Chemical solid grinding machine

A solid grinding and grinding machine technology, applied in the fields of food science, cocoa, grain processing, etc., can solve the problems of incomplete grinding, slow development, slow grinding speed, etc., to increase the grinding speed and avoid the effect of incomplete grinding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

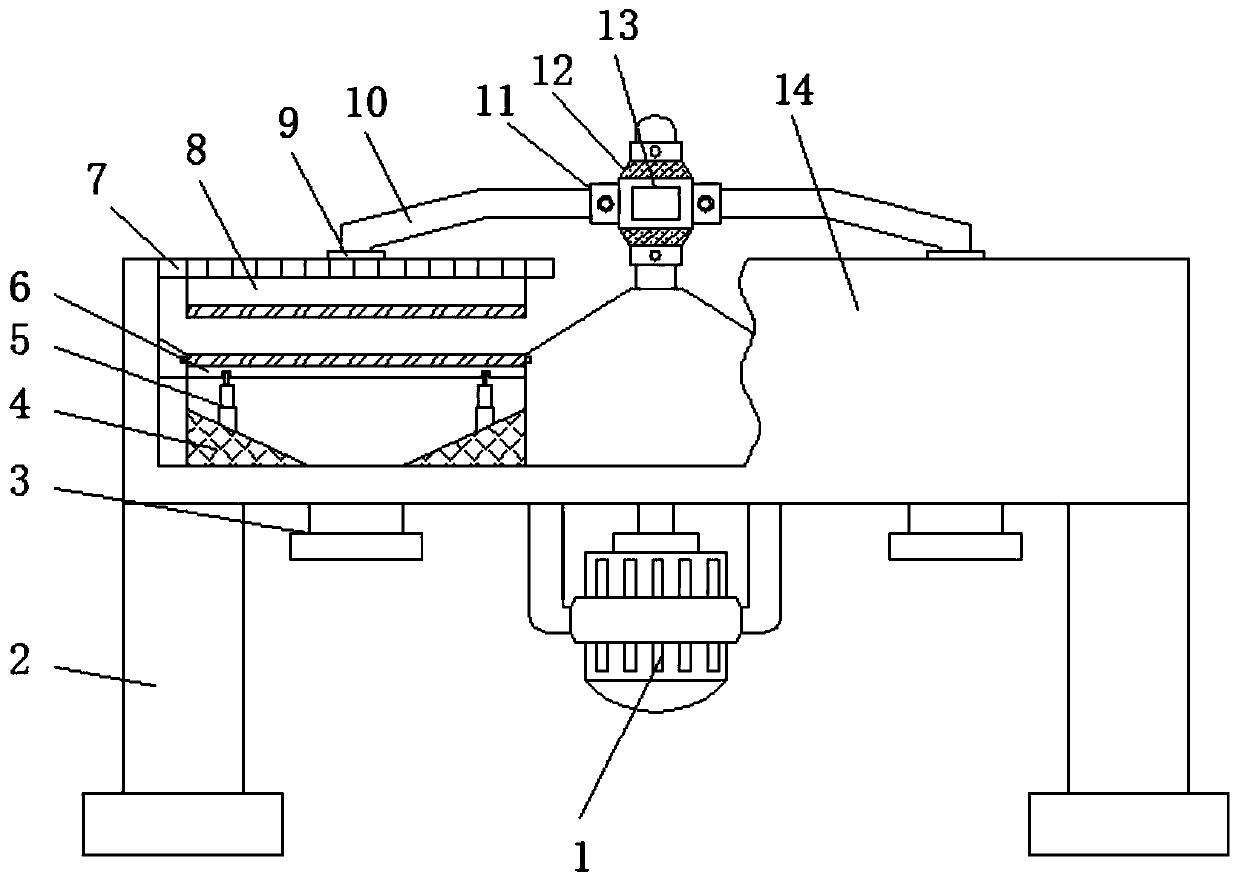

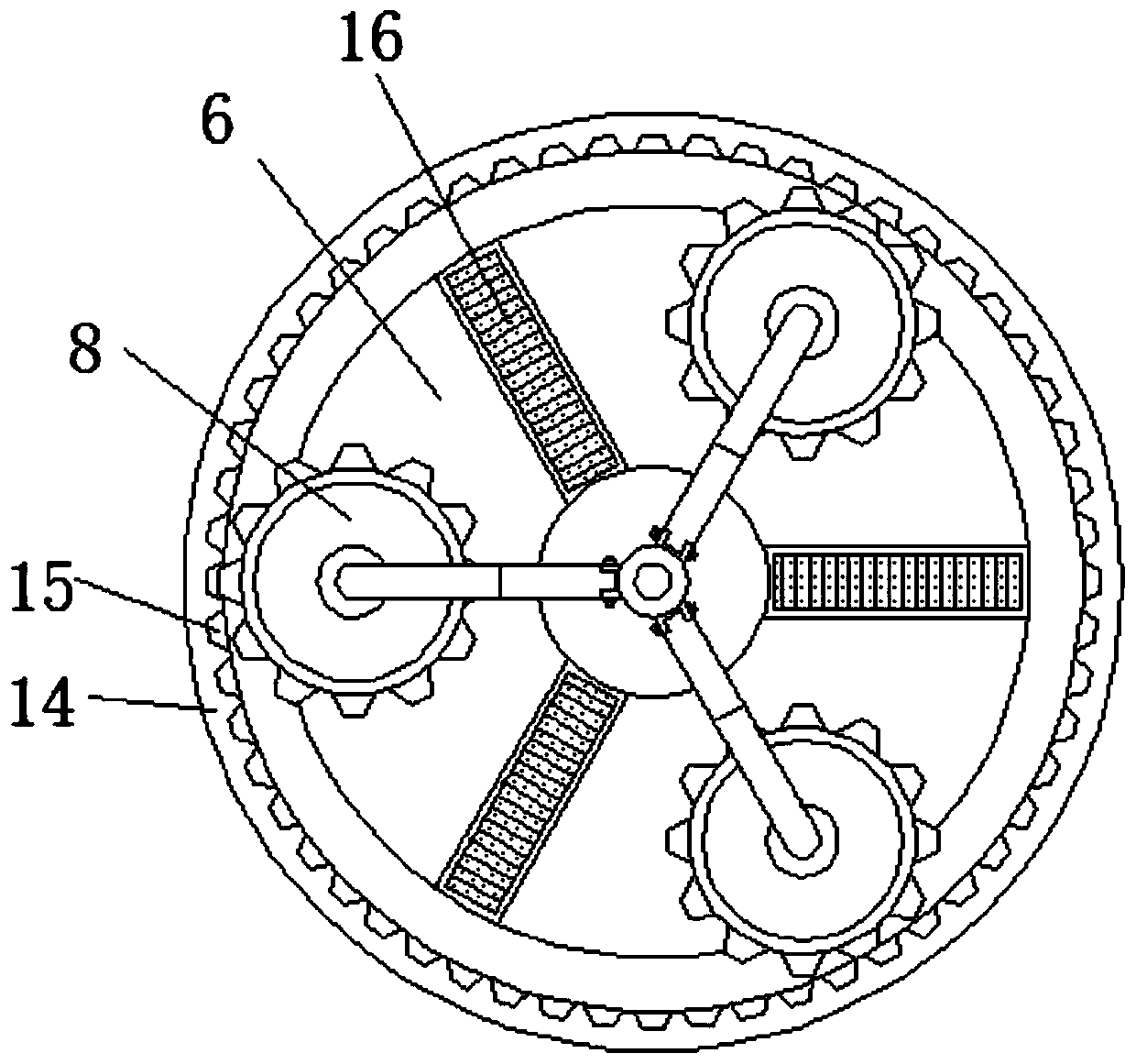

[0028] Embodiment 1, with reference to Figure 1-4 , a chemical solid grinding machine, comprising a grinding machine 14, a bracket 2 is arranged at the lower edge of the grinding machine 14, a servo motor 1 is fixed to the bottom center of the grinding machine 14, and the output shaft of the servo motor 1 runs through the bottom of the grinding machine 14 and extends To the inside of the grinding machine 14, the top of the output shaft of the servo motor 1 is sleeved with a set 13, and the output shaft of the servo motor 1 is located at the top and bottom of the set 13. The positioning card 12 is sleeved, and the outer wall of the set 13 is provided with multiple sets of side stand There are two plates 11 for each group of side risers 11, and a curved rod 10 is connected between the two side risers 11. One end of the bend rod 10 is connected with an upper grinding disc 8 through a bearing 9. The inside of the grinder 14 is horizontal. A lower grinding disc 6 is arranged at th...

