Patents

Literature

103results about How to "Reduce loading and unloading costs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

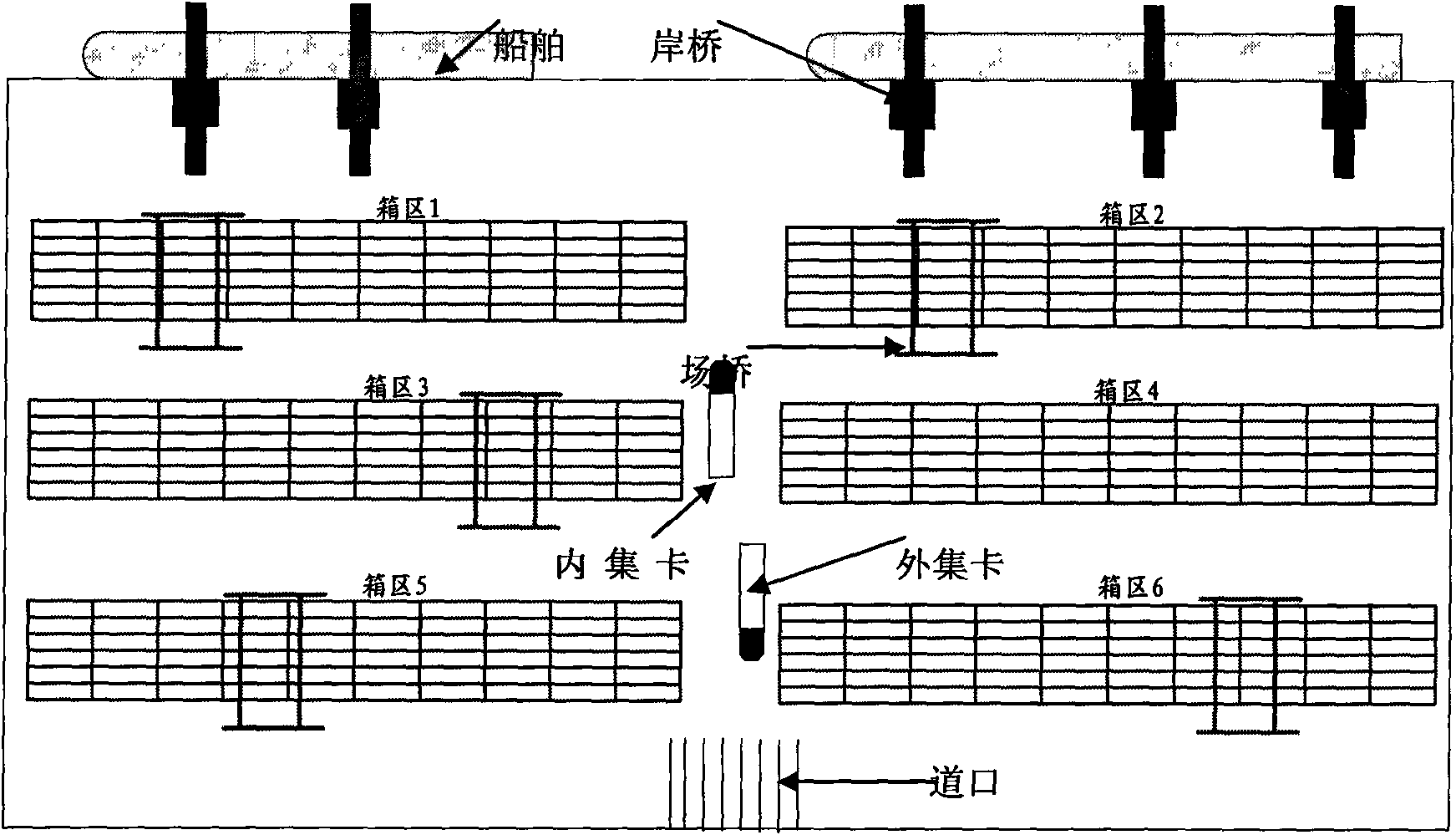

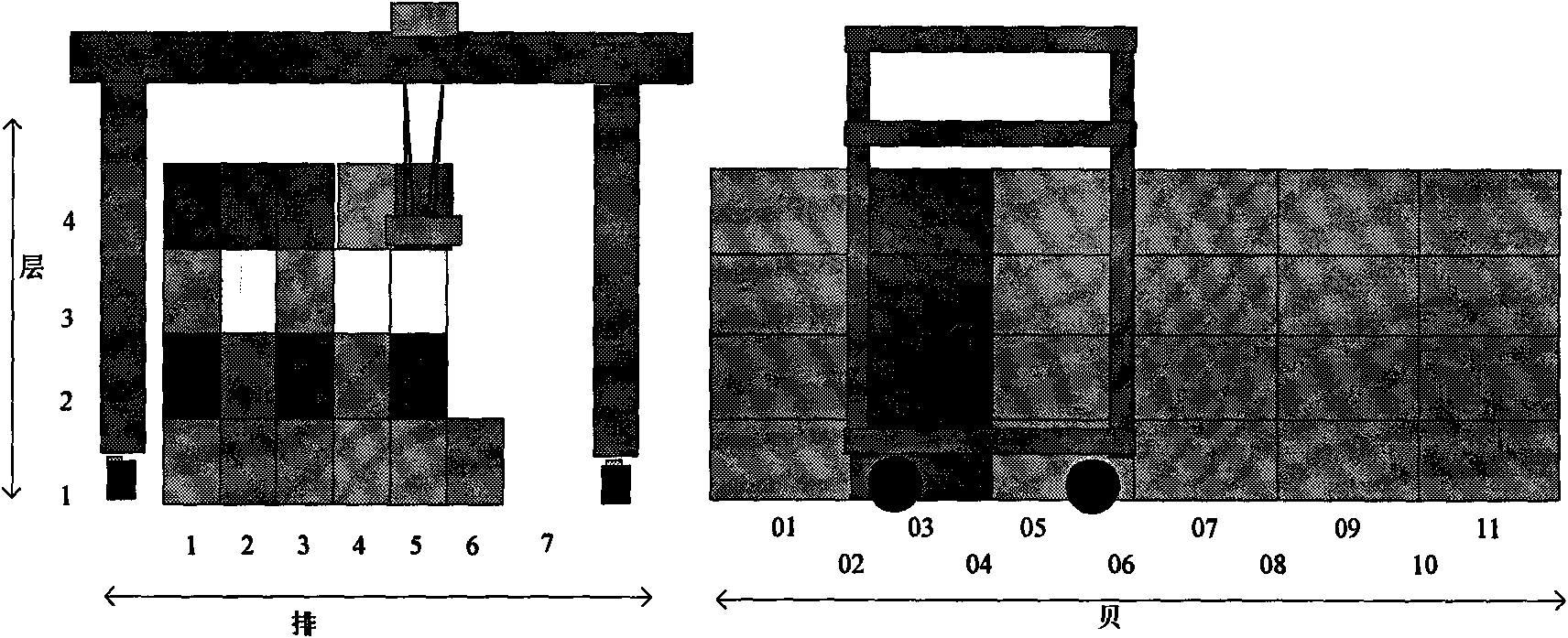

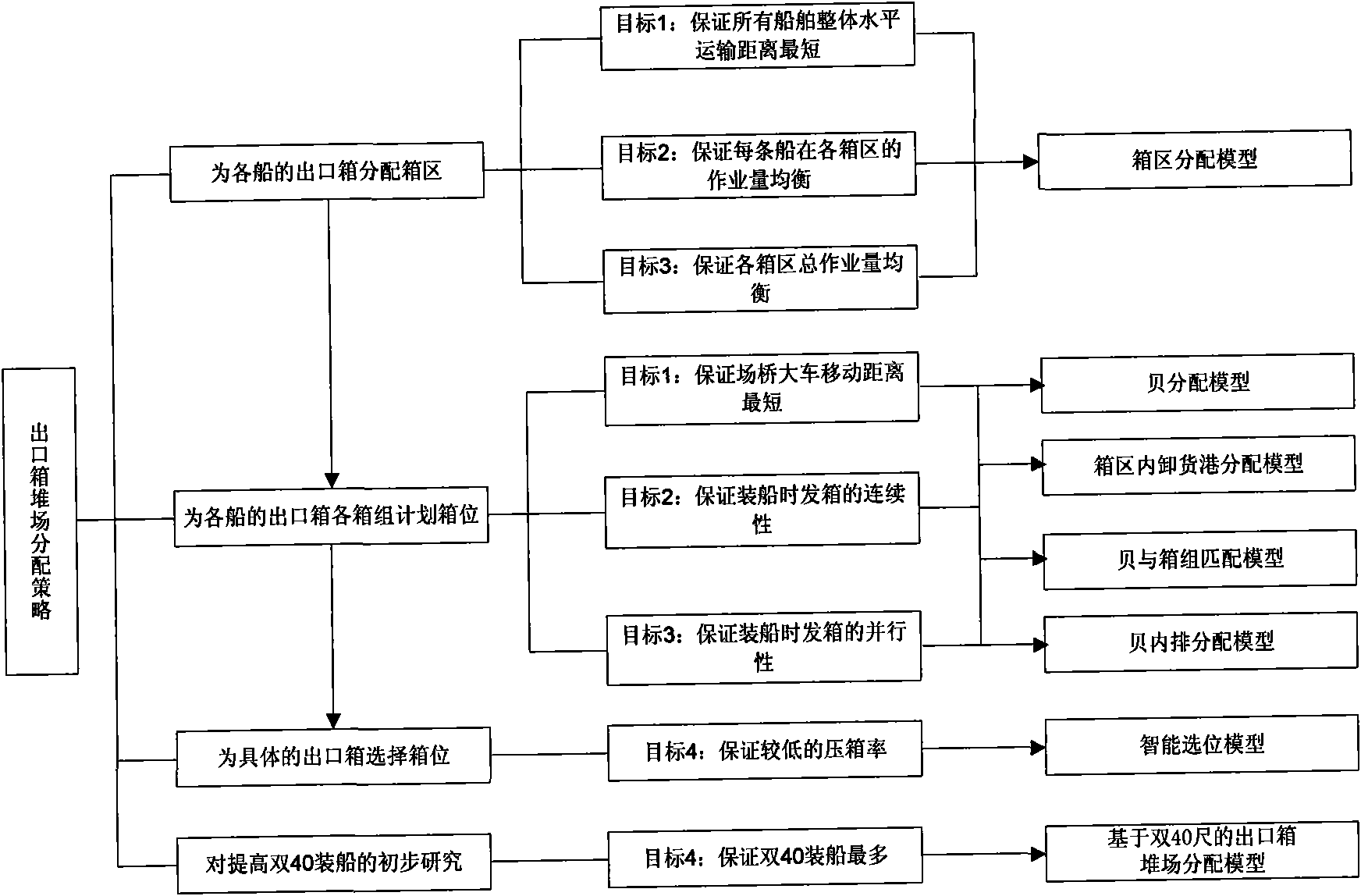

Distribution Method for export container yard of container wharf

InactiveCN101585453AReduce loading and unloading costsImprove service qualityData processing applicationsStorage devicesDistribution methodVolumetric Mass Density

The invention discloses a automatic distribution method for an export container yard of a container wharf, which comprises the following steps: firstly, distributing a container region for export containers of each ship; then, planning a container slot for each container set of the export containers of each ship; and finally, selecting the container slot for specific export containers. The method carries out deep research on the distribution of the export container regions, the planning of the container slots and the automatic slot selection of approach and preliminary consideration for improving the proportion of double 40 shipping, is favorable for improving the orderliness of the export container stacking under the predetermined yard density and has important significance in establishing good basis for the ordered organization of subsequent shipping operation.

