Patents

Literature

32results about How to "Implement variable" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

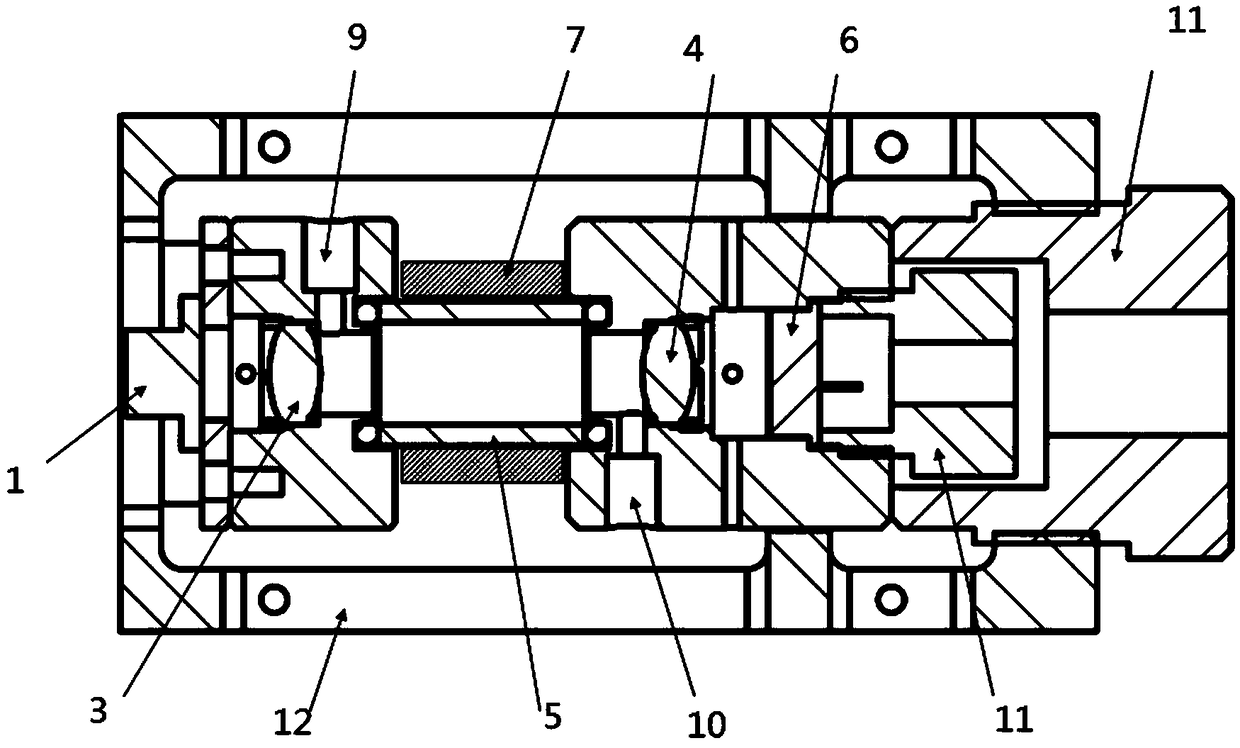

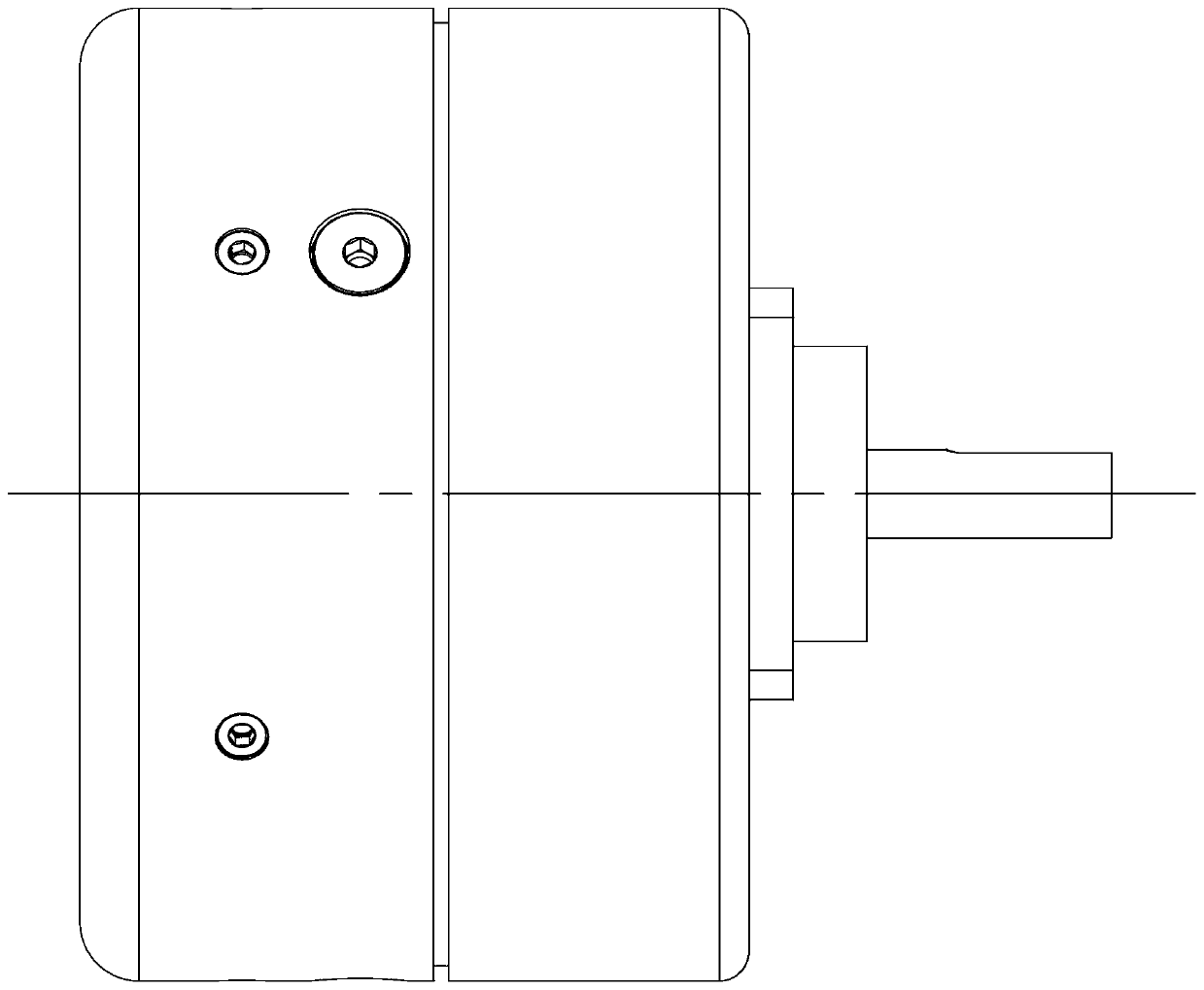

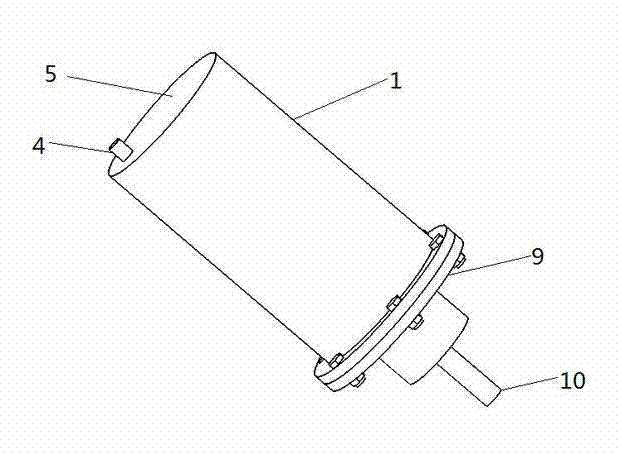

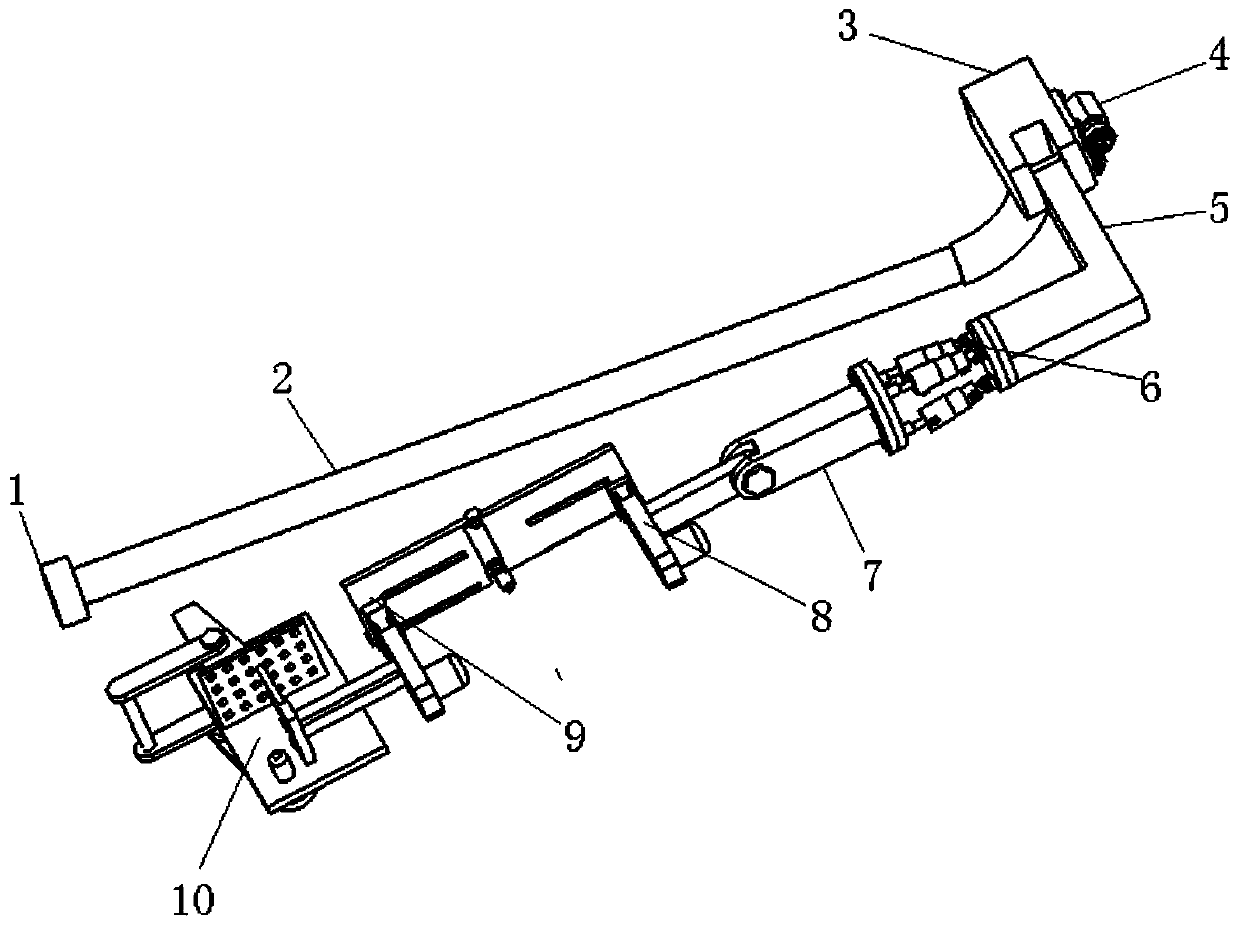

Linear motor-driven plunger pump

InactiveCN102305203AReduce in quantityImprove anti-pollution performancePumpsPositive-displacement liquid enginesPermanent magnet rotorReciprocating motion