Embodiment 2

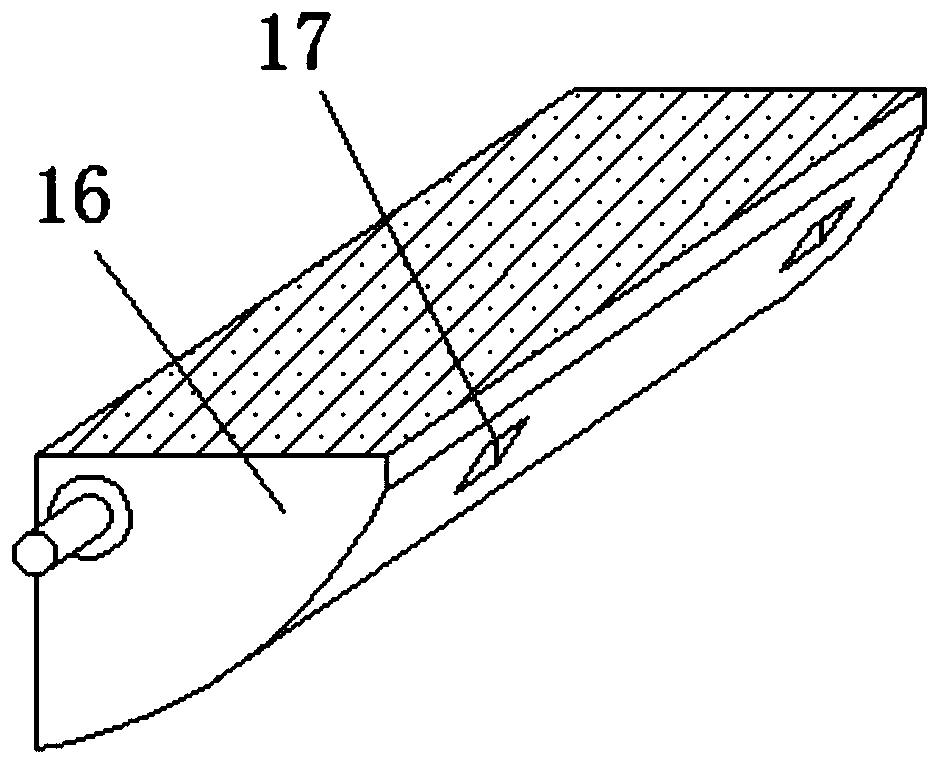

[0031] Embodiment 2, with reference to Figure 2-4 , the upper surface of the lower millstone 6 is equidistantly embedded with a plurality of discharge plates 16, the two ends of the discharge plate 16 are connected with the lower millstone 6 through pin shafts, the bottom of the discharge plate 16 is provided with a mounting groove 17, and the upper surface of the material guide device 4 The surface is located at the place below the discharge plate 16 and is provided with an electric push rod 5. The top of the electric push rod 5 is connected to the inner wall of the installation groove 17 through a pin shaft. The vertical section of the discharge plate 16 is a fan-shaped structure. The upper surface of the discharge plate 16 It is on the same plane as the upper surface of the lower grinding disc 6.

[0032] By adopting the above technical solutions:

[0033] The discharge plate 16 can be rotated. When the discharge plate 16 is rotated to a horizontal state, that is, the upp...

Embodiment 3

[0034] Embodiment 3, with reference to Figure 1-2 , the edge of the upper surface of the lower grinding disc 6 is a raised structure, the diameter of the upper grinding disc 8 is less than or equal to the width of the bottom surface of the lower grinding disc 6, and there are multiple upper grinding discs 8, and the spacing between the plurality of upper grinding discs 8 is equal.

[0035] By adopting the above technical solutions:

[0036] Since the edge of the upper surface of the lower grinding disc 6 is a tilted structure, when the material is scattered on the edge of the upper surface of the lower grinding disc 6, the material will be continuously guided to gather at the center of the lower grinding disc 6 to ensure that all materials can be ground. It can effectively avoid the phenomenon of incomplete grinding of materials.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com