Owner:SHANGHAI MARITIME UNIVERSITY

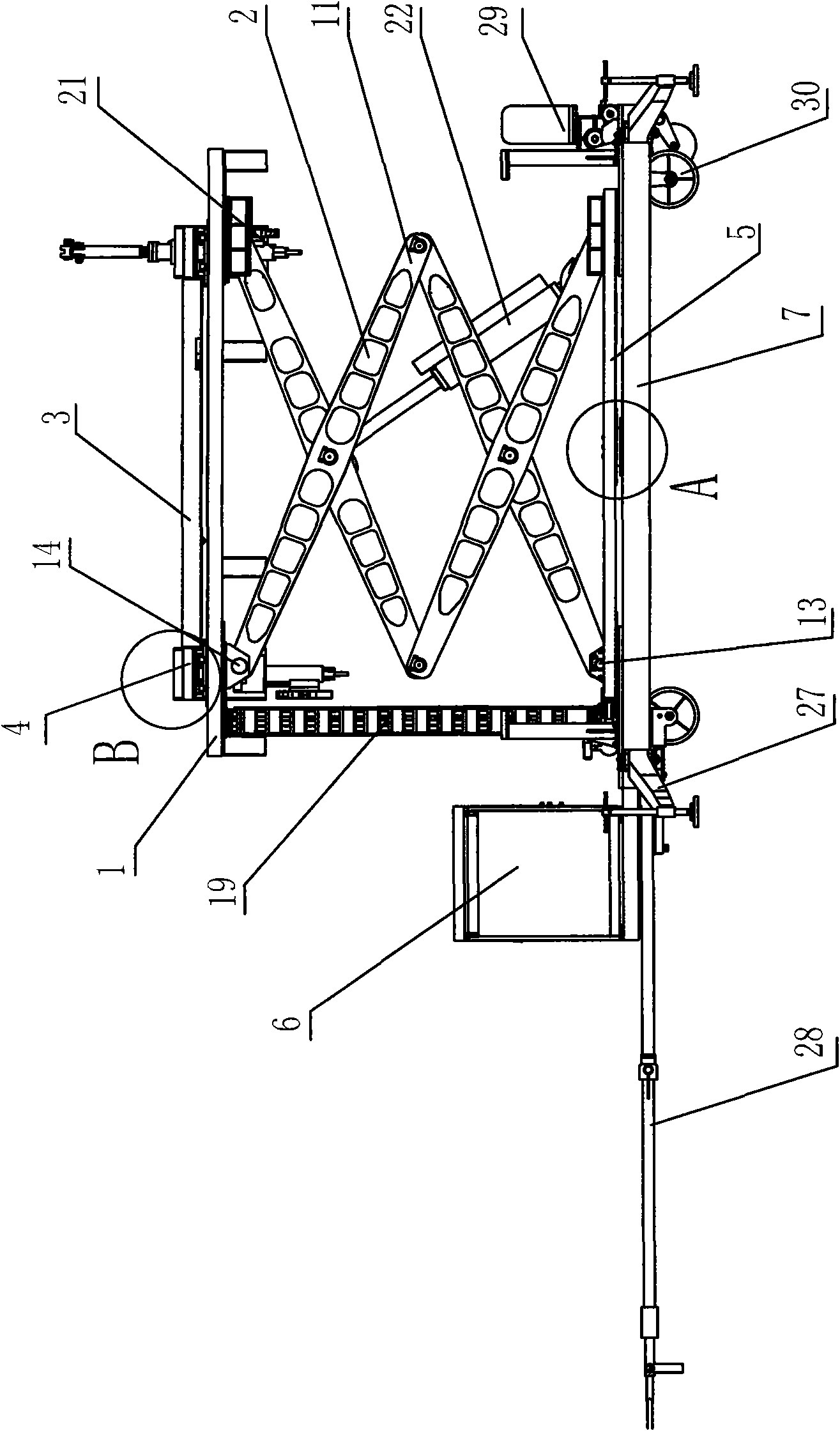

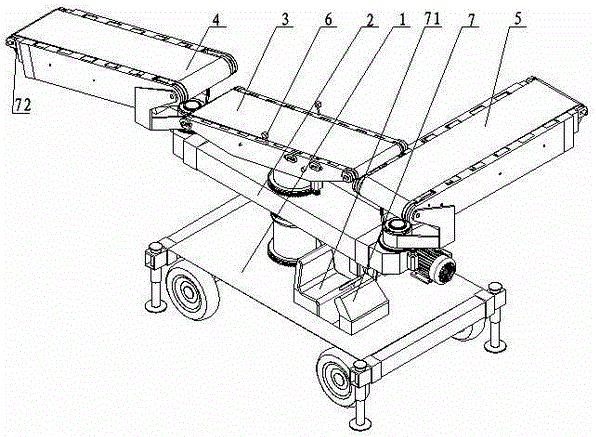

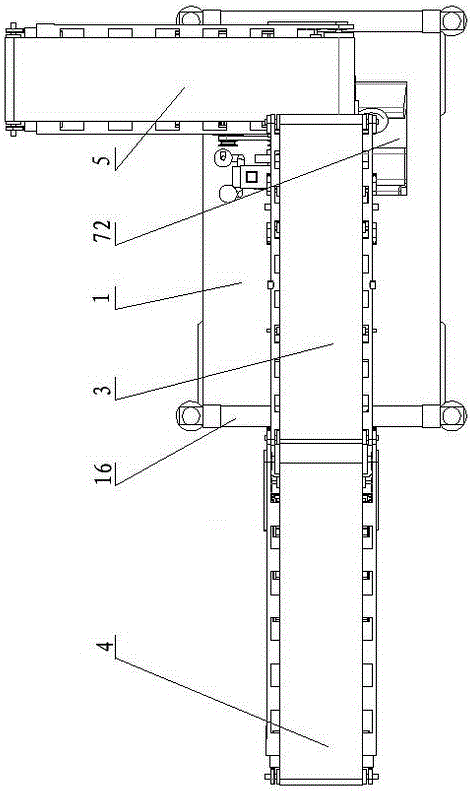

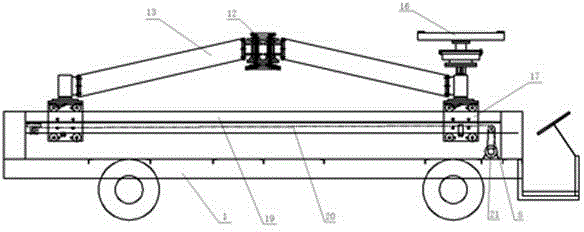

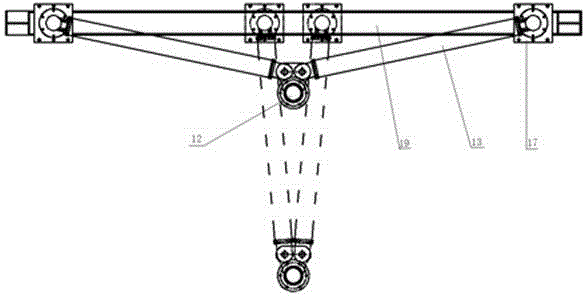

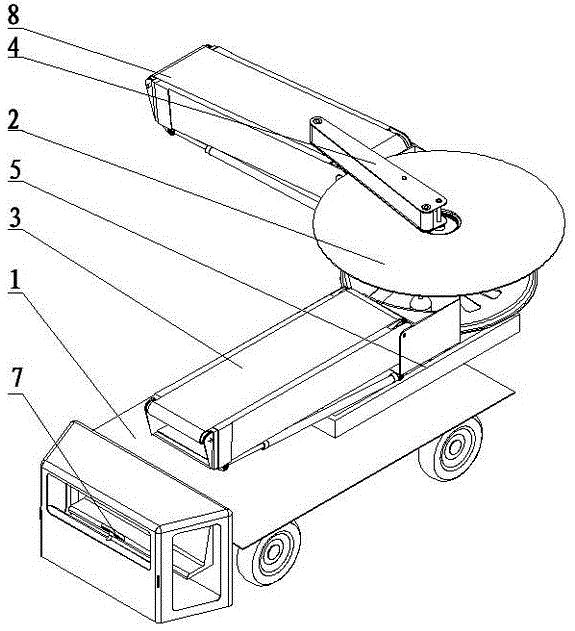

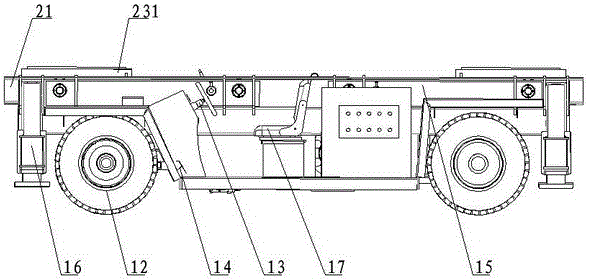

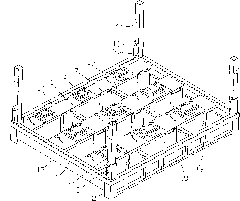

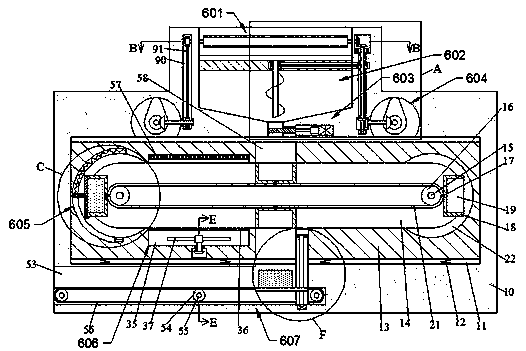

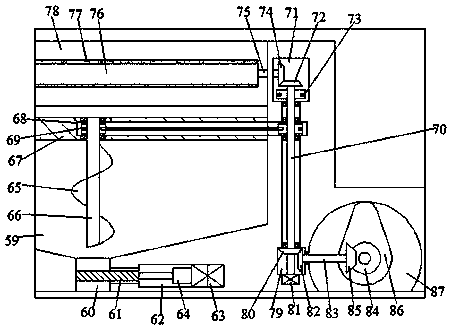

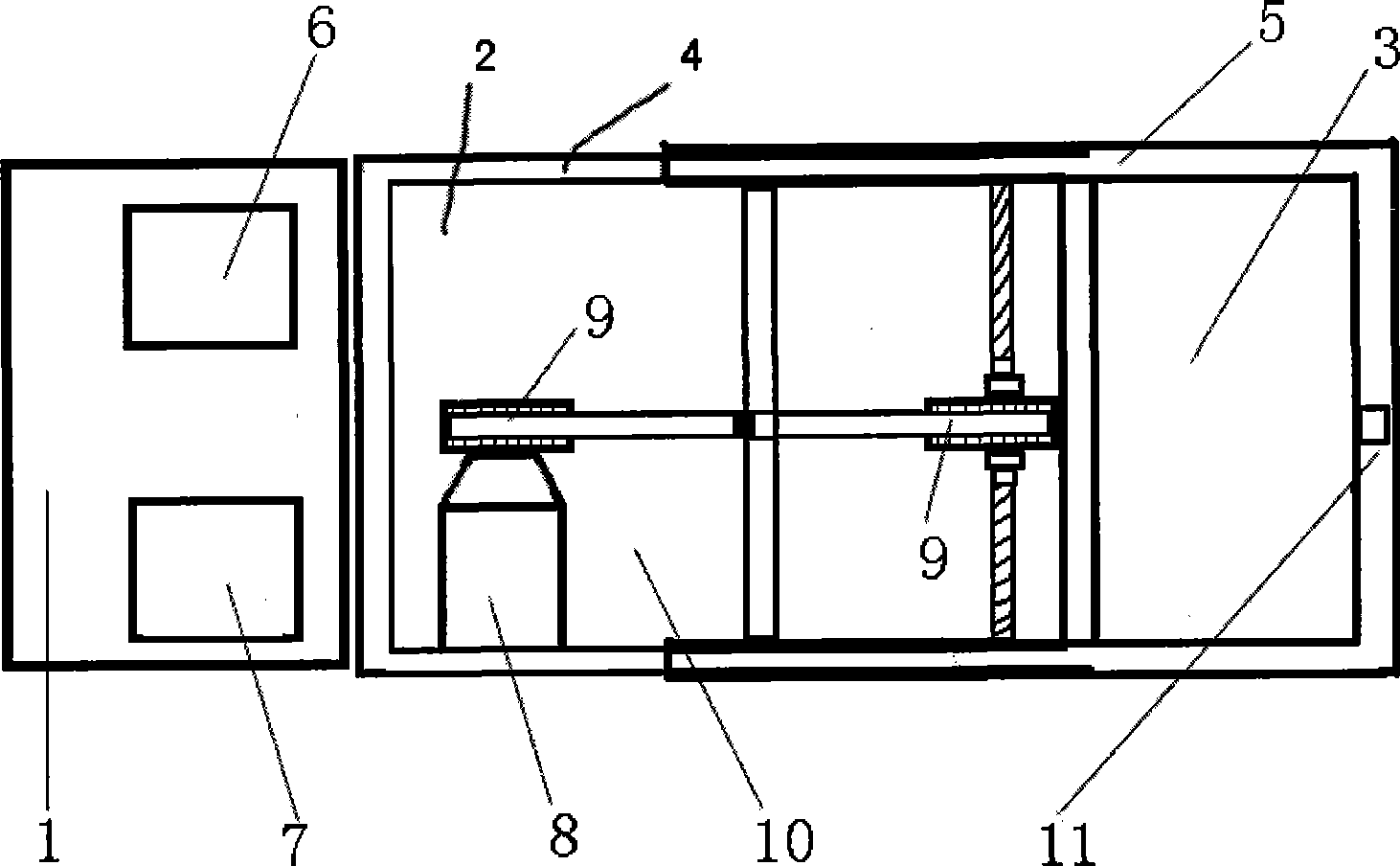

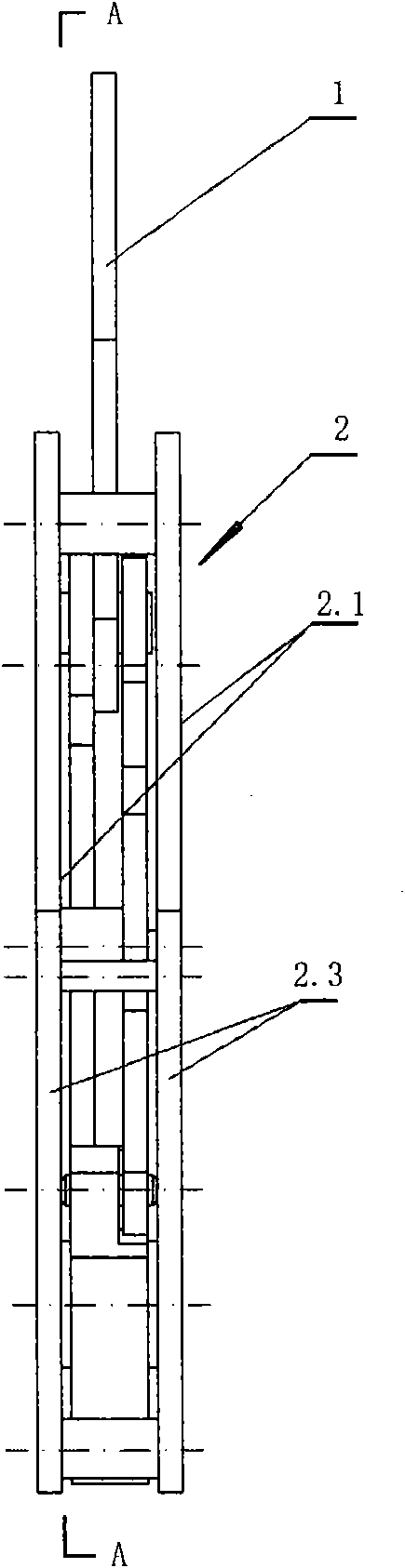

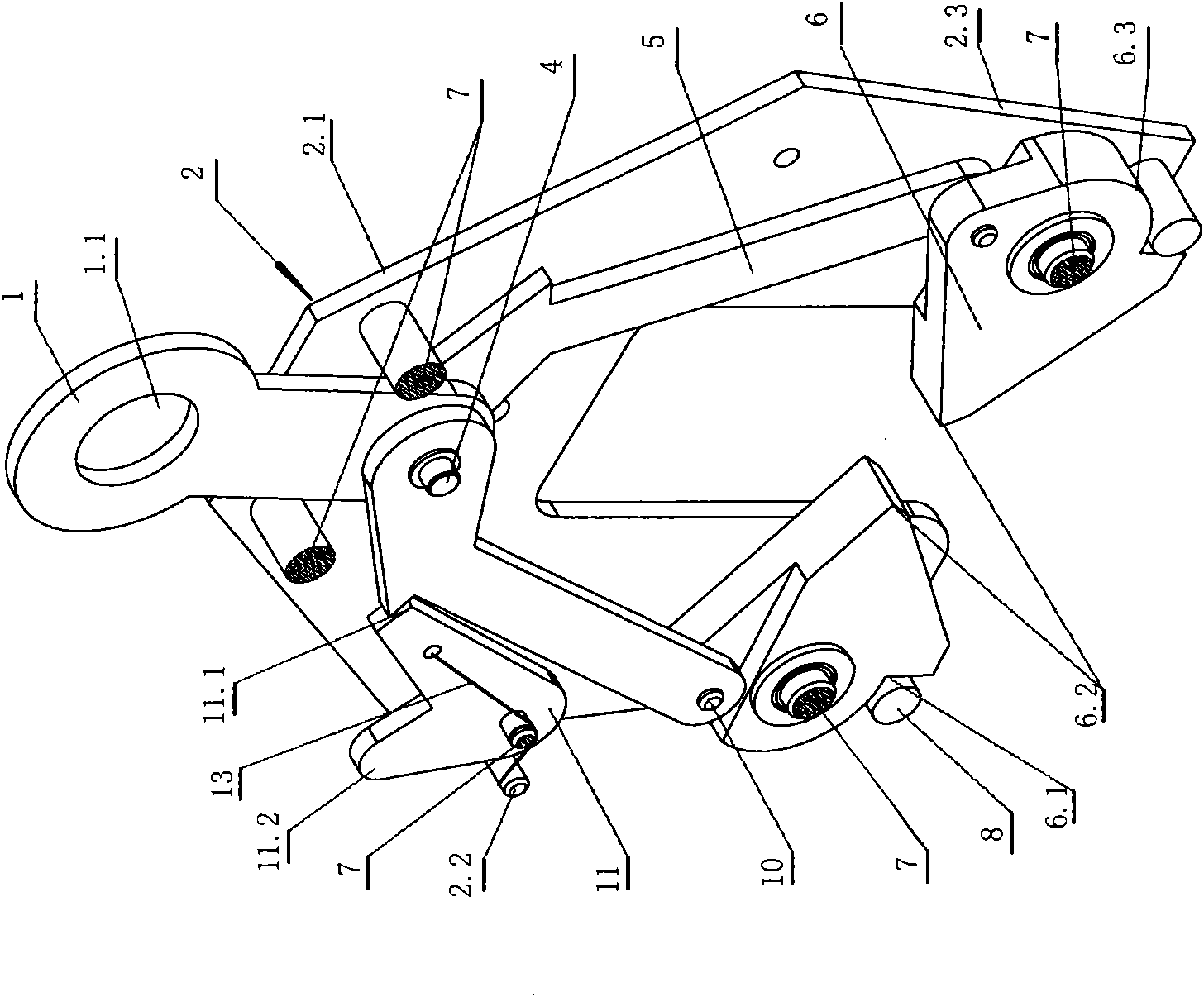

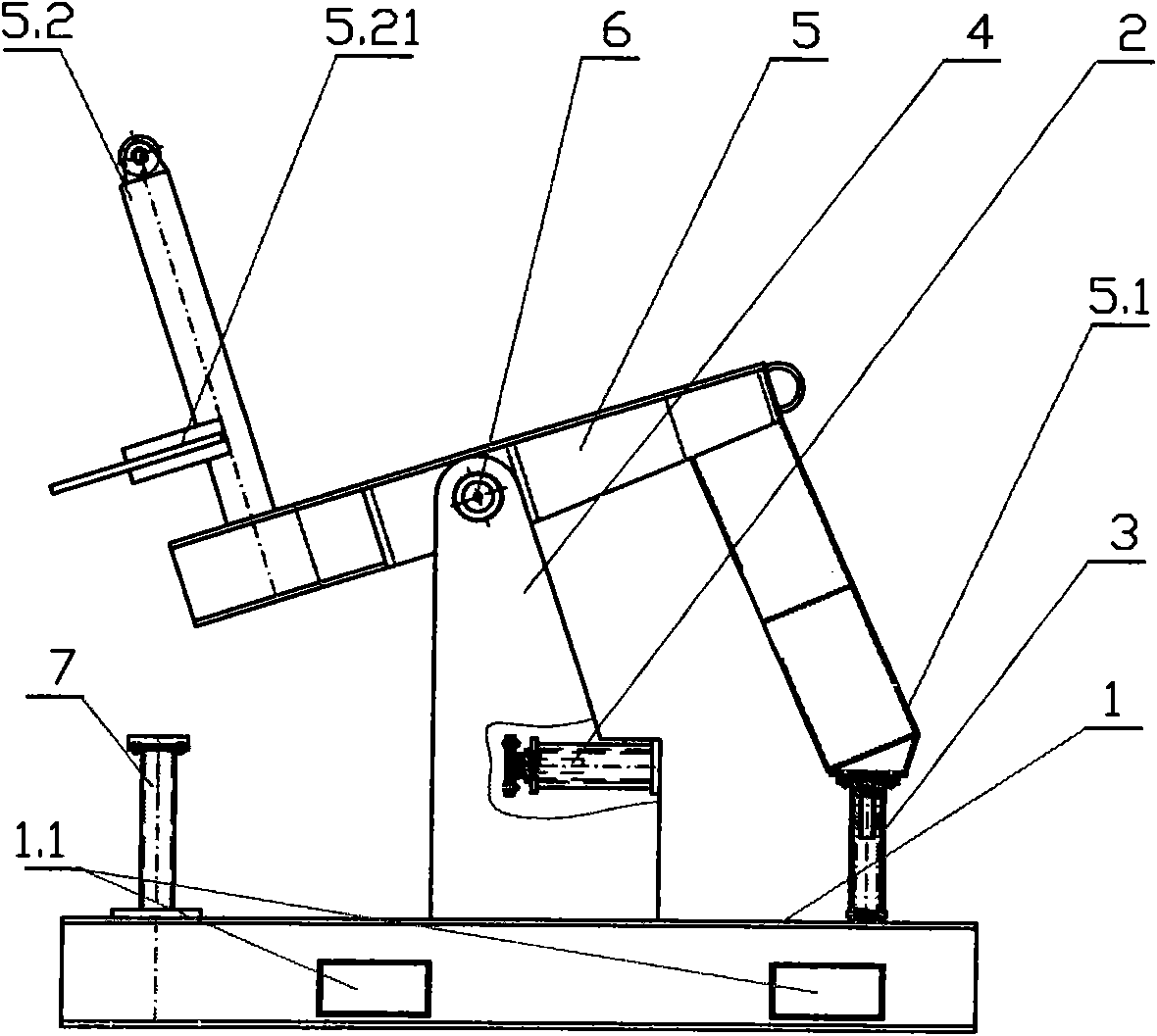

Aircraft engine mounting vehicle

InactiveCN102009340AHigh loading and unloading positioning accuracyHigh degree of automationAircraft assemblyMetal working apparatusAviationControl system

The invention discloses an aircraft engine mounting vehicle. The aircraft engine mounting vehicle comprises a lifting bracket (1), a shear type lifting mechanism (2), a back-and-forth moving frame (3), a left-right moving frame (4), a rotating disk mechanism (5), an electrohydraulic servo control system (6) and a vehicle body (7), wherein the lifting bracket (1) is provided with a longitudinal linear guide rail (15); the back-and-forth moving frame (3) is provided with a transverse linear guide rail (16) and a longitudinal slide block (17); the left-right moving frame (4) is provided with a transverse slide block (18); and the electrohydraulic servo control system (6) comprises a control unit (20) and an executing unit (21). In the aircraft engine mounting vehicle, a closed-loop servo control system consisting of the linear guide rail, a high-accuracy sensor, a high-response spaceflight servo valve, a precise servo oil cylinder and a programmable logic controller (PLC) is adopted, so 0.1mm absolute accuracy fine adjustment can be realized; and the aircraft engine mounting vehicle has the advantages of improving the aircraft engine assembling and disassembling efficiency and reducing the assembling and disassembling cost, along with high assembling, disassembling and positioning accuracy of an engine, and high automation degree and maneuverability.

Owner:成都立航科技股份有限公司

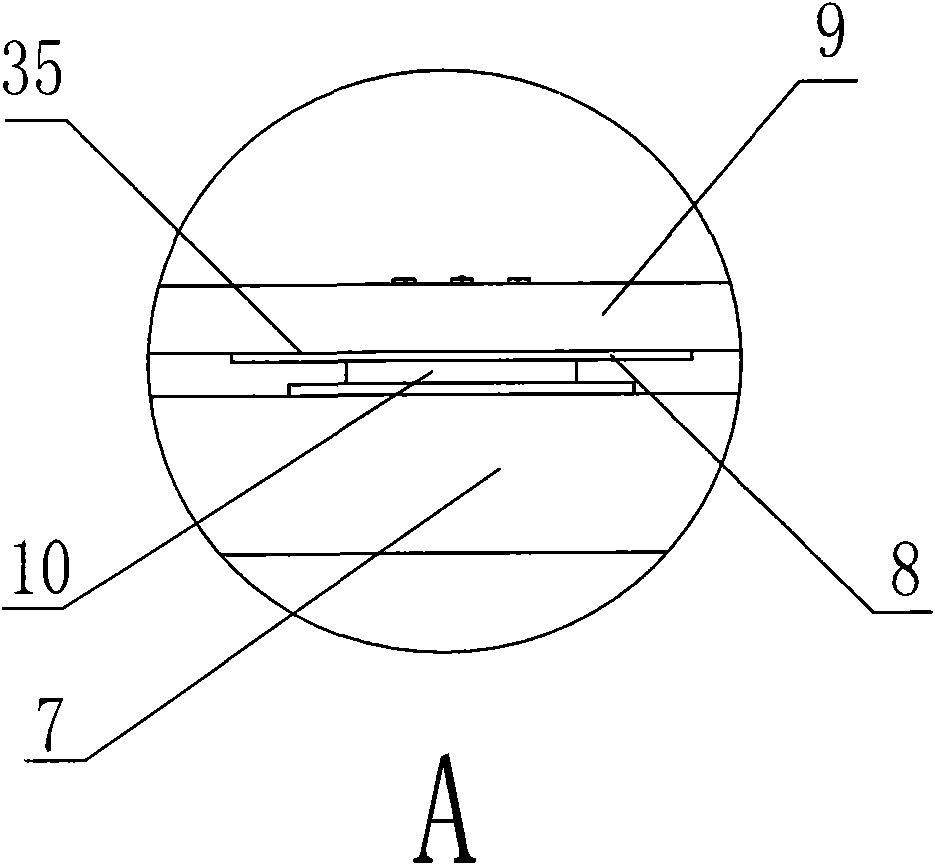

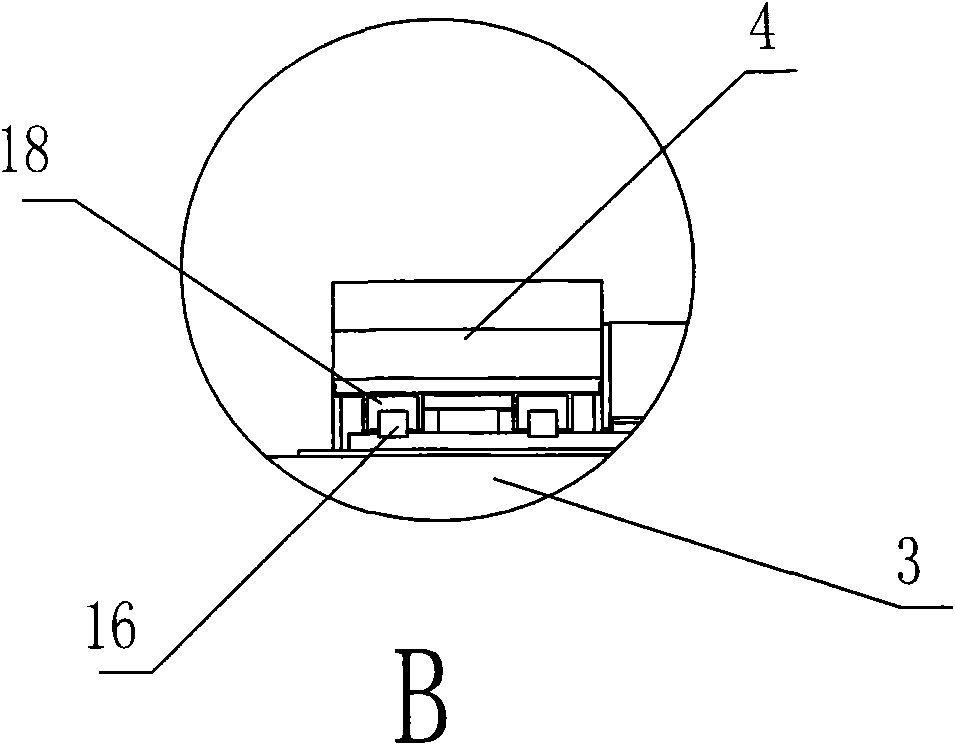

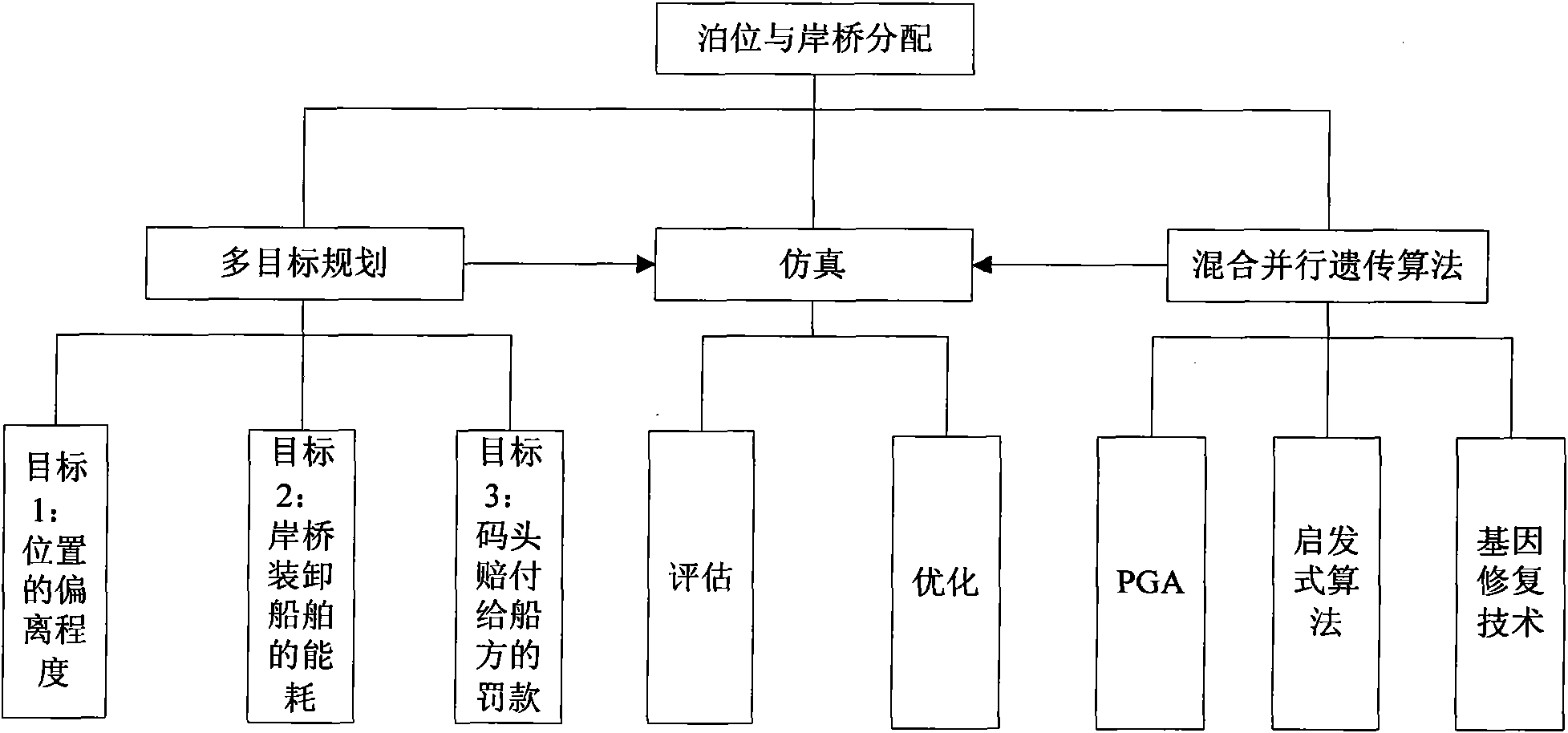

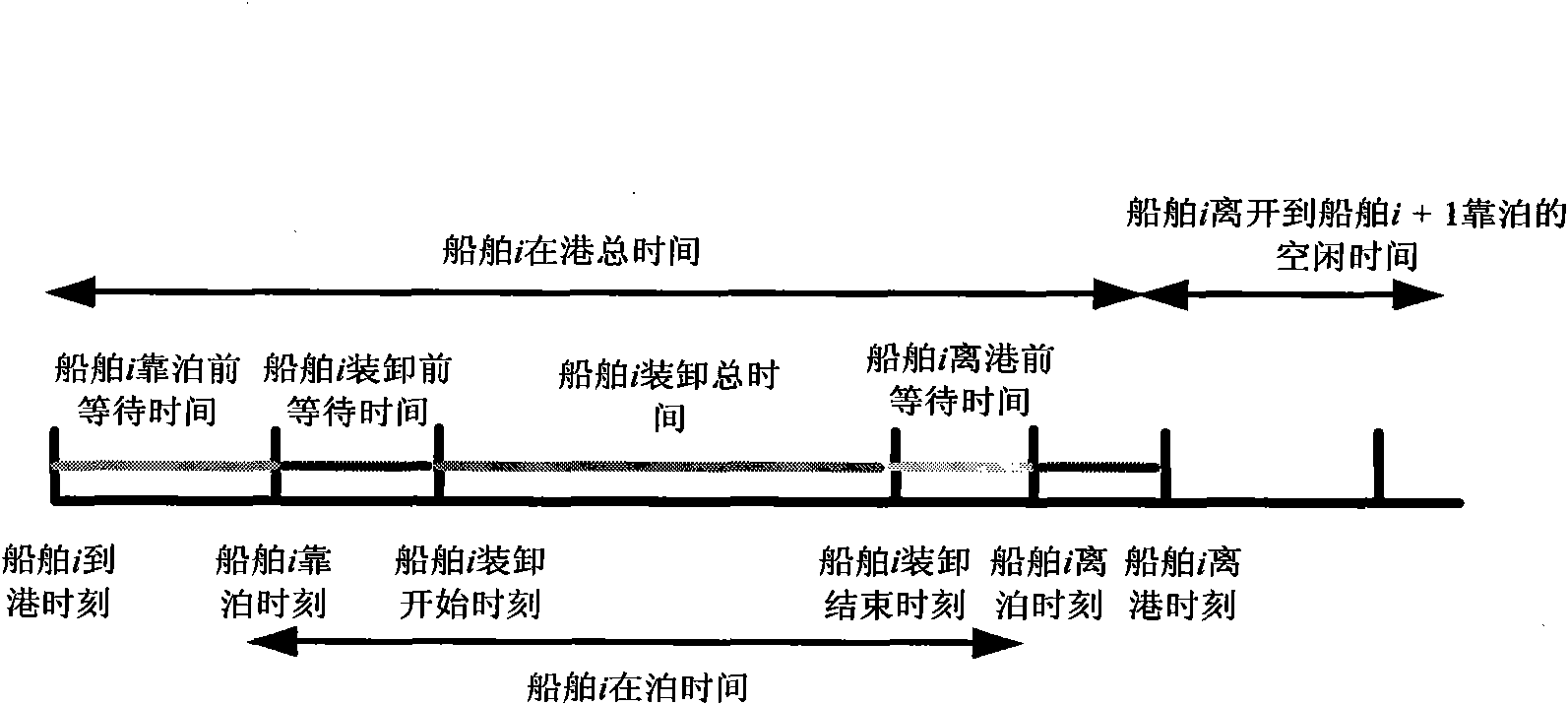

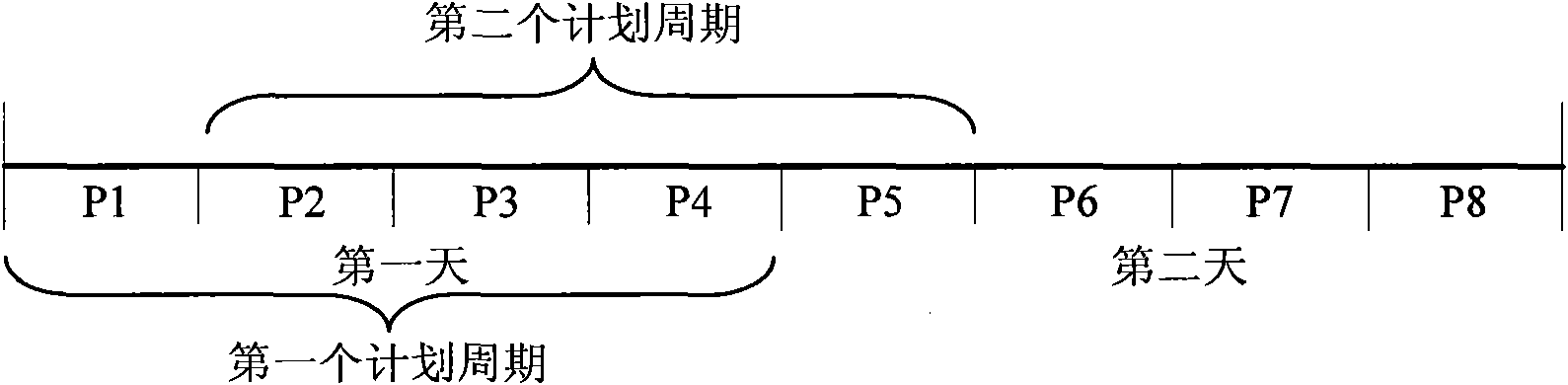

Distribution method of container quay berths and shore bridges

InactiveCN101789093AGlobal optimization is beneficialReduce loading and unloading energy consumptionForecastingDistribution methodPerformance index

The invention provides a distribution method of container quay berths and shore bridges. By adopting a rolling type plan distribution method, berth and shore bridge distribution models based on multi-objective planning are constructed; the models are based on a continuous quay wall line and are more closer to the actual berth conditions of a quay; a hybrid algorithm on the basis of combining a heuristic algorithm and a parallel genetic algorithm is adopted, and the performance of the hybrid algorithm is evaluated by a distribution simulation system of the container quay berths and the shore bridges; when a berth and shore bridge distribution scheme is generated, the simulation system simulates the distribution scheme, acquires corresponding performance indexes, compares with other schemes, and determines whether the scheme is better; and a method combining simulation and a gene repair technology is adopted to repair infeasible schemes, thereby being favorable for reducing the time in port of a ship, and reducing the horizontal transport distance when the ship is loaded or unloaded, the energy consumption of the shore bridges, and the fine that the quay pays to a ship owner, and further reducing the loading and unloading cost on the quay, improving the service quality of the quay and realizing the purpose of the invention.