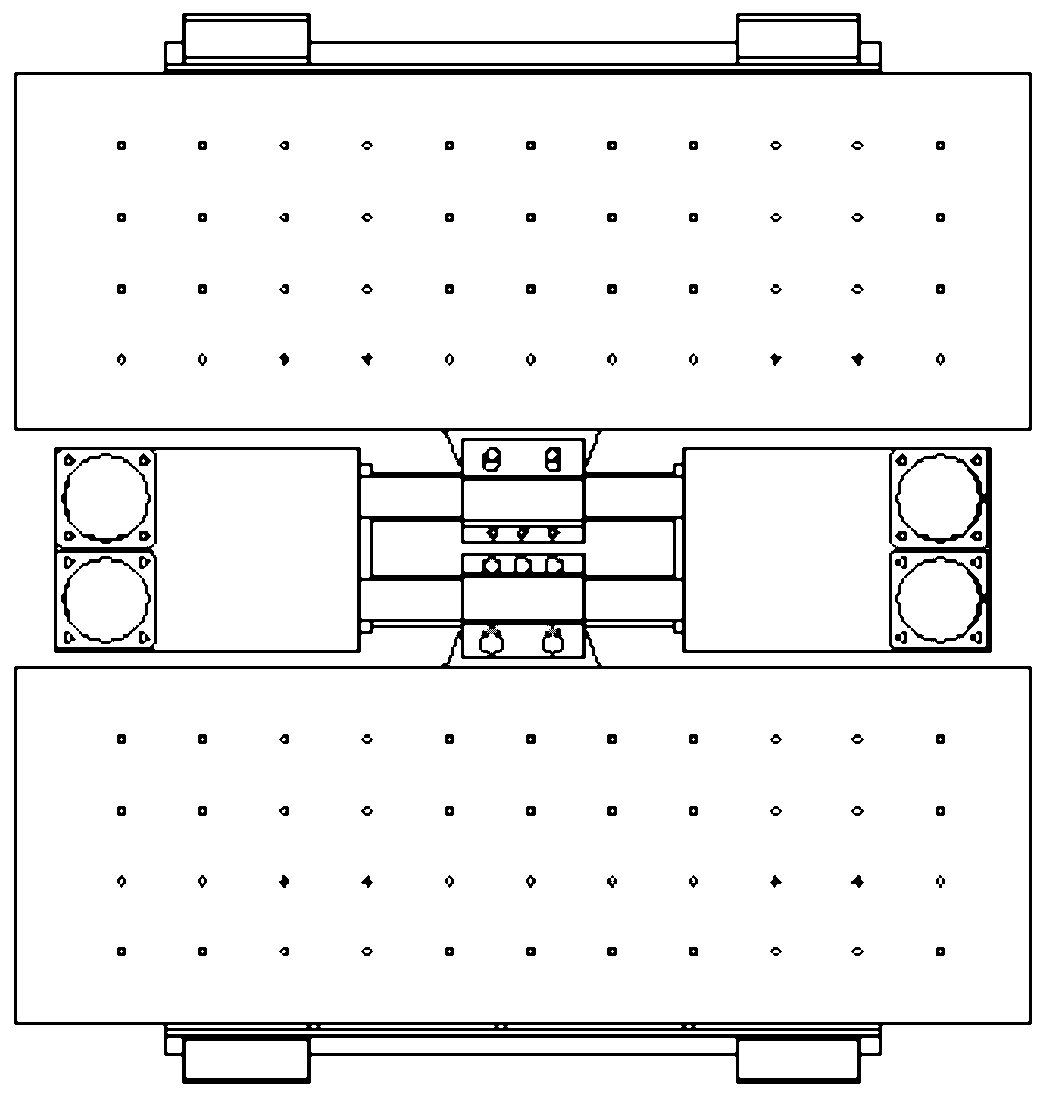

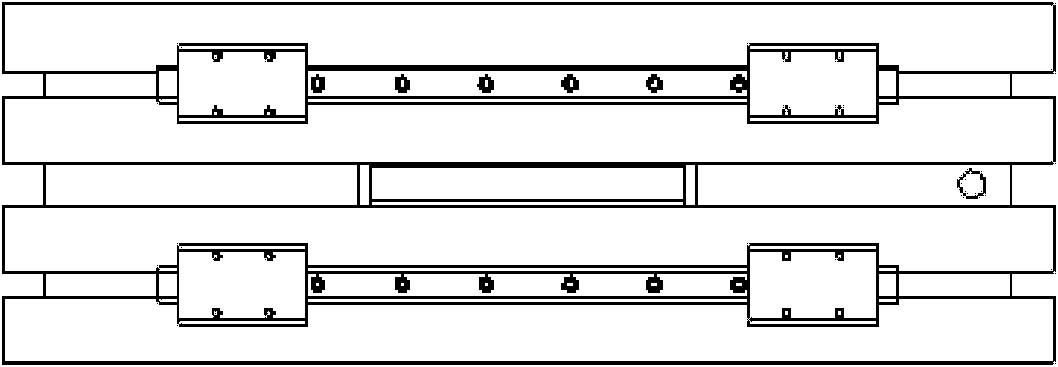

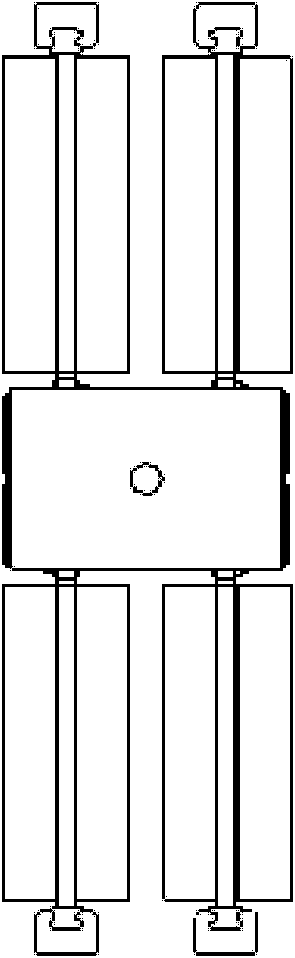

The invention relates to a linear motor-driven plunger pump. The mechanical part of the plunger pump comprises a cylinder body I, a cylinder body II, flow distribution valves, an in-sucking communication pipe, out-pressing communication pipes, compacting flanges, plunger rods, linear motor stators, linear motor rotors and guide rails; and the electric part mainly consists of linear motors, a controller, drivers and a position feedback device. The linear motor-driven plunger pump is characterized in that a group of coil-type stators drive a permanent magnet rotor in a combinational way, thus realizing high thrust output of the linear motors. Each flat-type linear motor drives two plungers at the two ends of one plunger rod, and while the double-action plunger rod reciprocates, one end of the double-action plunger rod sucks water and at the same time the other end of the double-action plunger rod presses water. The two cylinders realizes the effective communication between the water sucking loop and water pressing loop of the plunger pump by means of the in-sucking communication pipe and the two out-pressing communication pipes. Each plunger hole is communicated with a flow distribution valve consisting of an in-sucking valve and an out-pressing valve. The electric part controls the out-of-phase movement of the linear motors, thus ensuring the stable combinational flow output of the pump. The linear motor-driven plunger pump disclosed by the invention has the advantages of less mechanical transmission links and high system efficiency and reliability.

