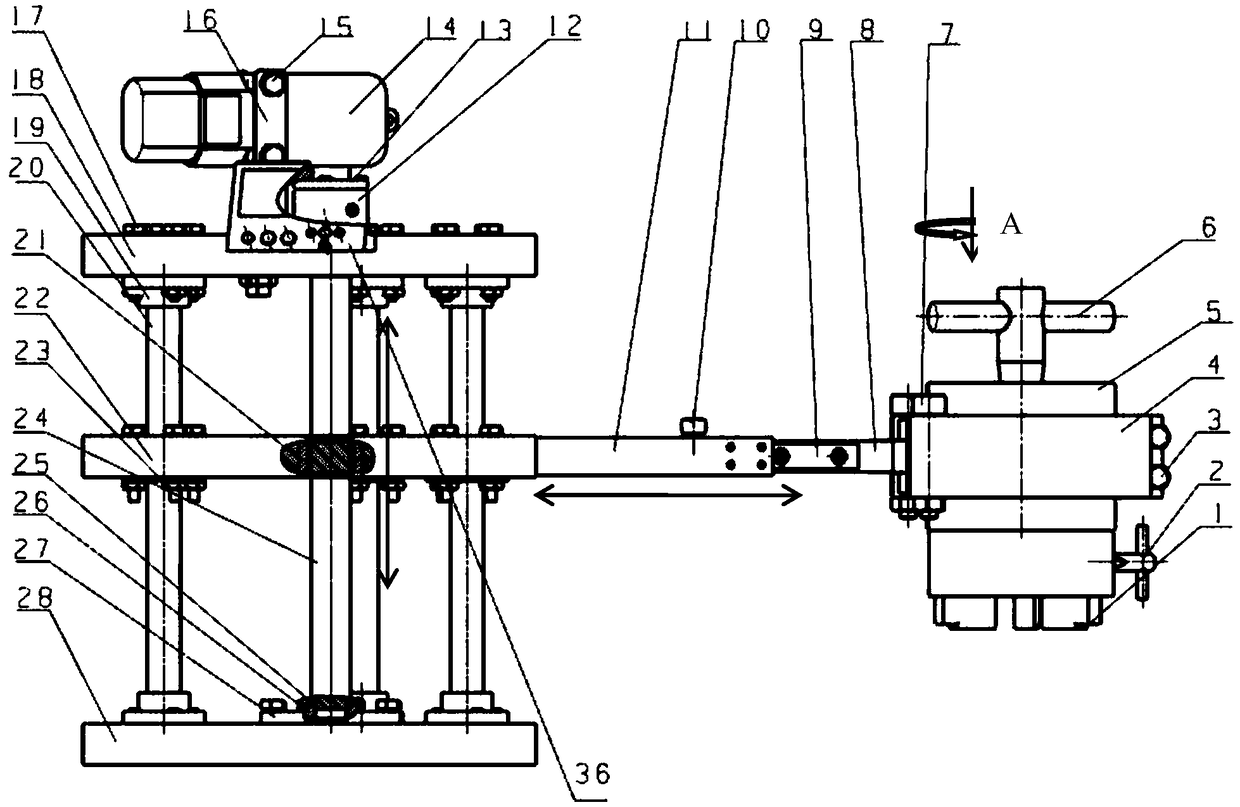

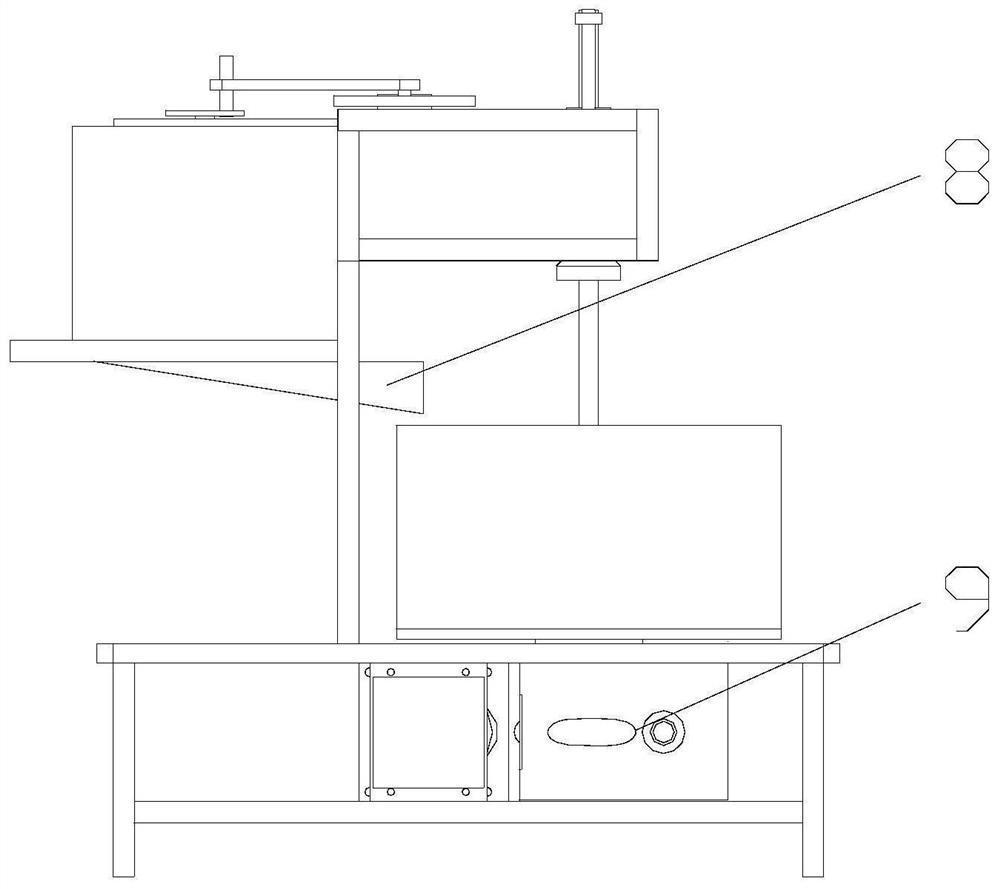

Metallographic specimen preparation device

ActiveCN109015211AImprove surface qualityIncrease profitGrinding machinesAutomatic grinding controlEngineeringSlide plate

The invention provides a metallographic specimen preparation device. The metallographic specimen preparation device comprises a dividing head rotating motion mechanism, a transverse horizontal reciprocating linear motion mechanism and a vertical direction reciprocating linear motion mechanism. A dividing head of the dividing head rotating motion mechanism is in direct contact with three uniformlydistributed floating cylindrical rollers without the requirement of coaxiality, four small grooves are uniformly distributed on the excircle surface of the dividing head, spring pins are embedded in the small grooves every time the dividing head rotates for 90 degrees to realize the accurate dividing of the dividing head on 4*90 degrees. The vertical direction reciprocating linear motion mechanismdrives a ball screw nut pair by a servo motor, can accurately control the distance of a sliding plate in the vertical direction, can accurately control the grinding dosage, and ensures the effects ofgrinding and polishing. The transverse horizontal reciprocating linear motion mechanism can enable a specimen to fully cover sandpaper by adjusting the lengthening or shortening of a front transversearm, the utilization rate of the sandpaper is greatly improved, and the cost is reduced. The metallographic specimen preparation device is simple in structure, stable in operation, accurate in transmission, uniform in grinding, high in efficiency and good in flexibility.