Owner:SHANGHAI MARITIME UNIVERSITY

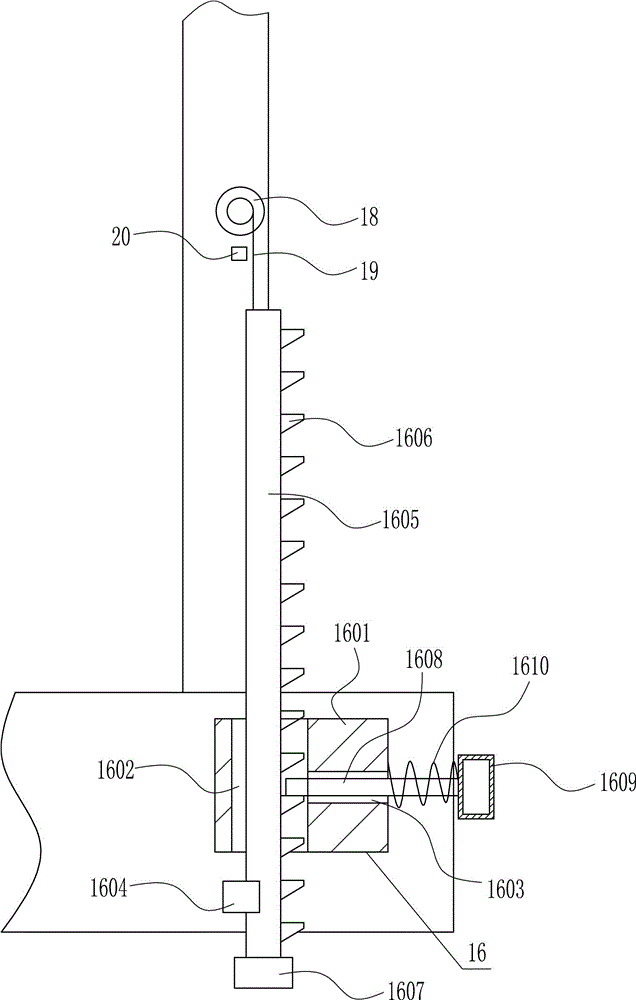

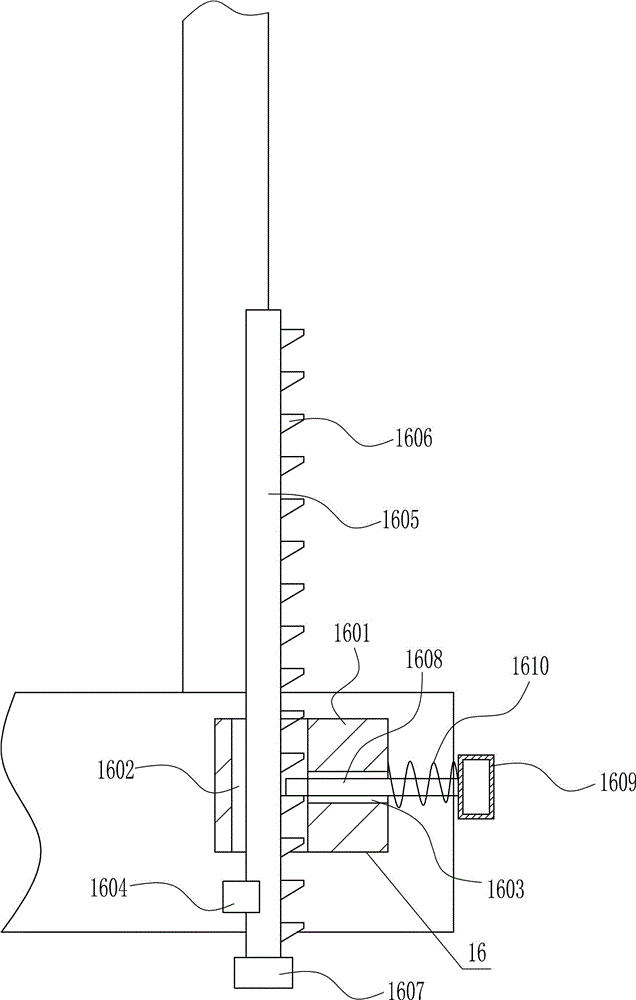

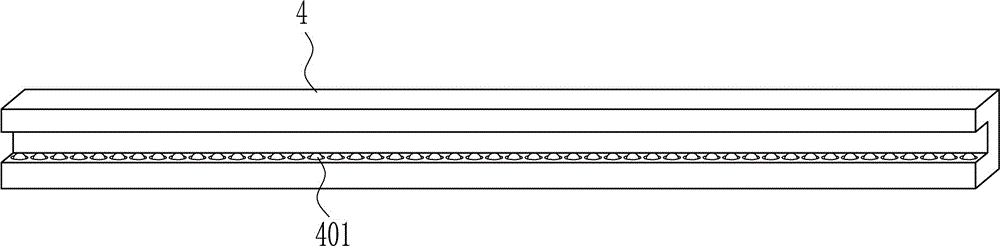

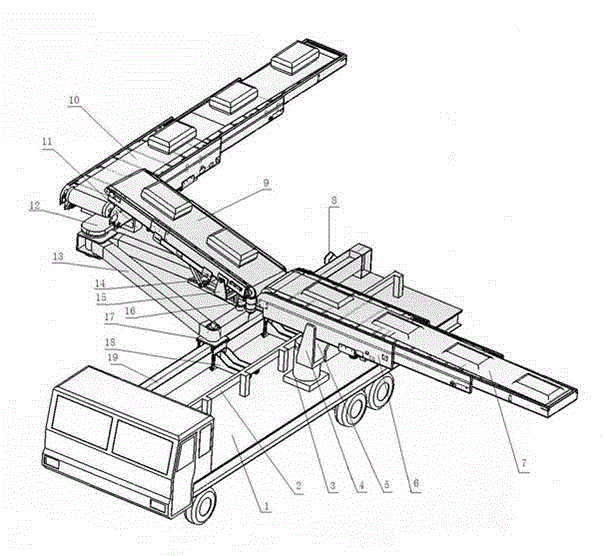

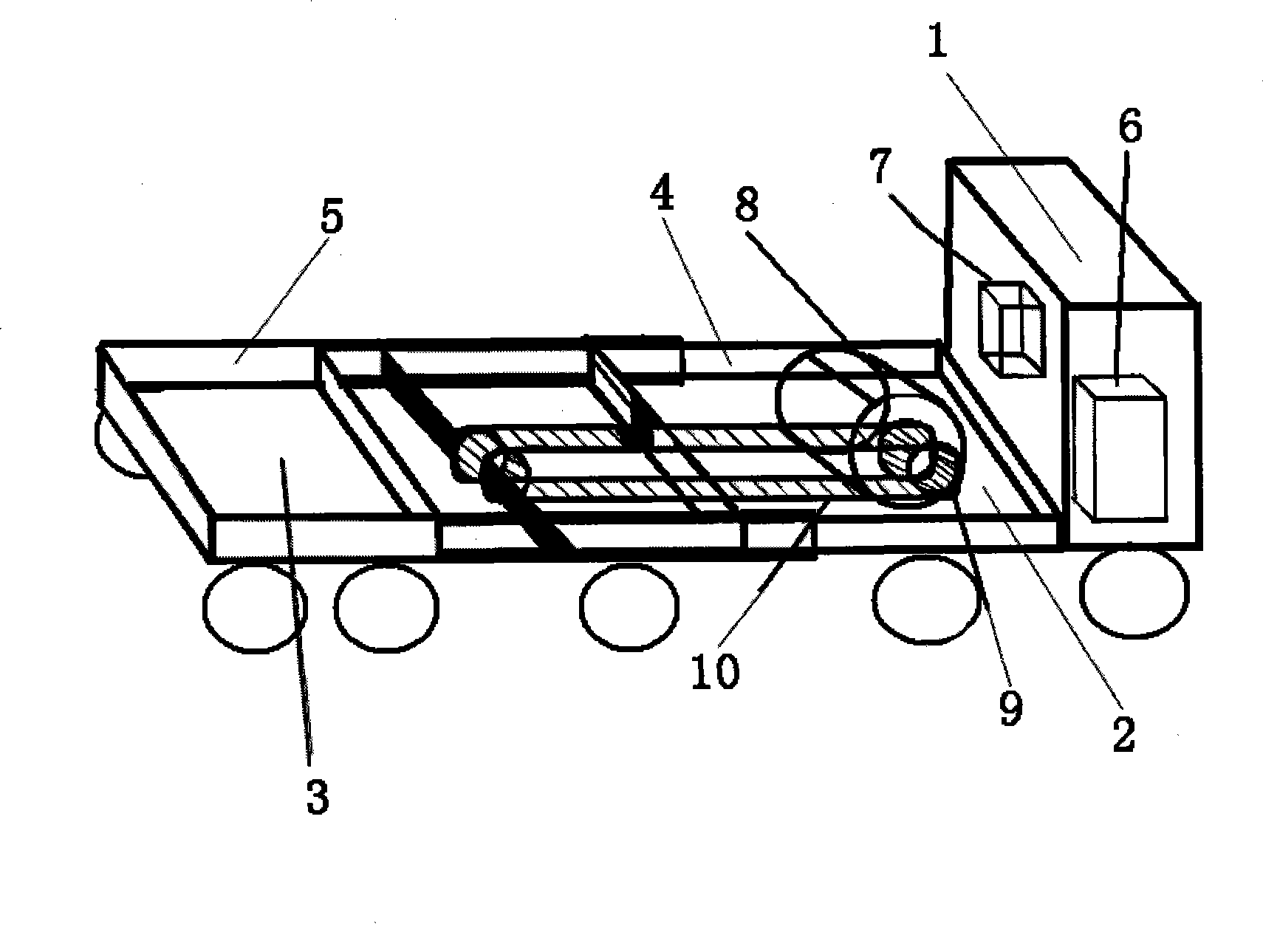

Prestressed pipe pile transport vehicle with loading and unloading functions

ActiveCN106740377AImprove securityReduce waiting timeVehicles with cranesItem transportation vehiclesPre stressEngineering

The invention belongs to the technical field of prestressed pipe pile transport, and particularly relates to a prestressed pipe pile transport vehicle with loading and unloading functions. Pipe piles can be loaded and unloaded by the prestressed pipe pile transport vehicle, the pipe pile loading and unloading time can be shortened, the pipe pile loading and unloading costs can be reduced, and the loading and unloading efficiency can be improved. The prestressed pipe pile transport vehicle with the loading and unloading functions comprises a vehicle, a vehicle plate, a plurality of N-shaped frames, two guide rails, balls, a driving mechanism, a movable transverse beam and the like. The vehicle plate is arranged at the rear of the vehicle, the N-shaped frames are mounted on the top of the vehicle plate in a bolt connection manner, and the two guide rails are connected with the middles of the tops of the inner sides of the N-shaped frames in a bolt connection manner. The prestressed pipe pile transport vehicle has the advantages that the pipe piles can be loaded and unloaded without waiting to be loaded and unloaded by cranes when the pipe piles are transported by the prestressed pipe pile transport vehicle, accordingly, the waiting time can be saved, the loading and unloading costs can be reduced, the work efficiency can be improved, and the prestressed pipe pile transport vehicle can run stably in loading and unloading procedures.

Owner:XUZHOU HUABANG SPECIAL VEHICLE

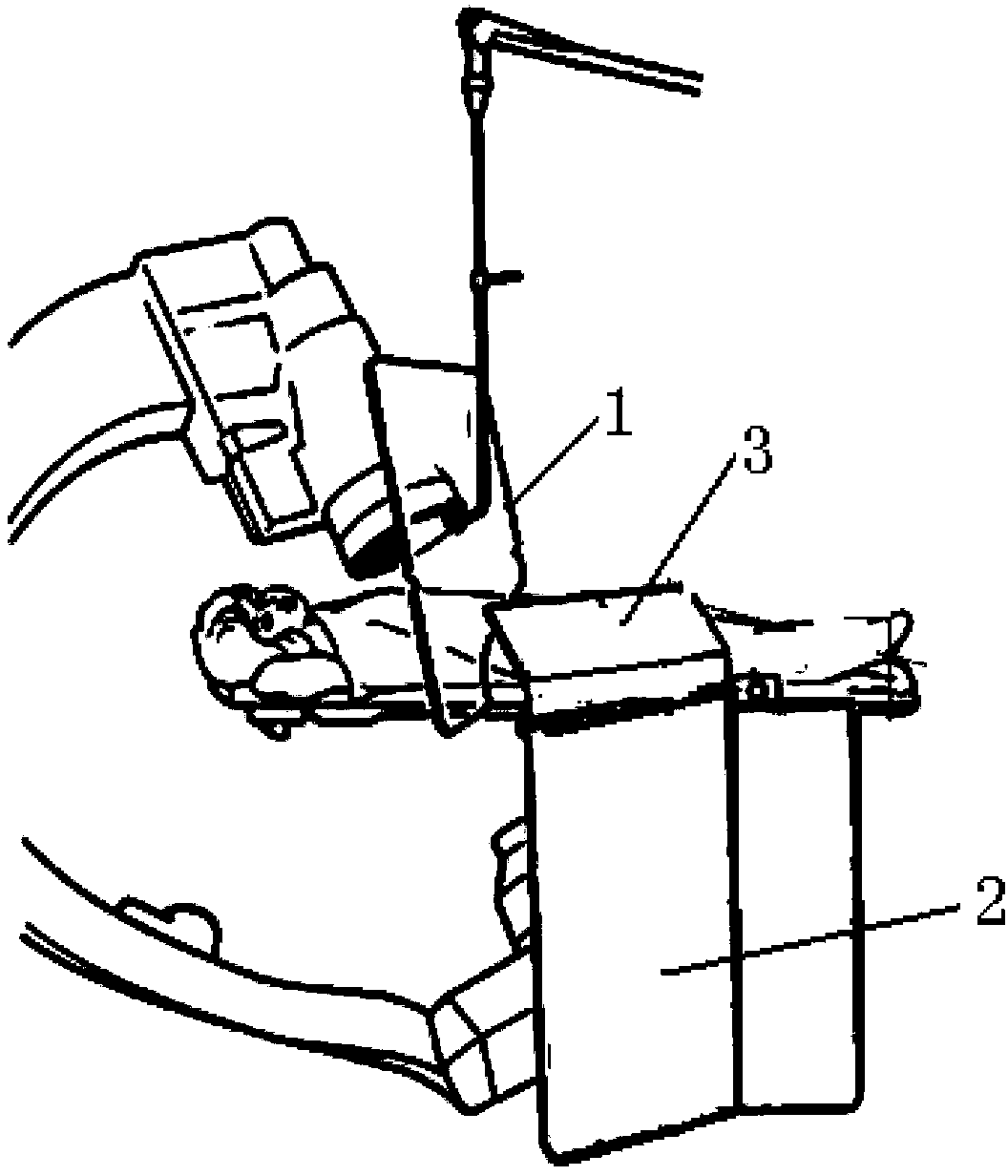

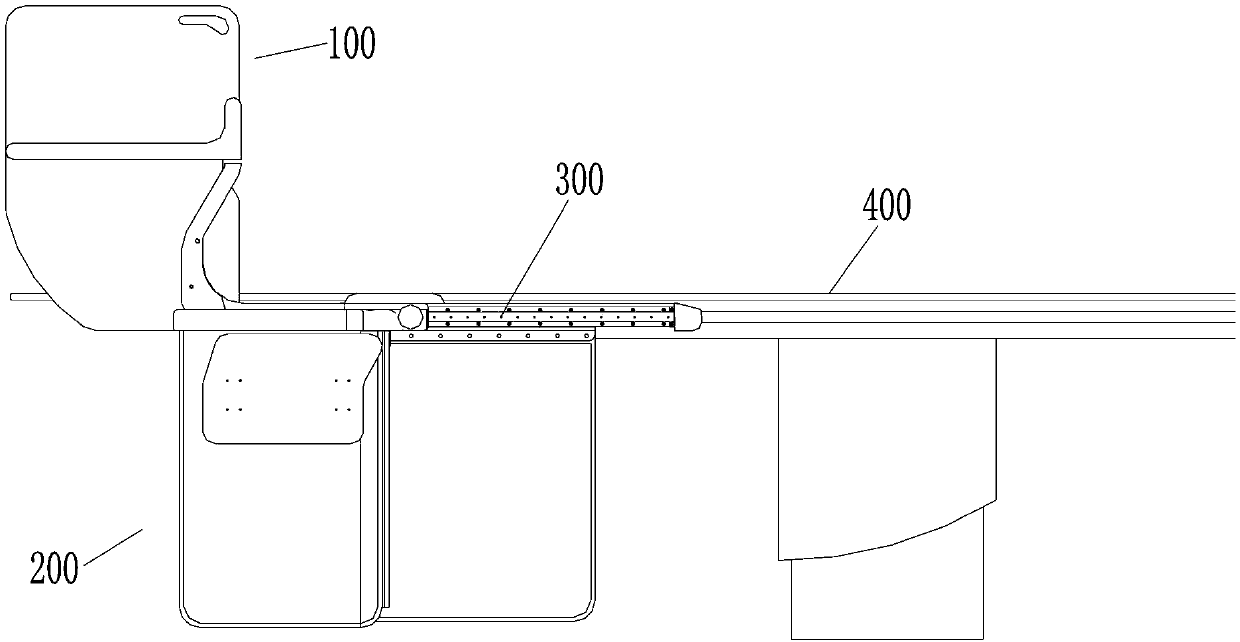

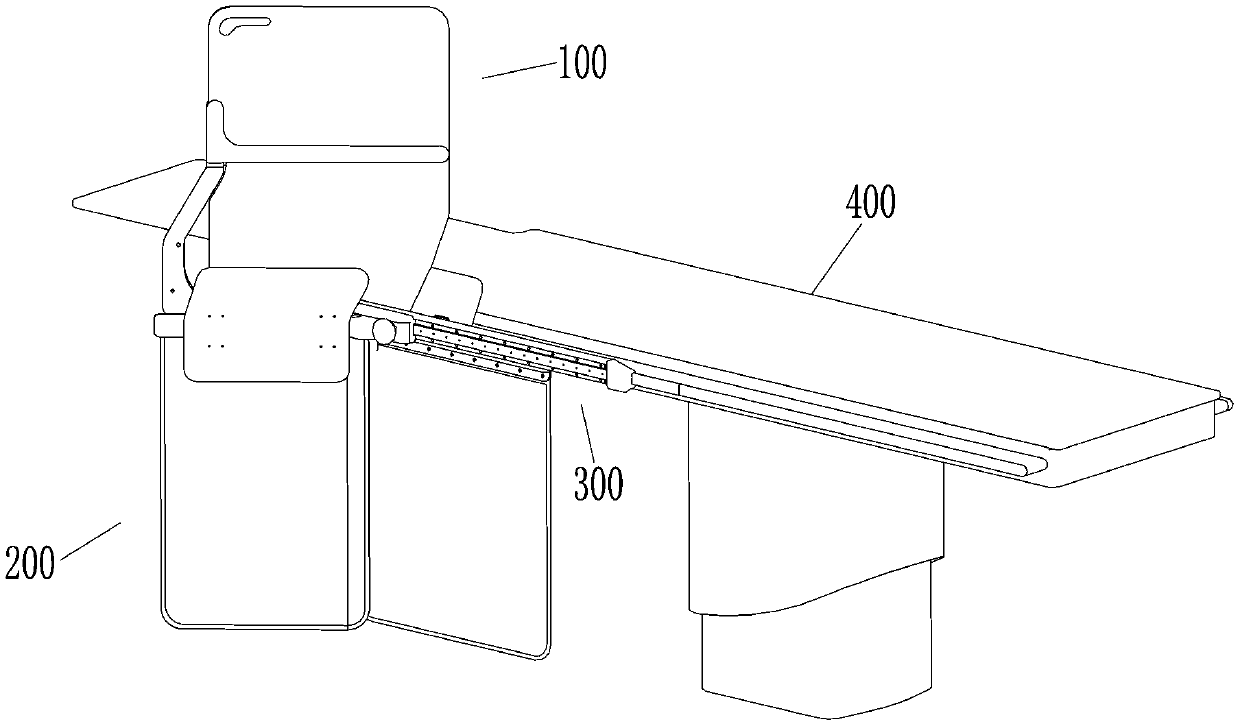

Integrated X-ray protection device on angiography machine

ActiveCN103385733ARealize simultaneous movement with the bedRealize synchronized movementRadiation safety meansAngiographyX-rayEngineering

The invention relates to the field of medical instruments, in particular to an X-ray protection device with an integrated structure for an angiography machine. The device comprises a protection screen unit, a protection curtain unit and a bedside sliding rail unit, wherein the protection screen unit is arranged on the protection curtain unit, and the protection curtain unit is fixed on the bedside sliding rail unit so as to enable the protection curtain unit and the protection screen unit to synchronously and horizontally move along a bedside. The protection device can synchronously move along with a bed, and in a moving process, the protection device is always in the best protecting state and close to a patient, so that the problem that the radiation, especially the secondary stray radiation caused by the rays reflected by the patient, can not be effectively shielded due to the movement of the bed surface of a conduit bed is effectively solved, and meanwhile, the problems of prolonged surgery time, increased surgery risk and the like that are caused by adjusting the protection screen unit during surgery in the prior art are effectively avoided.

Owner:BEIJING ORIENTAL E T MEDICAL EQUIP

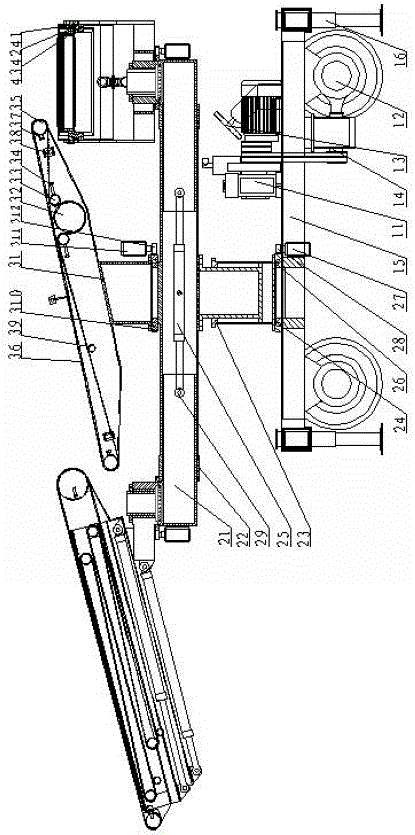

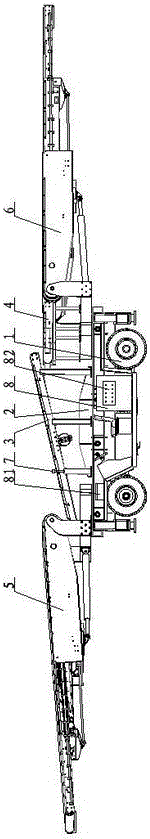

A derricking direction-changeable telescopic belt conveying bidirectional loader-unloader

InactiveCN106608551AAdjustable working heightRealize orientationConveyorsRollersControl systemStatistical analysis

The invention provides a derricking direction-changeable telescopic belt conveying bidirectional loader-unloader and relates to the field of logistics transportation cargo loading and unloading mechanical equipment. The derricking direction-changeable telescopic belt conveying bidirectional loader-unloader comprises a vehicle having bearing and walking functions, a telescopic cross arm having lifting, telescoping and swinging functions, a middle transition conveyor which has a swinging function and is capable of inclined conveying, a first belt conveyor and a second belt conveyor having derricking, swinging and telescoping functions, a metering device having metering, displaying, storing and printing functions, and an operating control system used for complete machine operation of the loader-unloader. The derricking direction-changeable telescopic belt conveying bidirectional loader-unloader has the advantages of simple structure, reliable work, convenient and rapid movement and transfer, and wide operating scope; the derricking direction-changeable telescopic belt conveying bidirectional loader-unloader can reduce manually-assisted carrying, reduce workload, shorten operating time, increase loading and unloading working efficiency, reduce the cost of loading and unloading carrying, improve working environment and work conditions, guarantee economical, rapid, convenient and safe loading and unloading and transportation, allow change of the direction of logistics conveying, and realize forward and reverse loading and unloading, automatic metering statistical analysis, and loading and unloading quantity / weight recording, displaying and storing.

Owner:襄阳忠良工程机械有限责任公司

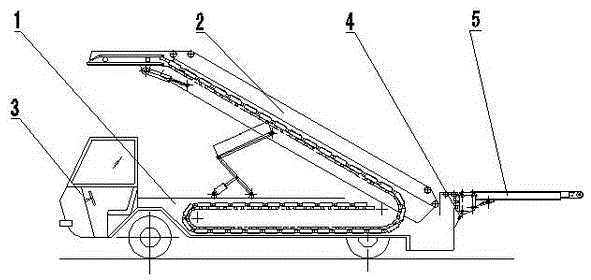

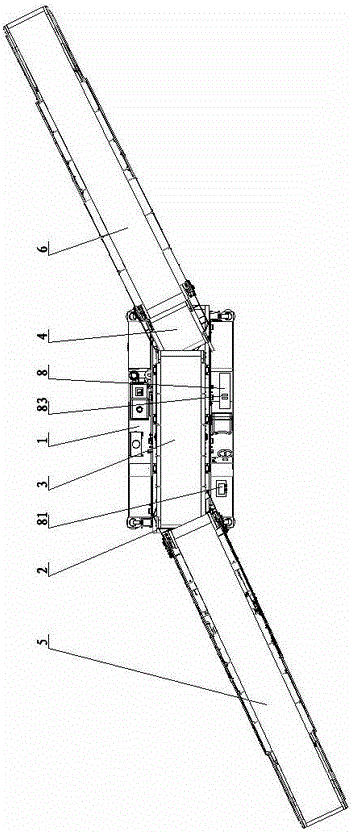

Movable loading and unloading machine with deflecting conveying function

ActiveCN105858269AReduce labor intensityRealize seamless dockingConveyorsLoading/unloadingEngineeringElectric control

The invention provides a movable loading and unloading machine with a deflecting conveying function and relates to the field of conveying equipment. The movable loading and unloading machine is composed of a vehicle chassis, a conveying device, an electric control system and a hydraulic system. The conveying device is arranged on the vehicle chassis and composed of a feeding conveyor, a middle conveyor and a front end conveyor. The vehicle chassis is driven to travel, steer and brake by controlling the electric control system and the hydraulic system, and accordingly the feeding conveyor can ascend, descend, stretch, retract, swing and turn, amplitude variation of the middle conveyor is achieved, the middle conveyor can carry objects of the feeding conveyor and convey the objects to the front end conveyor, and height adjustment, movable and inclinable belt conveying, and turnable conveying, formed by a plurality of conveying units, of the front end conveyor are achieved. By the adoption of the movable loading and unloading machine, nearby loading and unloading can be achieved to the maximum extent, the feeding conveyor and the front end conveyor can enter the internal operation environment of a compartment, the positions and states can be adjusted at any time according to the variation requirements for cargo loading and unloading points, the labor intensity of operators can be relieved, the cost can be reduced, the operation environment is improved, the operation efficiency is improved, and the personnel safety and cargo transferring safety are improved.