Owner:BEIJING UNIV OF TECH

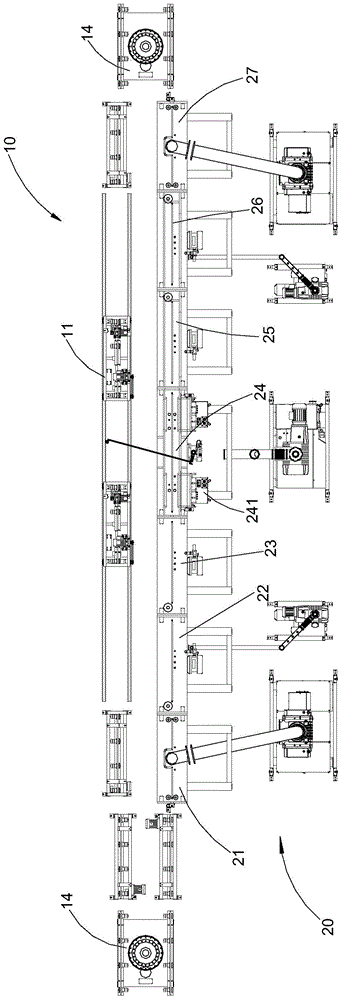

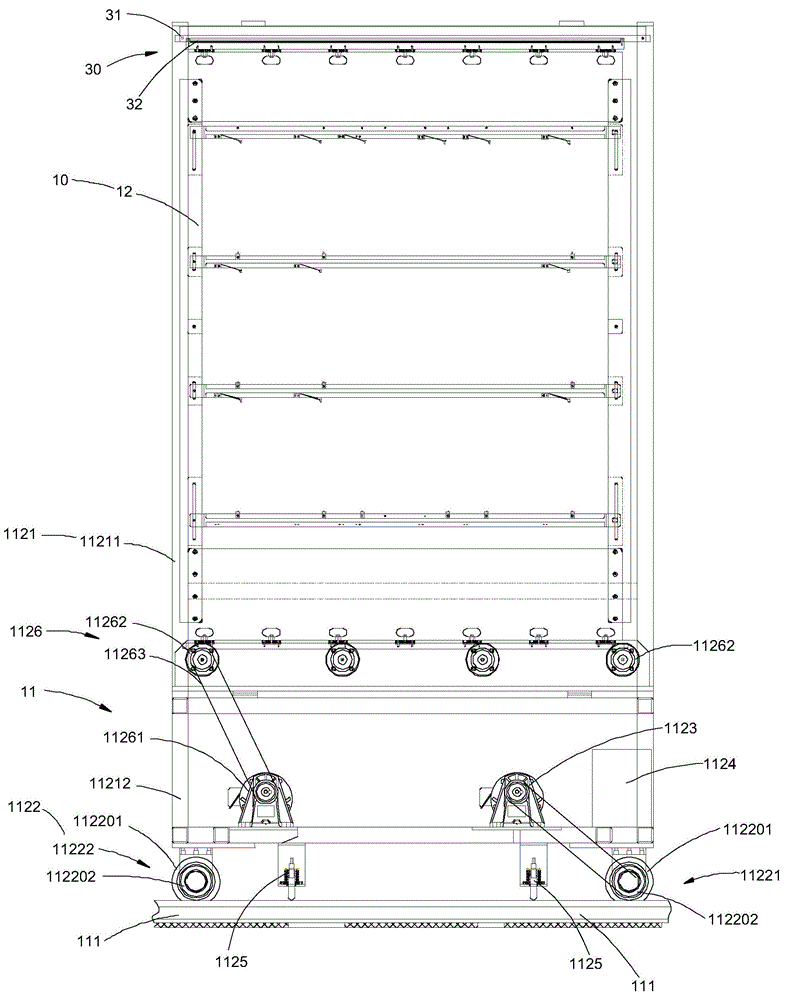

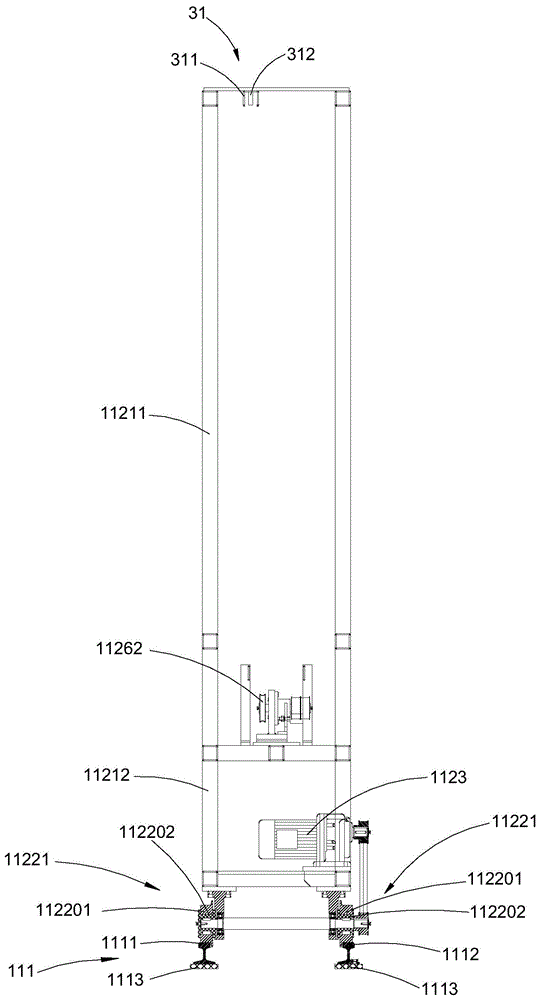

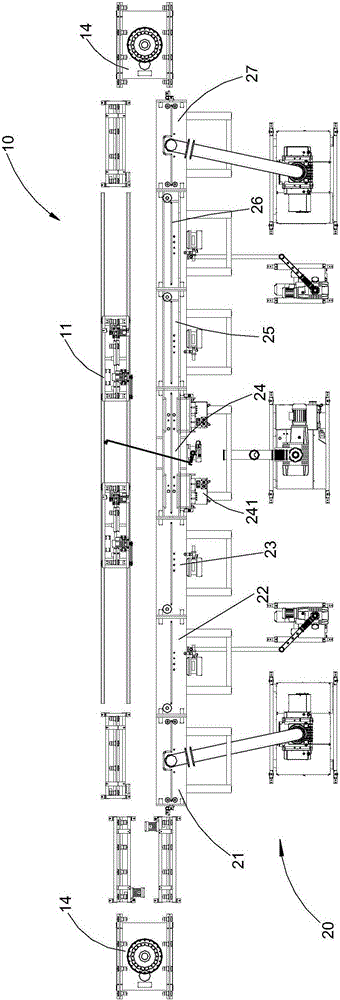

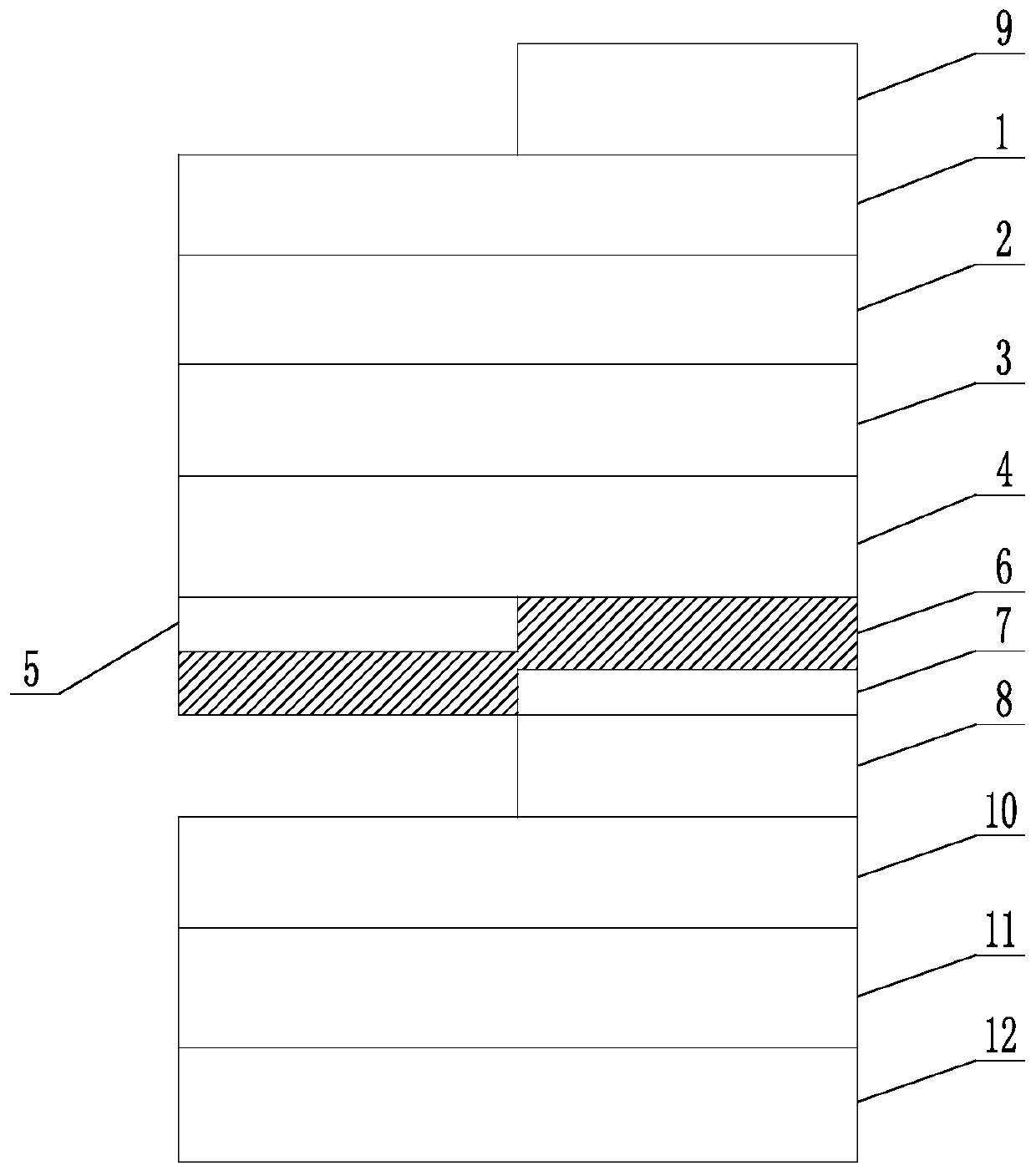

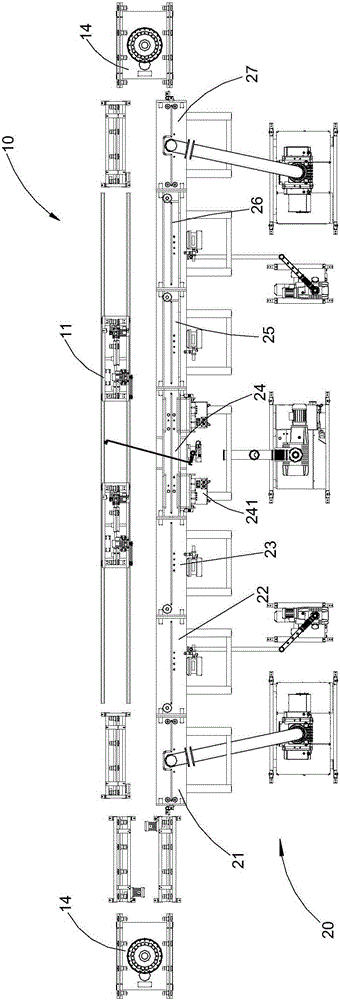

Vertical vacuum sputtering coating production line

ActiveCN104004999ASmall footprintHigh economic valueVacuum evaporation coatingSputtering coatingSputteringProduction line

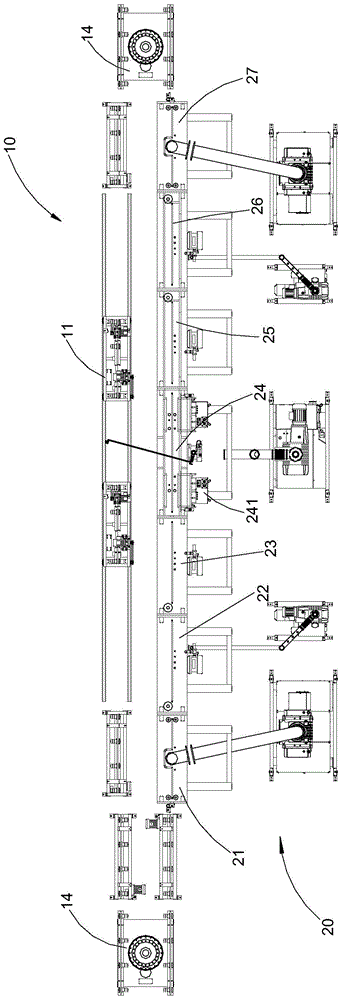

The invention discloses a vertical vacuum sputtering coating production line. The vertical vacuum sputtering coating production line comprises a transmission assembly line and a coating assembly line, wherein the coating assembly line is connected with the transmission assembly line. The transmission assembly line comprises a rail, at least one transmission trolley and at least one substrate carrying device. The transmission trolley runs on the rail and transmits the substrate carrying device. The coating assembly line comprises an inlet cavity, an inlet transition cavity, an inlet buffer cavity, a coating cavity, an outlet buffer cavity, an outlet transition cavity and an outlet cavity. Compared with the prior art, the transmission assembly line and the coating assembly line are connected end to end to form an annular assembly line, so that the occupied area is saved; intelligent control is adopted for substrate transmission in the whole coating production line, so that manpower and material resources are saved, and production efficiency is improved; all cavities in the coating assembly line are replaced or added according to requirements of products, so that the whole coating production line meets the requirements of various coating processes; andthe service life is prolonged, resources are saved, and therefore the vertical vacuum sputtering coating production line has quite wide application prospects.

Owner:XIANGTAN HONGDA VACUUM TECH CO LTD

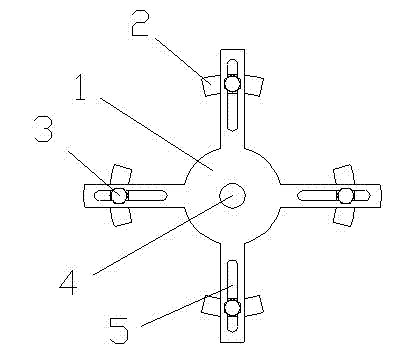

Coiling rod with changeable diameter

The invention discloses a coiling rod with a changeable diameter. The coiling rod with the changeable diameter comprises a cross-shaped supporting body, movable pads, fixing bolts, a positioning center hole and sliding regulating grooves, wherein the cross-shaped supporting body comprises a circular iron block and four supporting rods located on the periphery of the iron block, the positioning center hole is located in the center of the circular iron block, the number of the sliding regulating grooves is 4, the sliding regulating grooves are located on the four supporting rods respectively, each supporting rod is connected with the corresponding movable pad, and the movable pads are connected with the supporting rods through the fixing bolts. Through the mode, according to the coiling rod with the changeable diameter, the mode that fixation is achieved in a sliding mode through the bolts is adopted to change the center distances of the movable pads, and therefore the diameter of the coiling rod can be changed, the coiling rod can be adapted to different products, regulation is convenient and fast, and cost performance is high.

Owner:吴中区甪直渡岘工艺品厂

Vacuum coating production line

ActiveCN104018130ASmall footprintHigh economic valueVacuum evaporation coatingSputtering coatingProduction lineAssembly line

The invention discloses a vacuum coating production line which comprises a conveying assembly line and a coating assembly line, wherein the coating assembly line is connected with the conveying assembly line; the conveying assembly line comprises a rail, at least one conveying trolley and at least one mounting device; and the conveying trolley operates on the rail, and the mounting devices are conveyed by the conveying trolley; the coating assembly line comprises an inlet cavity, an inlet transition cavity, an inlet buffer cavity, a coating cavity, an outlet buffer cavity, an outlet transition cavity and an outlet cavity. Compared with the prior art, the conveying assembly line and the coating assembly line are connected end to end to form an annular assembly line, the occupied area is saved, substrate transmission in the whole coating production line is intelligently controlled, manpower and material resources are saved, the production efficiency is improved, each cavity in the coating assembly line is replaced or increased according to the product needs, the whole coating production line meets the requirements of multiple coating processes, the service life is prolonged, and the resources are saved. Therefore, the application prospect is wide.