Owner:JIANGSU UNIV

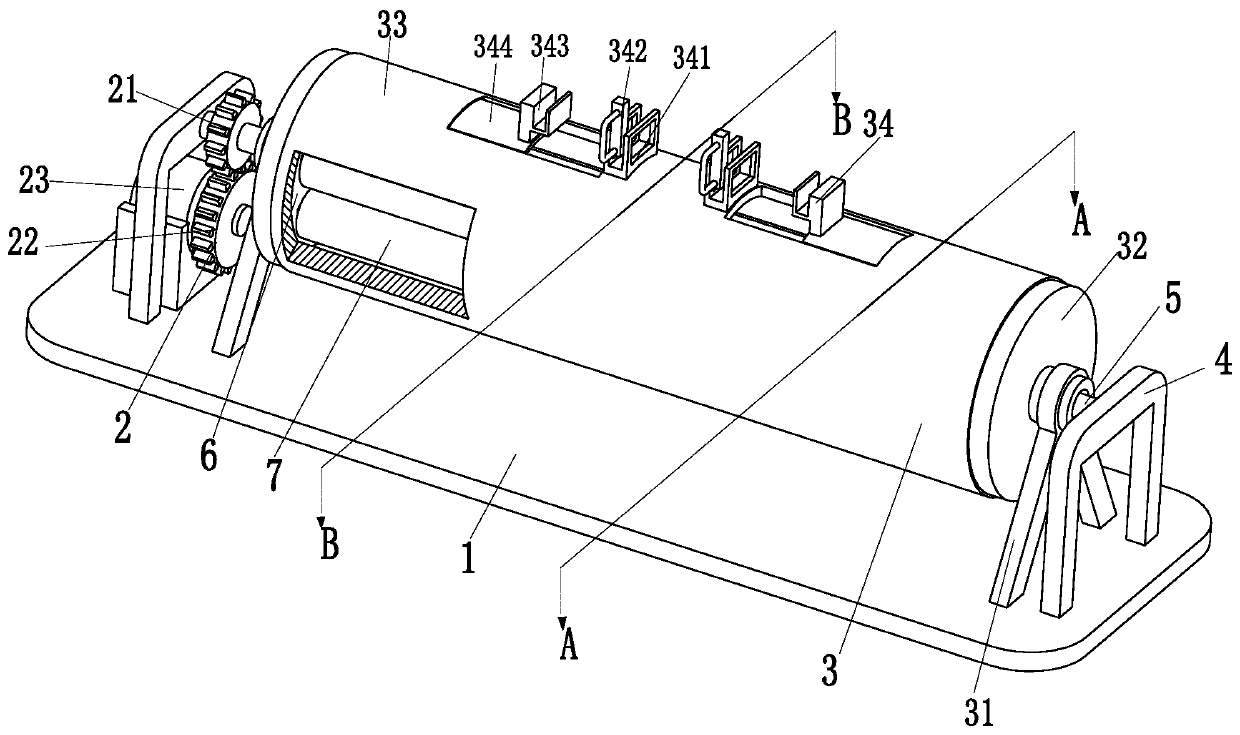

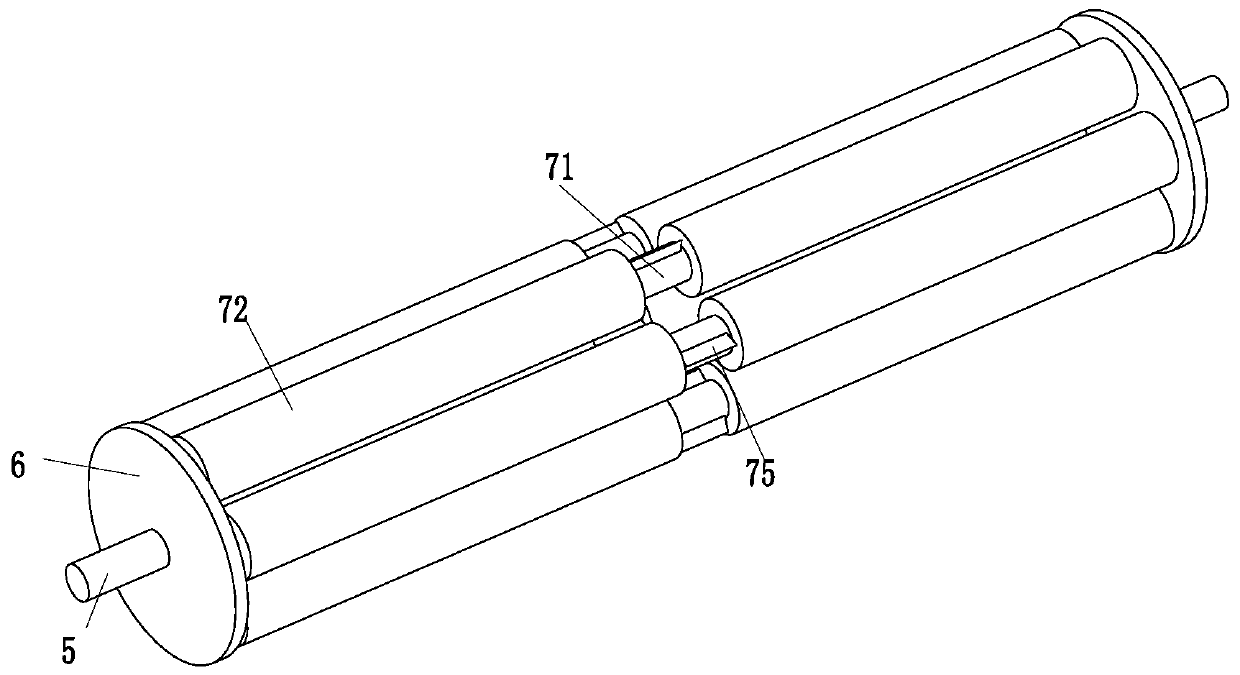

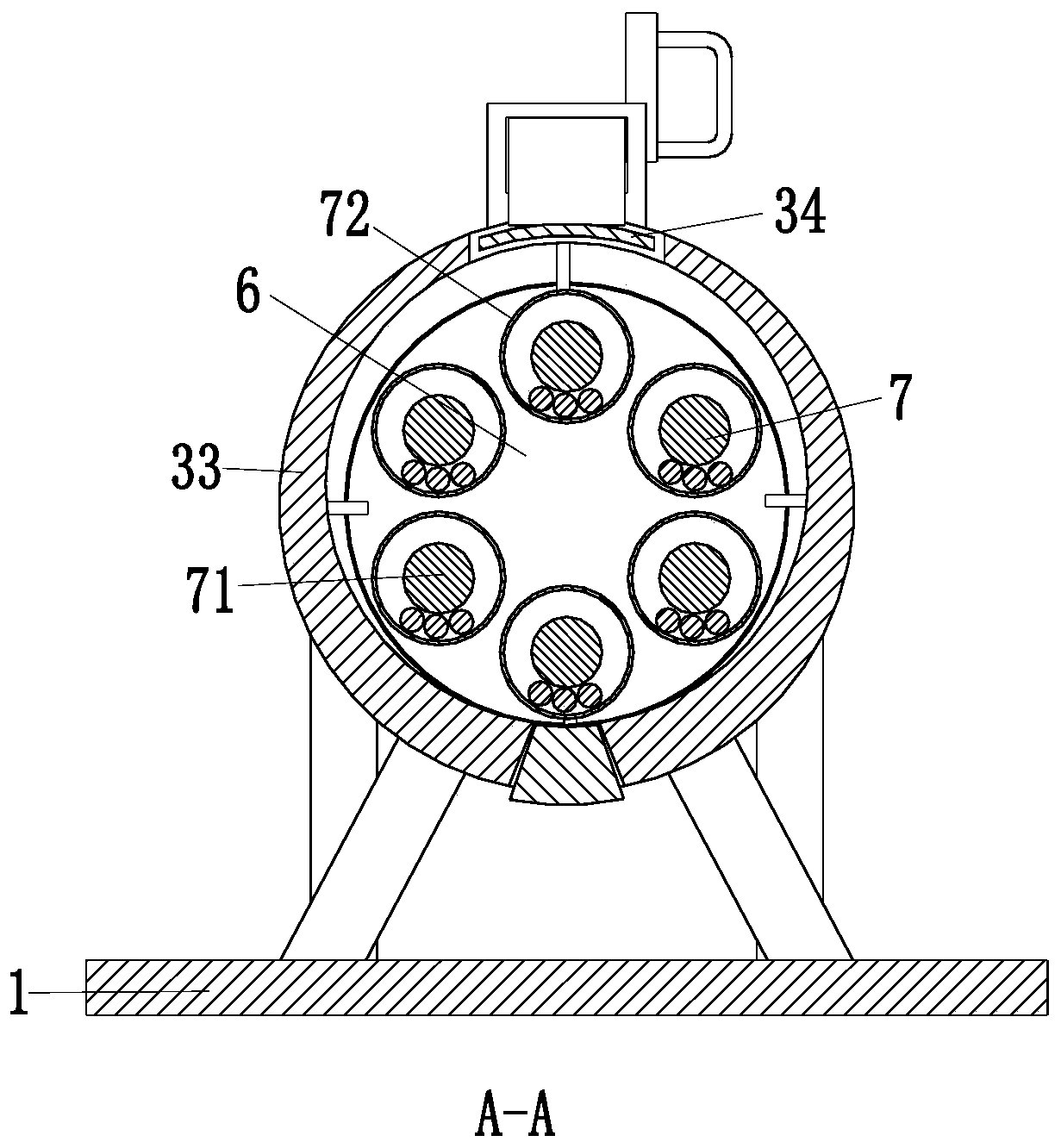

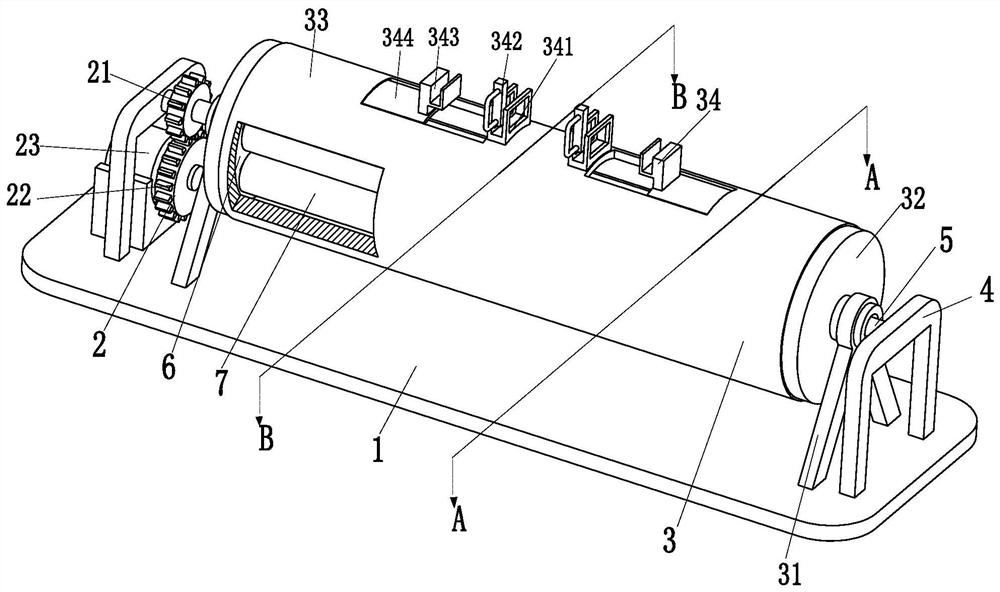

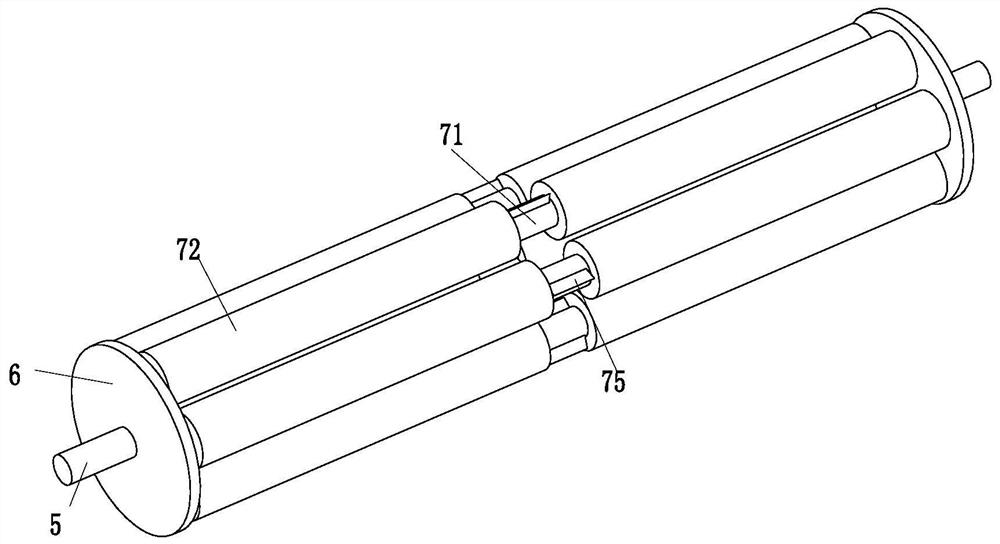

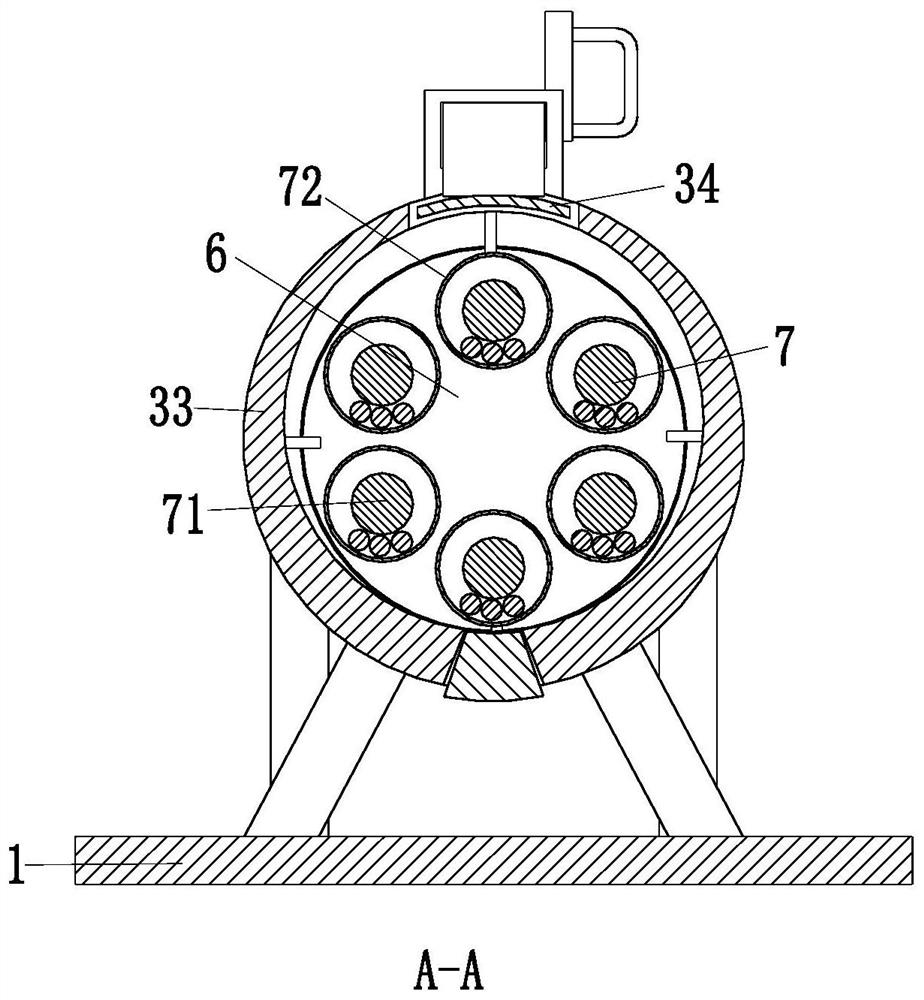

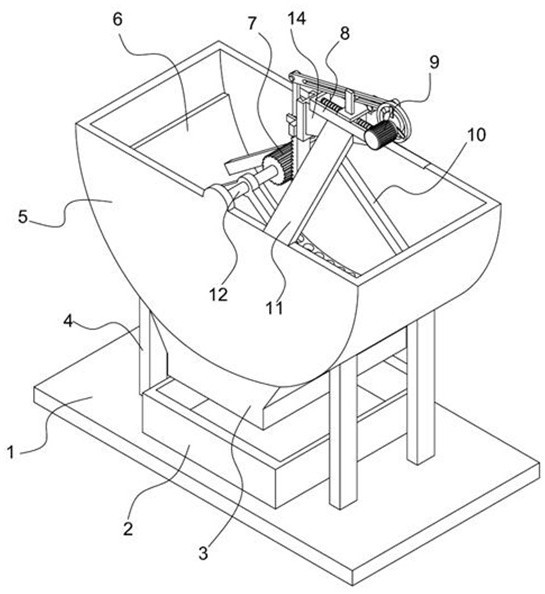

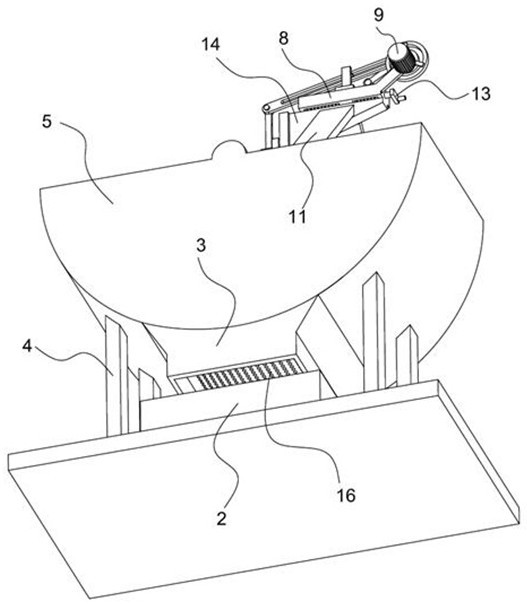

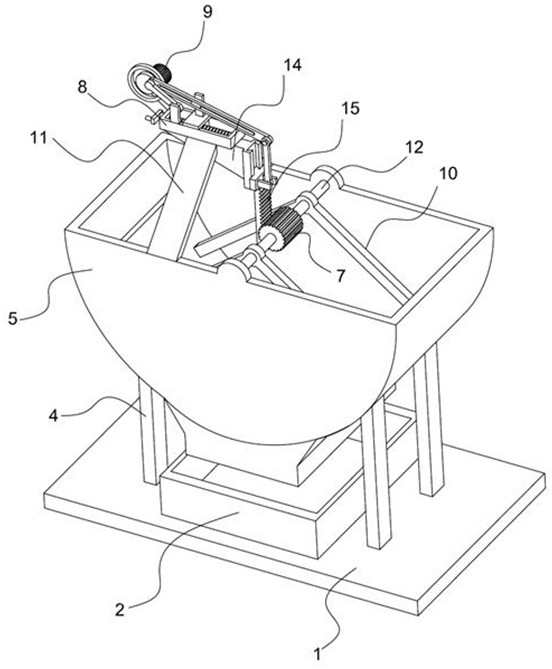

Material crushing and grinding machine and using method thereof

ActiveCN110142086AAvoid Difficult-to-Grind SituationsIncrease grinding rateGrain treatmentsEngineeringGrinding process

The invention relates to a material crushing and grinding machine and a using method thereof. The material crushing and grinding machine comprises a bottom plate, a speed change driving module, a fixed outer pipe, two U-shaped frames, two rotating shafts, two circular plates and a built-in grinding roller, wherein the fixed outer pipe is arranged at the upper end of the bottom plate, the left endand the right end of the fixed outer pipe are provided with the two rotating shafts through bearings, the inner ends of the rotating shafts are installed on the circular plates, the outer ends of therotating shafts are arranged on the U-shaped frames through bearings, the U-shaped frames are arranged on the bottom plate, the built-in grinding roller is uniformly installed between the two round plates through a pin shaft, and a speed change driving module is arranged at the left end of the bottom plate. According to the material crushing and grinding machine, in the existing grinding process,materials with different volumes can be mixed together to form a material layer, and during grinding, the materials with a large volume can be buried in a deeper position, a grinding body falls into the crushing process, the crushed materials on the upper surface of the material layer plays a role in relieving impact force on the falling grinding body, the grinding body has the weight, and the problem that the surface of a grinding cavity can be knocked out of the grinding cavity during falling can be solved.