Owner:襄阳忠良工程机械有限责任公司

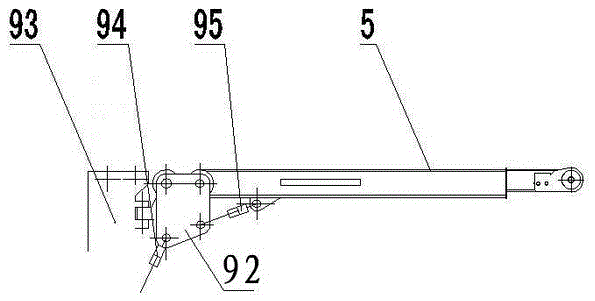

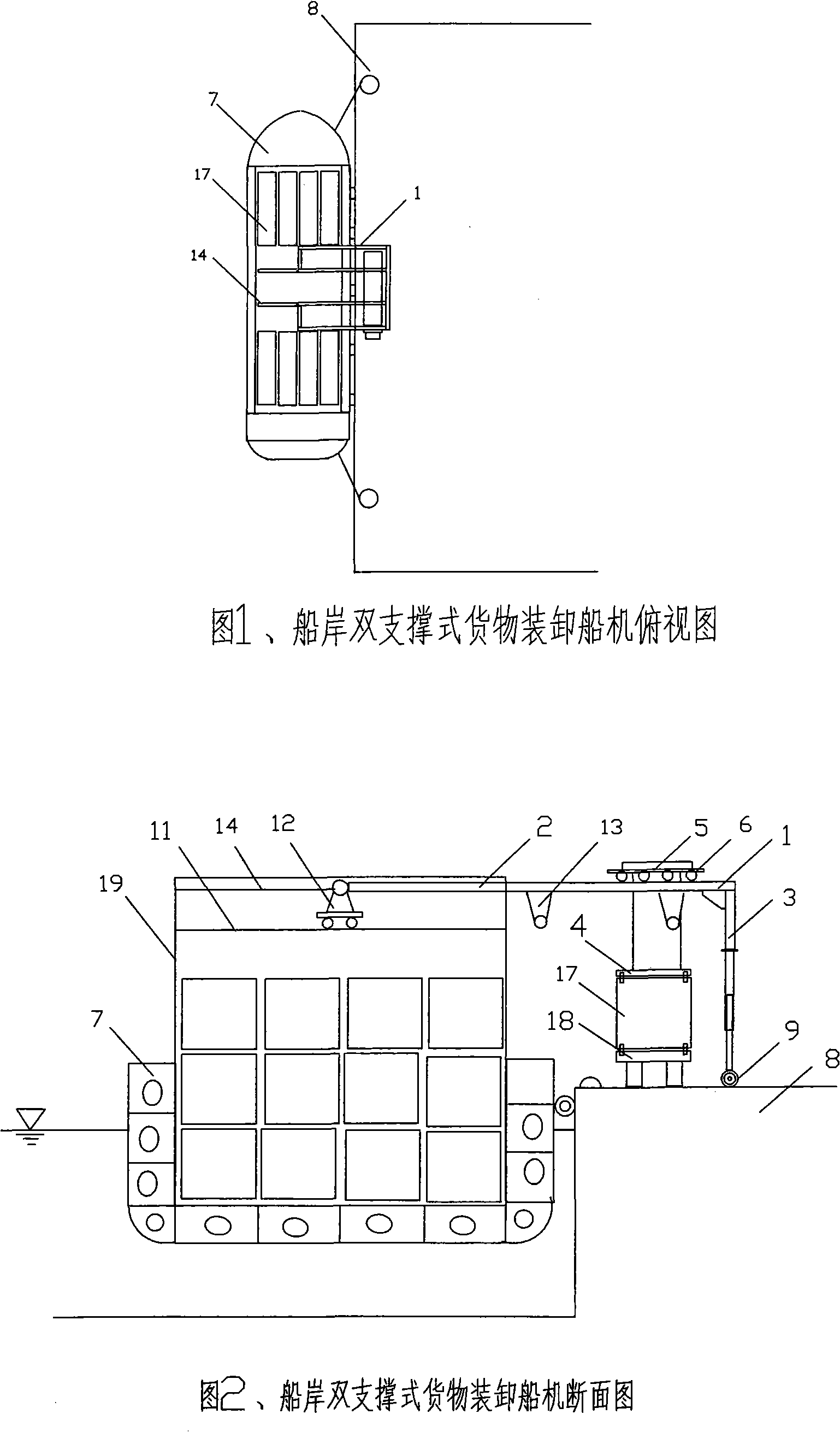

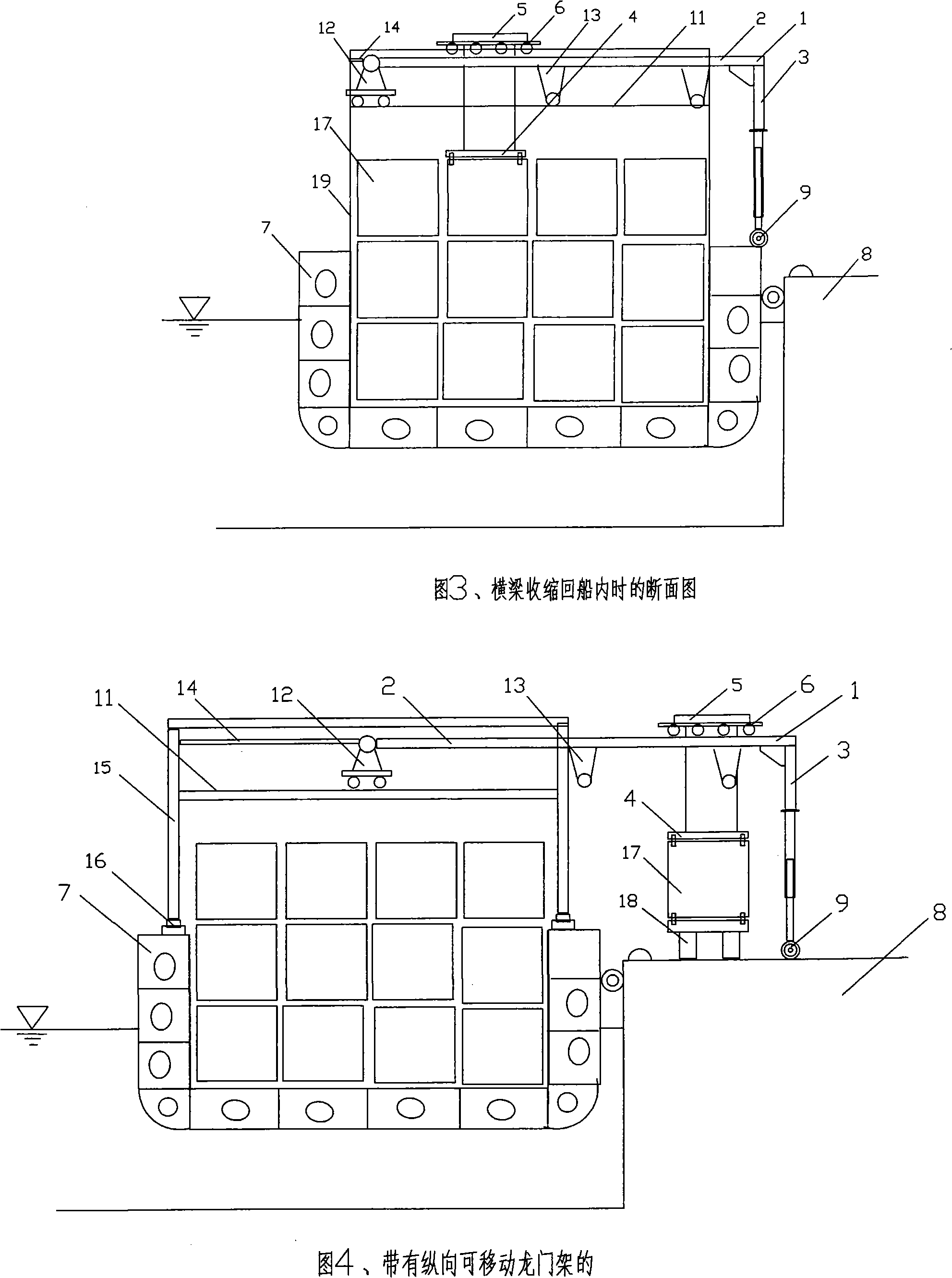

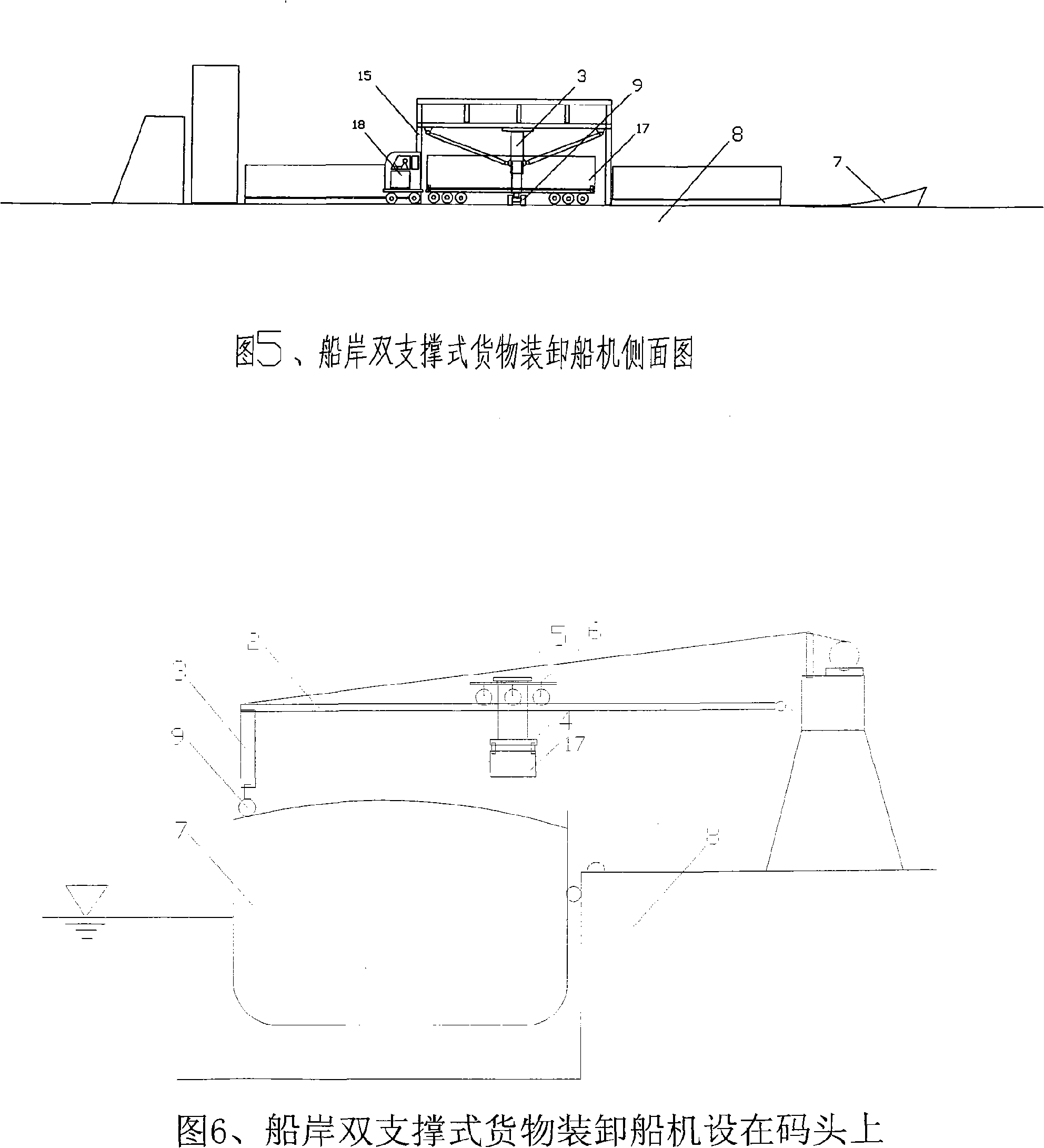

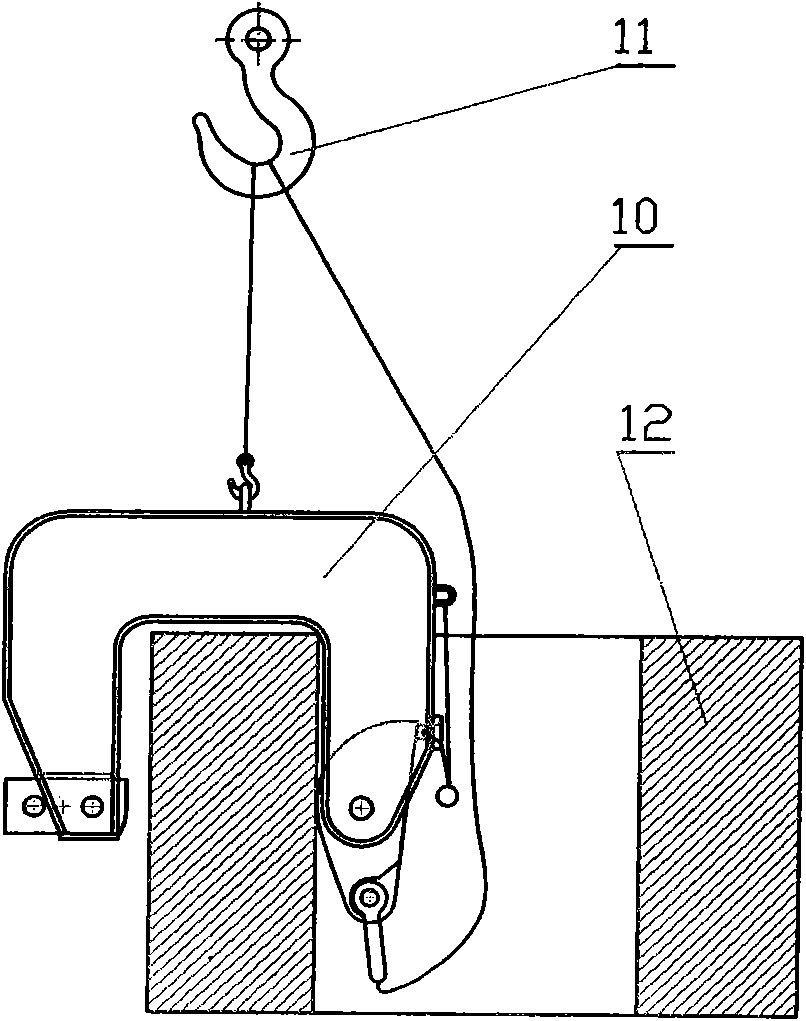

Ship-shore double supporting type cargo handling machine

ActiveCN101279640AReduce loading and unloading costsReduce insecurityCargo handling apparatusPassenger handling apparatusMarine engineeringControllability

The invention relates to a boat-bank double-support cargo loading and unloading ship machine with support points placed both on a boat and a bank, overcoming the disadvantages of various cantilevered slings used in the past for transferring cargos between the boat and a dock. The invention adopts the method of the boat-bank double-support cargo loading and unloading ship with one support point placed on the boat and the other placed on the bank, forming a freely supported beam mechanism, simplifying the structure of a loop wheel machine, reducing weight, and reducing the air lifting distance of cargos; the cargo travels along a straight line in air, thus greatly increasing the controllability and stability of cargo in air, greatly improving the efficiency and safety, and realizing the quick transfer of cargos between the boat and the dock; meanwhile, the simplified structure is favorable to be carried in boats, in particular small boats, and the ship machine is convenient and flexible, economical and practical.

Owner:游勇

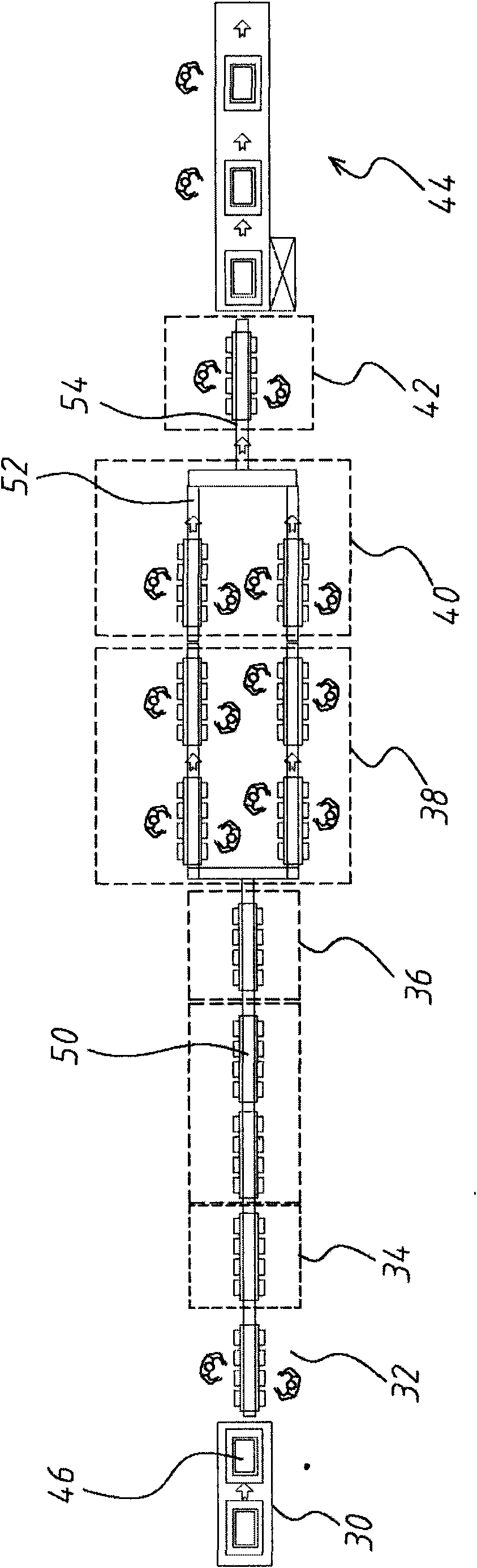

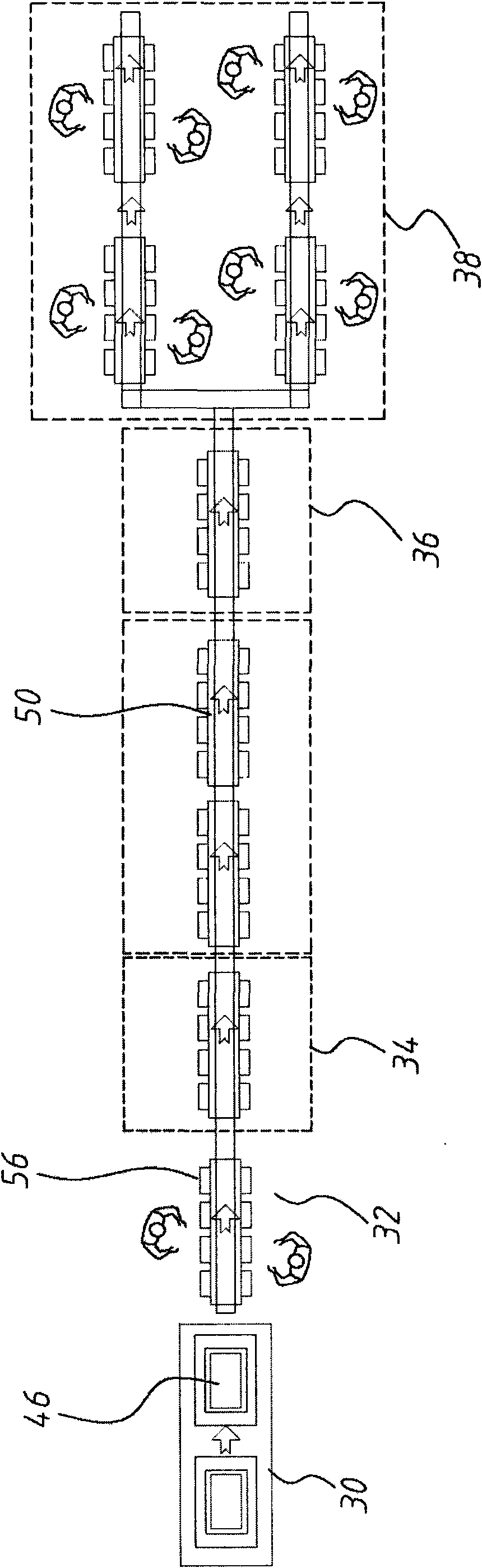

Multifunctional conveying machine

ActiveCN104609203AReduce labor intensityFaster turnaroundLoading/unloadingMechanical conveyorsElectronic control systemElectric control

The invention provides a multifunctional conveying machine, and relates to railway freight transportation load and unload in the field of engineering machinery. The multifunctional conveying machine is composed of a vehicle chassis, a hydraulic supporting leg, a load and unload mechanism, a hydraulic system and an electronic control system. The hydraulic system and the electronic control system are adopted for driving the vehicle chassis to walk, turn, brake and drive, the hydraulic supporting leg to transversely stretch and longitudinally adjust a height ,and the load and unload mechanism to unfold, fold, locate, and adjust a posture. The multifunctional conveying machine is used to load and unload cargo in bag among a train, an automobile, a freight house and a railway platform, and has the advantages of reasonably using a load and unload device, being capable of saving the labor force and reducing the labor intensity of a work, improving the efficiency of loading, unloading and carrying, reducing the load and unload operation cost, being beneficial for the cargo integrity and operation safety, and the like.

Owner:大连佳和彩板构件有限公司

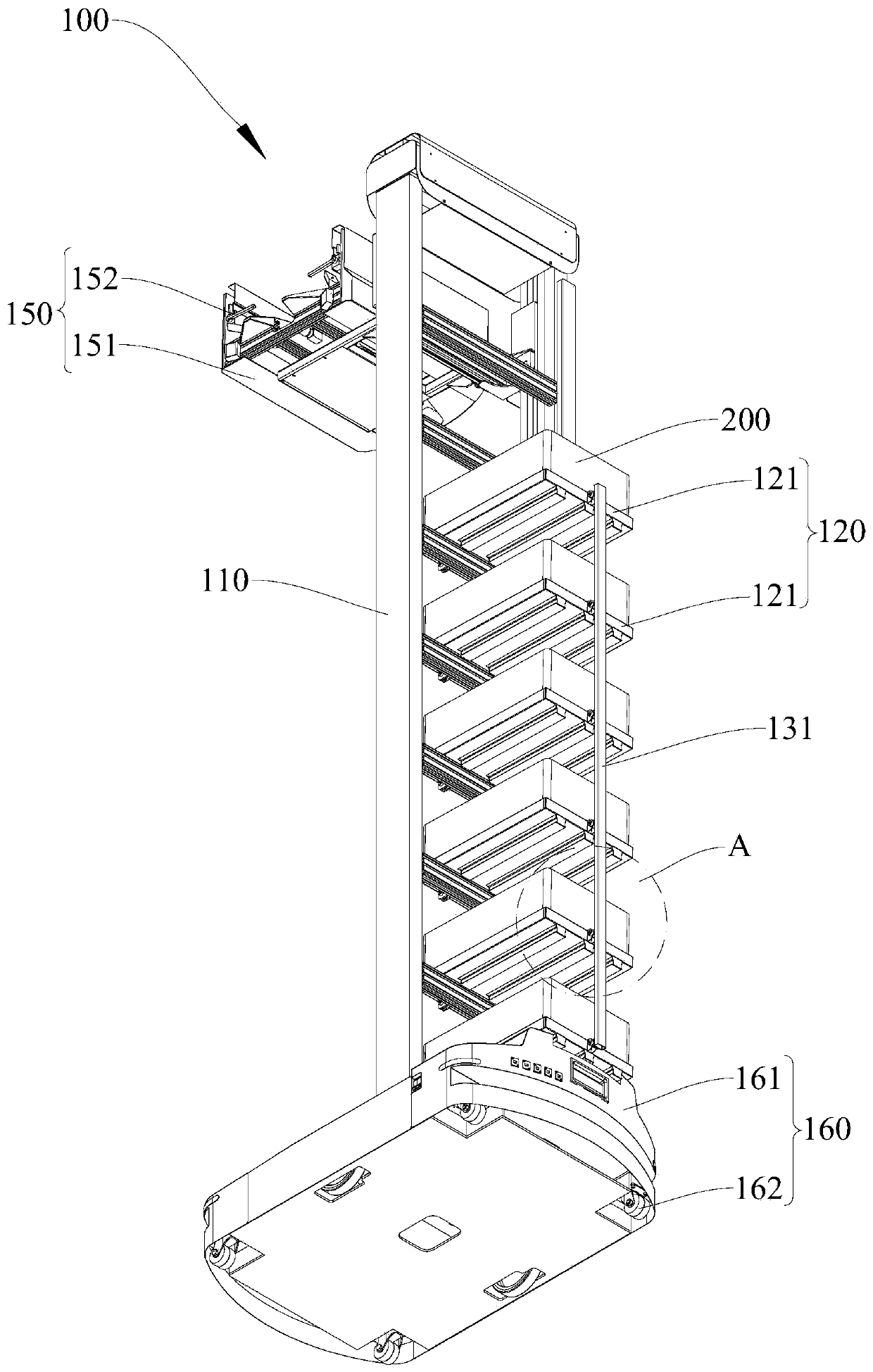

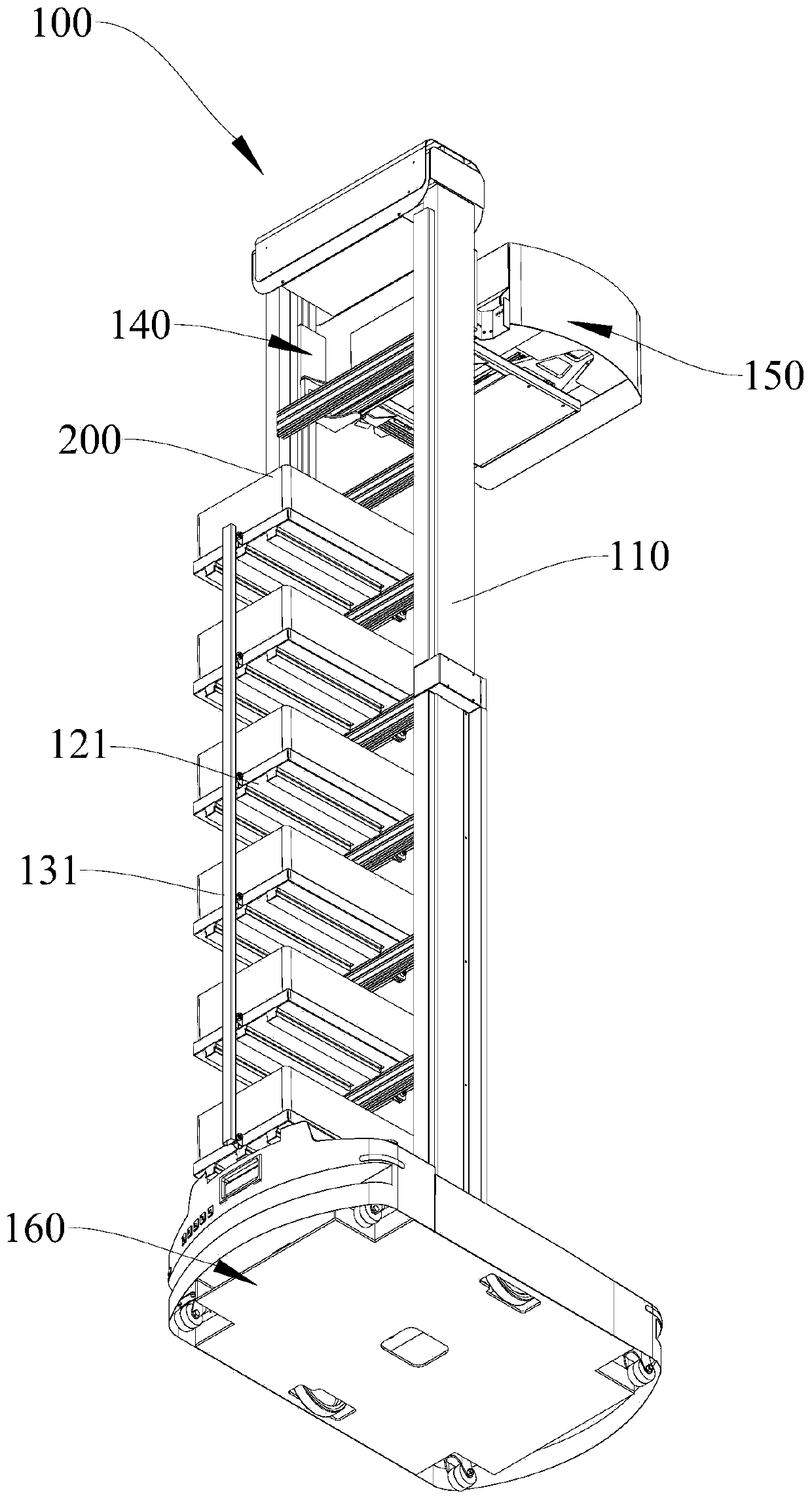

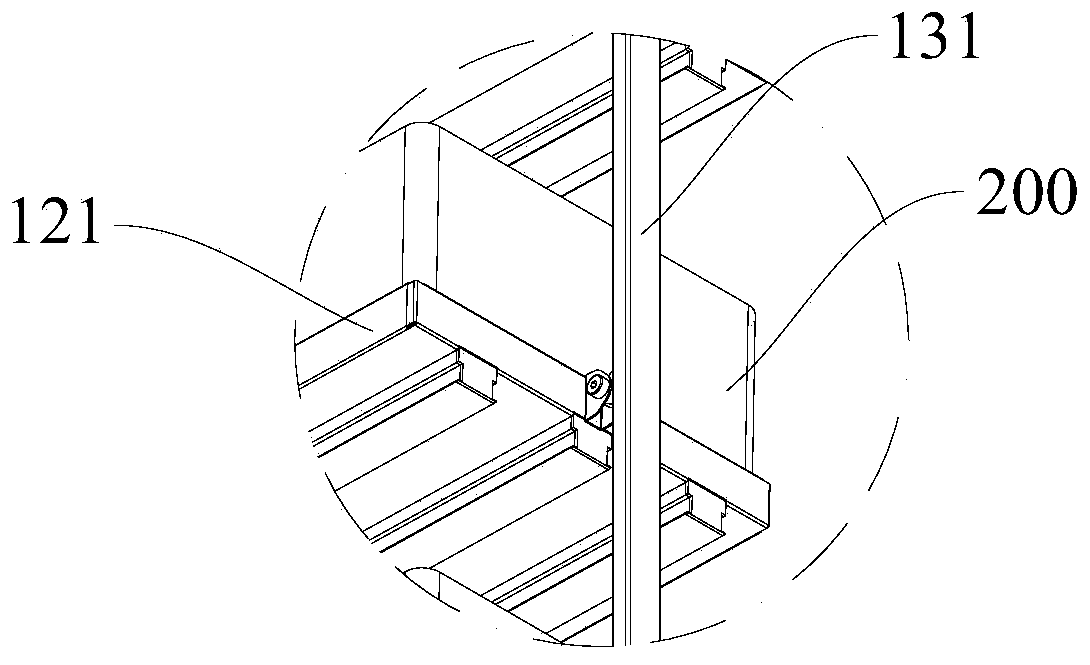

Transfer robot and handling system and handling method of transfer robot

ActiveCN111470242AReduce loading and unloading costsImprove loading and unloading efficiencyStorage devicesControl engineeringHandling system

The invention provides a transfer robot and a handling system and a handling method of the transfer robot. The transfer robot comprises a chassis capable of being moved on the ground, a vertical frame, a lifting mechanism, a storing mechanism and a handling mechanism used for handling goods, wherein the vertical frame is arranged in the vertical direction and located on the chassis; the lifting mechanism is arranged on the vertical frame and can be lifted or lowered in the vertical direction relative to the vertical frame; the storing mechanism comprises a plurality of storing assemblies usedfor storing goods to be transferred, and the multiple storing assemblies are arranged on the vertical frame in the vertical direction at intervals; and the handling mechanism is movably arranged on the vertical frame in the vertical direction and connected with the lifting mechanism, and the handling mechanism can be driven by the lifting mechanism to rise and fall vertically to deliver the goodsin the handling mechanism to the corresponding storing assemblies. Through the cooperation between lifting mechanism and the handling mechanism, the automation of loading and unloading of the goods isrealized, and the loading and unloading cost is reduced.

Owner:HAI ROBOTICS CO LTD

Rotating plate transition type two-way loading and unloading machine

ActiveCN105883375AReduce dropPrevent falling damageSupporting framesRotary conveyorsWorking environmentMechanical equipment

The invention discloses a rotating plate transition type two-way loading and unloading machine and relates to the field of logistics transportation goods loading and unloading mechanical equipment. The rotating plate transition type two-way loading and unloading machine is composed of a bearing trolley, a middle conveyor, two belt conveyors, a material blocking device, a slippage device, a lifting device and an operation control system of the rotating plate transition type two-way loading and unloading machine. The rotating plate transition type two-way loading and unloading machine is simple in structure, reliable in work, economical, practical, capable of saving energy and environment-friendly; the rotating plate transition type two-way loading and unloading machine is closed up during walking, the appearance size is small, and movement and field transferring are convenient and fast; the rotating plate transition type two-way loading and unloading machine is unfolded in work, the operation range is large, the logistics direction can be guided and changed, and positive and negative two-way loading and unloading are achieved; the work orientations and postures of the belt conveyors can be adjusted so that the rotating plate transition type two-way loading and unloading machine can adapt to goods loading and unloading point changes, and direct reaching of goods is achieved through one time of loading and unloading; the goods can directly enter a compartment, a goods cabinet and a container to be operated, auxiliary carrying is reduced, the labor intensity is relieved, the operation time is shortened, the loading and unloading work efficiency is improved, and the loading and unloading carrying cost is reduced; and the goods falling difference is small in the loading and unloading conveying process, transition is stable and free of impacting, dust discharge can be reduced, the work environment is improved, falling damage during transition delivery of articles is avoided, and the loading and unloading safety of the goods is guaranteed.