Owner:XIANGTAN HONGDA VACUUM TECH CO LTD

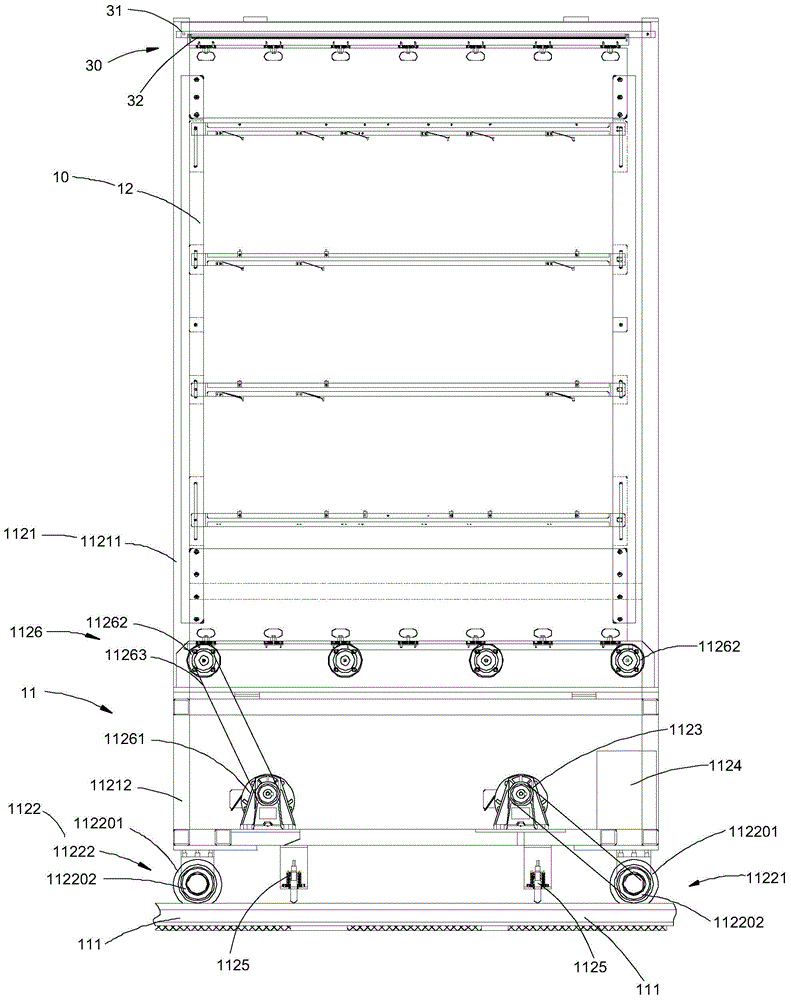

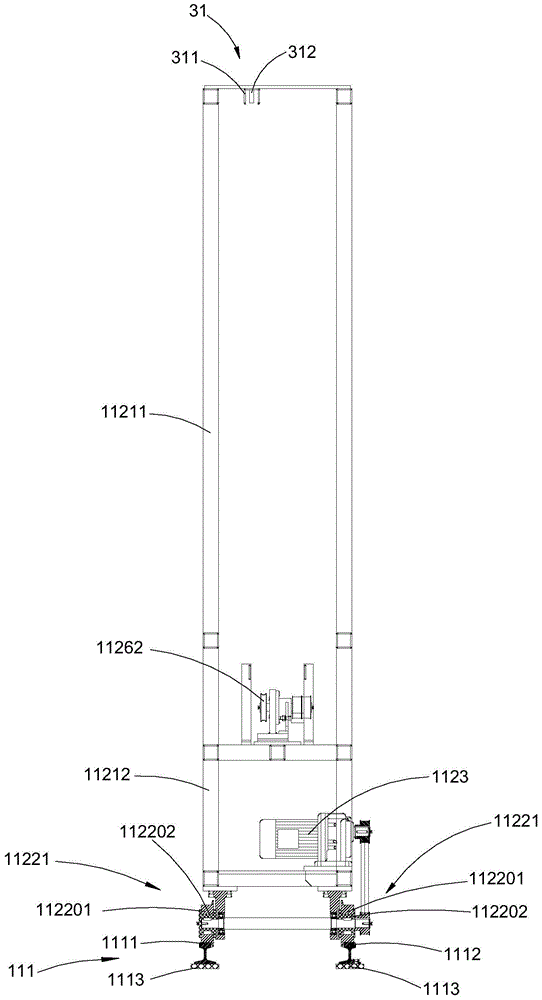

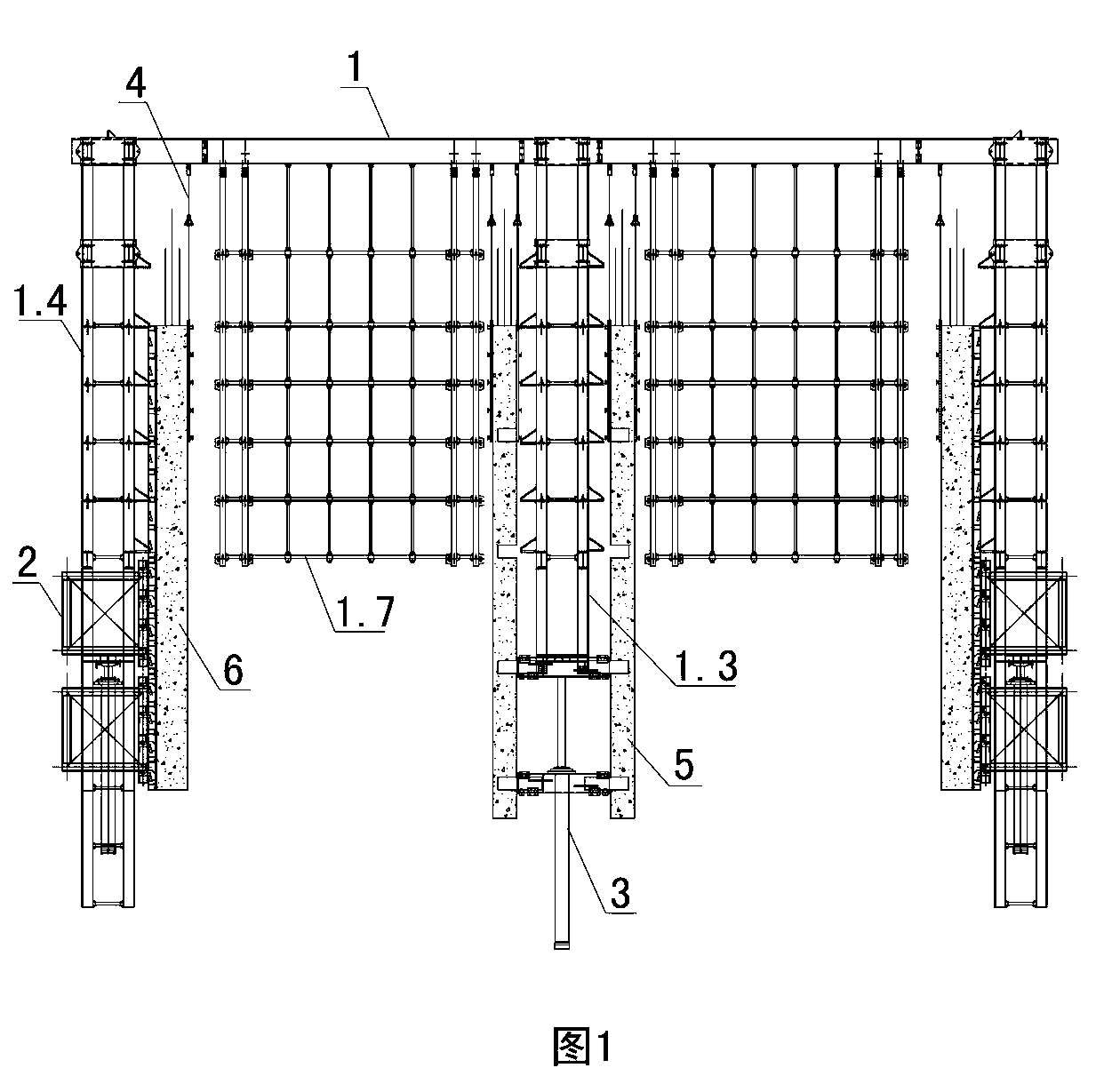

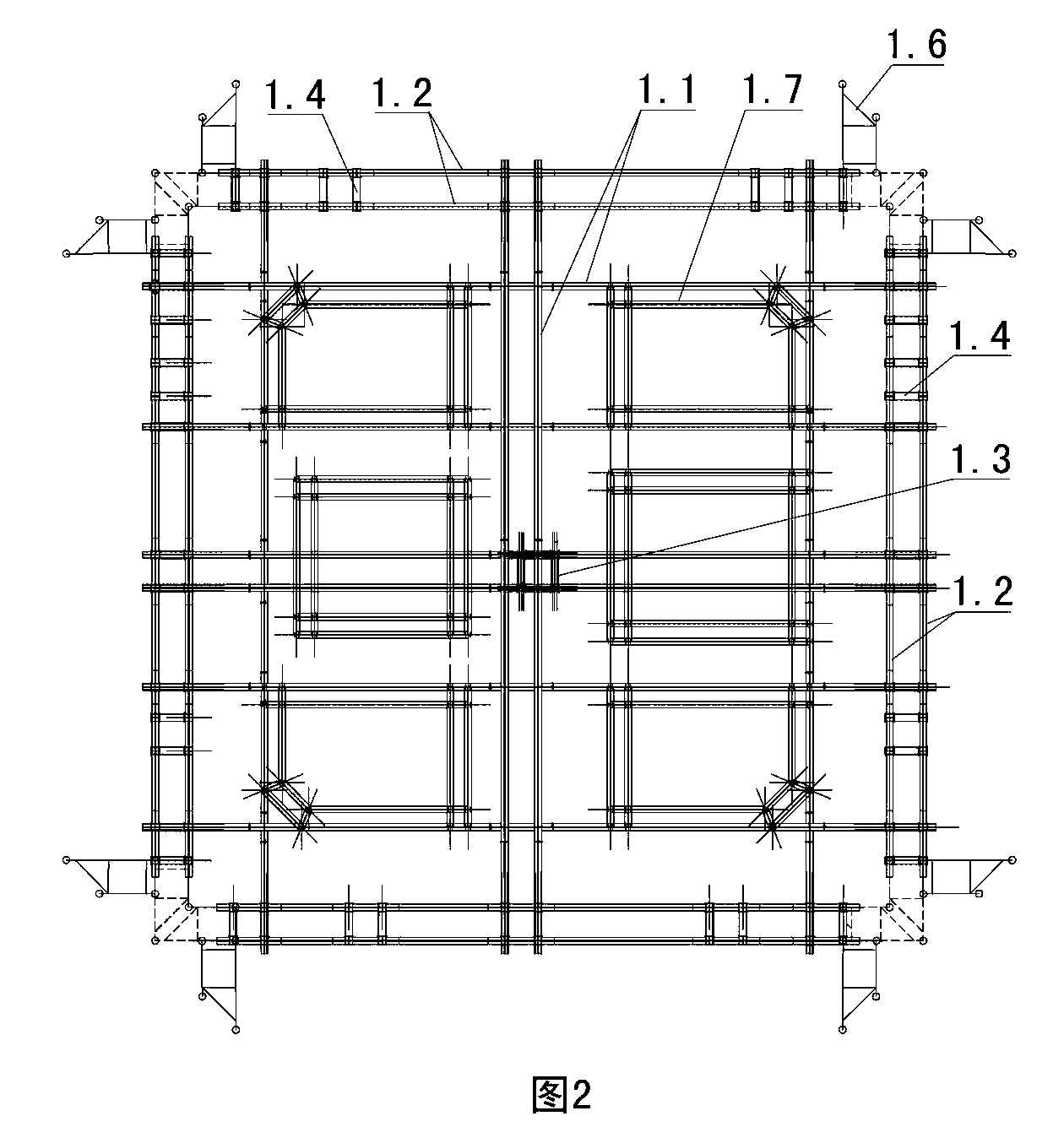

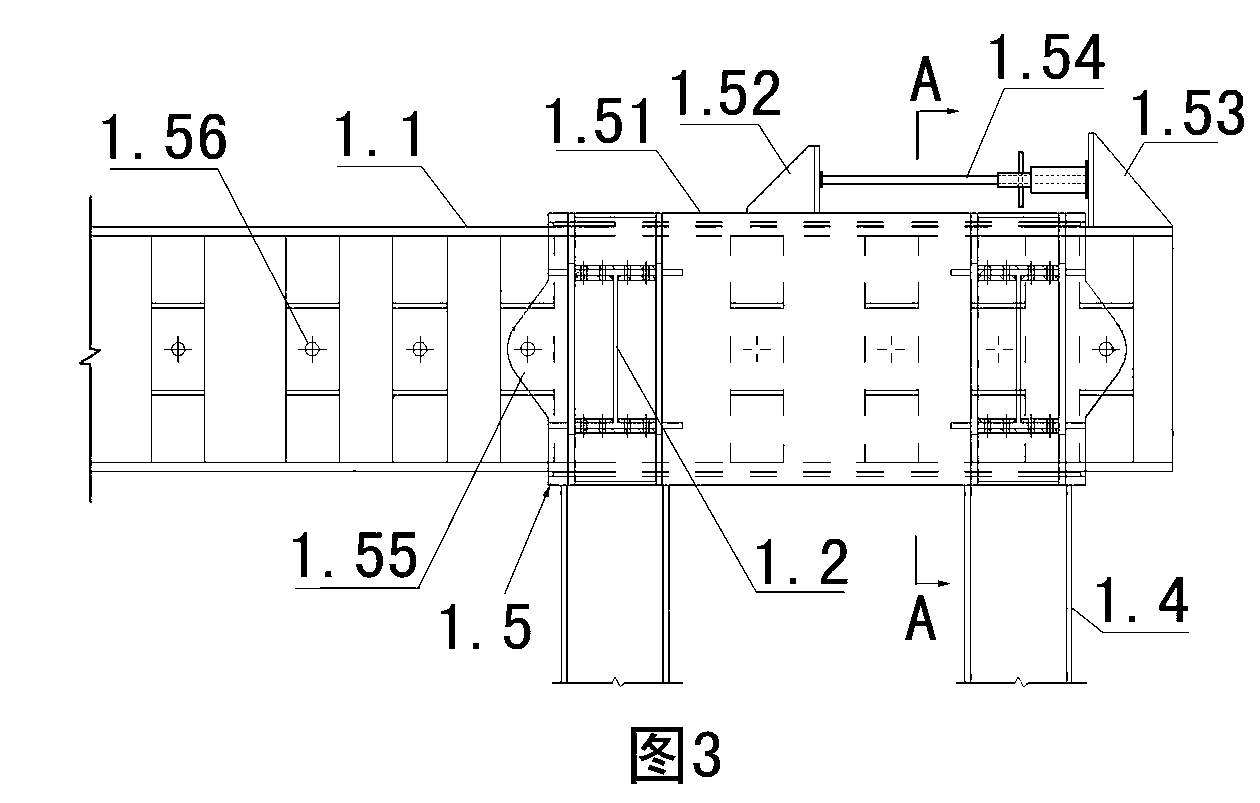

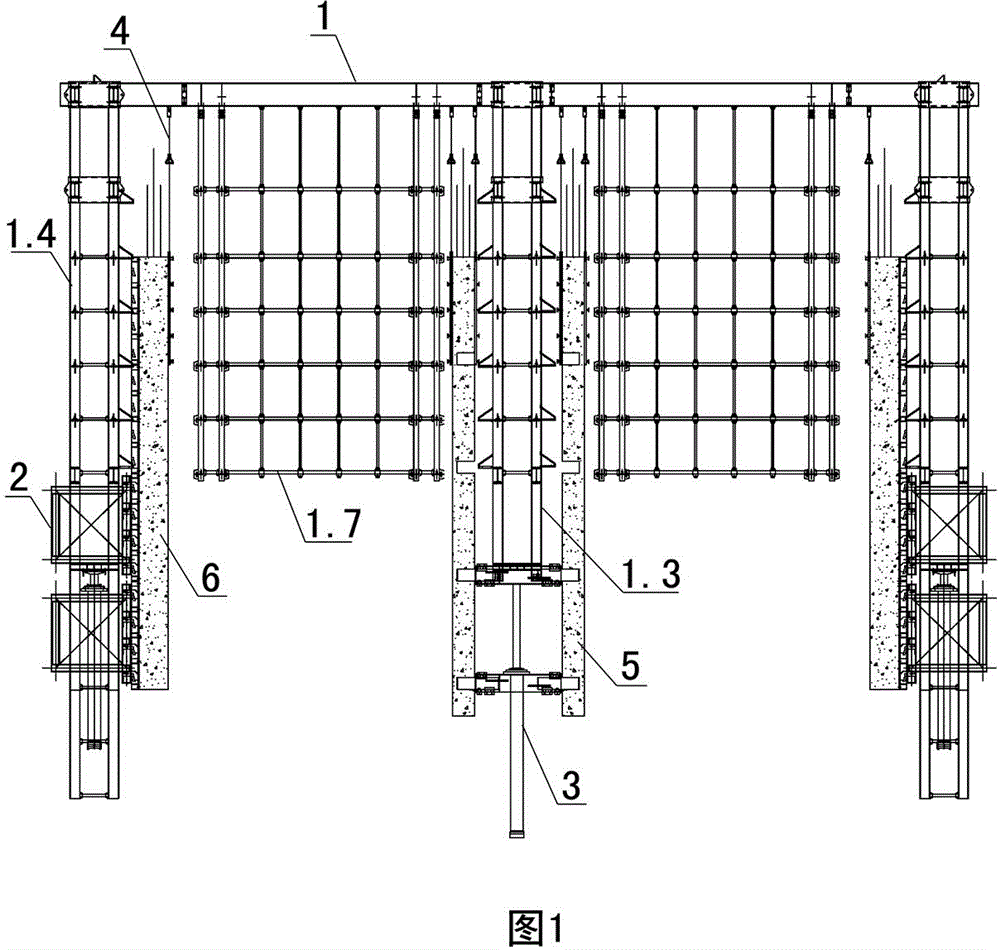

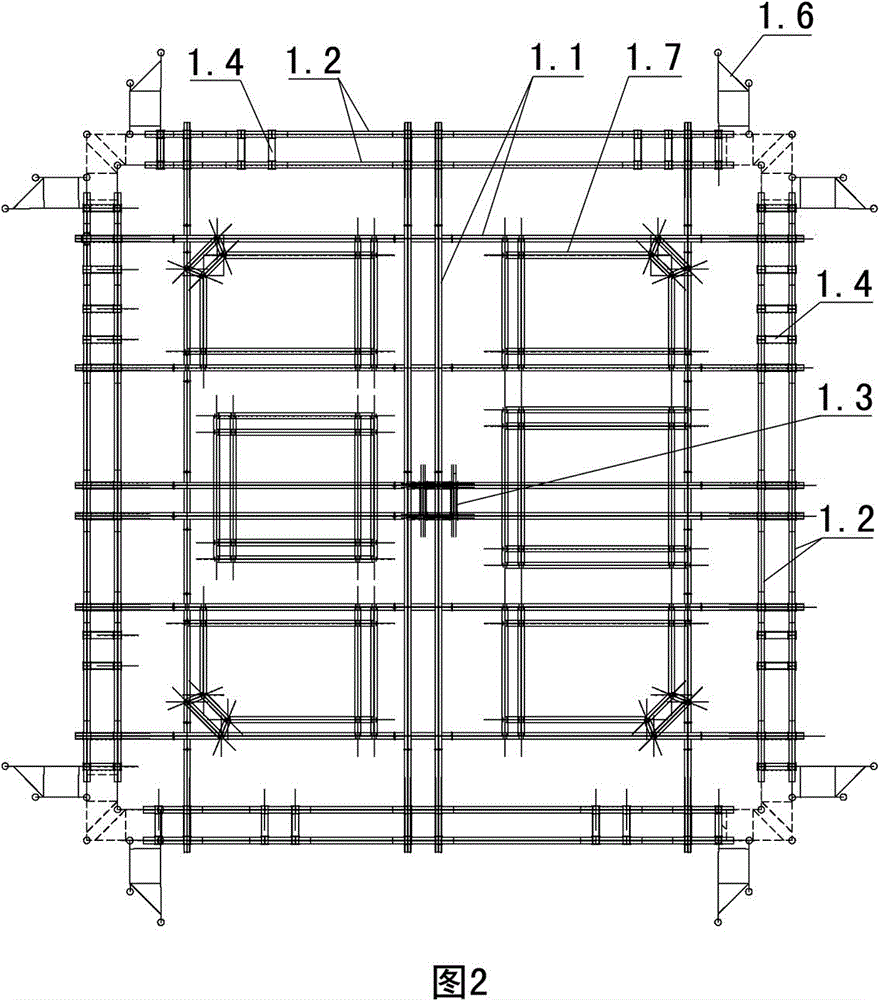

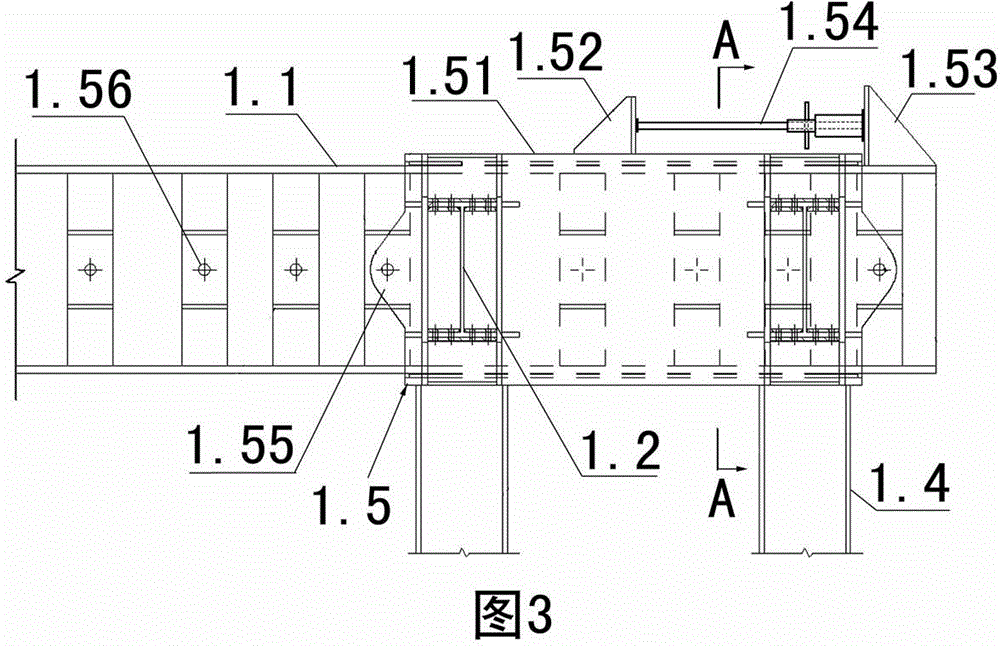

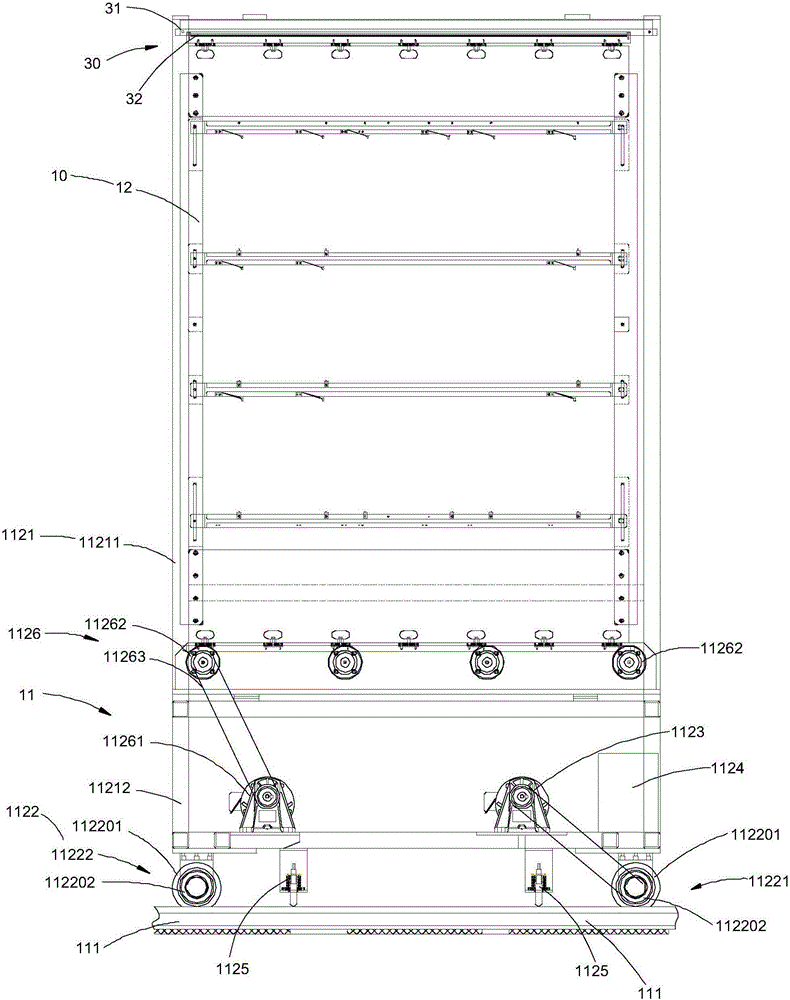

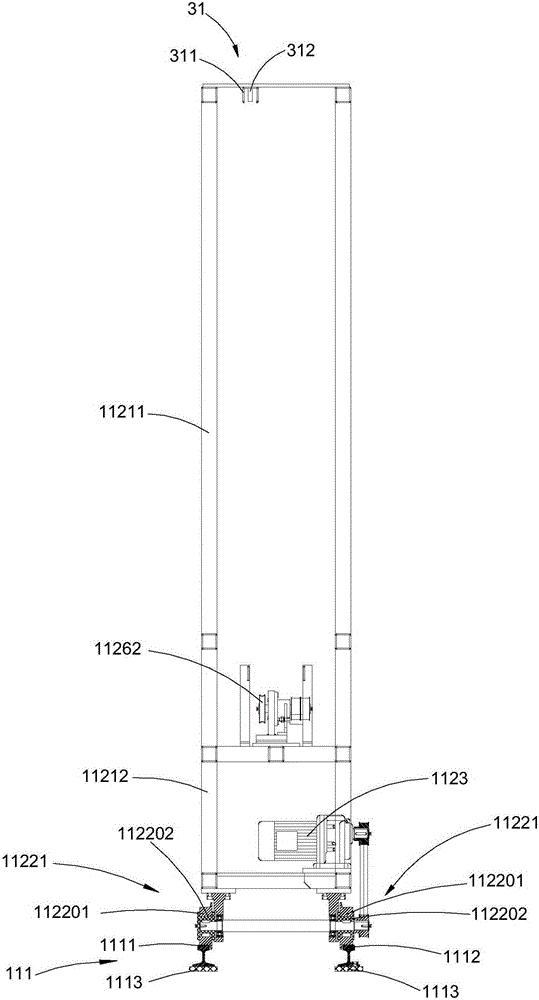

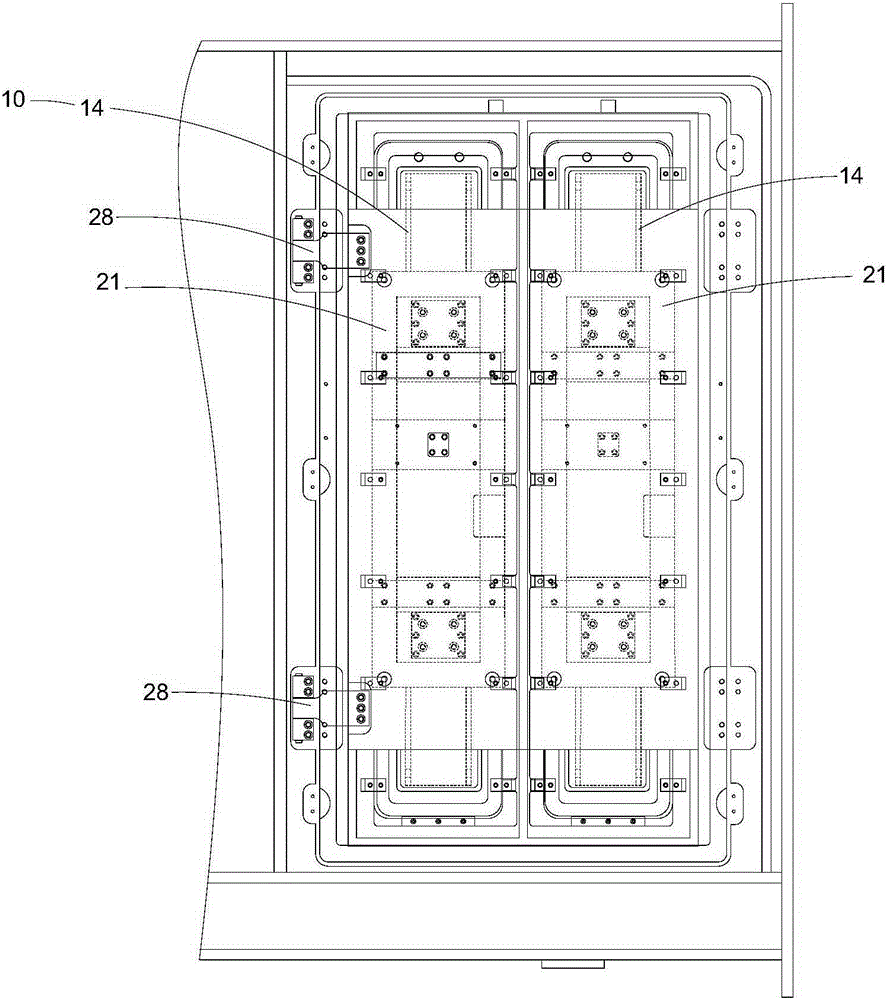

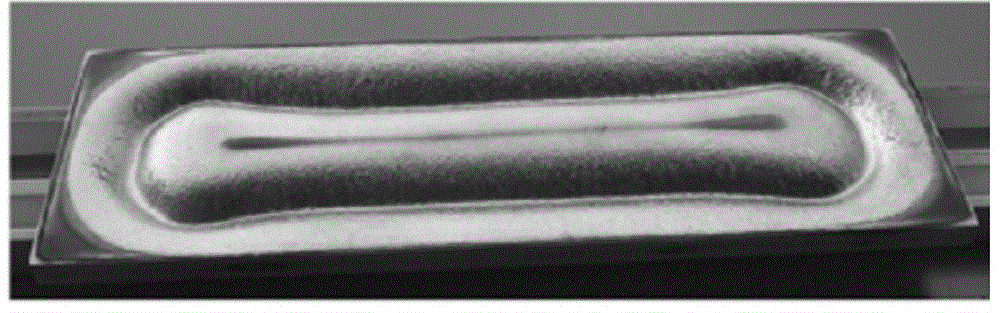

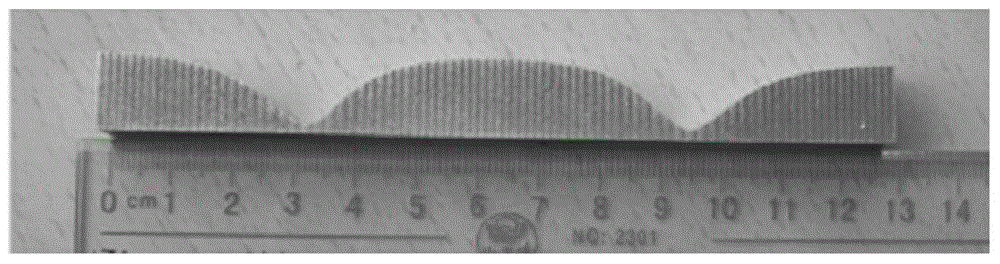

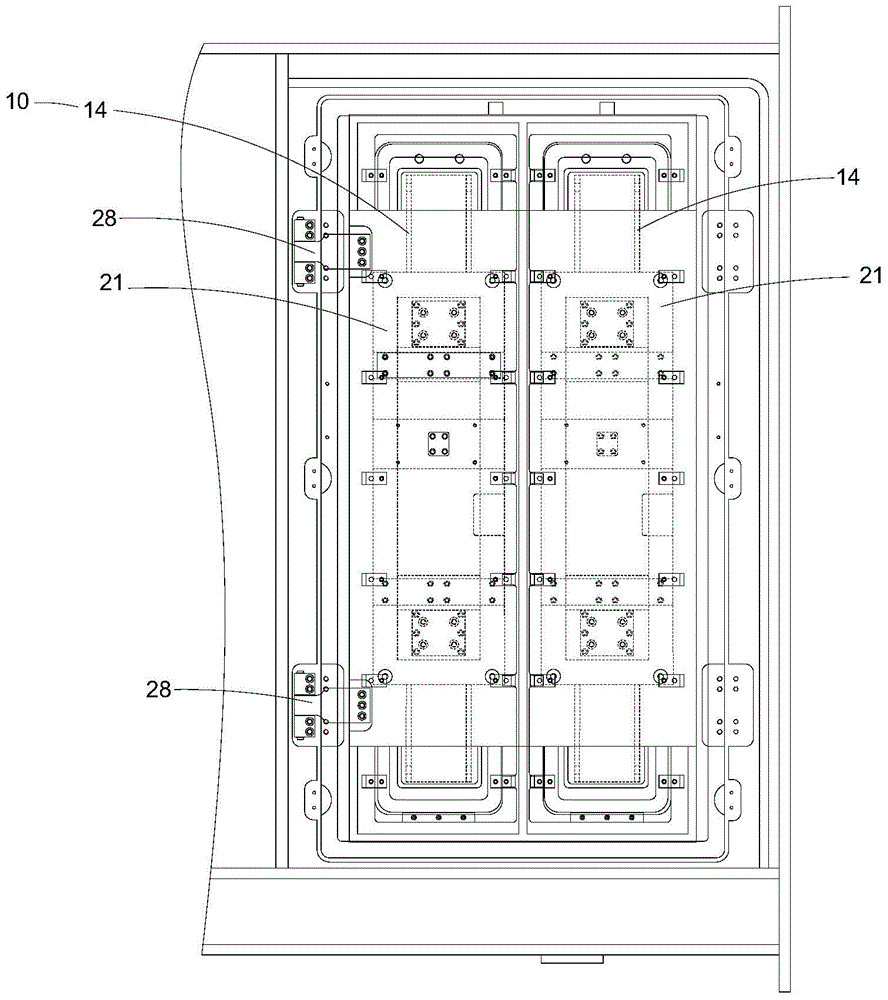

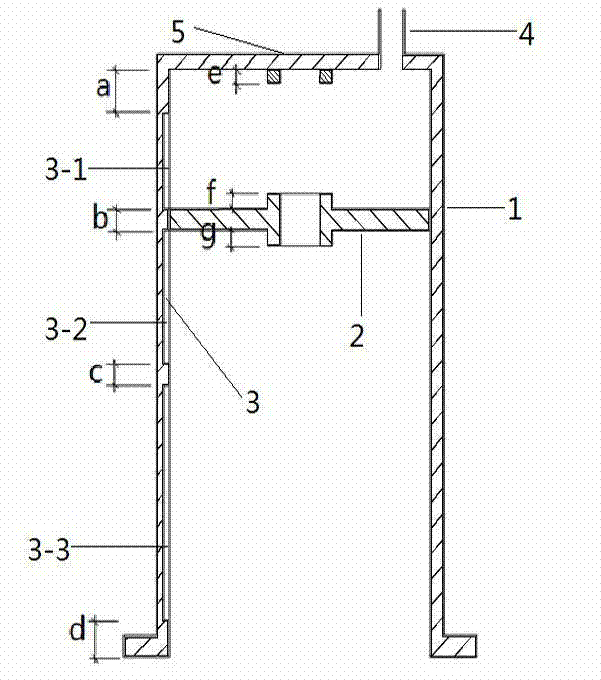

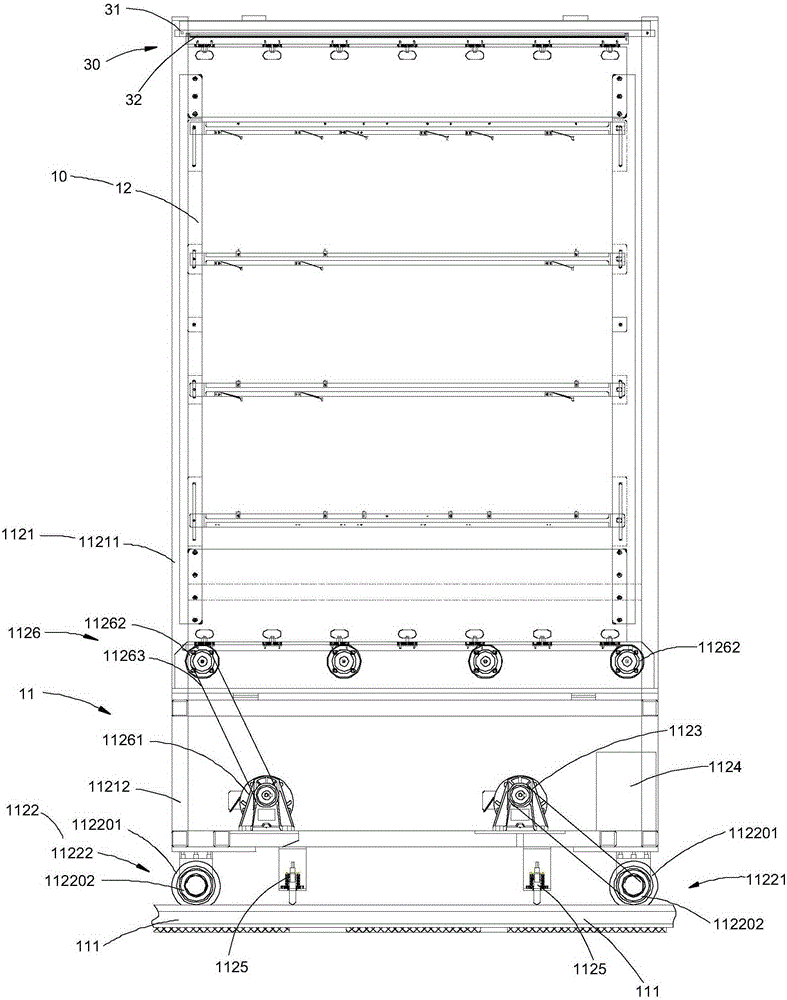

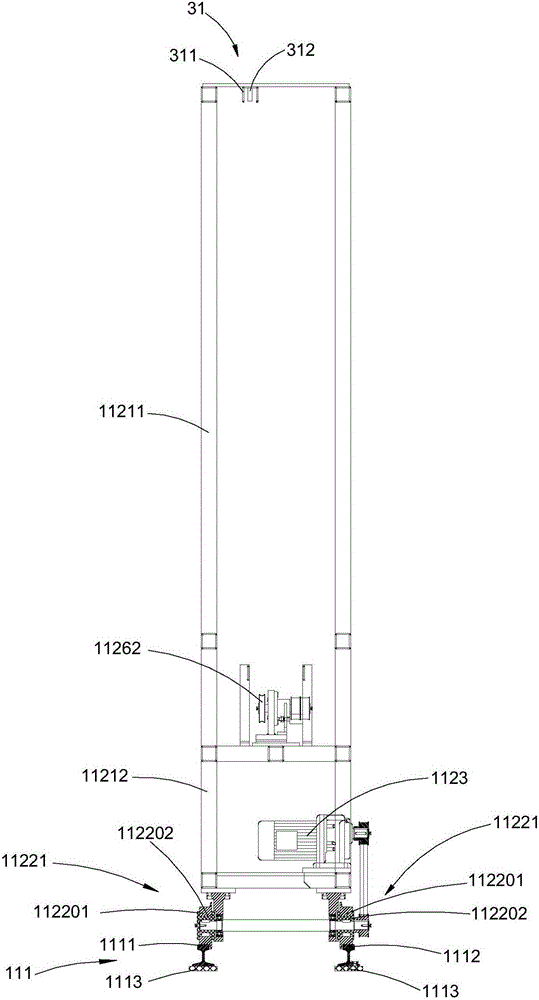

Intelligent construction platform for construction of super high-rise building

ActiveCN102839812AMonitor the force conditionEasy to climbBuilding support scaffoldsSteel frameHigh rise

An intelligent construction platform for construction of a super high-rise building comprises a support and jacking system, a steel frame system and a template system, wherein the support and jacking system is connected with a shear wall in a support manner; the steel frame system is connected with the support and jacking system in a support manner; the template system is hung on the steel frame system; the steel frame system comprises a