Owner:BOYEE SHENZHEN IND TECH CO LTD

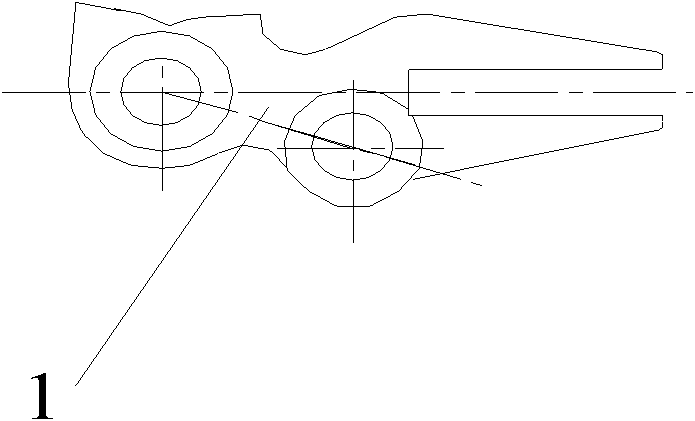

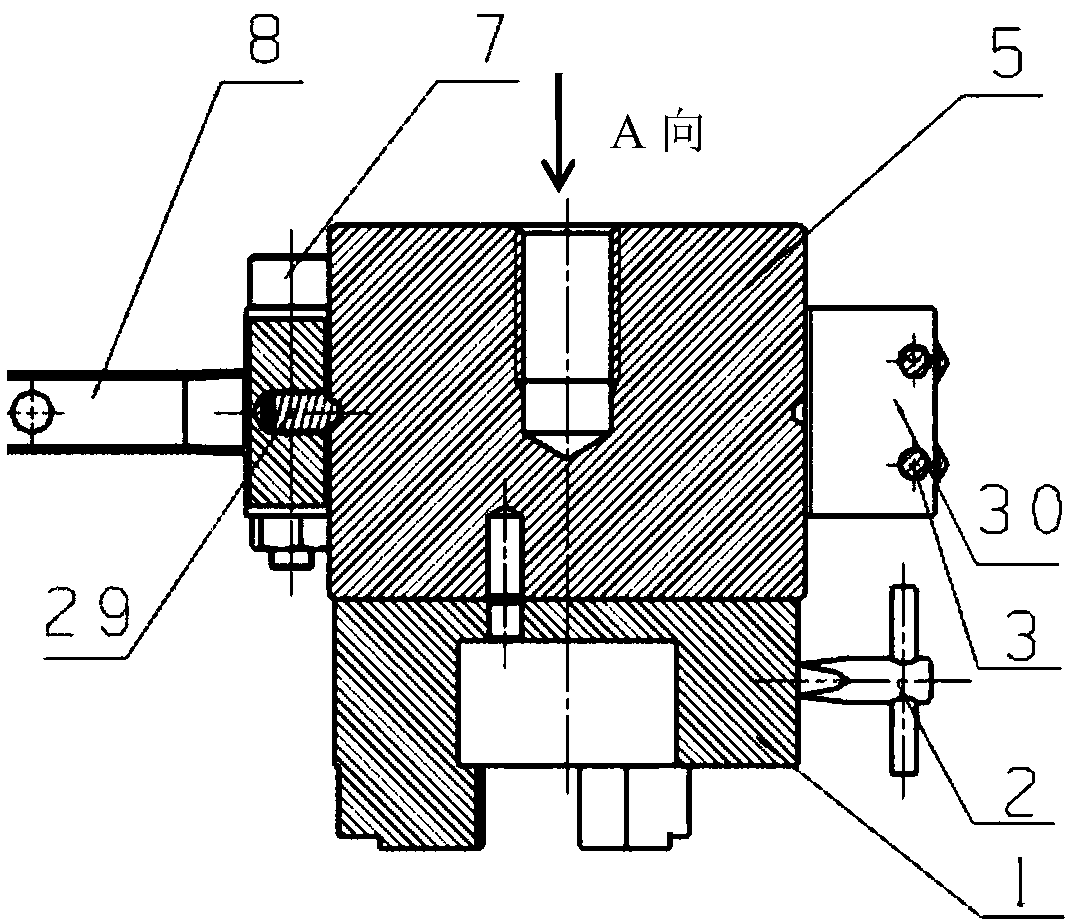

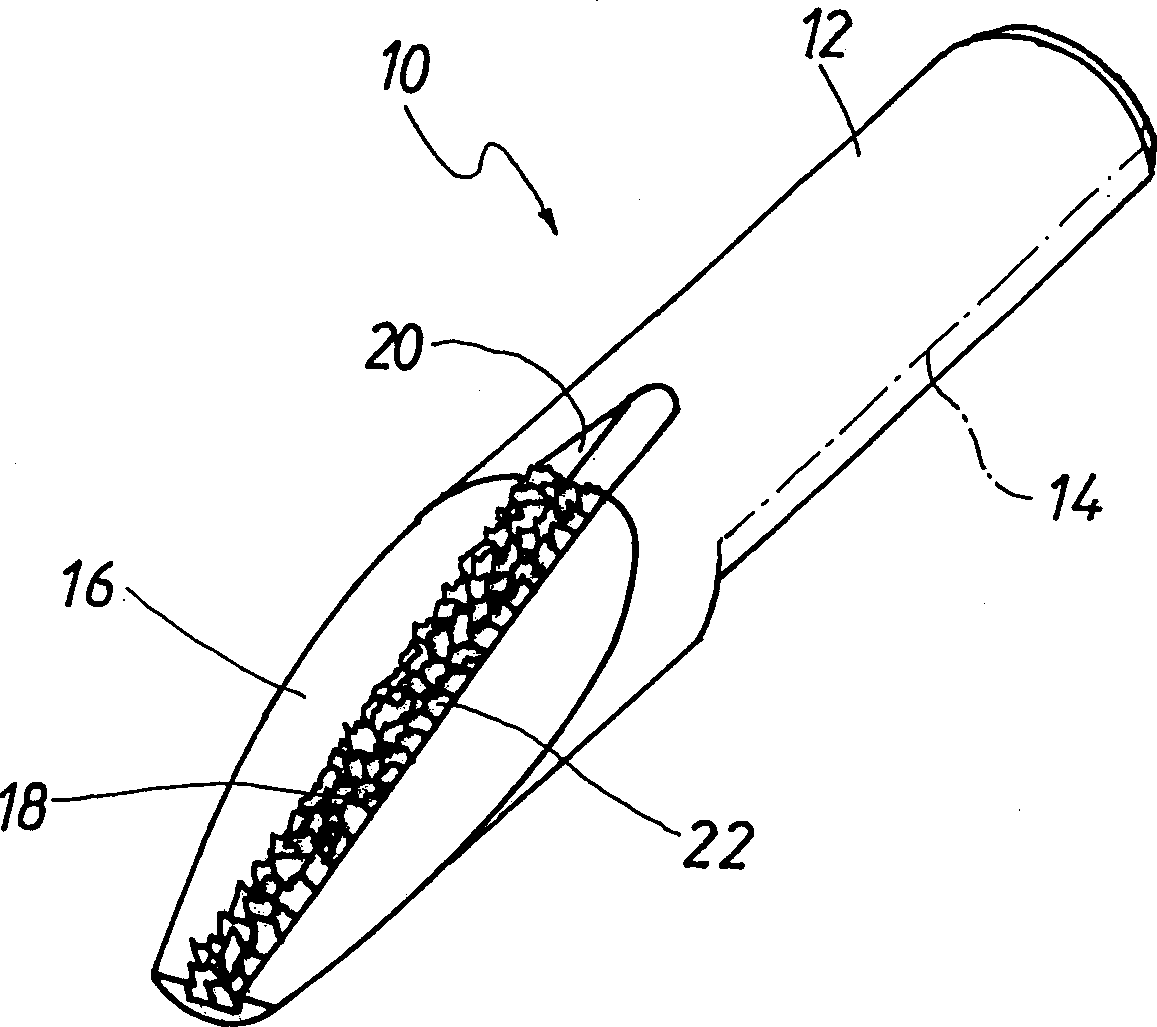

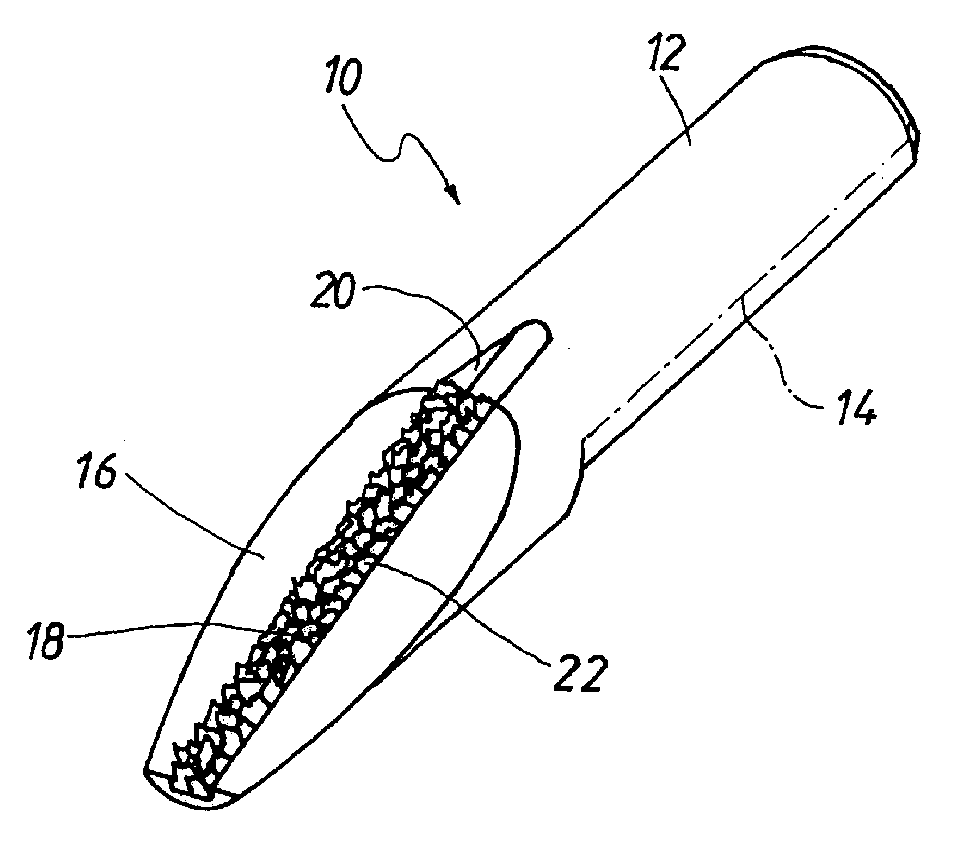

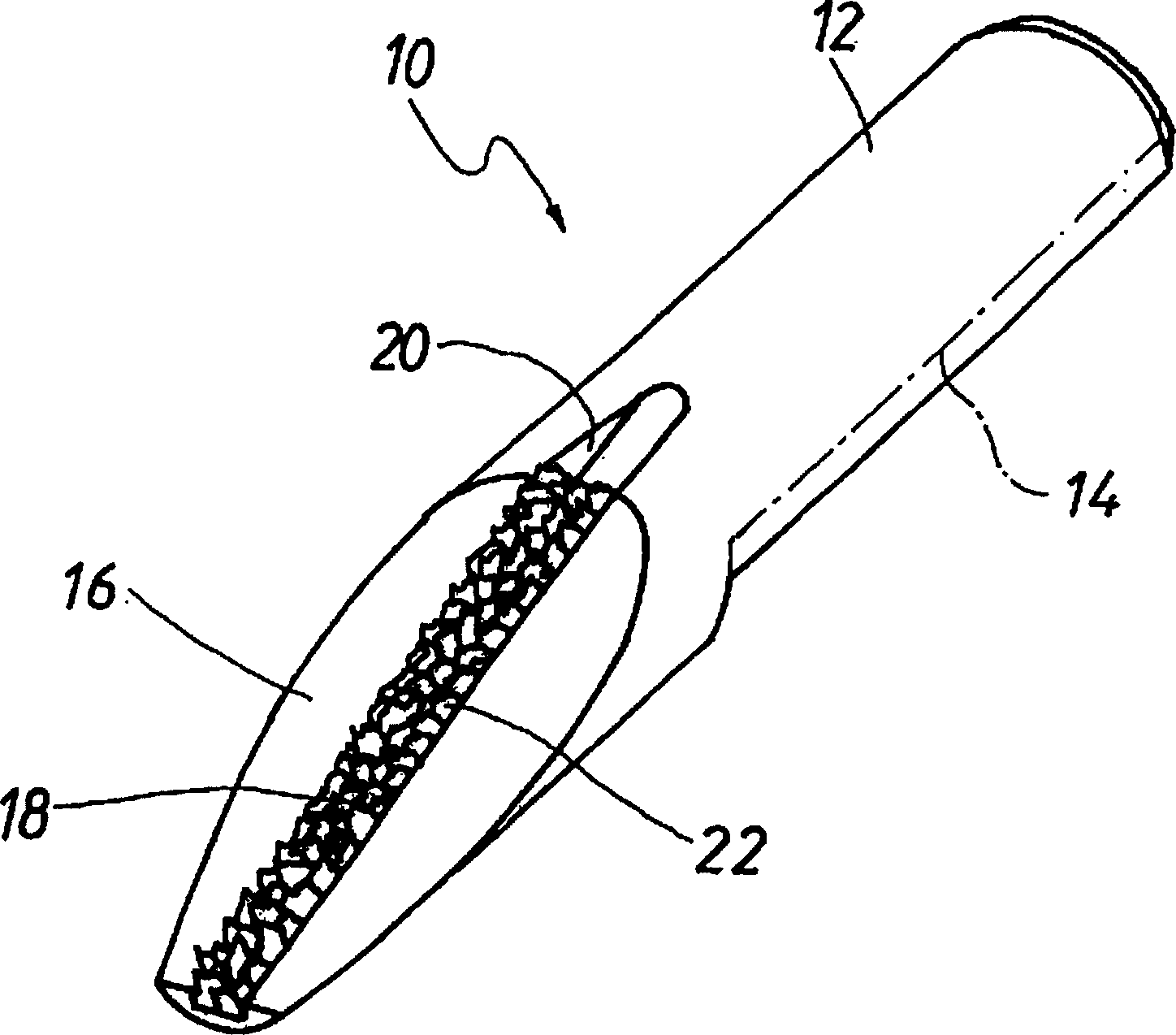

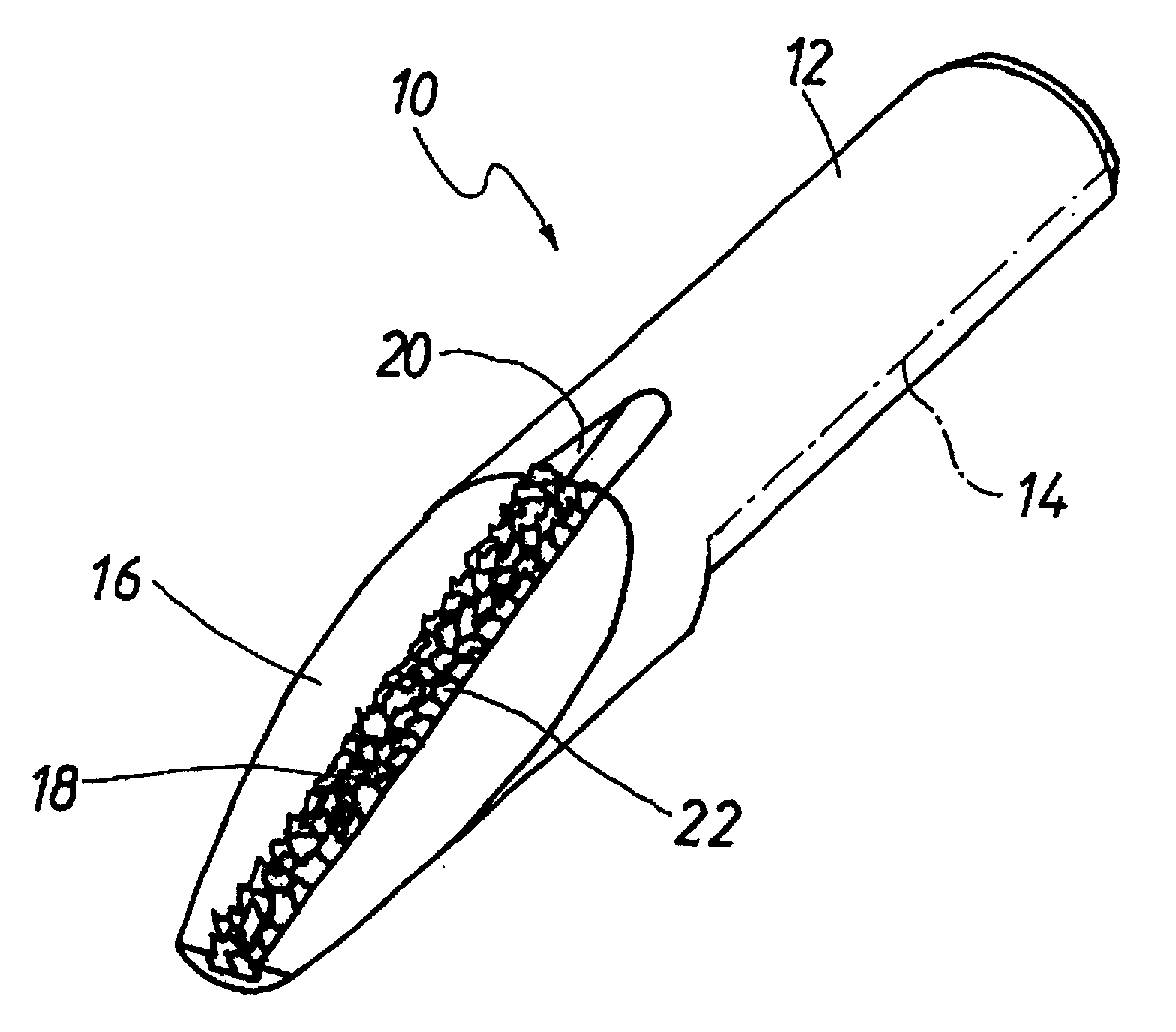

Jack catch for paw type chuck

This invention is related to a grip jaw 10 for a jaw chuck which includes a metal body 12 waxing a hard alloy. In order to prevent a grip jaw from transforming because of hard waxing treatment, this invention provides a grip jaw whose surface 18 has a hard alloy particle 22 instead of using one hard alloy plates.

Owner:UNITED HARDMETAL GMBH +1

Novel solid wrapping slurry removing equipment

The invention relates to novel solid wrapping slurry removing equipment. The novel solid wrapping slurry removing equipment comprises a rack, a barrel, a rotary shaft, and a driving device arranged on the rack. The driving device is connected with the rotary shaft and used for driving the rotary shaft to rotate. The barrel is fixed to the rotary shaft to enable the barrel to rotate around the rotary shaft, the barrel and the horizontal plane are arranged obliquely, and the barrel is used for containing solids to be subjected to wrapping slurry removal; a feed port is formed in one end of the barrel, a first discharge port is formed in the other end of the barrel, and the position of the feed port is higher than that of the first discharge port. A second discharge port is formed in the side, close to the horizontal face, of the outer wall of the barrel. Wrapping slurry in the solids can be separated, the solids with the wrapping slurry removed are convenient to recycle, and the wrapping slurry is conveniently subjected to resource reuse.

Owner:HENAN WINNER VIBRATING EQUIP

Watch dial plate convex punching processing technology

The invention discloses a watch dial plate convex punching processing technology which specifically comprises the following steps: 1, blanking and blank making: punching and forming a brass plate by using a blank punching die to make a dial plate blank; 2, electroplating ground color: electroplating the dial plate blank obtained by blanking and blank making in the step 1; 3, convex punching: punching a protruded hour hand nail on the dial plate blank obtained in the step 2; 4, paint spraying: performing paint spraying