Owner:襄阳忠良工程机械有限责任公司

Moving belt type conveying loading and unloading machine

InactiveCN106629136AReduce wasteReduce investmentConveyorsSupporting framesWorking environmentEngineering

The invention discloses a moving belt type conveying loading and unloading machine and relates to the field of logistic transporting cargo loading, unloading and carrying equipment. The moving belt type conveying loading and unloading machine comprises a bearing vehicle, a sliding trolley, a middle conveyor, a transition conveyor, a feeding conveyor, a discharging conveyor, a metering device and an operation control system of the moving belt type conveying loading and unloading machine. The sliding trolley is arranged on the bearing vehicle. The two ends of the sliding trolley are symmetrically installed on the feeding conveyor and the discharging conveyor. The middle conveyor is installed at the middle portion of the sliding trolley. The metering device is installed on the middle conveyor. The transition conveyor is fixed to a bracket of the discharging conveyor. The moving belt type conveying loading and unloading machine is simple in structure and reliable in work, moving and field transferring are convenient and fast, the work range is large, manual auxiliary carrying can be reduced, the labor intensity is lowered, the work time is shortened, the loading and unloading work efficiency is improved, the loading and unloading carrying cost is reduced, the work environment and labor conditions are improved, it is ensured that loading and unloading transporting is economic, fast, convenient and safe, the logistic conveying direction can be changed, positive and negative bidirectional loading and unloading are achieved, and the loading and unloading number and weight are automatically metered, counted and recorded and are displayed and stored.

Owner:襄阳忠良工程机械有限责任公司

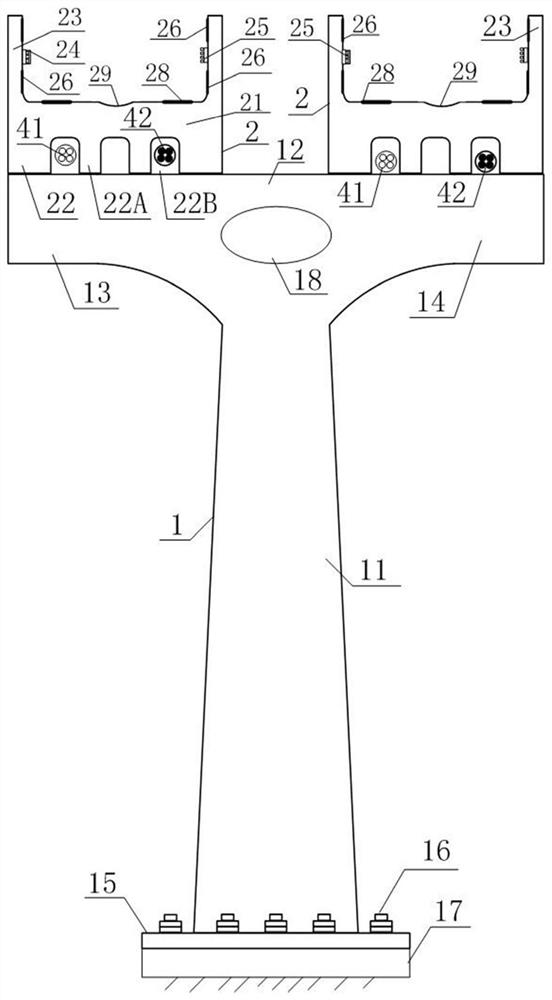

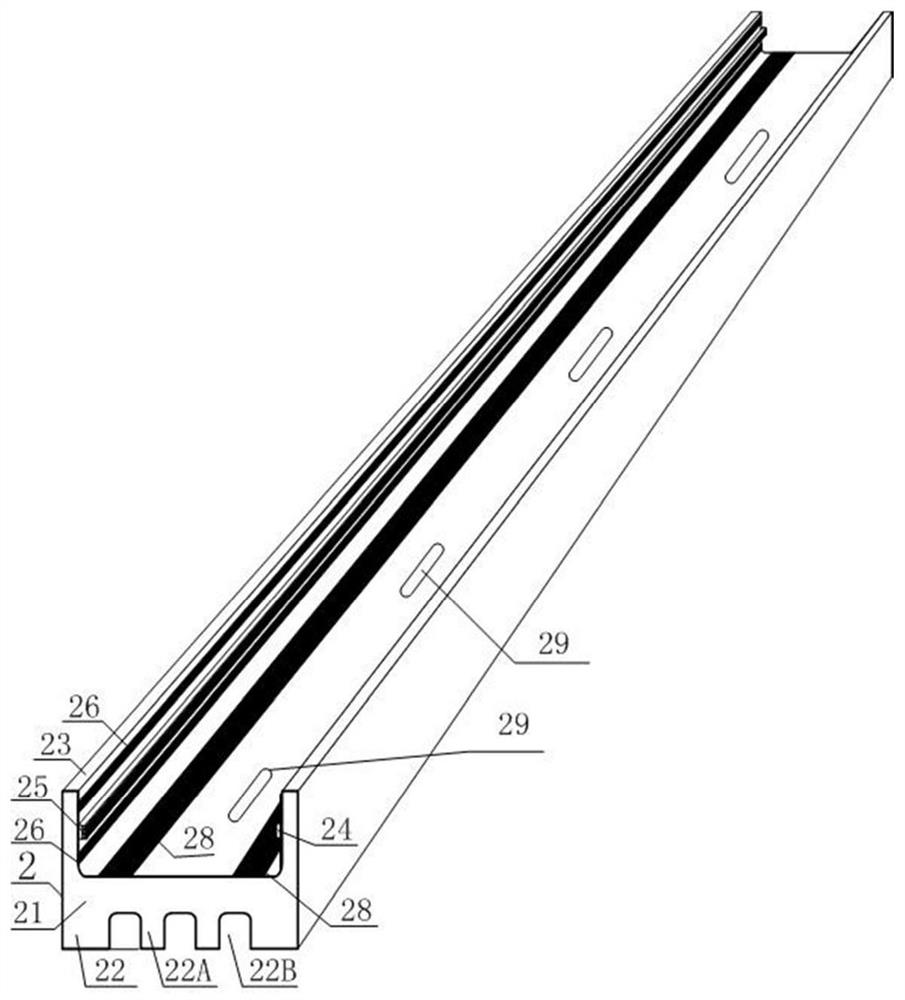

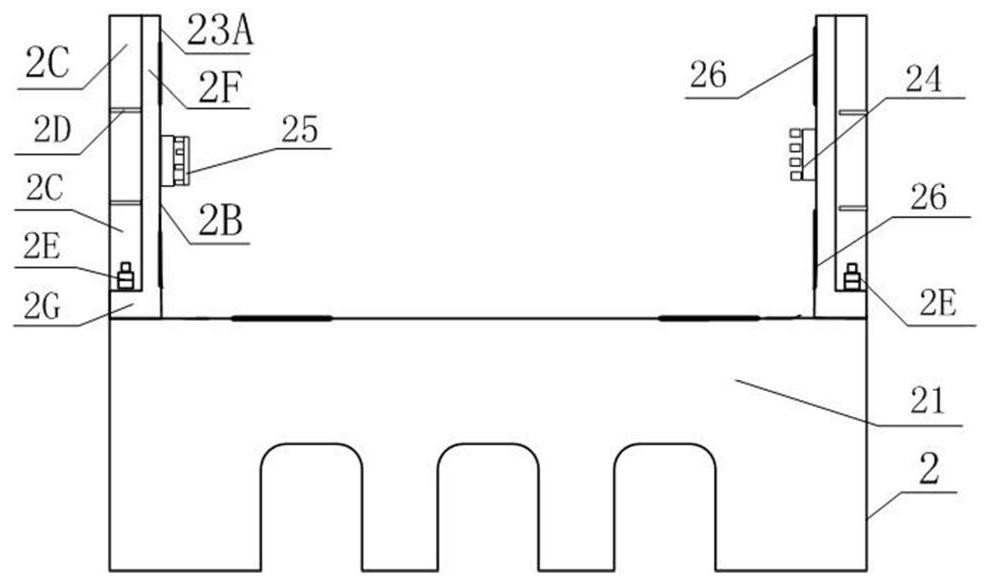

Multi-mode combined transportation composite rail transport system

ActiveCN112109736AImprove efficiencyFlexible choiceRoadwaysRailway tunnelsTransport systemCommunications system

The invention relates to a multi-mode combined transportation composite rail transport system. The system can run on overhead rails in the air, ground rails and underground tunnel rails, can be transported on ferryboats and railways and can also be used for communicating with ports, airports, trains, logistics distribution centers and production bases to directly reach users. The system is composed of a multi-mode combined transportation rail beam, pier columns, a power supply system, a signal communication system and a suspension rail beam. The multi-mode combined transportation rail system is adopted, a new energy unmanned multi-mode combined transportation vehicle, an unmanned suspension rail vehicle, the 5G Internet of Things, the artificial intelligence technology and the like are matched, the system directly reaches the user from the production place or the port, the whole process is transparent and visible, the efficiency is high, the speed is high, the cost is low, energy is saved, the environment is protected, the all-weather operation planning rate is high, and safe and reliable effects can be achieved. The multi-mode combined transportation rail utilizes road slopes or green belts or underground tunnels, is less in demolition, saves land, is low in construction cost, does not increase congestion, and is an important component of future urban intelligent logistics newecology.

Owner:SHANDONG QIHE CLOUD SHUTTLE LOGISTICS TECH CO LTD

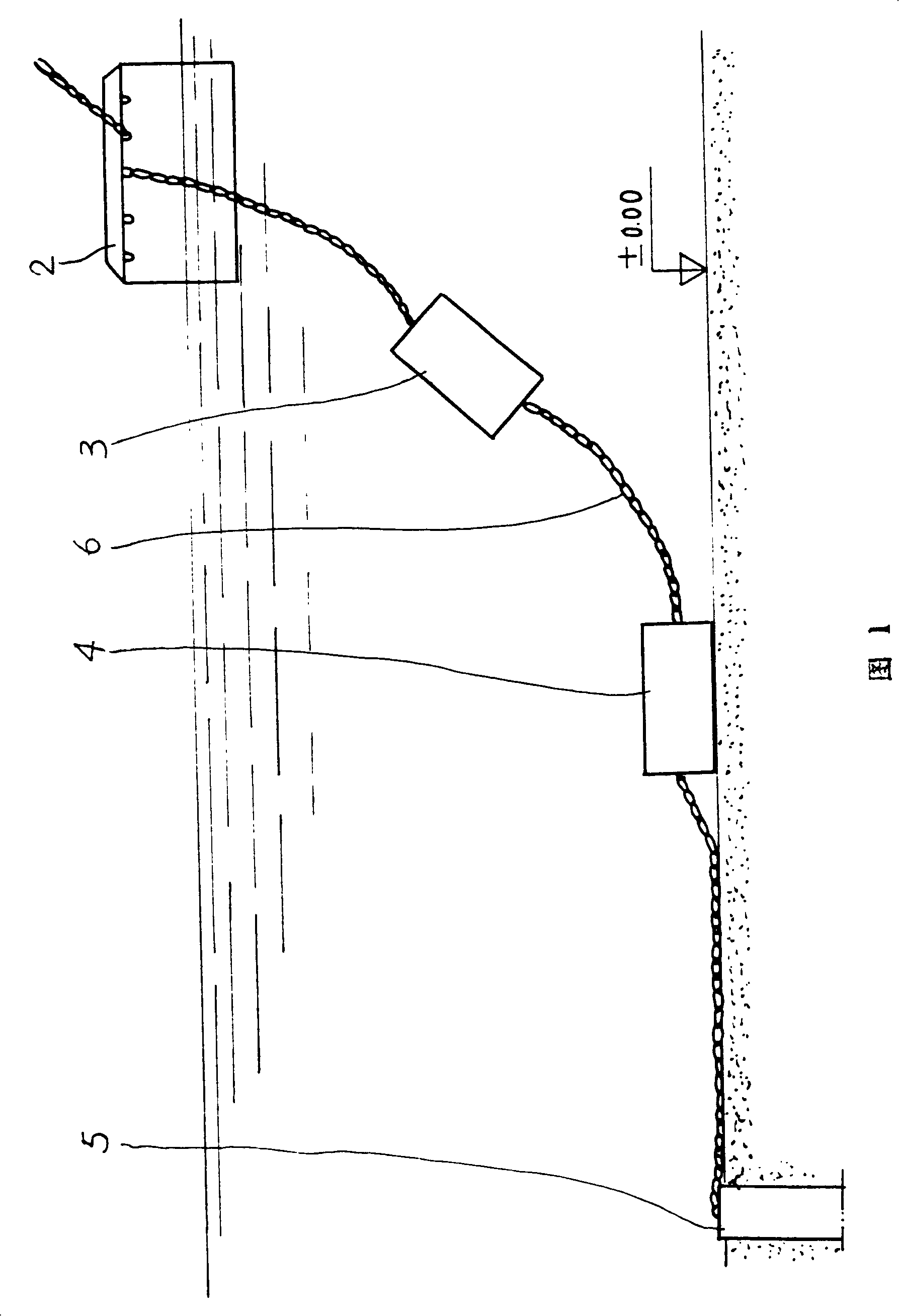

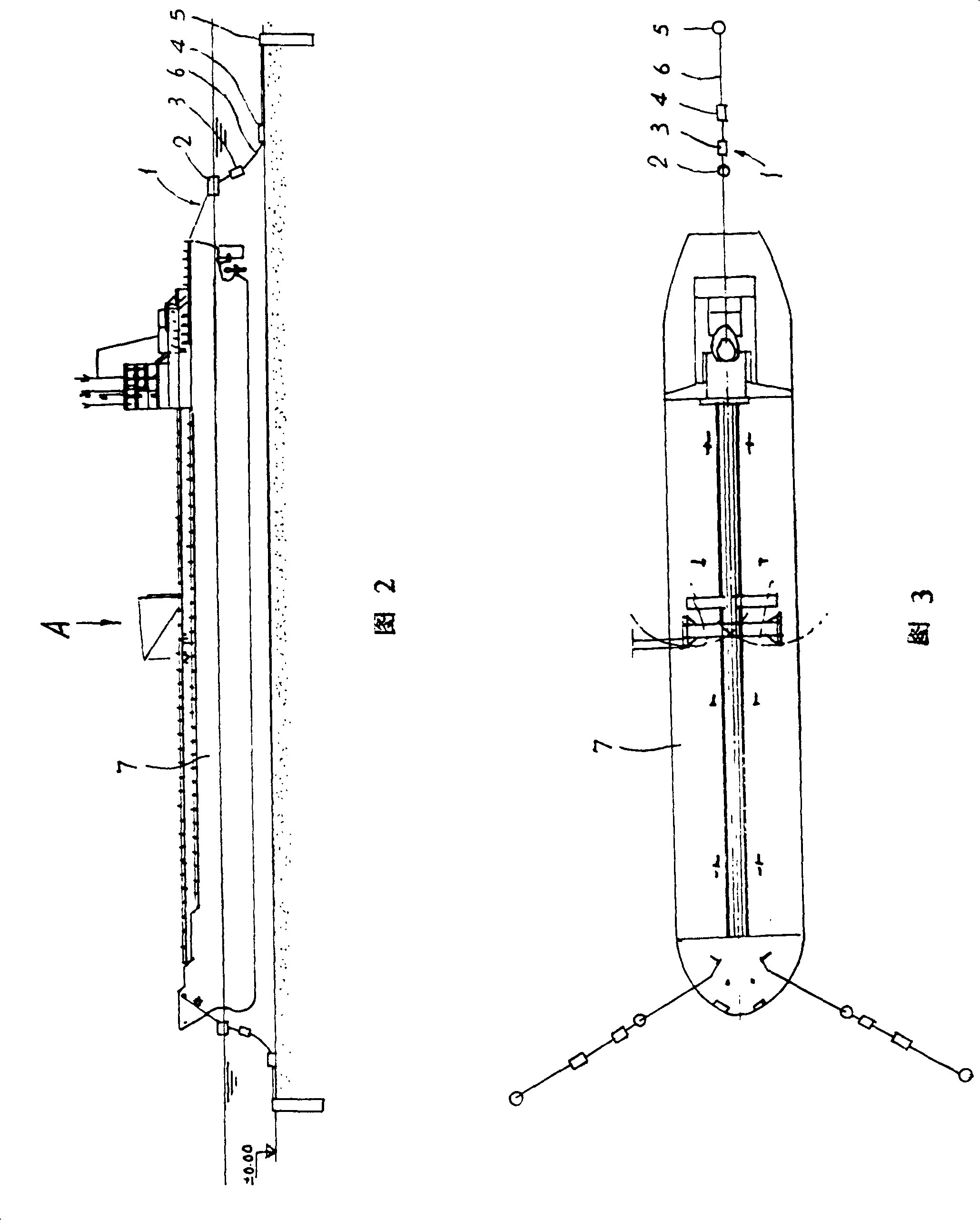

Off land loading and unloading anchoring system and anchoring method for liquid bulk cargo carrier

InactiveCN101157378AIncreased vertical downward forceImprove stabilityAnchorsBulk cargoMooring system

The invention relates to an offshore loading, unloading and mooring system for liquid bulk carriers as well as a mooring method, and the invention is characterized in that the mooring system consists of three sets of mooring device; the mooring device is formed by using connecting components to connect a buoy, a suspension bullback-weight, a chassis bullbacke weight and a anchoring base one by one; when in mooring, each set of mooring device connects the buoy and a carrier together by connecting components, wherein, two sets of mooring device are connected with the head of the liquid bulk carrier; another set of the mooring device is connected with the stern of the liquid bulk carrier; the three sets of mooring device are in Y-shaped arrangement; the mooring system can anchor the liquid bulk carrier in an off-shore sea area to load or unload materials; compared with the prior art, the invention has the advantages of small occupation sea area, low investment, short construction cycle, convenient operation, safety and reliability. Moreover, the invention does not take up shore-line resources, and is easy to be recovered and ruled, as well as especially suitable for the loading and unloading of the liquid bulk carriers.

Owner:陈杰诚

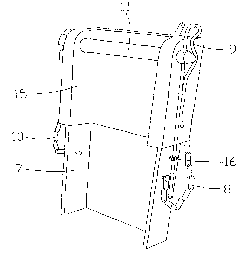

Recyclable motorcycle engine transportation bracket

InactiveCN101823600AQuick disassemblyGuaranteed reliabilityPackage recyclingPackaging vehiclesCircular economyEngineering

The invention relates to a recyclable motorcycle engine transportation bracket; the bottoms of the corners of a frame are supported by bottom pillars, and the tops of the corners of the frame are fixed with locating pillars, each of which is connected with a folding support pillar; the frame is internally provided with bases distributed in a matrix way, a spring hook is positioned besides each base, and each base is provided with a groove-shaped bracket; the tops of the two sides of the groove-shaped bracket are symmetrically provided with through holes; and the lower part of one side of the groove-shaped bracket is connected with a lock pin by a first chain, and the lower part of the other side thereof is connected with a penetrating pin by a second chain. The recyclable motorcycle engine transportation bracket has the structure of high-density loading and high-density folding recyclable structure, and is the product advocating 'low-carbon economy' and 'circular economy'; an engine can be conveniently and rapidly assembled and folded on the bracket; and the bracket is firm, safe and reliable in the transportation process, and can greatly reduces the loading and transporting costs of the engine.

Owner:赵永庆

Container

InactiveCN102689751AGuaranteed stability and securityNo damageLarge containersEngineeringMechanical engineering

The invention provides a container used to be arranged in a stacking area that possesses multiple first corner fittings and second corner fittings. The container at least comprises: a tank and multiple positioning buffers, first corner fittings correspondingly connected to various first corner fittings which are respectively arranged on the corner fittings of the tank, wherein sidewall of the tank outside the first corner fitting respectively possesses a cavity. The multiple positioning buffers are arranged inside the cavities. The multiple positioning buffer comprises a buffer unit and a second corner fitting, and an center distance between the first corner fitting and the second corner fitting is equal to a standard center distance between the first corner fitting and the second corner fitting in the stacking area. The buffer unit stretches out of the tank to contact the second corner fitting under the drawing of the second corner fitting in a state of tank hanging in the air, and the buffer unit retracts into the cavity with a constant speed by compression of tank gravity to play a role of tank buffer at the time when the second bottom corner fitting is combined with the corner fitting in the stacking area, thereby nonoccurrence of cargo damage in the tank in loading and unloading operations is guarantied.

Owner:NIPPON EXPRESS CO LTD +1

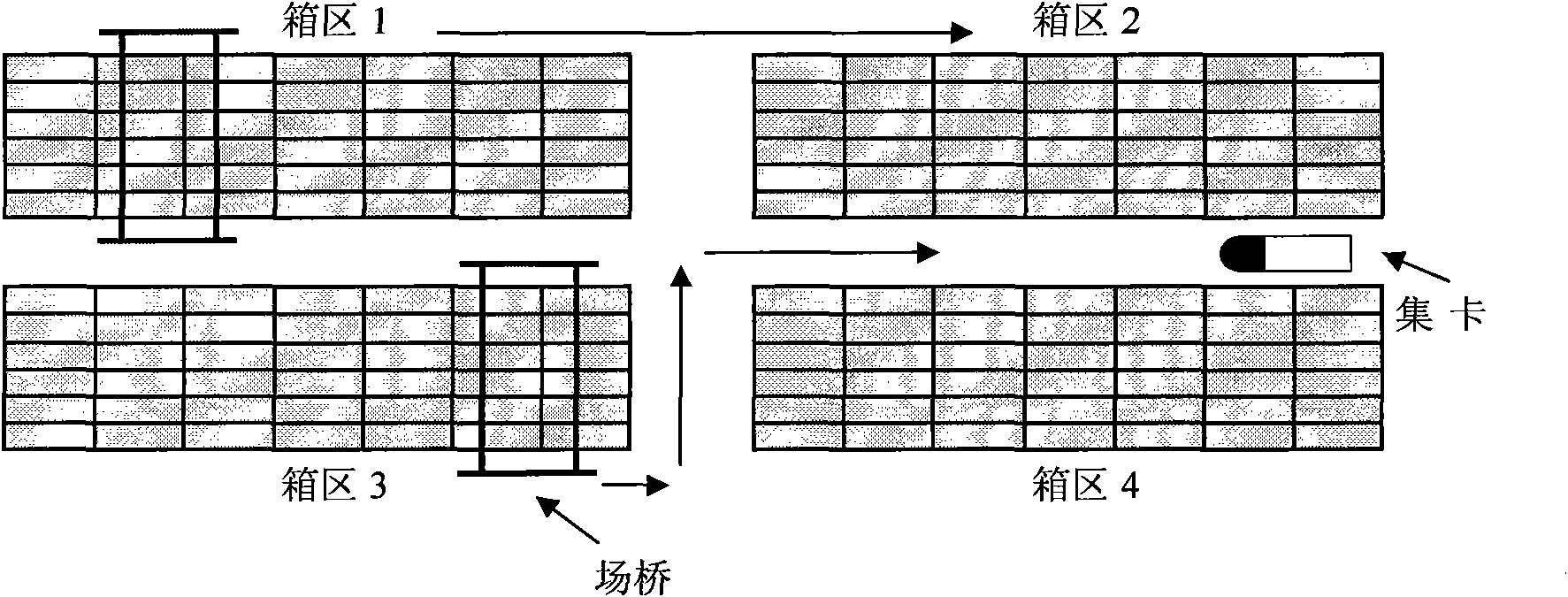

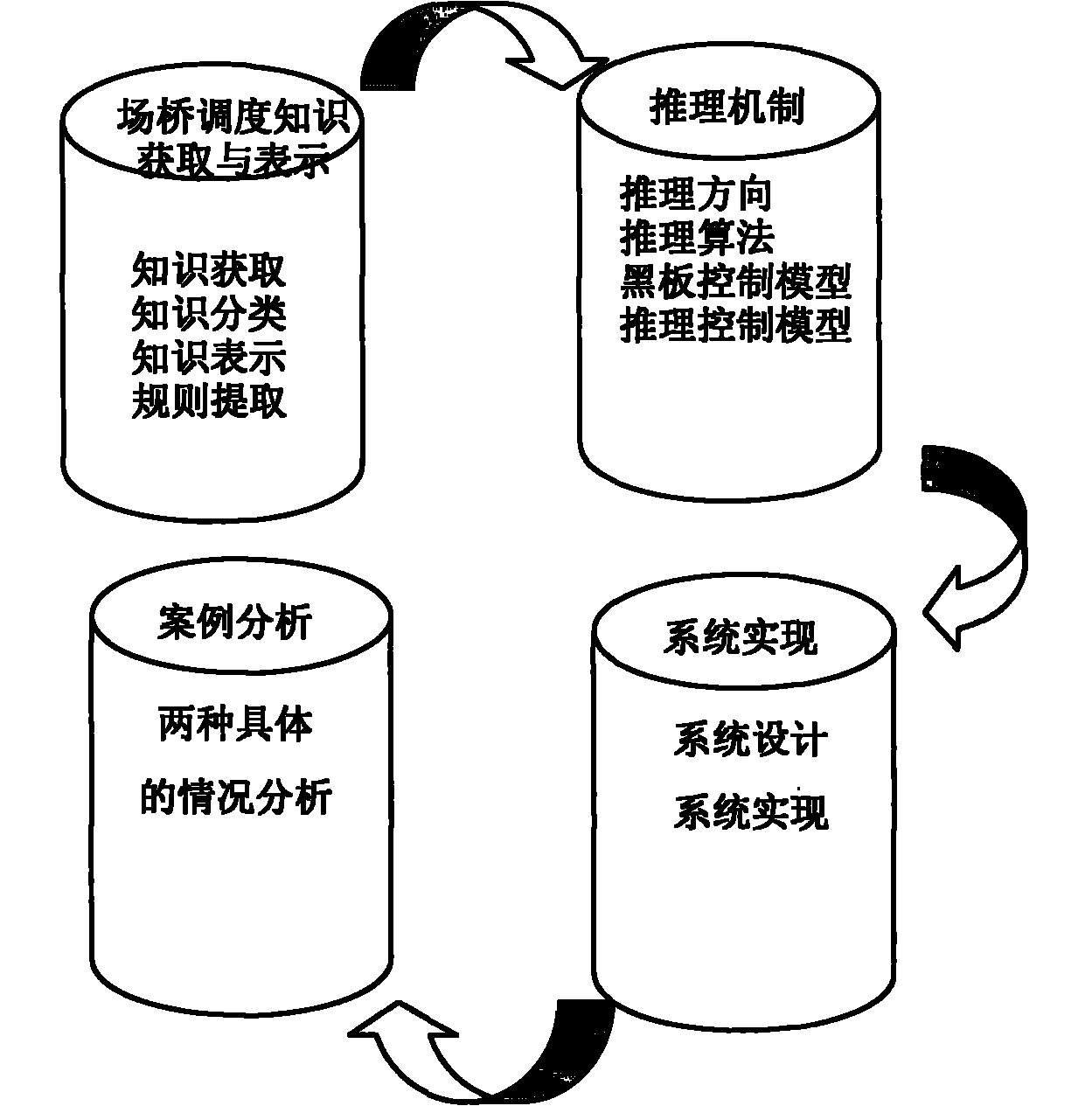

Dispatching method for container gantry crane of knowledge engineering based container terminal

InactiveCN101782988AReduce loading and unloading costsImprove work efficiencyResourcesInference methodsSystems designControl engineering

The invention relates to a dispatching method for a container gantry crane of a knowledge engineering based container terminal. A knowledge system of container gantry is systematically designed and realized by the following steps: firstly, sorting out the knowledge of container gantry crane dispatching of the container terminal obtained by using the knowledge sorting process (KSP); secondly, designing the reasoning mechanism of the knowledge system of container gantry crane dispatching; then, analyzing the system structure of the knowledge system of container gantry crane dispatching, elaborating the main framework and basic constitution thereof; realizing the knowledge system of container gantry crane dispatching through the software ExsysDevelope 7.0.18 based on the representation of knowledge studied at prior and the reasoning mechanism; and finally, carrying out case study on the knowledge system of container gantry crane dispatching, changing the container area where work is to be done under same condition to obtain different dispatching results, and verifying the validity and the reliability of the knowledge of container gantry crane dispatching of the container terminal.