main platform rack with a rectangular platform surface, an external frame located on the four sides of the main platform rack, a hanging rack, an internal support upright, and an external support upright arranged at the lower part of the external frame; the hanging rack and the internal support upright are arranged at the lower part of the main platform rack; the support and jacking system consists of an internal frame support and jacking system and an external frame support and jacking system; the internal support upright is connected with an internal shear wall in a support manner by the internal frame support and jacking system; and the external support upright is connected with an external shear wall in a support manner by the external frame support and jacking system. The construction platform can climb quickly and conveniently, has a better adaptability to the change in the cross section of a core tube shear wall, and can reduce conflicts among a formwork system, and steel structure construction and vertical transportation facilities in the process of core tube structure construction.

Owner:CHINA CONSTR THIRD ENG BUREAU GRP CO LTD

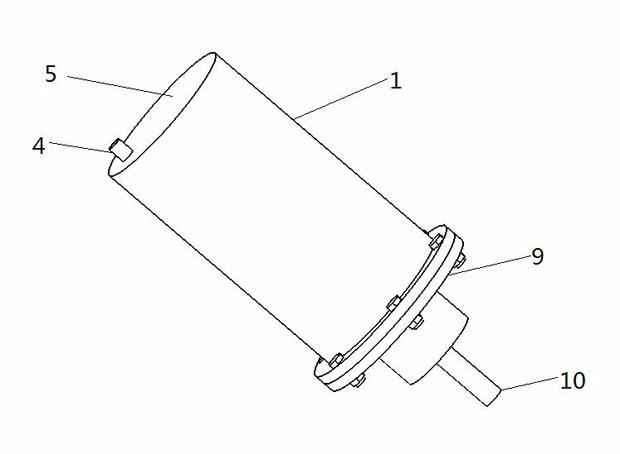

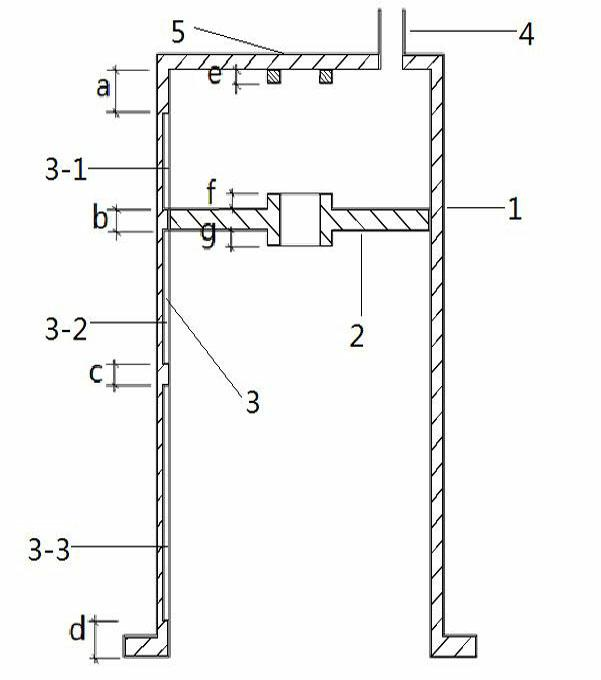

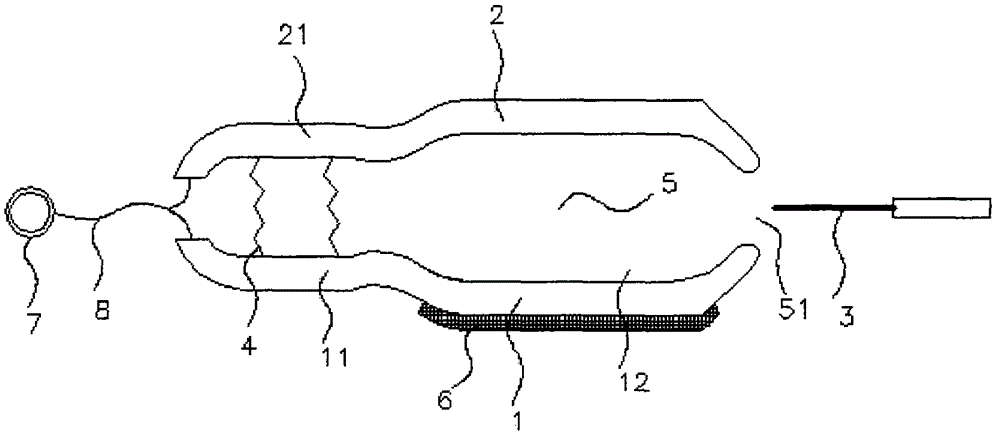

Air spring appending air chamber structure with variable volume

The invention discloses an air spring appending air chamber structure with variable volume for a vehicle, and the structure comprises a cylindrical appending air chamber cavity body of which the two ends are provided with openings, wherein the middle axle of the inner cavity of the appending air chamber cavity body is provided with a screw rod of which the upper end is connected with an external driving device; the screw rod in the appending air chamber cavity body is sheathed with a piston by a screw rod pair, the outer wall of the piston is tightly matched with the inner wall of the appending air chamber cavity body, and the appending air chamber cavity body is divided into an effective volume cavity and a spare volume cavity; the whole inner wall of the appending air chamber cavity body is provided with a piston rotation-limiting groove along the axial direction, and the edge of the piston is provided with a protruding part which is clamped in the piston rotation-limiting groove; the inner wall of the appending air chamber cavity body is provided with three vent grooves at interval along the axial direction; and a gap between every two vent grooves and the thickness of the piston are equal. The air chamber structure provided by the invention has the advantages of simple structure and small volume, and can be used for effectively and reliably achieving the variable volume ofthe appending air chamber.