operation on the dial plate blank punched with the protruding hour hand nailin the step 3; 5, grinding: grinding the hour hand nail by adopting a plane grinding machine so that the hour hand nail is highlighted; 6, cutting the protruding positions of the batch nails and thehour nails to form shapes and patterns; and 7, electroplating the hour hand pin: electroplating the hour hand pin on the dial plate blank with the split patterns; by stamping the dial plate blank, thedial plate shading and the hour hand pin are integrally formed, the cost is saved, the hour hand pin cannot fall off, the processing procedures are reduced, the process is simple and reliable, and the service life of the watch is longer.

Owner:广州恒上钟表有限公司

Industrialized recovery method and apparatus of waste liquid crystal display glass panel

InactiveCN103331295BImprove recycling efficiencyImprove environmental benefitsSolid waste disposalRecovery methodOrganic solvent

The invention discloses an industrialized recovery method and an apparatus of a waste liquid crystal display (LCD) glass panel. The recovery method comprises following steps: a glass substrate is placed on a conveyor belt, with the surface where a membrane is arranged being upward, and self-locking and positioning of the glass substrate are realized by the static friction force between the glass substrate and the conveyor belt; the LCD glass substrate and the membrane are separated from each other by grinding, grinding dust is collected to obtain indium metallurgy raw materials; and at last the grinded glass substrate is crushed, immersed in an organic solvent and centrifuged successively, so that classification collection of glass and a polaroid is realized. The recovery method is simple and practical, can be industrialized, is high in efficiency, and can be used for classification collection of waste liquid crystal display glass panel with high quality.

Owner:HEFEI UNIV OF TECH

Jack catch for paw type chuck

InactiveCN1292876CGuaranteed GrindingEasy to installSleeve/socket jointsPliersAlloyMaterials science

This invention is related to a grip jaw 10 for a jaw chuck which includes a metal body 12 waxing a hard alloy. In order to prevent a grip jaw from transforming because of hard waxing treatment, this invention provides a grip jaw whose surface 18 has a hard alloy particle 22 instead of using one hard alloy plates.