Owner:SHANGHAI MARITIME UNIVERSITY

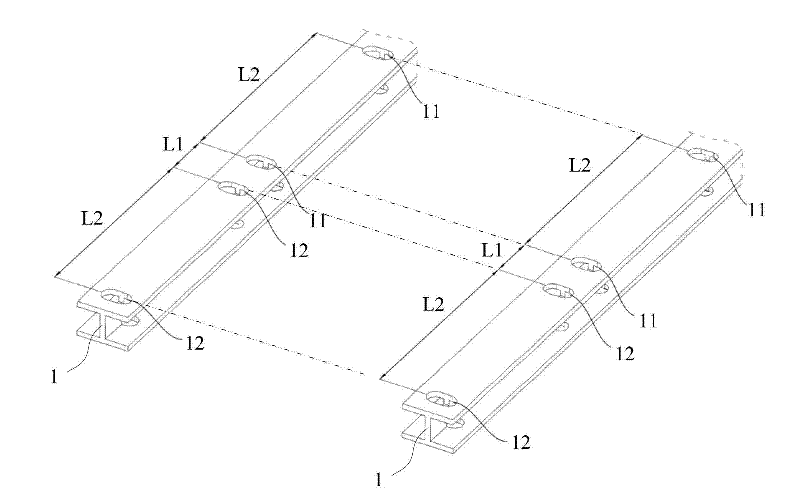

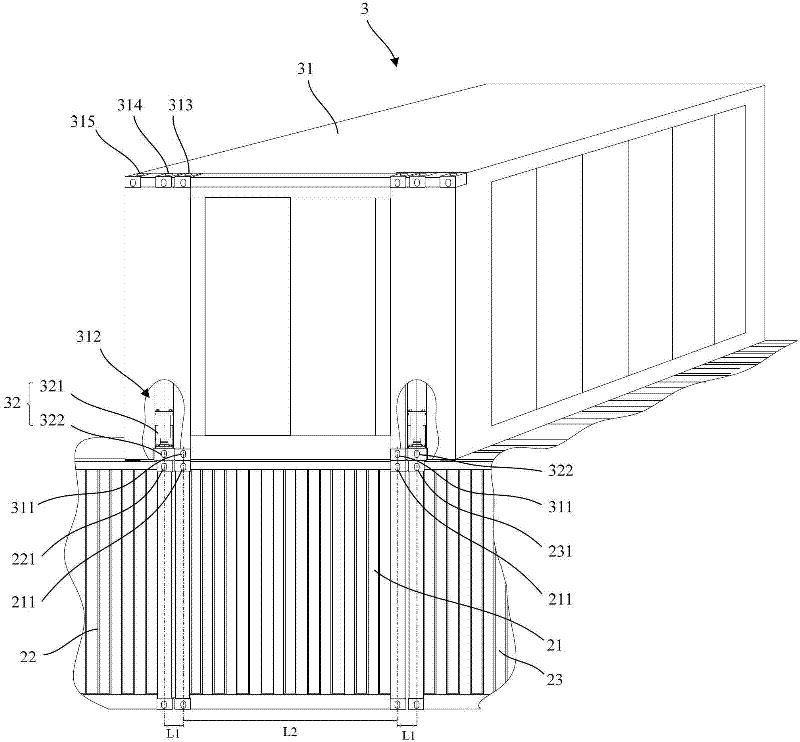

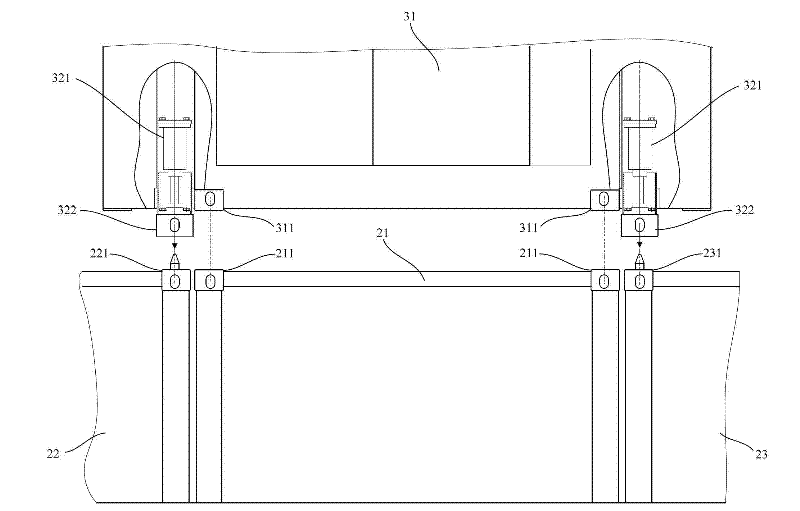

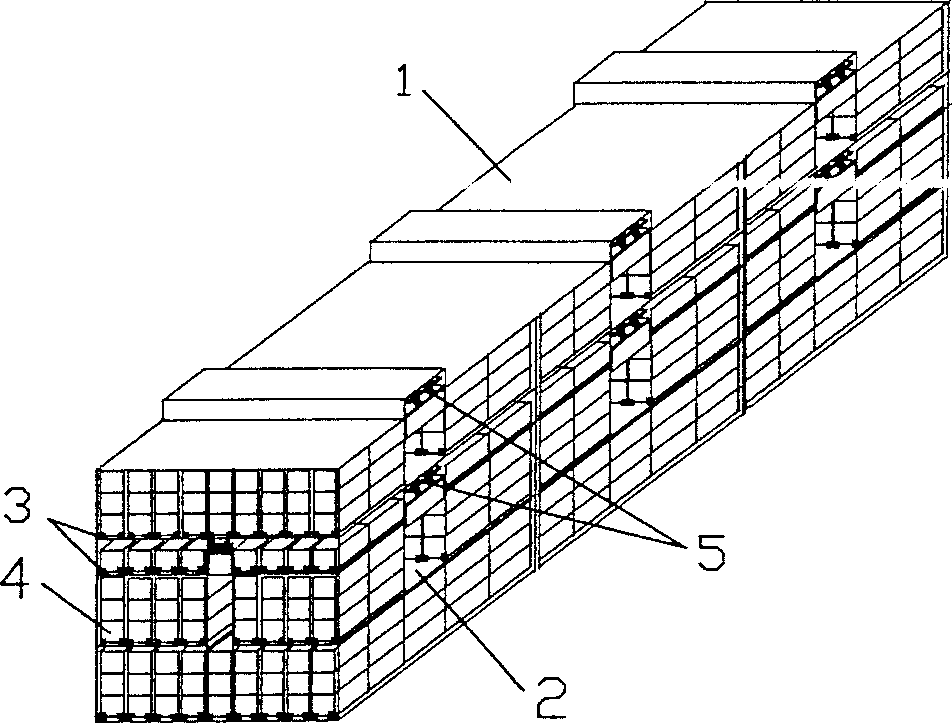

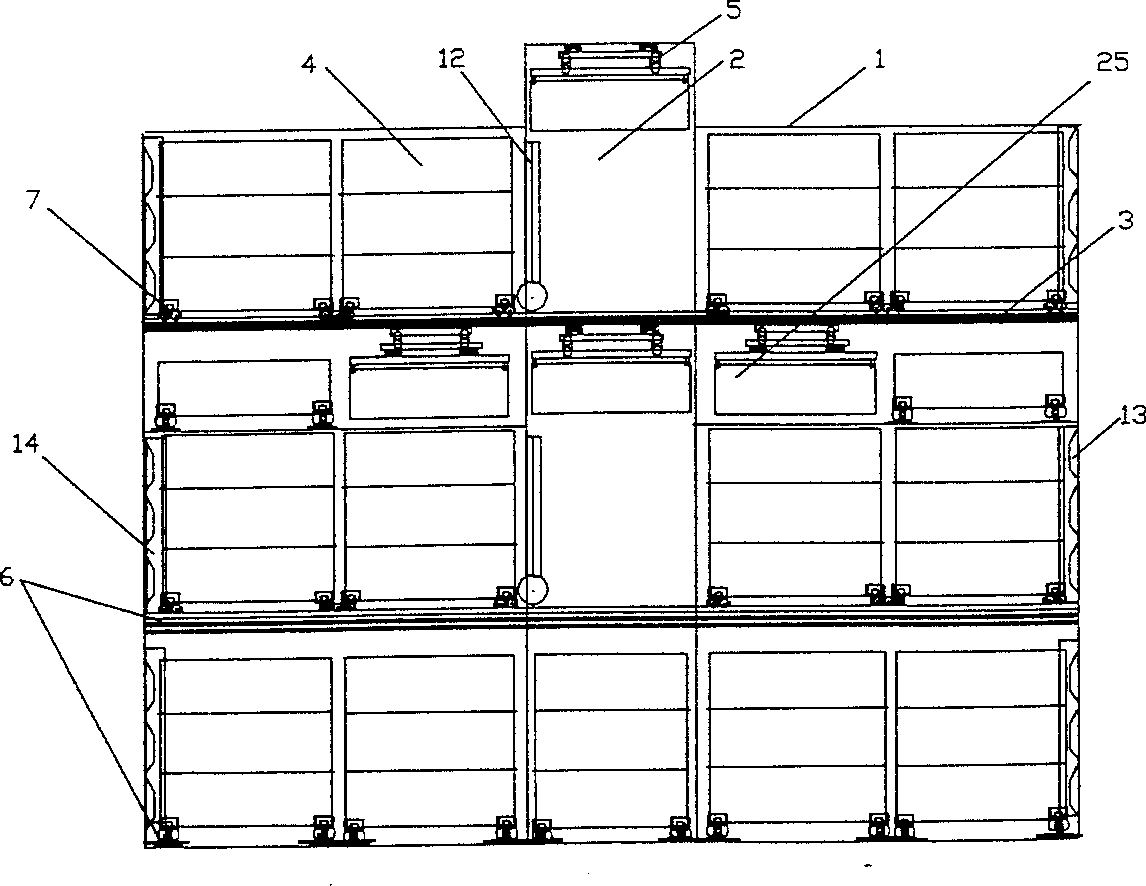

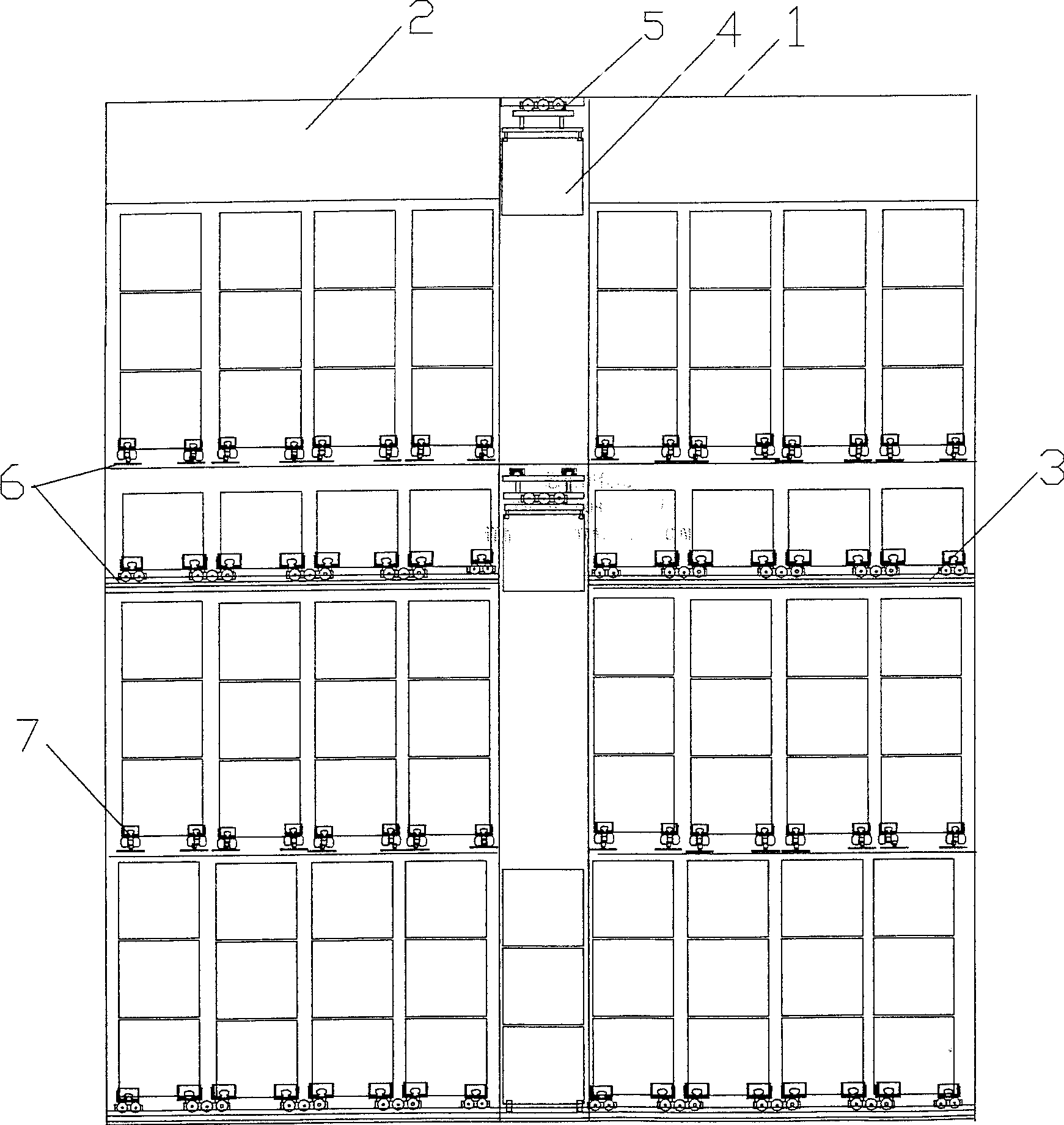

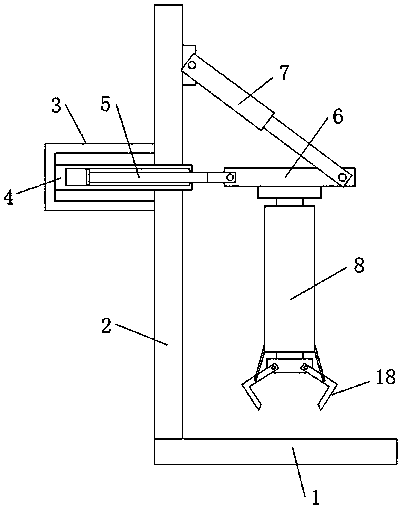

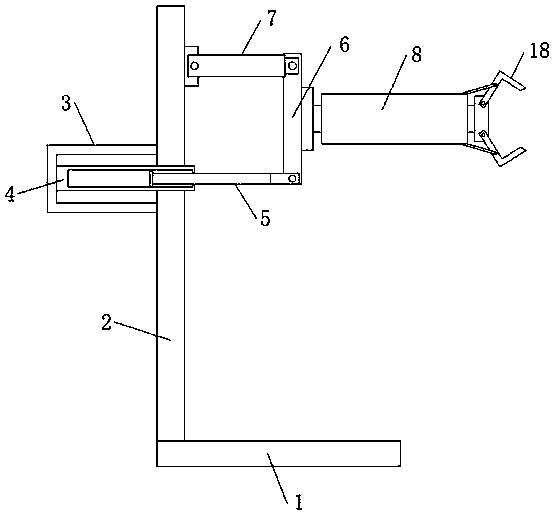

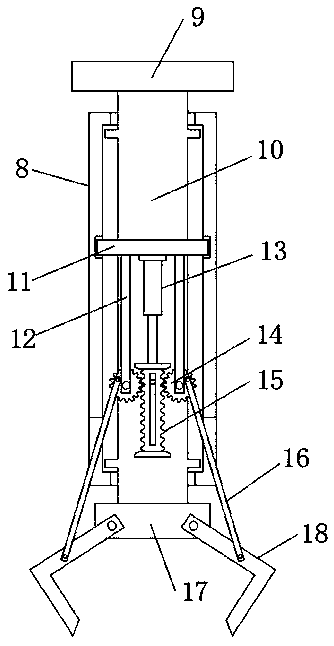

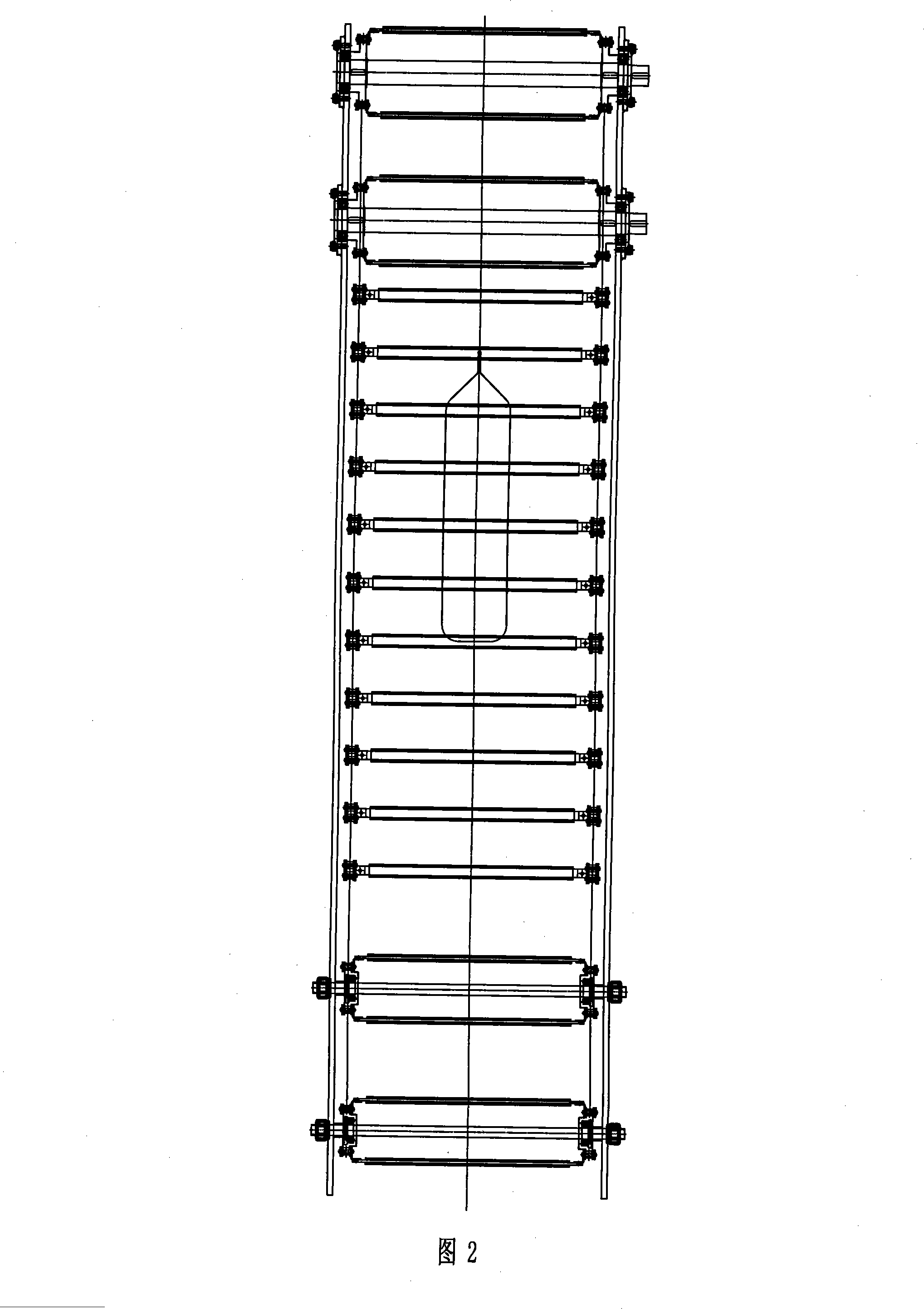

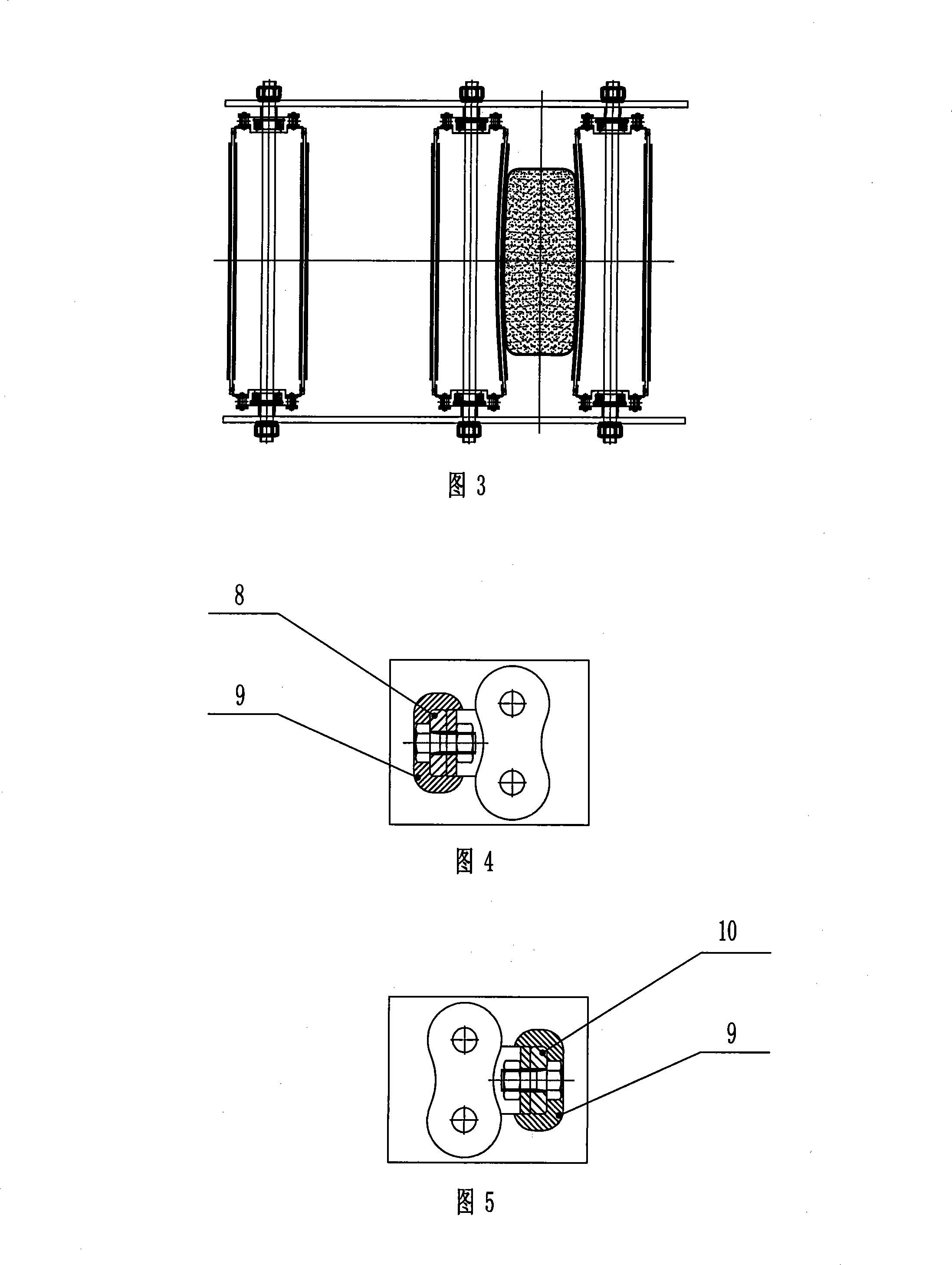

Automatized storing, loading and unloading facility for container

InactiveCN101428710AReduce loading and unloading costsReduce insecurityTrolley cranesLoading/unloadingArray data structureEngineering

The invention relates to a container automatic storing and automatic loading and unloading device, which comprises a container automatic storage library, caterpillar tracks, and a running mechanism and a hoisting mechanism which drive the container to move; the device is characterized in that the container automatic storage library which is a cube-type space steel structural body is arranged in a sectional manner and in a layered manner; a passage is arranged at the middle part of the section; a plurality of groups of caterpillar tracks are arranged on the bottom surface of the layer on the two sides of the passage along the length direction of the library; the group of caterpillar tracks comprise two caterpillar tracks; the distance between the two caterpillar tracks is the same as the width of a standard container; the containers are respectively arranged in rows above the group of caterpillar tracks along the length direction of the library; more than one container can be arranged in the row; the caterpillar tracks can move along the length direction of the library and further drive all rows of containers thereon to move in a grouped manner; furthermore, the row of the containers can move to the position of the passage; a conveyer which can cause the containers to move along the library height direction and the width direction of the library are arranged in the passage; and an end part of the passage, that is, a container loader is arranged on the side surface of the container storage library, so that the automation of all the containers is realized from the library inflow to the library outflow.