Owner:JIANGSU UNIV

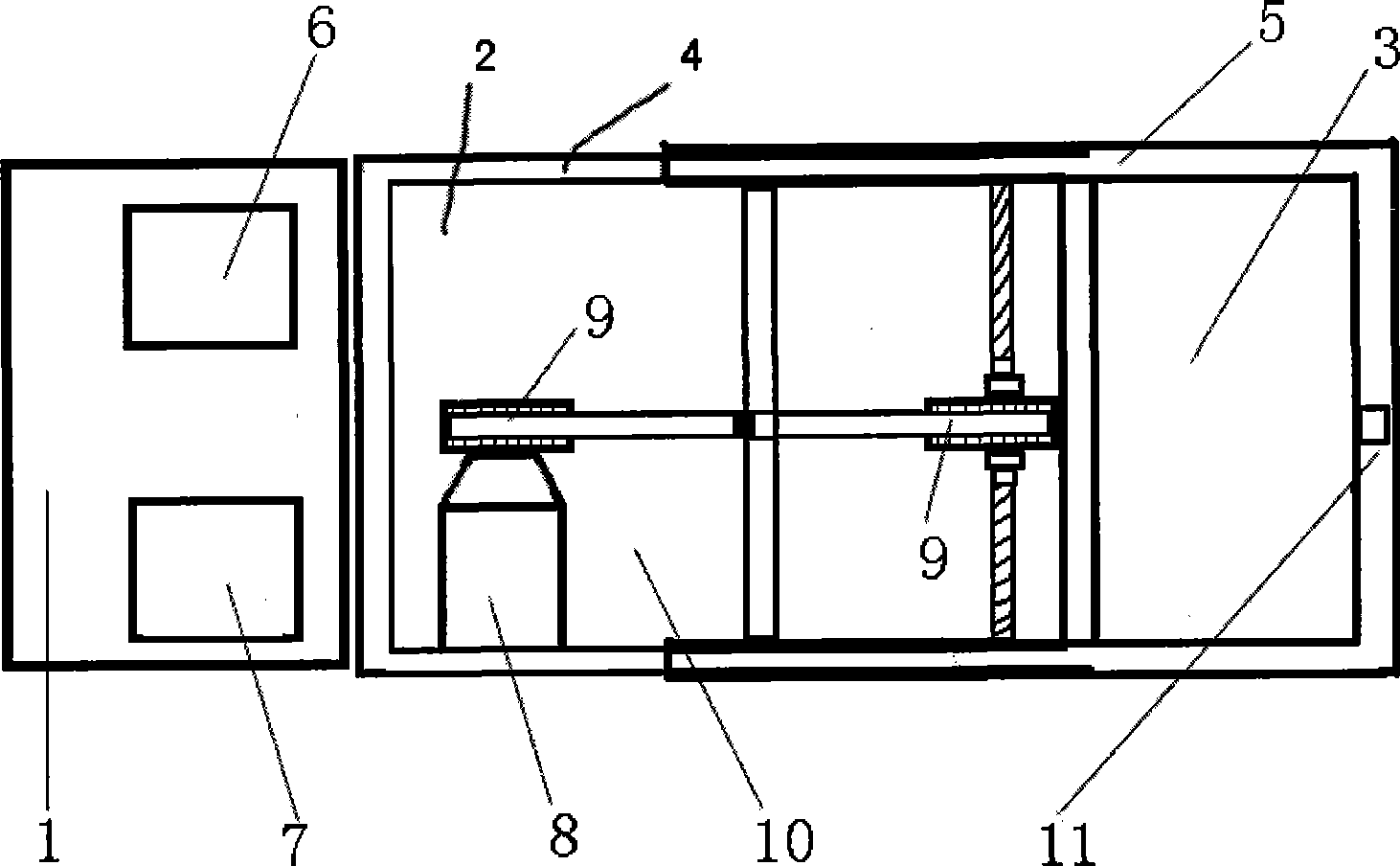

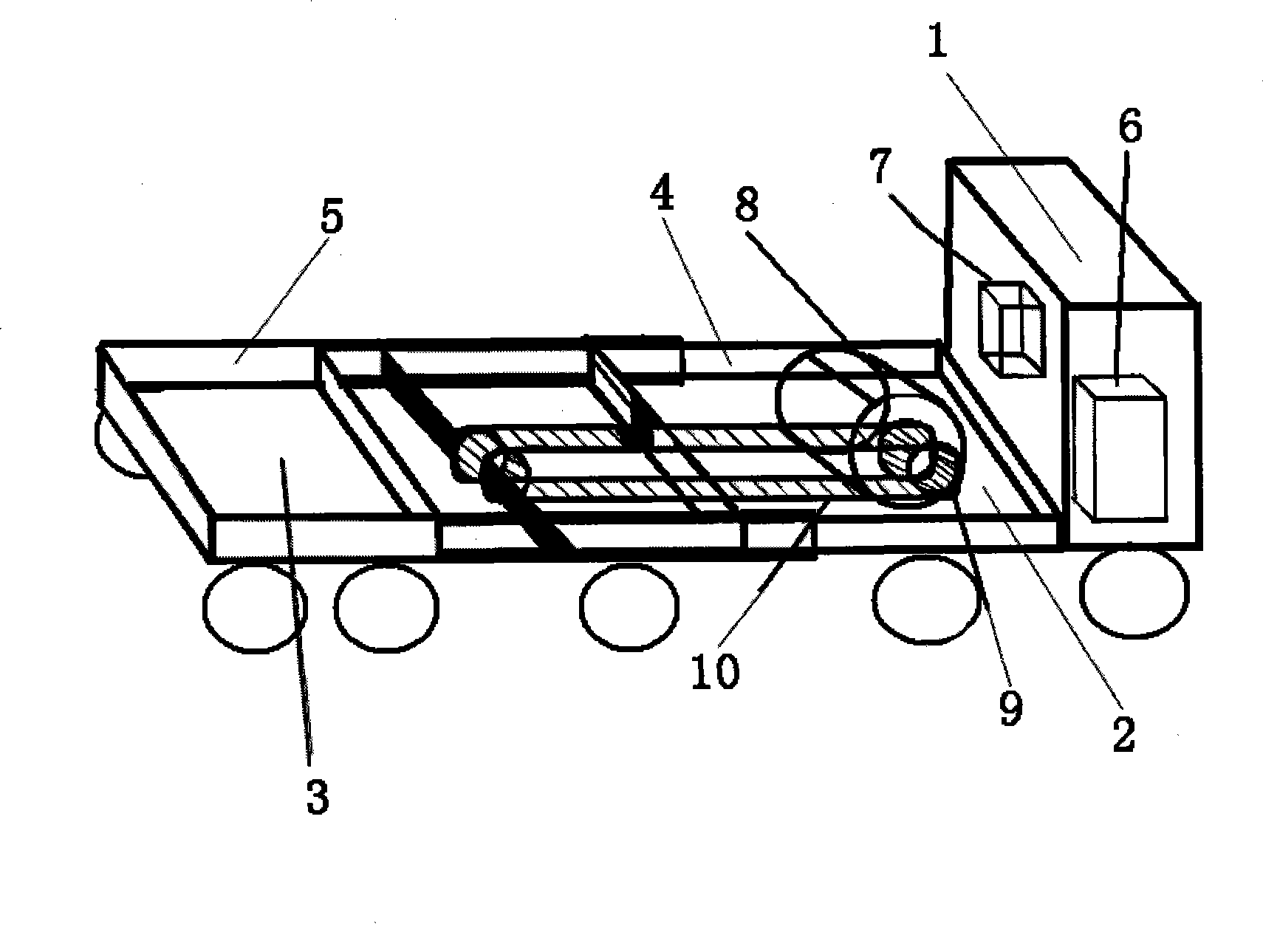

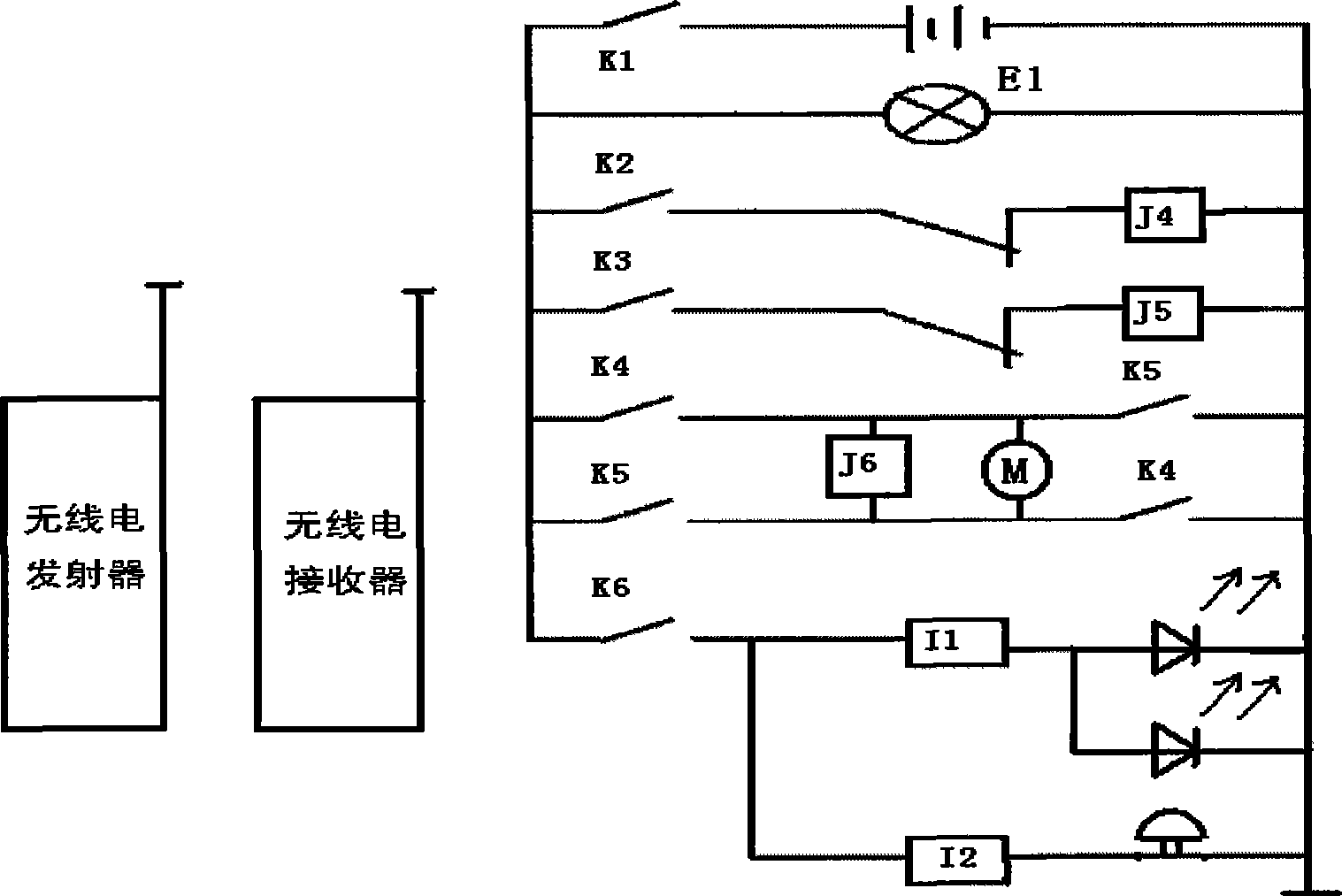

Automatic deforming truck

InactiveCN101391622AImplement variableTo achieve the effect of automatic deformationUnderstructuresVehiclesElectric machineryEngineering

The technical problem needs to be solved by the invention is to provide a truck with the automatic deformation function. The adopted technical proposal is as follows: the truck with the automatic deformation comprises a base and is characterized in that: the base is divided into a front part and a back part which both adopt U-shaped base frameworks, wherein, one U-shaped base framework is hollow, and the other U-shaped base framework can be inserted in the hollow base framework. The truck with the automatic deformation further comprises a motor and at least one belt gear which is driven by the motor and respectively positioned at the front and the back bases, and the belt gears of the front and the back bases are connected through a synchronous belt. The adoption of the heavy container truck with the automatic deformation can save the space of a dock, accelerate the handling efficiency of a container and reduce the handling costs.

