Grinding method based on margin constraint condition

A constraint condition and grinding technology, which is applied in the field of grinding and processing of blade parts, can solve the problems such as the difficulty of self-adaptive grinding of CNC abrasive belts, and achieve the effect of easy operation, guaranteeing grinding accuracy and ensuring accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

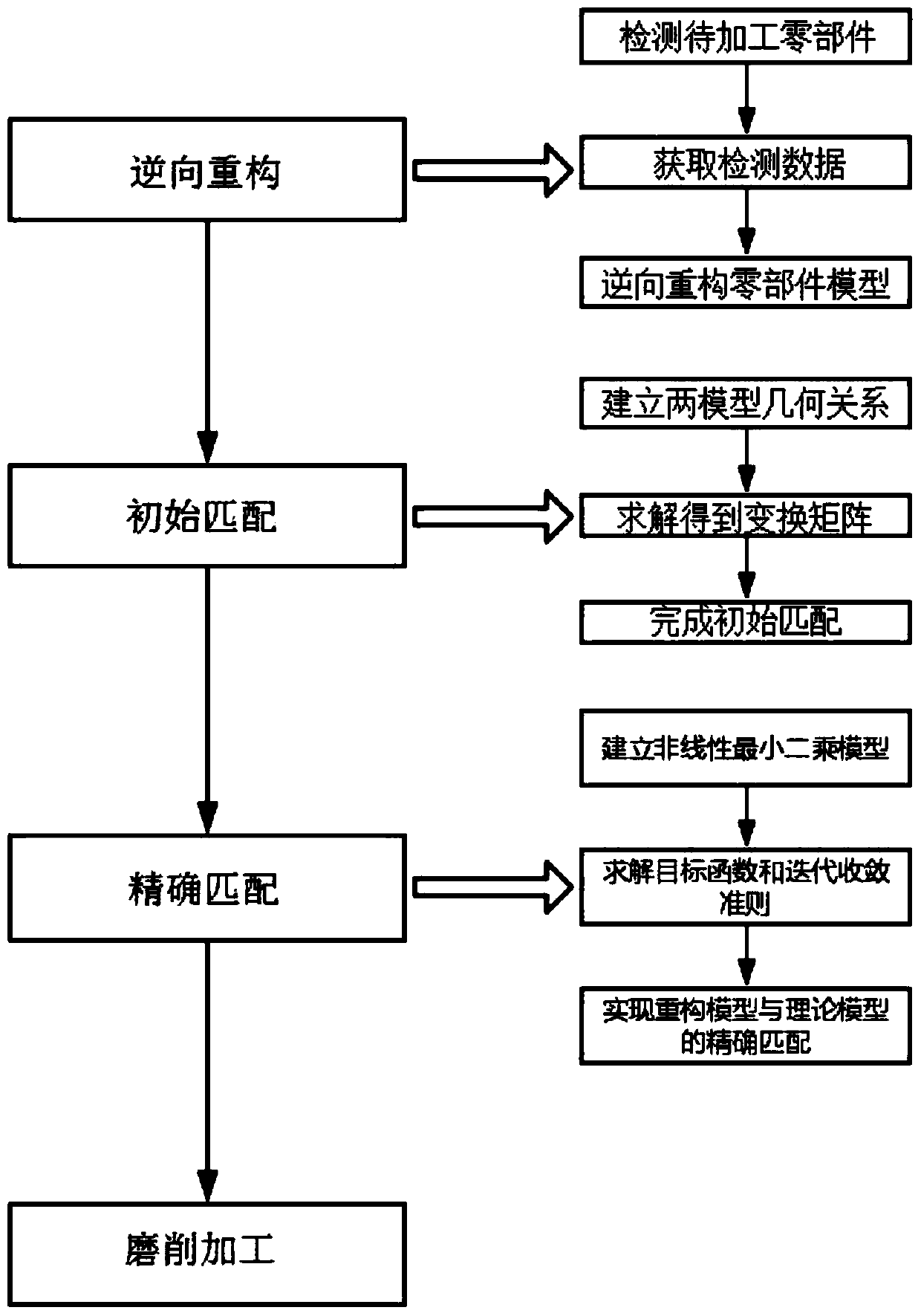

[0033] The molding process of marine integral propellers generally adopts blank casting without mechanical processing, so there is no processing standard. At the same time, due to the large size, large volume and weight of marine propellers, and the need for multiple processes to complete the processing, this embodiment uses a robot to clamp the grinding head. Subsequent adaptive grinding and polishing of marine propellers, see figure 1 , shows the grinding method based on allowance constraints, which includes the following steps.

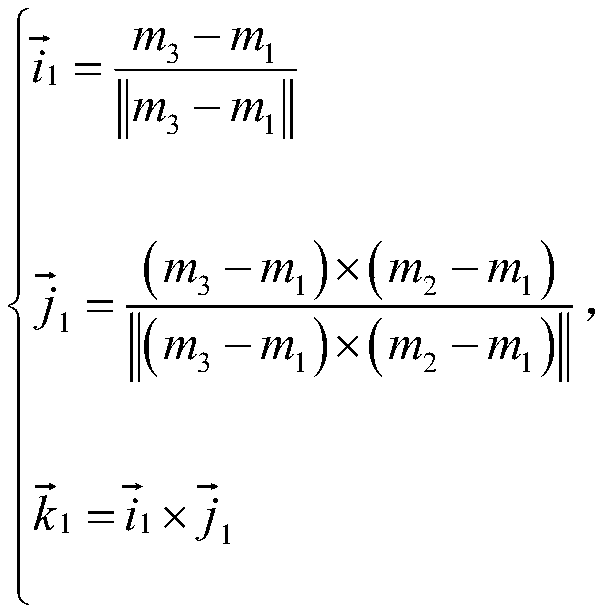

[0034] Step 1, use Hexagon GLOBAL SILVER CLASSIC SR 05.07.05 contact type three-coordinate measuring machine to test it. According to the propeller point cloud data obtained by detection, using NX8.5 three-dimensional modeling software, the three-dimensional non-uniform rational B-spline curve surface algorithm i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com