Owner:游勇

Loading and unloading device capable of converting tool bit direction

ActiveCN107585564AImprove loading and unloading efficiencyReduce transmission timeStacking articlesDe-stacking articlesHydraulic cylinderMechanical engineering

The invention discloses a loading and unloading device capable of converting the tool bit direction. The device comprises a fixing base and a supporting plate. The supporting plate is perpendicularlyinstalled on one side of the top of the fixing base. The device further comprises a steering mechanism and a loading and unloading mechanism at the bottom of the steering mechanism, wherein the steering mechanism installed on the supporting plate comprises a fixing support and a hydraulic cylinder, the fixing support is welded to the side, away from the fixing base, of the supporting plate, a horizontally-arranged fixing plate is welded to the interior of the fixing support, a stretchable plate on the same horizontal plane with the fixing plate is movably installed on one side of the fixing plate, one end of the stretchable plate is rotationally connected with one end of a steering plate, the steering plate is located over the fixing base, the hydraulic cylinder is rotationally installed on the side, close to the fixing base, of the supporting plate, and a piston rod of the hydraulic cylinder is rotationally connected with the other end of the steering plate. The device is reasonable in design, easy to operate and capable of conveniently converting the goods loading and unloading direction, meeting the requirement for clamping and fixing goods of different specifications and sizes,lowering the cost and improving the goods loading and unloading efficiency.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

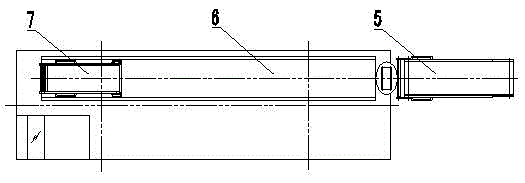

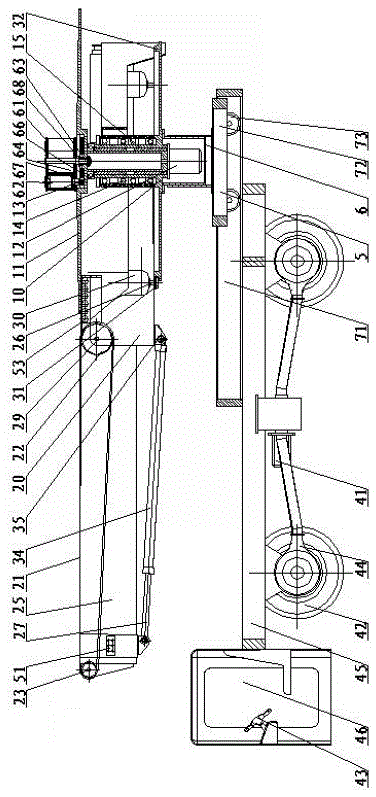

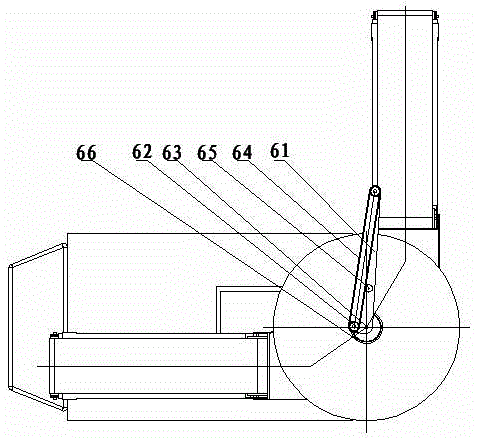

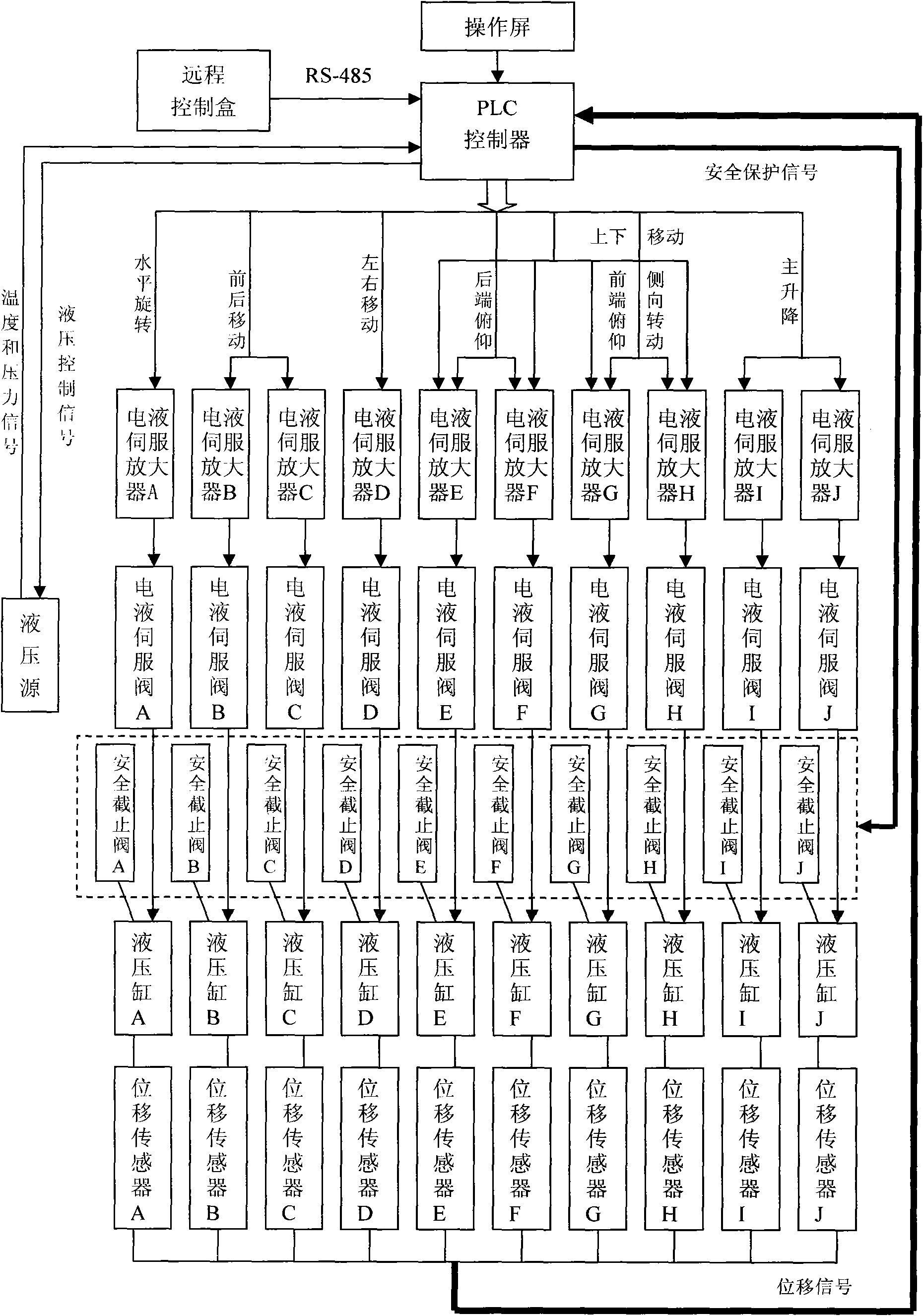

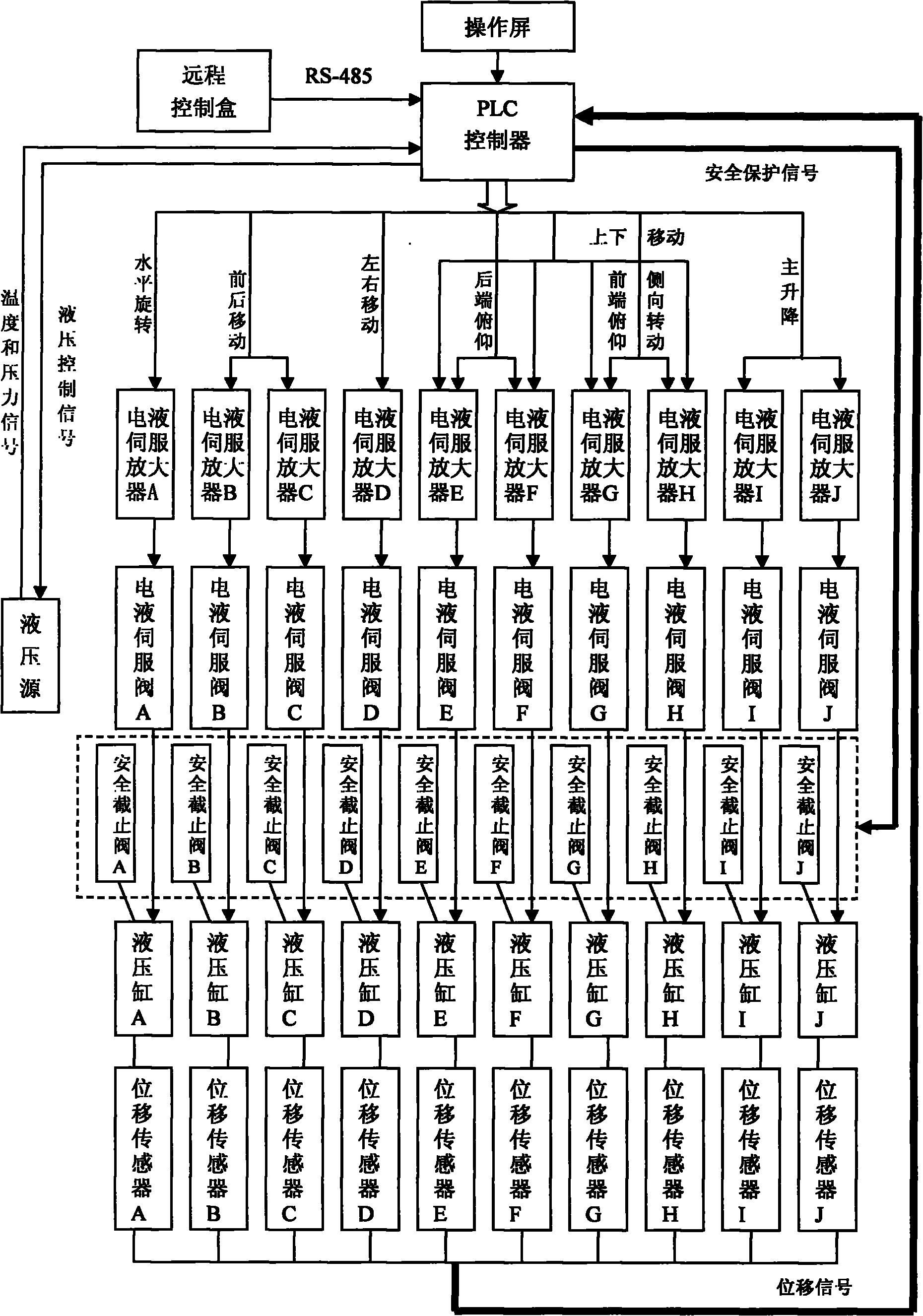

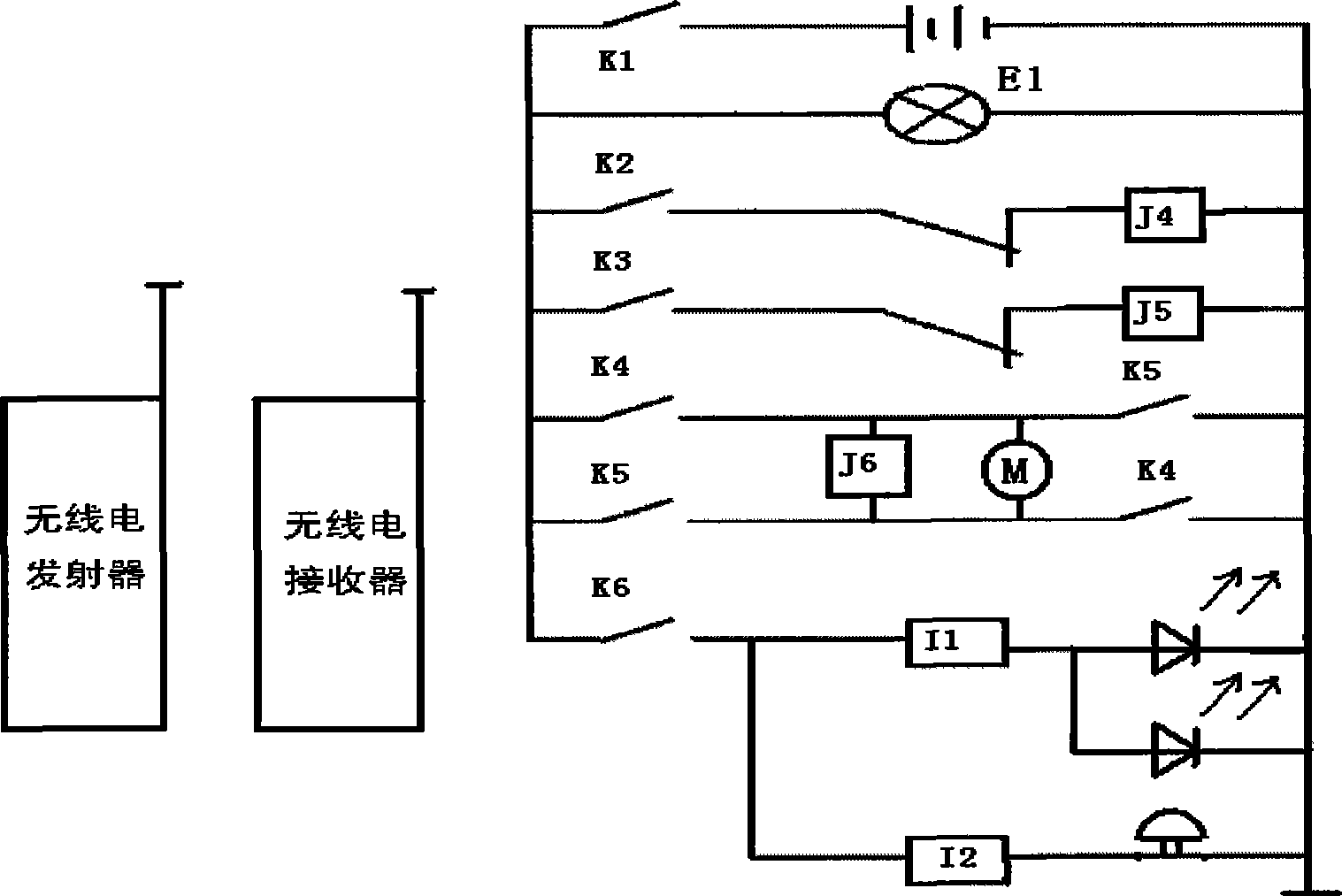

Control system of aeroengine mounting vehicle

InactiveCN102012695ASimplify loading and unloading processIncrease mobility and automationAircraft assemblyTotal factory controlElectro hydraulicSix degrees of freedom

The invention discloses a control system of an aeroengine mounting vehicle, which comprises a PLC (programmable logic controller), an operation screen, an electro-hydraulic servo amplifier group, a hydraulic system and a built-in displacement sensor group, wherein the hydraulic system comprises an electro-hydraulic servo valve group, a hydraulic source, a pipeline system and a hydraulic oil cylinder group, the electro-hydraulic servo valve group is arranged in the pipeline system for connecting the hydraulic source with the hydraulic oil cylinder group, the operation screen is connected with the PLC through a bus, a control signal outputted by the PLC is amplified by the electro-hydraulic servo amplifier group and then connected with the electro-hydraulic servo valve group, the hydraulic oil cylinder group is equipped with a safety shutoff valve group, the displacement sensor group is arranged in the hydraulic oil cylinder group, and the output of the displacement sensor group is connected with the PLC. The control system has the beneficial effects of realizing six-degree-of-freedom precise control of main lifting, horizontal rotation, front and back movement, left and right movement, back end pitching, lateral rotation, front-end pitching, and up and down movement of the aeroengine mounting vehicle and has the advantages of high control precision, high degree of automation and the like.

Owner:成都立航科技股份有限公司

Smashing and brick making device of crop straw

InactiveCN110216768AImprove operational efficiencyGuaranteed stabilityCuttersDomestic articlesBrickBiochemical engineering

The invention discloses a smashing and brick making device of crop straw. The device comprises a machine body, a smashing cavity is formed in the machine body, a smashing device is arranged in the smashing cavity, a stirring cavity is formed in the lower side of the smashing cavity, a stirring device is arranged in the stirring cavity, the stirring device is in movable connection with the smashingdevice, a brick making cavity is formed in the lower side of the stirring cavity, a discharging device is arranged between the brick making cavity and the stirring cavity, and a vibration device is arranged on the upper side of the brick making cavity. Through the smashing device, the crop straw is directly smashed, and is stirred and mixed directly with other raw materials to make brick making materials, through a brick making device, molding is carried out, the device is a smashing and brick making integrated device, mechanical loading and unloading cost is saved, the device can continuously work at the same time, and the brick making operation efficiency is high.

Owner:简胜坚 +2

Automatic deforming truck

InactiveCN101391622AImplement variableTo achieve the effect of automatic deformationUnderstructuresVehiclesElectric machineryEngineering

The technical problem needs to be solved by the invention is to provide a truck with the automatic deformation function. The adopted technical proposal is as follows: the truck with the automatic deformation comprises a base and is characterized in that: the base is divided into a front part and a back part which both adopt U-shaped base frameworks, wherein, one U-shaped base framework is hollow, and the other U-shaped base framework can be inserted in the hollow base framework. The truck with the automatic deformation further comprises a motor and at least one belt gear which is driven by the motor and respectively positioned at the front and the back bases, and the belt gears of the front and the back bases are connected through a synchronous belt. The adoption of the heavy container truck with the automatic deformation can save the space of a dock, accelerate the handling efficiency of a container and reduce the handling costs.

Owner:上海市吴淞中学

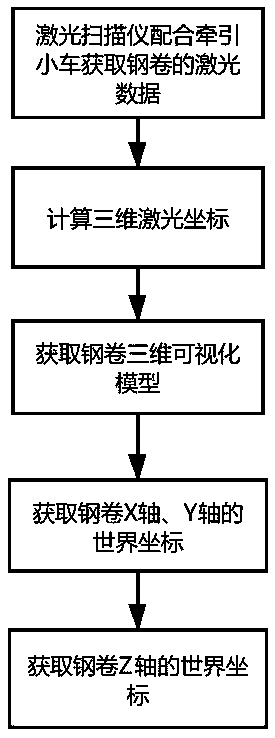

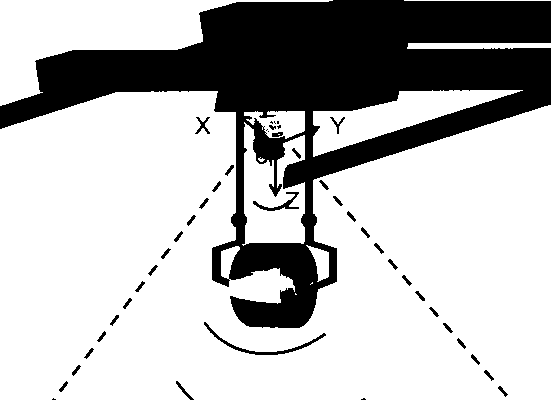

Steel coil identifying and positioning method based on laser technology

InactiveCN111023965AReduce occupancyAchieve acquisitionUsing optical meansMinimum bounding rectangleLaser scanning

The invention discloses a steel coil identifying and positioning method based on a laser technology. The method comprises the steps of (1) matching a linear laser scanner with a traction trolley to obtain laser data and a trolley position value; (2) synchronizing the laser data and the position value, and calculating three-dimensional space coordinates of a measurement point; (3) processing the three-dimensional discrete data by adopting a regular grid DEM, and then obtaining a steel coil three-dimensional visualization model by using Direct3D; (4) acquiring world coordinates of a steel coil in the X axis and the Y axis by using a contour tracking algorithm and a minimum bounding rectangle algorithm; and (5) carrying out circle feature fitting by using an image obtained after fusion and superposition of projection images so as to obtain a world coordinate of the steel coil on the Z axis. According to the method, the position of the steel coil can be accurately identified and positioned, the laser scanning period is shortened, and the logistics efficiency of a finished product warehouse is improved.

Owner:SHANGHAI UNIV

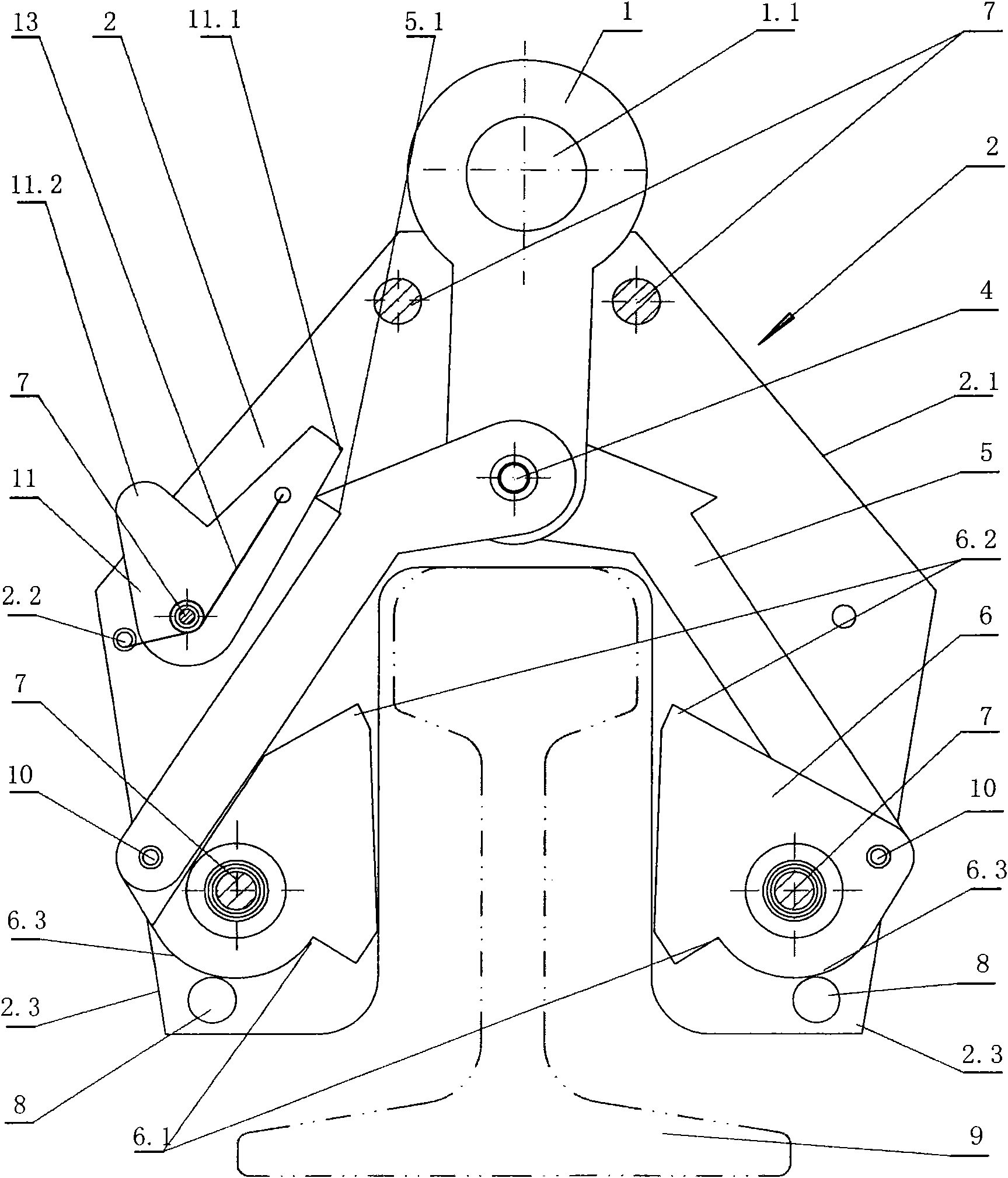

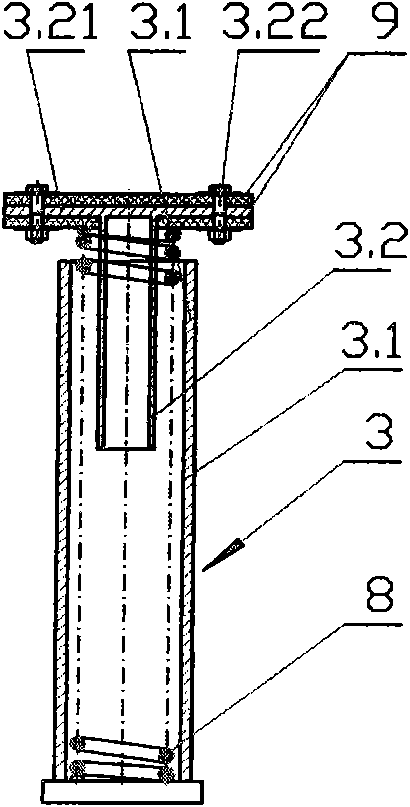

Special hanger for loading and unloading steel rails

InactiveCN101857167AImprove efficacyReduce loading and unloading costsLoad-engaging elementsScrapEngineering

The invention discloses a special hanger for loading and unloading steel rails, aiming at overcoming the defects of increase of loading-unloading cost, low loading-unloading efficiency and unsafety caused by damage and scrap of steel ropes as the steel rope is buckled at two ends of a steel rail for lifting and unloading conveying in the prior art. In a vertical supporting frame, a floating support is provided with lifting lugs which are movably connected with the upper ends of two pull rods which are eudipleural, the lower ends of both pull rods are movably connected with two rotating tongues which are oppositely arranged, and the rotating tongues are respectively and oppositely supported on the supporting frame; the supporting frame and the rotating tongues are provided with a locking device which can enable two tongue tips of the rotating tongues to oppositely rest on the horizontal position when the lifting lugs are lifted and to rest on the vertical position when the two tongue tips are put down. As the supporting frame is provided with the locking device which can enable the tongue tips of both rotating tongues to oppositely rest on the horizontal position and the vertical position, the tongue tips of both rotating tongue tips can be hooked and unhooked at the lower edge of the rail surface of a steel rail, thereby the steel rail down can be lifted and put down. The special hanger for loading and unloading steel rails has the advantages of no need of steel rope buckles, high efficiency, no consumption of raw materials, low loading and unloading cost, simple operation and safe and reliable use.

Owner:QINGDAO PORT GRP

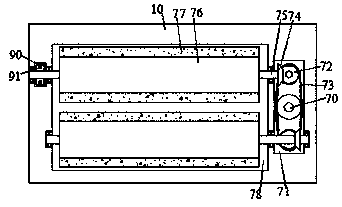

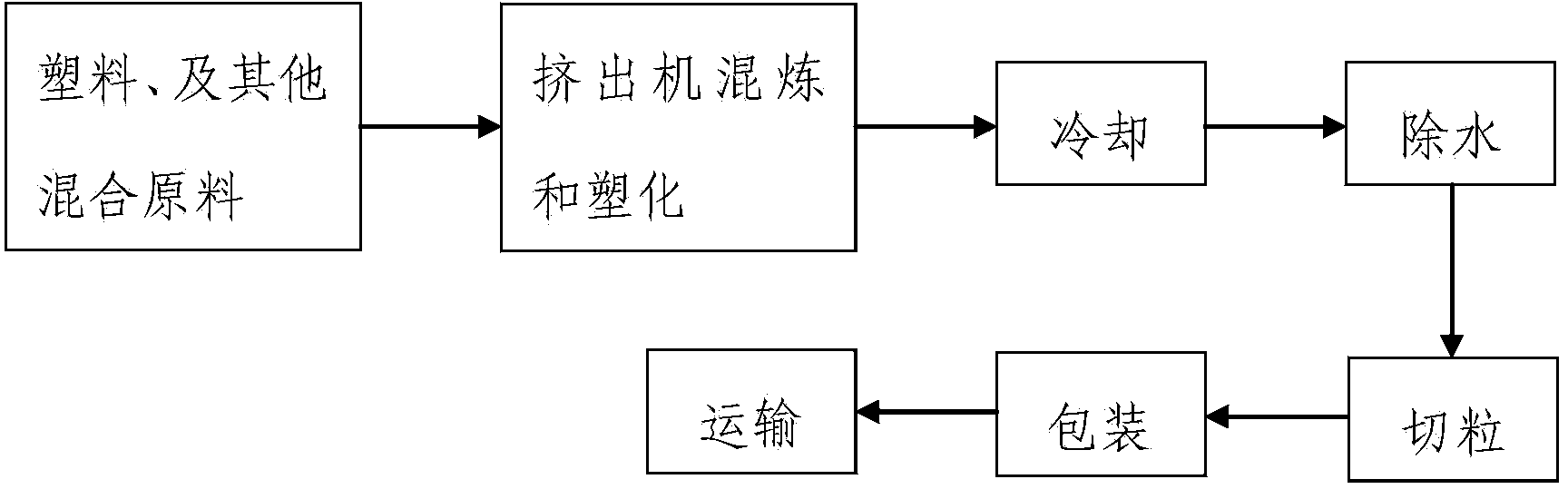

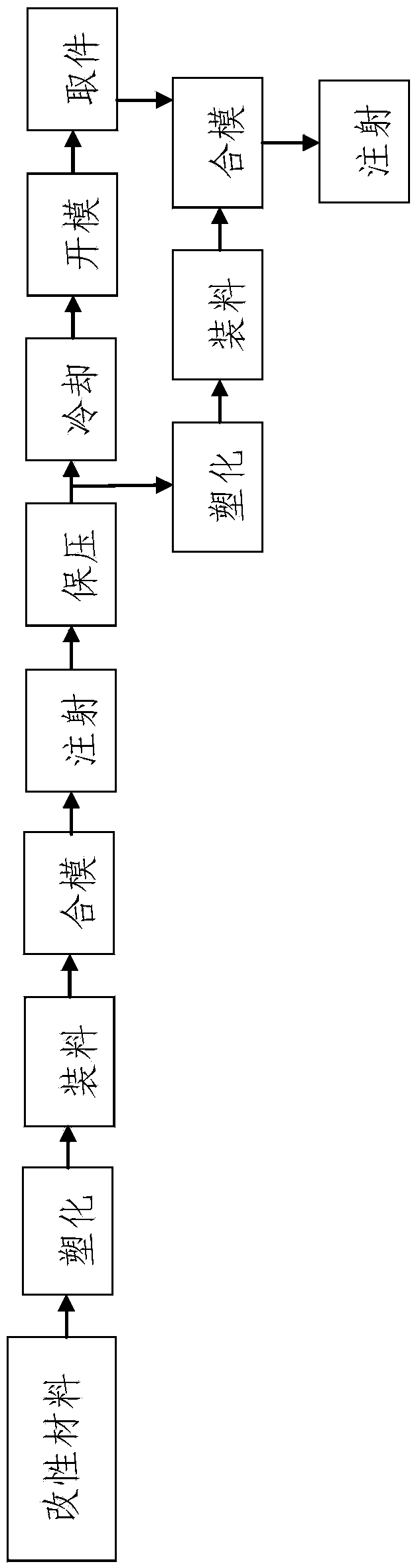

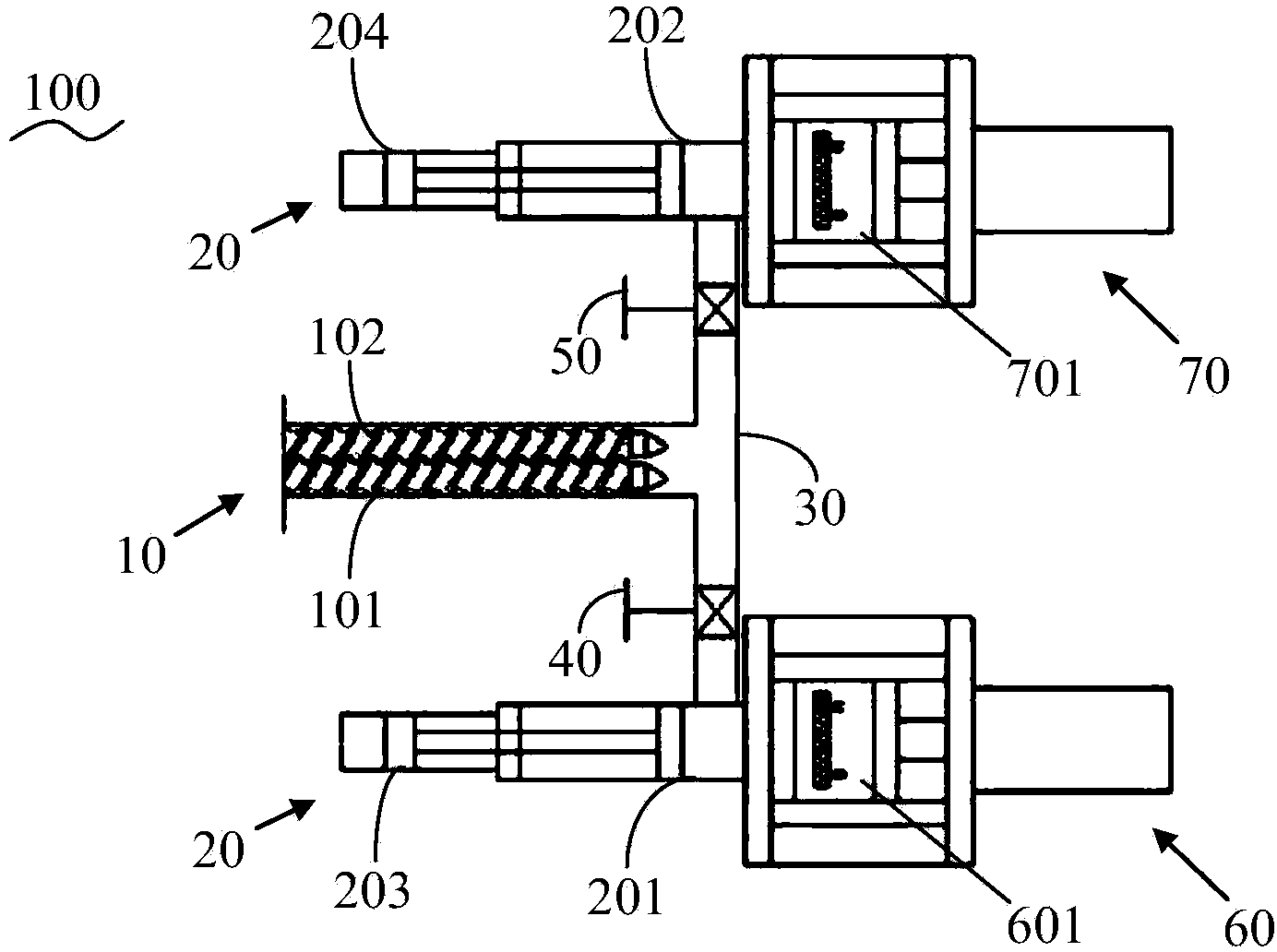

Continuous mixing and injection moulding equipment

InactiveCN103817852AReduce energy consumptionReduce loading and unloading costsContinuous/uninterruptedContinuous mixing