Owner:UNITED HARDMETAL GMBH +1

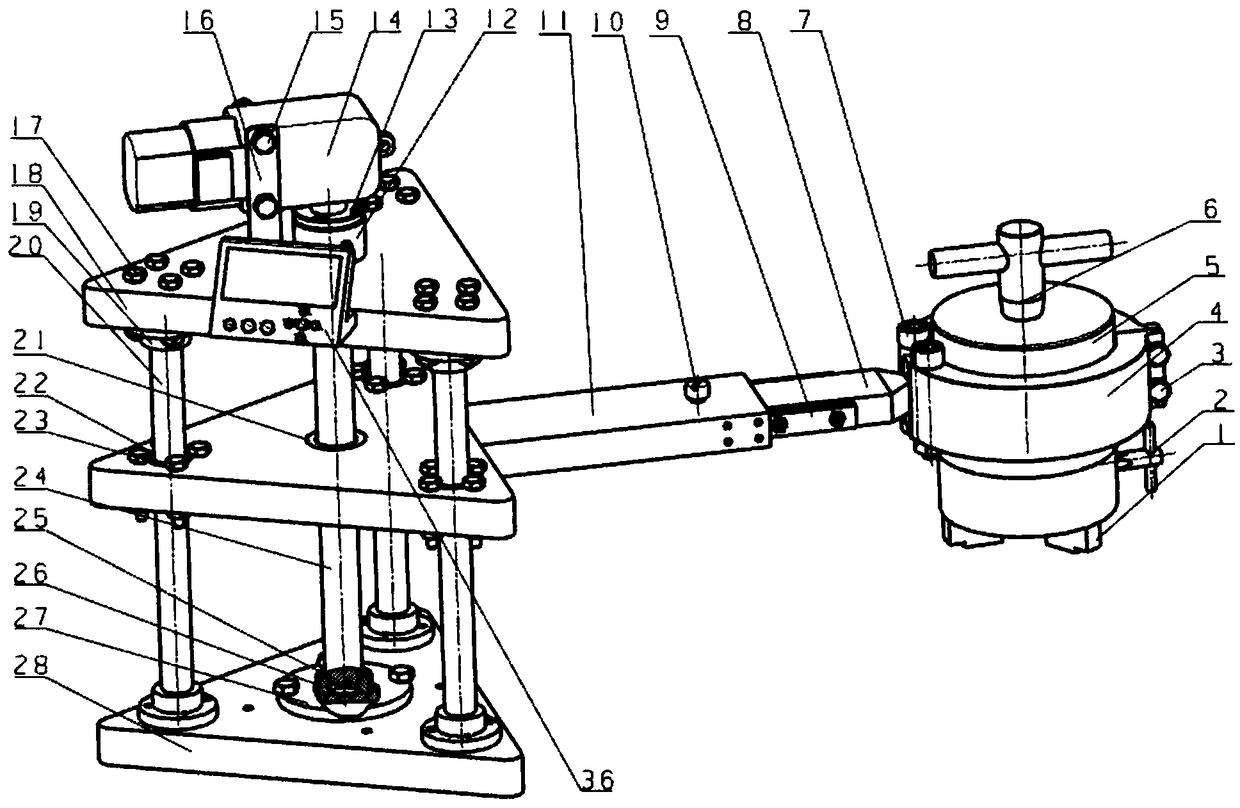

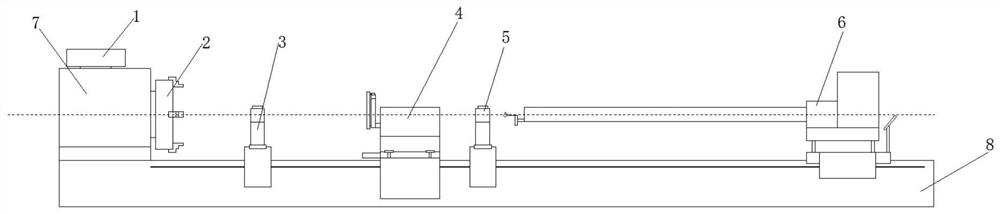

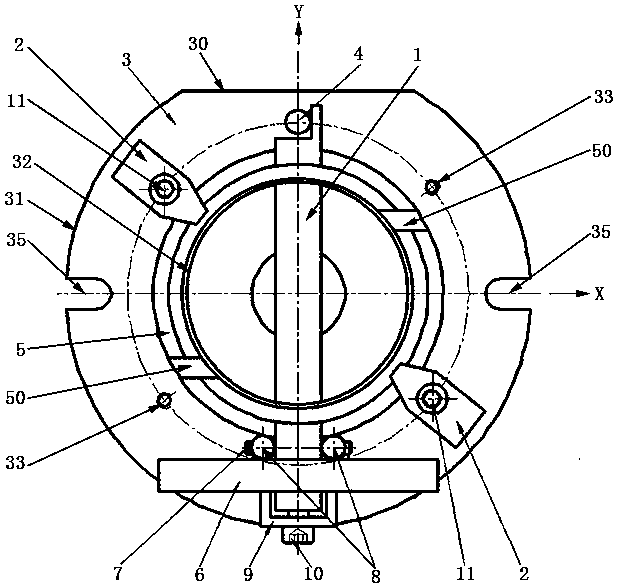

End socket inner and outer wall grinding device for high-pressure gas cylinder aluminum alloy inner container

PendingCN112536692ADoes not affect production efficiencyDoes not affect appearance qualityGrinding carriagesGrinding drivesGas cylinderEngineering

The invention provides an end socket inner wall and outer wall grinding device for a high-pressure gas cylinder aluminum alloy inner container. The end socket inner wall and outer wall grinding devicecomprises a rack, and further comprises a main shaft mechanism, a first centering supporting mechanism, an outer circle grinding mechanism, a second centering supporting mechanism and an end socket inner wall grinding mechanism which are arranged on the rack in sequence. According to the device, grinding of the inner wall of an end socket and grinding of the outer circle of the end socket are combined on one piece of equipment, and the linear section and the curved section of the inner container can be continuously or separately ground under one-time clamping; and the inner wall of the linerend socket can be continuously or locally ground under one-time clamping. The outer circle grinding part in the device can grind the inner container with the bumped or scratched surface, and the end socket inner wall grinding part can find scratches or defects on the inner surfaces of different positions at any time; and high-speed grinding of the inner surface of the inner container end socket isachieved, and the grinding quality is guaranteed.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

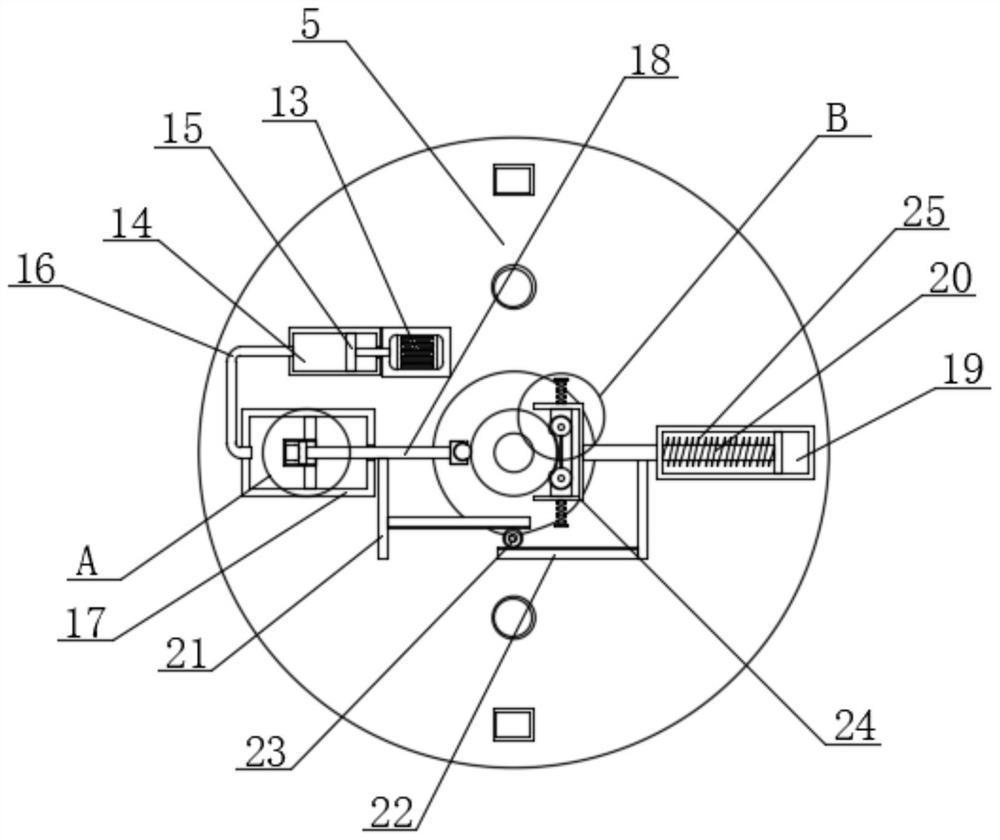

Efficient precipitated particle grinding device for textile fabric dyeing

InactiveCN111534946AUniform dyeingSimple structureTextile treatment machine arrangementsDynamo-electric machinesTextile technologyWater flow

The invention relates to the technical field of textiles, and discloses an efficient precipitated particle grinding device for textile fabric dyeing. The efficient precipitated particle grinding device comprises a base, a power generation device comprises a rotating column, a swing rod, a metal wire, a floating plate and a magnetic group plate, a driving device comprises a rack, a magnetic block and a coil, and a gear corresponding to the rack is arranged on an upper portion of a rotating shaft; an outer side of the grinding frame is connected with grinding balls, and each grinding ball comprises a through hole, a conical groove, a filter screen, a stopping column and a rubber ball. A magnetic field generated by the coil drives the rack to move left and right through the magnetic block, the rack drives the rotating shaft and spiral fan blades to rotate through the gear, the spiral fan blades rotate clockwise, and the grinding balls adsorb solid particles at the bottom of a dyeing box through the through holes; the spiral fan blades rotate anticlockwise, and the rubber balls block the through holes, so that water flow driven by the spiral fan blades is prevented from pushing solid particles in the through holes in the lower side, and the structure solves the problem that an existing textile fabric dyeing device is large in number of precipitated particles and not easy to remove.

