Novel solid wrapping slurry removing equipment

A new type of technology for solids, applied in the field of new-type solids removal equipment, can solve the problems of waste of resources, the inability to separate the slurry and stones, etc., so as to improve the utilization rate, facilitate subsequent utilization, and reduce production costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

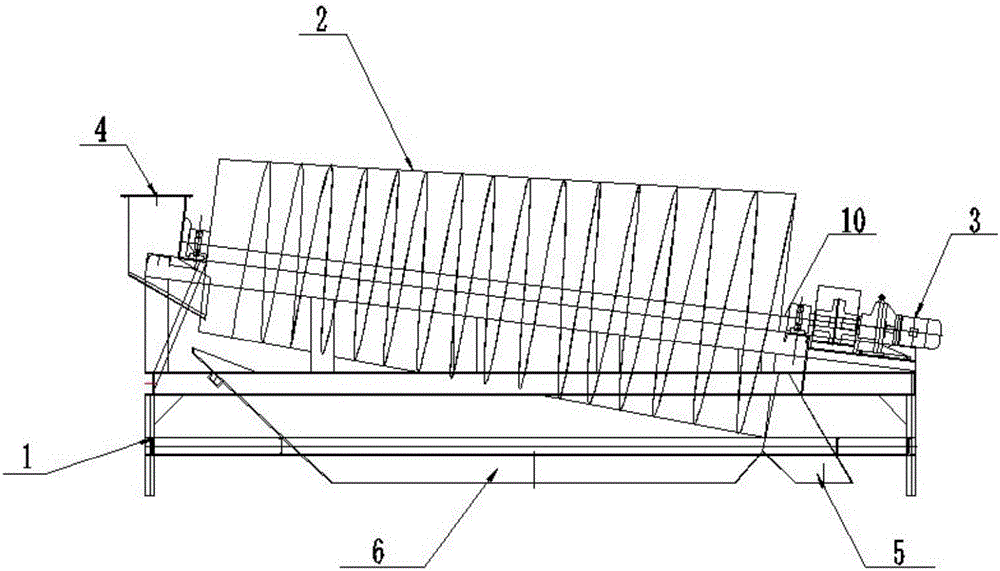

[0035] The new solid matter removal equipment provided in this embodiment includes a frame, a cylinder, a rotating shaft and a driving device arranged on the frame; the driving device is connected with the rotating shaft and is used to drive the The rotating shaft rotates; the cylinder is fixed on the rotating shaft so that the cylinder rotates around the rotating shaft, and the cylinder is inclined to the horizontal plane to accommodate the solid matter to be removed; One end of the cylinder body is provided with a feed port, and the other end of the cylinder body is provided with a first discharge port, and the position of the feed port is higher than that of the first discharge port; A second outlet is provided on the outer wall of the cylinder near the horizontal plane.

[0036] The new type of solid matter removal equipment provided in this embodiment can efficiently remove construction waste by setting the cylinder inclined, feeding from one end of the high position of t...

Embodiment 2

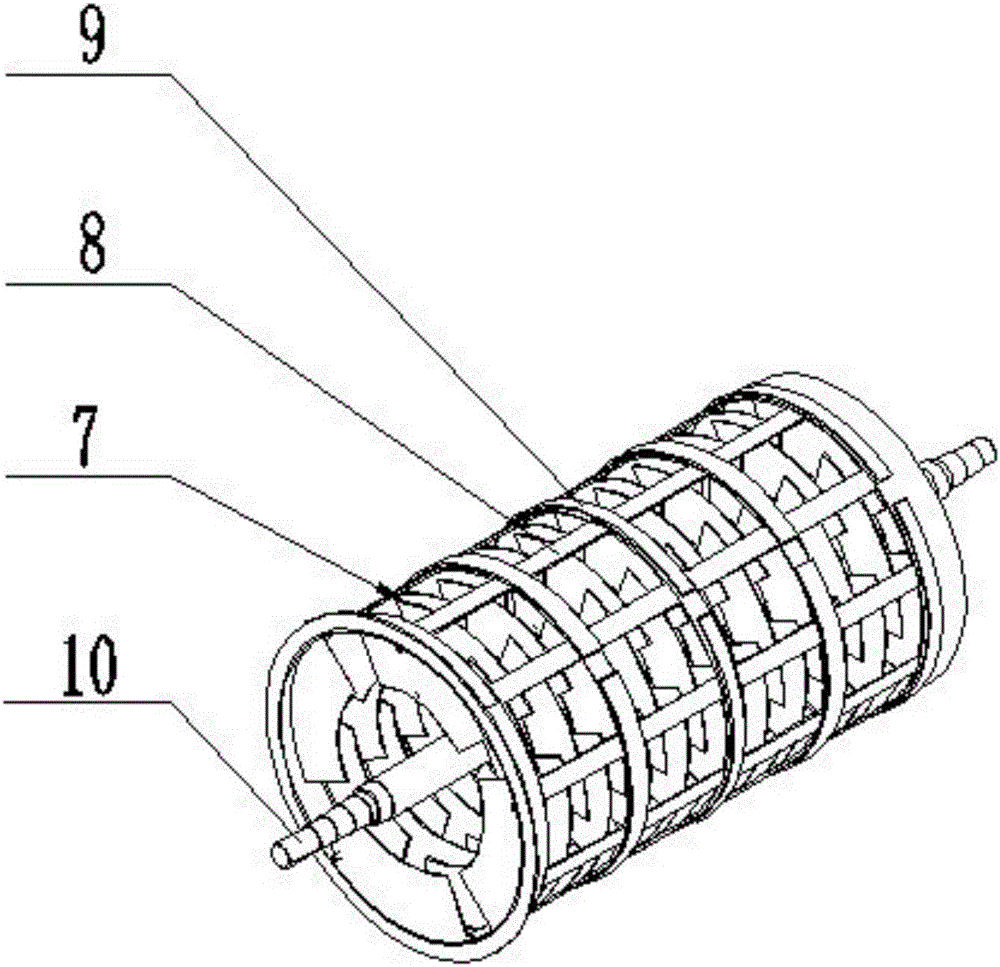

[0038] Such as figure 1 , 2 As shown, the novel solid matter removal patina equipment provided by the present invention comprises a frame 1, a cylinder body 2, a rotating shaft 10 and a driving device 3 arranged on the frame 1; the driving device 3 and the The rotating shaft 10 is connected to drive the rotating shaft 10 to rotate; the cylindrical body 2 is fixed on the rotating shaft 10 so that the cylindrical body 2 rotates around the rotating shaft 10, and the cylindrical body 2 and the horizontal plane It is inclined to accommodate the solid matter to be removed; one end of the cylinder body 2 is provided with a feed port, and the other end of the cylinder body 2 is provided with a first discharge port, and the feed port is provided with a first discharge port. The position at is higher than the position of the first discharge port; the outer wall of the cylinder 2 is provided with a second discharge port on the side close to the horizontal plane.

[0039] Wherein, the v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com