The invention discloses continuous mixing and injection moulding equipment. The equipment comprises a mixing and plasticizing device (10) and injection moulding devices (20), wherein the mixing and plasticizing device (10) comprises a casing (101) and a screw arranged inside the casing (101), and a charging port is formed in one end of the casing (101); the injection moulding devices (20) comprise a first injection head (201), a second injection head (202), a first injection power device (203) and a second injection power device (204), the first injection power device (203) and the second injection power device (204) are used for providing power for the first injection head (201) and the second injection head (202) respectively, the first injection head (201) and the second injection head (202) are communicated with the charging port through a pipeline, a first unidirectional control switch (40) is arranged between the first injection head (201) and the charging port, and a second unidirectional control switch (50) is arranged between the second injection head (202) and the charging port. According to the continuous mixing and injection moulding equipment, uninterrupted work of the equipment is realized; and the two injection heads are adopted, so that alternate conduct of charging and injection moulding is realized. The equipment has the advantages of operation continuity, high efficiency, low energy consumption, low cost, simple structure and the like.

Owner:王子博

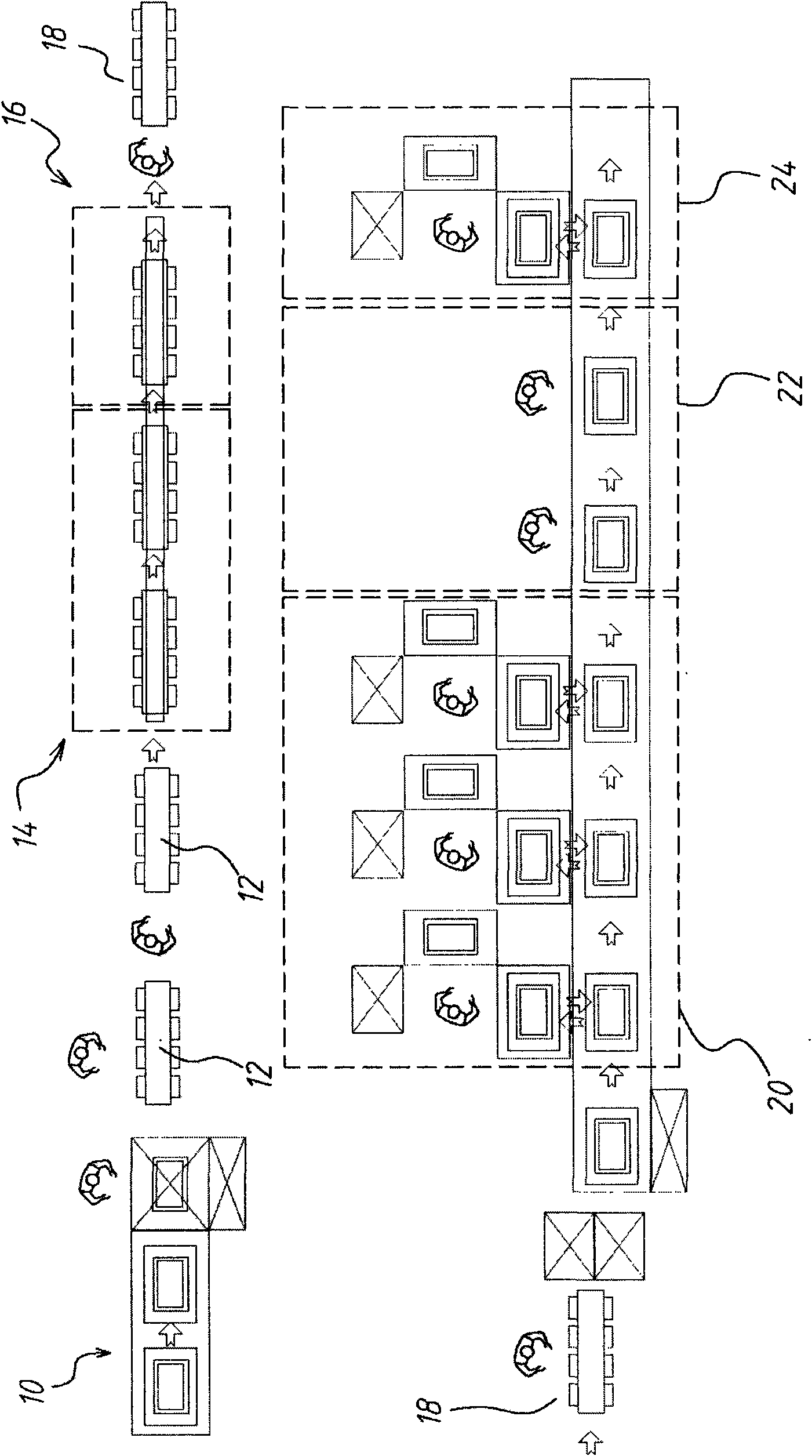

Framework of conveying system on backlight module production line and method thereof

InactiveCN101571636AReduce manual handlingReduce loading and unloading costsNon-linear opticsProduction lineLogistics management

The invention mainly relates to a technology for improving the efficiency of a production line, in particular to a framework of a conveying system on a backlight module production line and a method thereof. The framework of the conveying system comprises a plurality of testing areas and at least one conveyer belt, wherein the conveyer belt runs through each testing area and connects the testing areas in series. Assembled products are directly conveyed by the conveyer belt to each testing area for testing, thus the ineffective working hours of staff for loading, conveying and unloading is saved, and moreover, the cost of conveying the whole boxes is saved. Through an integrative production line, the condition of integral logistics can be instantly controlled.

Owner:CENTURY DISPLAY (SHENZHEN) CO LTD

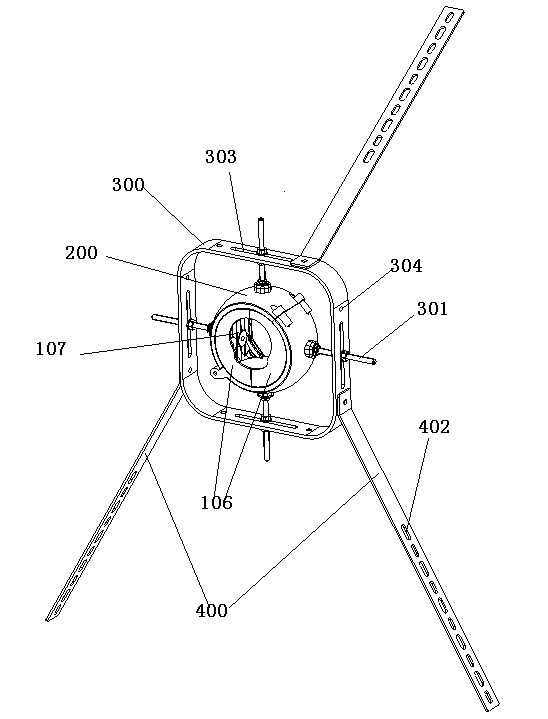

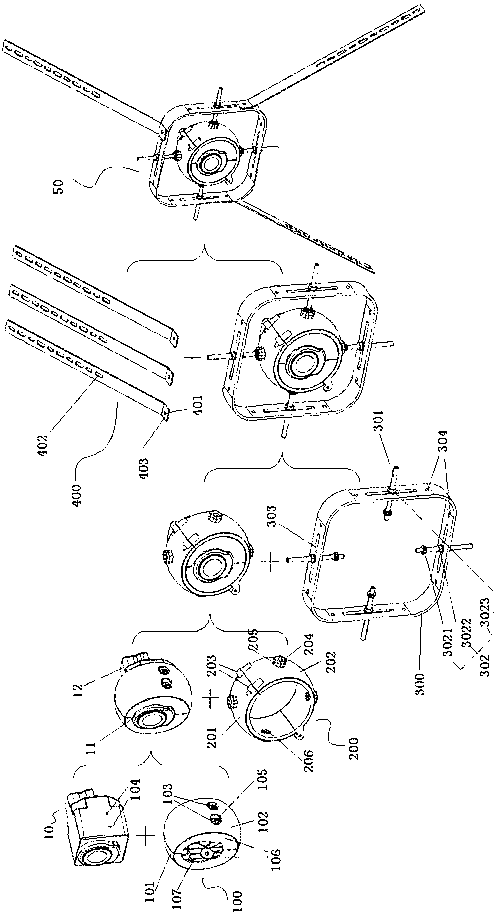

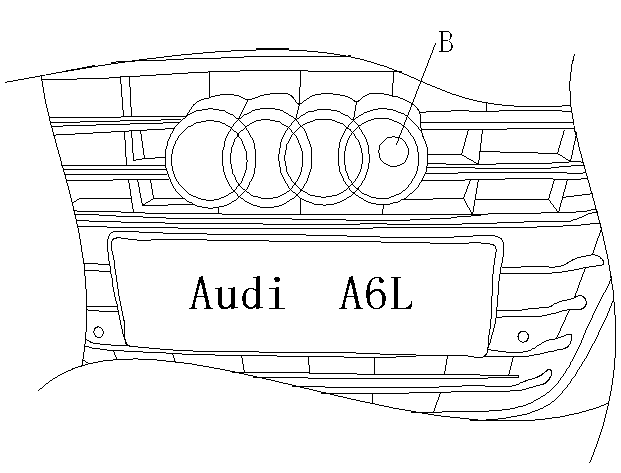

Installing device and installing system for installing camera

InactiveCN102975664AEasy to operateReduce loading and unloading costsVehicle componentsFixed positionEngineering

The invention discloses an installing device and an installing system for installing a camera. The installing device comprises an angle adjusting mechanism, a position adjusting mechanism and an installing support frame. The angle adjusting mechanism loops the camera. The position adjusting mechanism arranged outside the angle adjusting mechanism is used for controlling the angle adjusting mechanism to move in the plane. The installing support frame arranged on the position adjusting mechanism is used for fixing the position adjusting mechanism. The angle adjusting mechanism, the position adjusting mechanism and the installing support frame are connected in sequence. According to the installing device and the installing system for installing the camera, the camera angle of the camera is adjusted through the angle adjusting mechanism, and then the positions of the camera are adjusted from top to bottom and from left to right in the vertical plane through the position adjusting mechanism and are fixed, the position adjusting mechanism in the position of a car head is fixed through the installing support frame, and therefore an owner of a car is enabled to install and uninstall the camera. The operation is simple and convenient. The installing device and the installing system for installing the camera is suitable for different types of cars, and installing and uninstalling cost is saved.

Owner:广东骏弘精工汽车部件有限公司

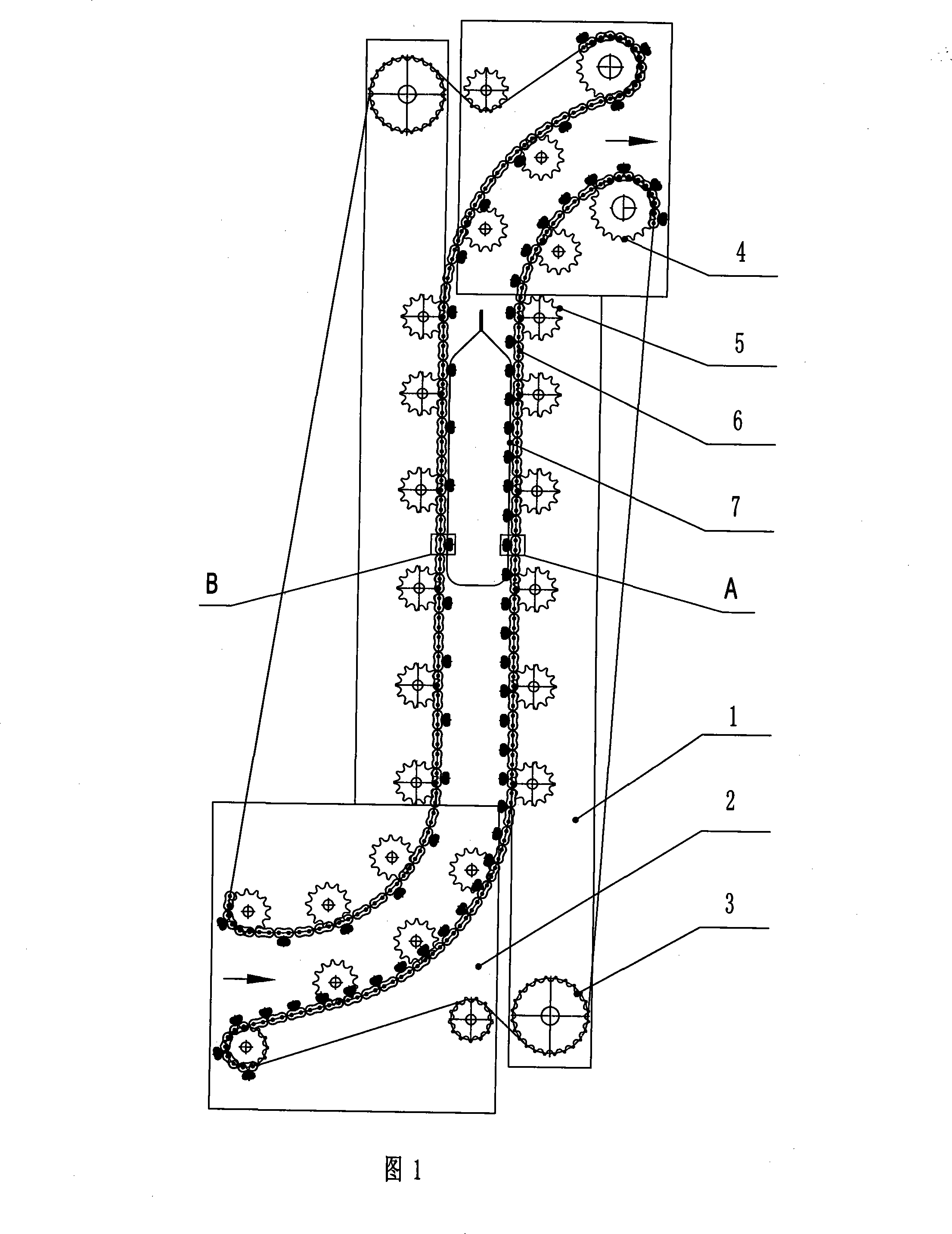

Packed material large-slope lifting device

The invention relates to a high gradient lifting device, specifically speaking, a high gradient lifting device for bagged material, which includes a left frame and a right frame; each of the left frame and the right frame is respectively provided with a driving sprocket, a supporting sprocket and a tensioning sprocket; two sets of short-pitch transfer chains are respectively engaged and connected with the driving sprocket, the supporting sprocket and the tensioning sprocket arranged on the left frame and the right frame to make cycle motion. The invention is characterized in that a lower bolster and an upper pressure board are respectively articulated with the transfer chain so as to form a lower bolster group and an upper pressure plate group, an S-shaped bagged material lifting transfer passage is formed between the lower bolster group and the upper pressure plate group of the two transfer chains. The invention has the advantages that: (1) the device reduces the labor input, decreases the handling cost, and improves the labor intensity of the worker and the work efficiency; (2) the bag is difficult to be clamped or damaged; (3) the lifting transportation of bagged material can be realized within the angle range of 30-90 DEG and the transfer speed and the reliability of the bagged material can be effectively improved.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

Support for turning over coiled steel

ActiveCN101857148ASo as not to damageThere will be no shipping quality problemsLoading/unloadingState of artProne position

The invention discloses a support for turning over coiled steel, which is provided for overcoming the shortcomings that when the coiled steel is unloaded from a transport vehicle and shipped for transportation in the prior art, the standing posture needs to be turned over to the lying posture, the turning over occupies manpower and equipment and is easy to damage a carriage or the ground by collision, and a product is easy to deform and unsafe during the turning over process. A seesaw type turning plate is supported on a base, a support part which can lead the gradient of the upper surface to be consistent with the gradient of the bottom surface when hoisting the coiled steel and is positioned in the balance state during the empty load of the turning plate is fixedly arranged below one end of the turning plate, and cantilever beams which can support the coiled steel in the lying posture state when the turning plate is in the heavy load vertical state are arranged on two sides above the other end of the turning plate. As the coiled steel is turned over from the standing posture to the lying posture for shipping, only a hanging tool needs to be used for hanging the coiled steel onto one end mounting the cantilever beams on the turning plate of the support for turning over, the turning plate drives the coiled steel to automatically downwards turn over in place, then a fork truck can be used for transporting the coiled steel to a cabin for shipping, the turning over does not occupy the equipment and the manpower, the operation is convenient, time-saving and effort-saving, and the loading and unloading cost is low.

Owner:QINGDAO PORT GRP

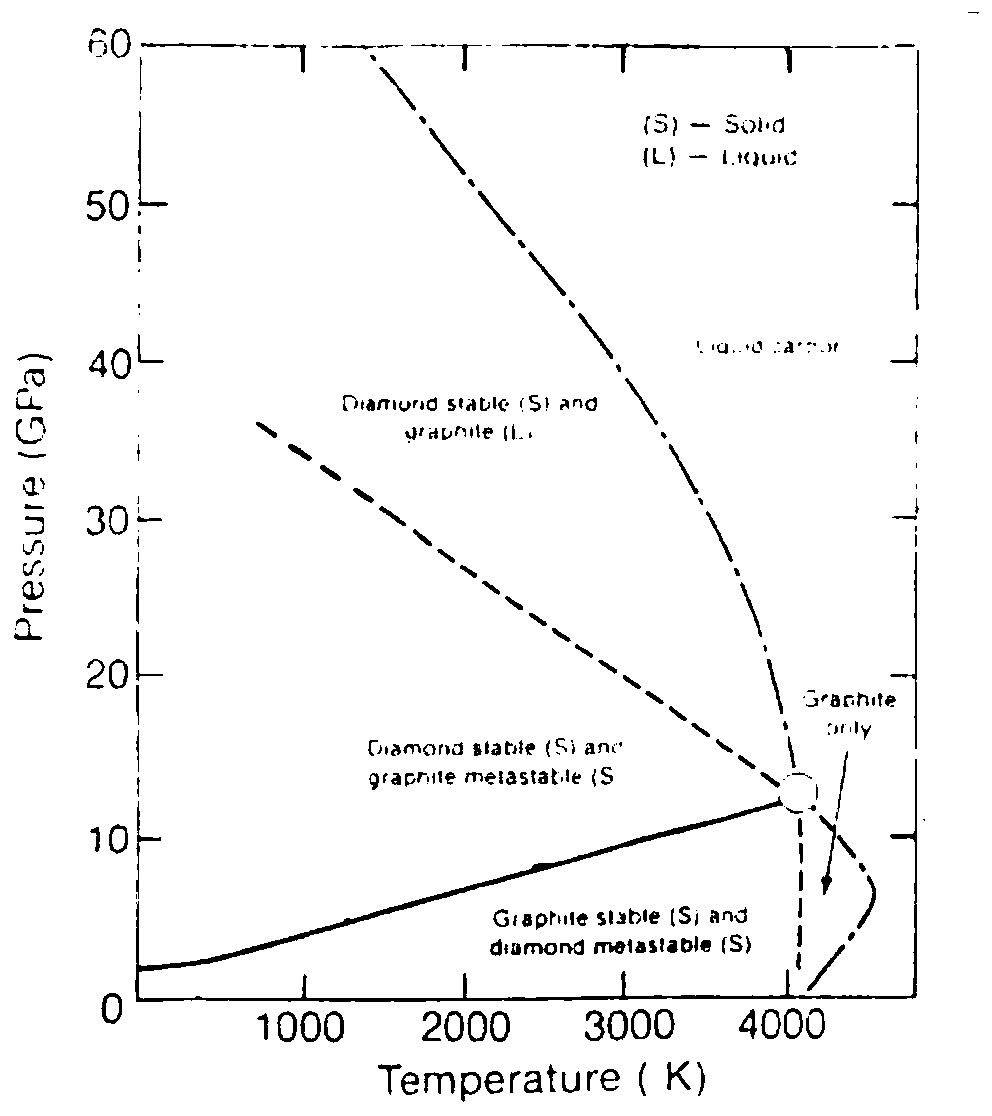

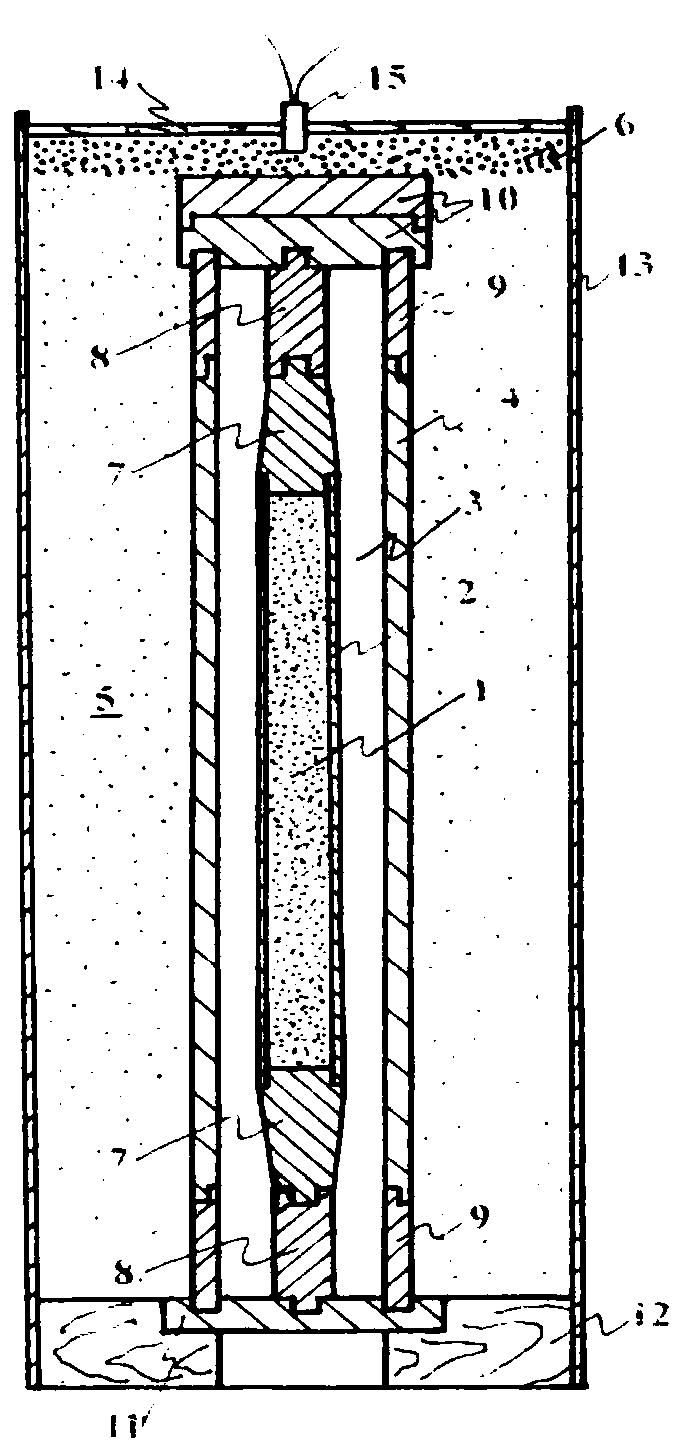

Detonation type synthesis device

ActiveCN111195506APrevent blastingImprove conversion ratePolycrystalline material growthUltra-high pressure processesDouble tubeGraphite

The invention discloses a double-tube connecting structure for detonation synthesis and a detonation synthesis device based on the double-tube connecting structure. The double-tube connecting structure comprises a driving tube, a sample tube and an end plug arranged at the port of the sample tube, wherein the driving tube sleeves the sample tube, and cavities exist between the driving tube and thesample tube and between the driving tube and the end plug. The structure further comprises fixing pieces, and the top end opening and the bottom end opening of the driving tube are covered with the fixing pieces. After detonation, detonation waves are sequentially transmitted from top to bottom and are impacted, and the driving tube performs centroid sliding motion towards the axis of the sampletube from top to bottom, so that the driving tube sequentially coats the top end plug of the sample tube, the sample tube and the bottom end plug of the sample tube from top to bottom. According to the device, a graphite sample can be effectively converted into high-purity diamond, the conversion rate can reach 90% or above, the converted product high-purity diamond can be completely recycled, therecycling rate reaches 100%, and industrial production can be achieved easily.

Owner:CHENGDU INFINITE SINGULARITY TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com