Owner:杭州懂倒科技有限公司

An online measuring device and method for measuring the end face flange of a cage

ActiveCN108286926BGuaranteed GrindingFast and convenient online measurement requirementsMechanical thickness measurementsMeasurement deviceClassical mechanics

An online measuring device and a measuring method for cage end flanges are provided. The device comprises a clamping tool and a measuring tool. The clamping tool comprises a base plate, a positioningplate, a long cylindrical pin and pressing plates. The pressing plates are installed on the base plate. The positioning plate is arranged in a window hole of a cage in a penetrating manner. The long cylindrical pin is fixed on the base plate, and abuts against the wall of the positioning plate. The measuring tool comprises a pressing ring, a measuring plate, short cylindrical pins and two cylindrical rollers. The short cylindrical pins are vertically connected with one end of the positioning plate. The two cylindrical rollers are arranged on the short cylindrical pins in a penetrating manner.The measuring plate vertically sleeves the positioning plate. The length of the measuring plate is the same with the maximum outer diameter of the cage. The pressing ring abuts against the outer sideof the measuring plate, and is tightly pressed on the outer side of the measuring plate by a screw I connected with one end of the positioning plate. The problem that online grinding and measuring cannot be realized by a surface grinder is solved. The purpose of fast and convenient online measurement is achieved. The production efficiency is improved.

Owner:LUOYANG BEARING RES INST CO LTD

Material crushing and grinding machine and using method thereof

ActiveCN110142086BAvoid Difficult-to-Grind SituationsIncrease grinding rateGrain treatmentsEngineeringMachine

The invention relates to a material crushing and grinding machine and a using method thereof. The material crushing and grinding machine comprises a bottom plate, a speed change driving module, a fixed outer pipe, two U-shaped frames, two rotating shafts, two circular plates and a built-in grinding roller, wherein the fixed outer pipe is arranged at the upper end of the bottom plate, the left endand the right end of the fixed outer pipe are provided with the two rotating shafts through bearings, the inner ends of the rotating shafts are installed on the circular plates, the outer ends of therotating shafts are arranged on the U-shaped frames through bearings, the U-shaped frames are arranged on the bottom plate, the built-in grinding roller is uniformly installed between the two round plates through a pin shaft, and a speed change driving module is arranged at the left end of the bottom plate. According to the material crushing and grinding machine, in the existing grinding process,materials with different volumes can be mixed together to form a material layer, and during grinding, the materials with a large volume can be buried in a deeper position, a grinding body falls into the crushing process, the crushed materials on the upper surface of the material layer plays a role in relieving impact force on the falling grinding body, the grinding body has the weight, and the problem that the surface of a grinding cavity can be knocked out of the grinding cavity during falling can be solved.

Owner:BOYEE SHENZHEN IND TECH CO LTD

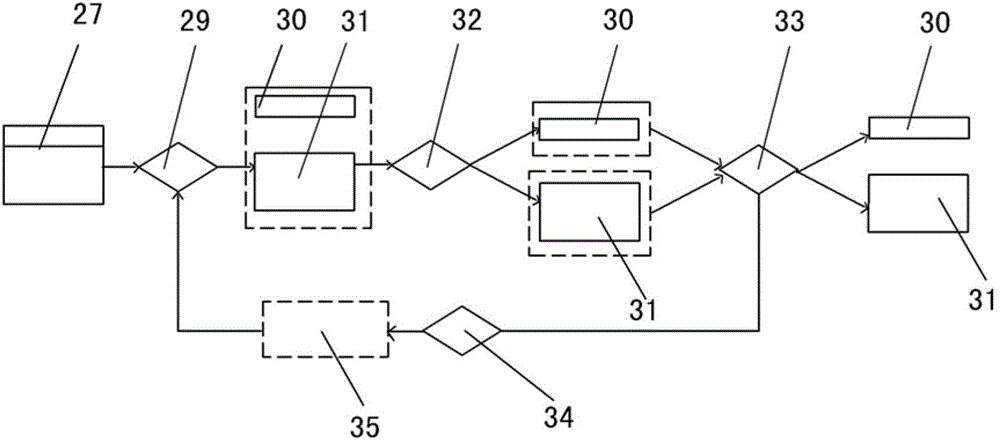

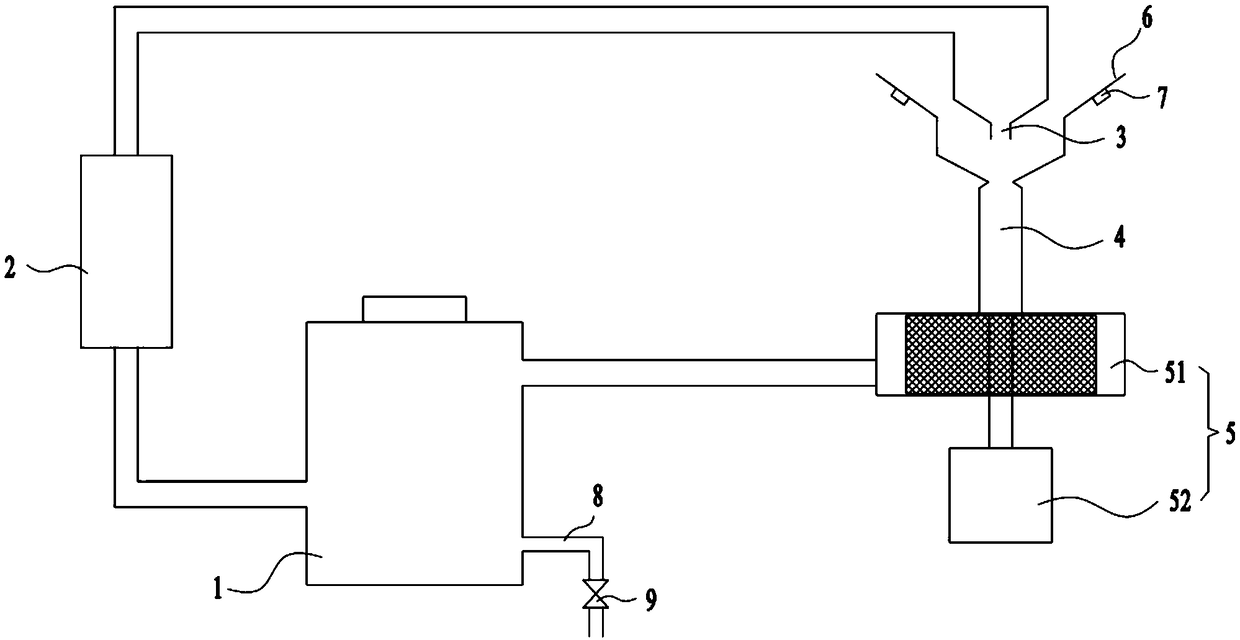

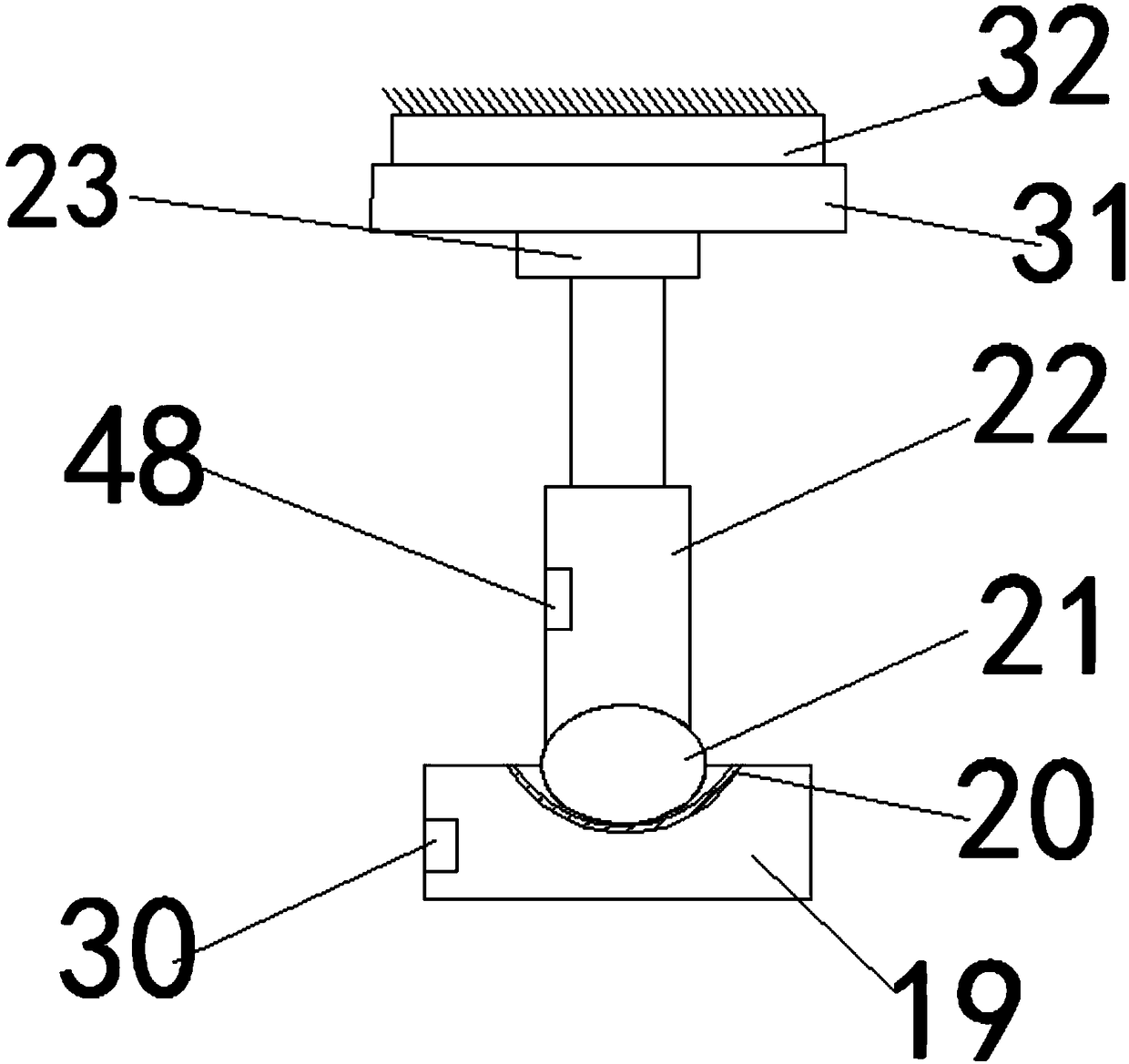

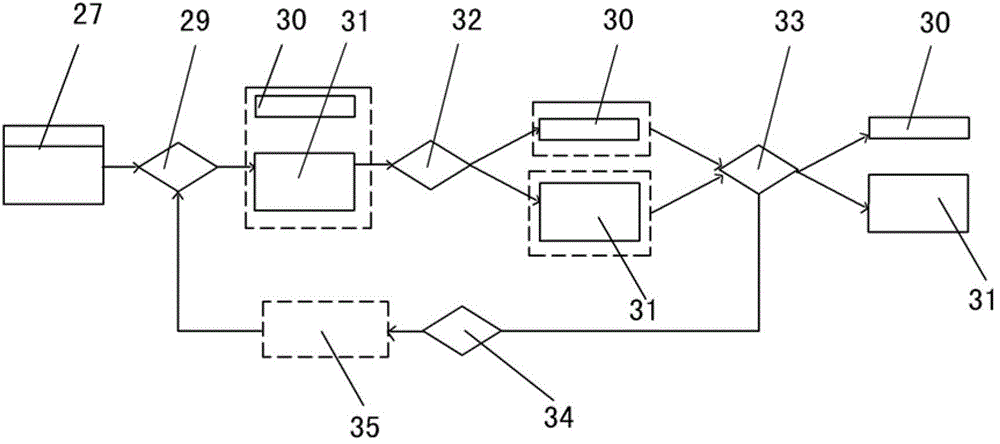

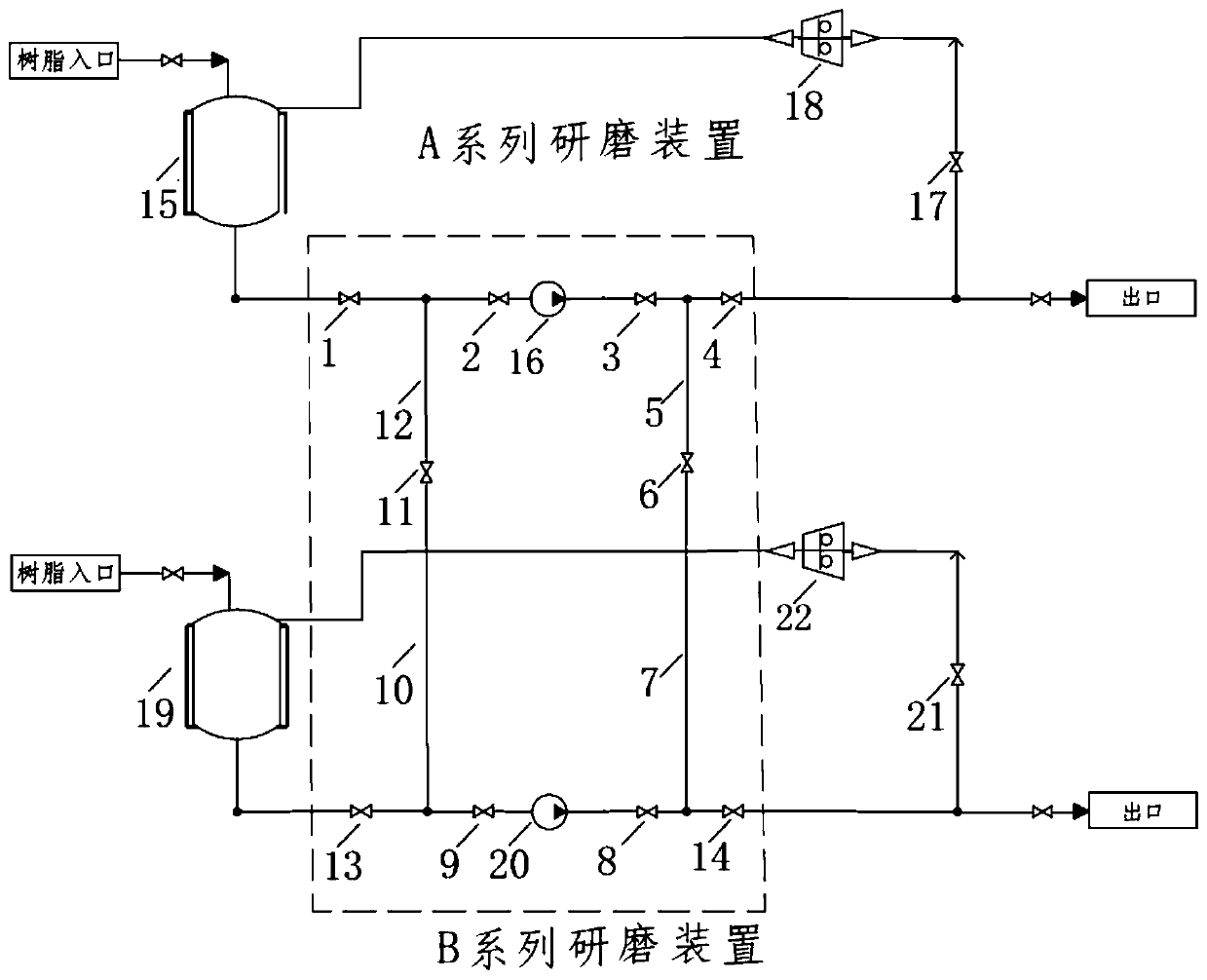

Radioactive waste resin grinding system with redundant device

PendingCN109849238AAchieve mutual inversionGuaranteed GrindingPlastic recyclingIsolation valveNuclear power

The invention belongs to the field of treatment of nuclear power station radioactive three wastes and particularly discloses a radioactive waste resin grinding system with a redundant device. The radioactive waste resin grinding system with the redundant device comprises a temporary storage tank A, a pump A, an isolation valve A, a grinding machine A, a temporary storage tank B, a pump B, an isolation valve B and a grinding machine B and further comprises multiple isolation valves and pipelines, wherein the multiple isolation valves and the pipelines are arranged between the temporary storagetank A and the pump A, between the pump A and the isolating valve A, between the temporary storage tank B and the pump B, between the pump B and the isolation valve B. The temporary storage tank A communicates with the grinding machine A. The grinding machine A communicates with the isolation valve A. The temporary storage tank B communicates with the grinding machine B. The grinding machine B communicates with the isolation valve B. The radioactive waste resin grinding system with the redundant device can ensure that when one of the two series of grinding devices loses the grinding and conveying capacity and waste resin cannot be normally grinded as a result, the redundant device guides the unground waste resin into the normal series from the faulty series so as to continue completing grinding of the waste resin.

Owner:JIANGSU NUCLEAR POWER CORP

A livestock feed screening device

ActiveCN114653586BReasonable structureInnovative designSievingScreeningAgricultural scienceCrop livestock

Owner:诸城市中裕机电设备有限公司

A deburring device and method for multi-robot arms

ActiveCN112975673BPrecise positioningClose contactGrinding carriagesGrinding drivesElectric machineryEngineering

The present invention belongs to the technical field of processing machinery, especially a deburring device and method of multi-robot arms. Aiming at the problem that the existing grinding method of rods still relies on manual operation, so the efficiency is relatively low, the following proposal is now proposed. It includes a base, a support cover and a drive motor are fixedly installed on the top of the base, and the drive motor is located in the support cover, a mounting bracket is fixedly installed on the top of the support cover, and the output shaft of the drive motor extends above the support cover And a support plate is fixedly installed, and the top of the support plate is clamped with a rod. The present invention can continuously grind the rod with the same pressure according to the shape of the rod, so as to remove the burrs on the rod , Compared with traditional manual grinding, this technical solution realizes fully automatic operation, so it can improve work efficiency and has good convenience.

Owner:江苏中科云控智能工业装备有限公司

A chemical laboratory grinding device

The invention discloses a grinding device for a chemical laboratory, which comprises a base, a grinding tank and a vertical plate are arranged on the top of the base, a grinding mechanism and a fixing table are arranged inside the grinding tank, and the fixing table is installed on the grinding tank. The bottom of the tank, the bottom of the grinding mechanism is installed on the fixed table. The crushing mechanism of the present invention can carry out preliminary crushing treatment on chemicals, and crush the agglomerated chemicals through the rotation of the crushing blade, and the lifting mechanism can drive the grinding mechanism to lift through the action of the pneumatic cylinder, which is convenient for cleaning the device. The service life of the device is improved, the transmission mechanism can drive the grinding tank to move, prevent the second motor failure, the device cannot work, and improve the efficiency of the experiment. The crushing blade on the first grinding wheel in the grinding mechanism can crush and grind chemicals. The second grinding wheel grinds the chemicals again, not only will not break the crushing blade, but also the crushing is more uniform.

Owner:济南工程职业技术学院

Chemical solid grinding machine

PendingCN109806939AGrinding speed is fastAvoid incomplete grindingCocoaGrain treatmentsCompound (substance)Pulp and paper industry

The invention discloses a chemical solid grinding machine. The chemical solid grinding machine comprises a grinding machine body, wherein supports are arranged at the lower edge of the grinding machine body, a servo motor is fixed at the bottom center of the grinding machine body through a bolt, an output shaft of the servo motor penetrates through the bottom of the grinding machine body and extends into the grinding machine body, and the top of the output shaft of the servo motor is sleeved with an external member; the portions, located at the top and the bottom of the external member, of theoutput shaft of the servo motor are sleeved with positioning clamps; multiple sets of side vertical plates are arranged on the outer wall of the external member, each set has two side vertical plats,and a curved bar is rotationally connected between every two side vertical plates of each set; one end of each curved bar is rotationally connected with an upper grinding plate through a bearing; anda lower grinding plate is arranged at the horizontal center line of the interior of the grinding machine body. The chemical solid grinding machine is suitable for chemical solid grinding. During grinding, the upper grinding plates carry out turnover grinding around the vertical center line of the grinding machine body as well as rotation grinding, the grinding speed is high, and the efficiency ishigh.

Owner:安徽英特力工业工程技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com