Owner:上海市吴淞中学

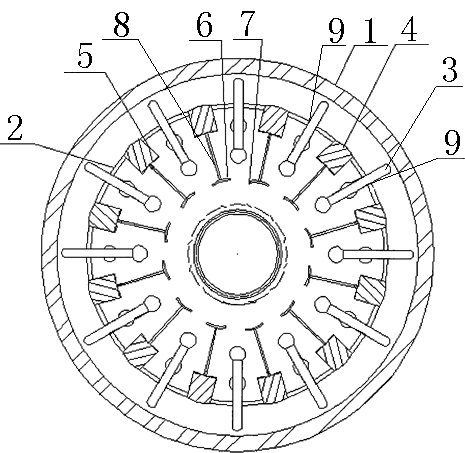

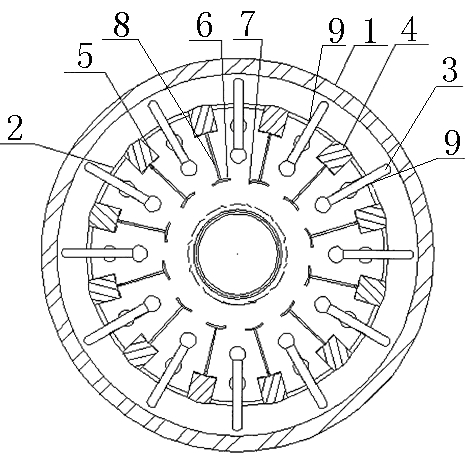

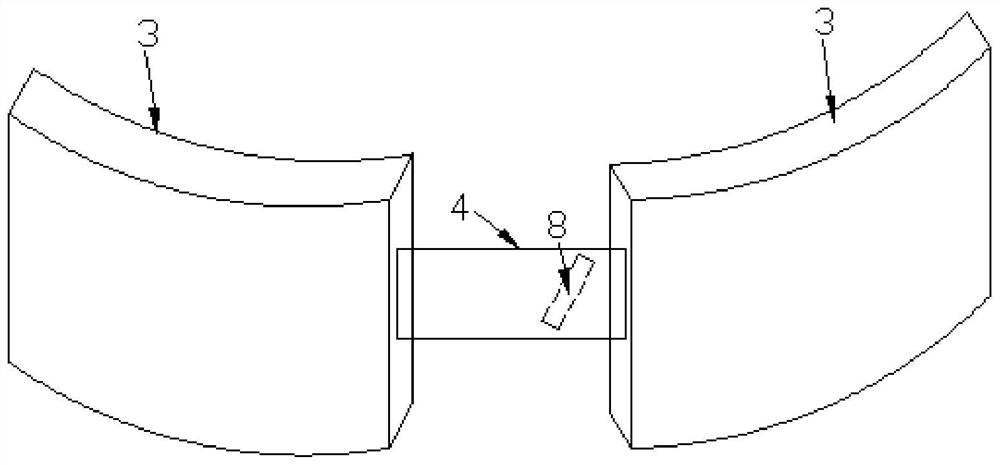

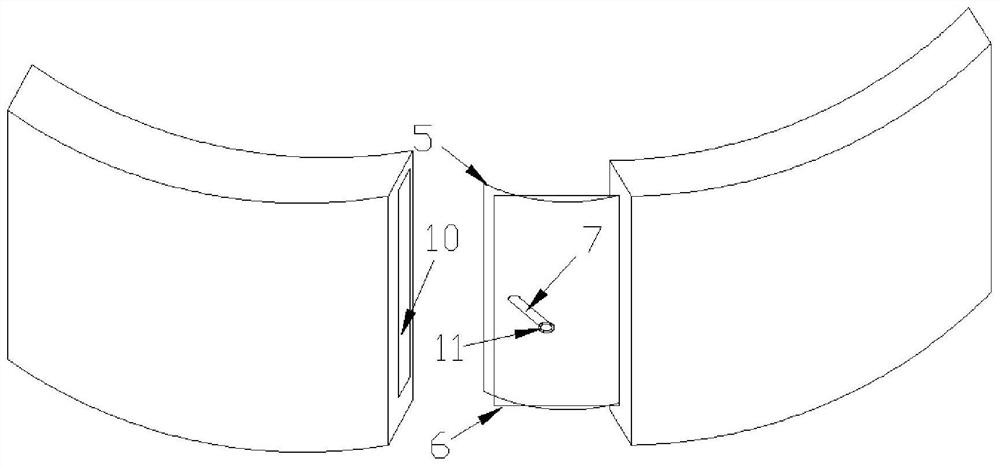

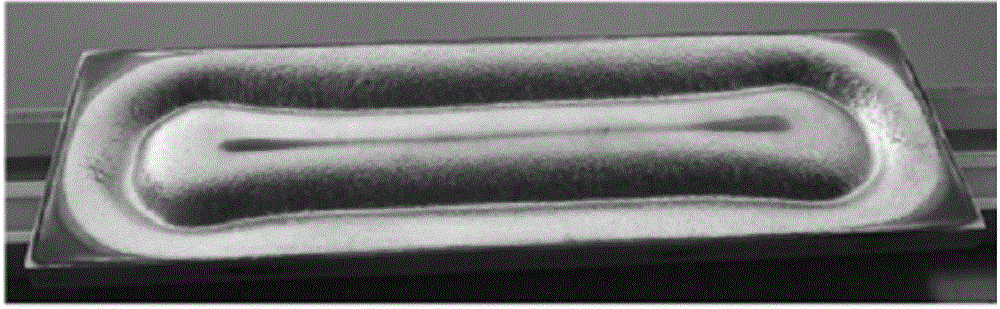

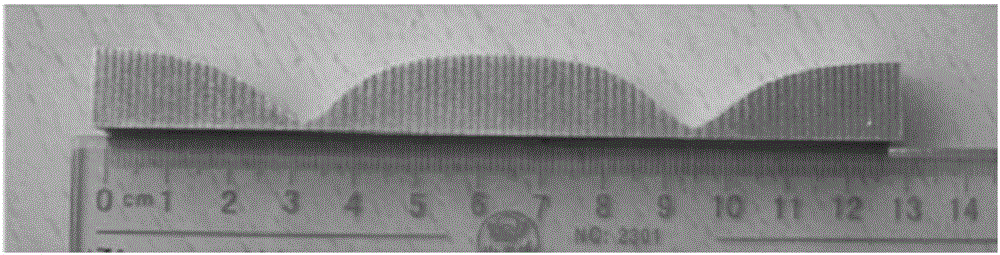

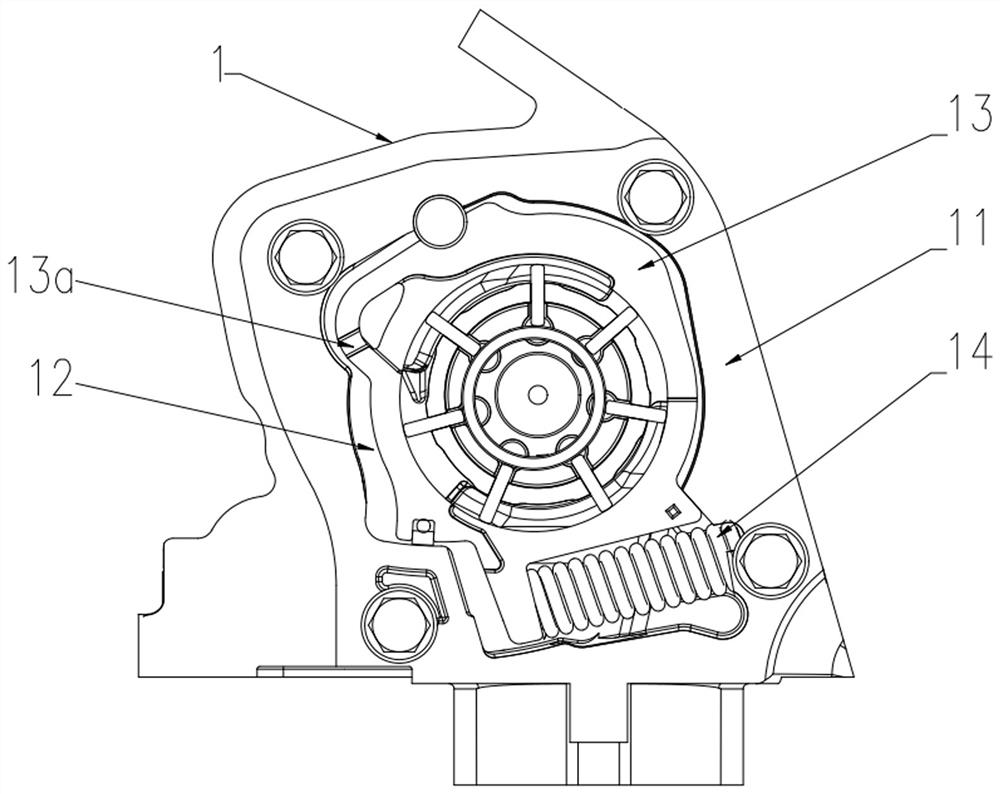

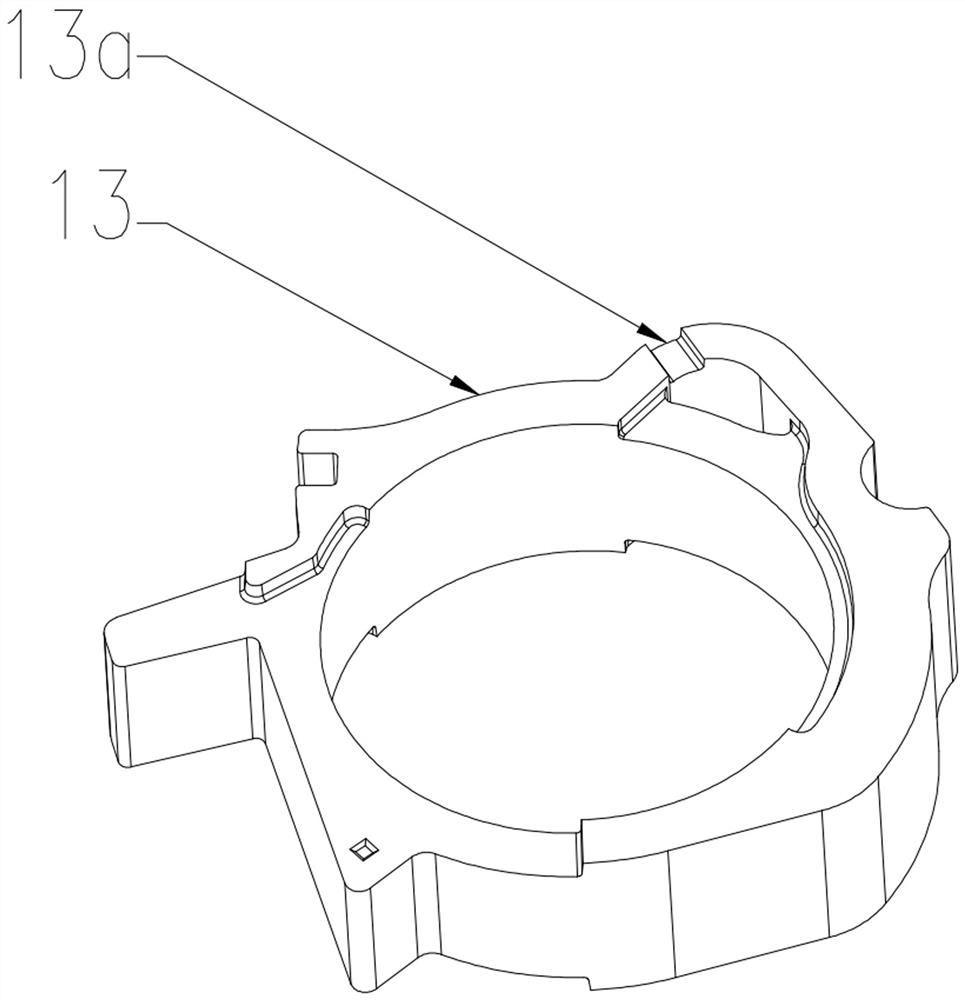

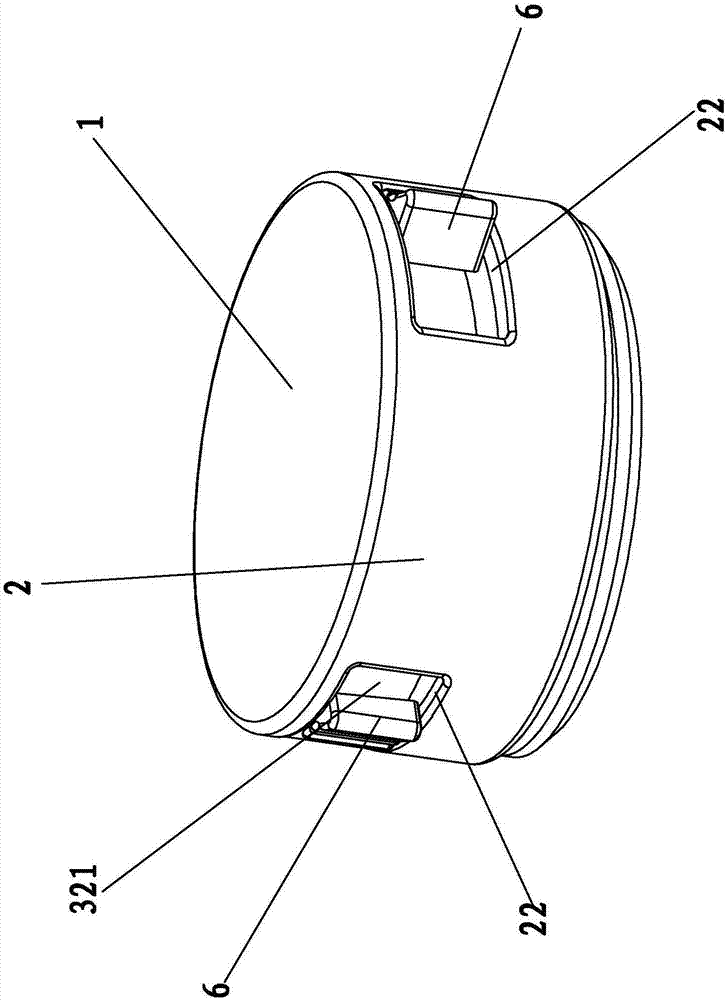

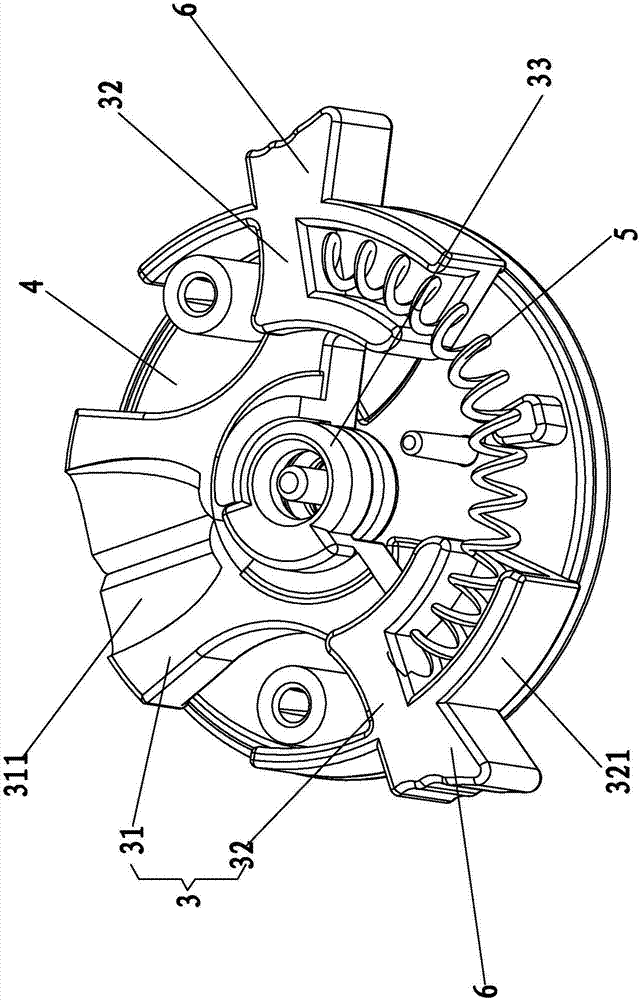

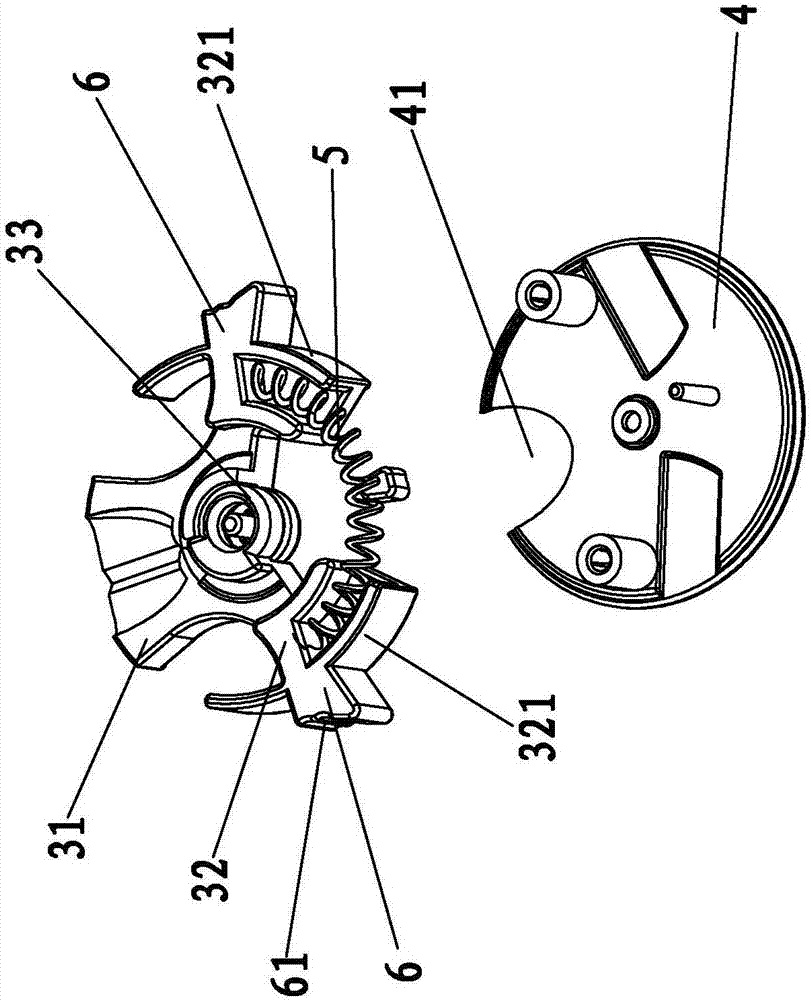

Steering pump device of double-acting variable vane

InactiveCN101985932ALarge effective volumeImplement variableRotary piston pumpsRotary piston liquid enginesEnergy lossLeaf spring

The invention discloses a steering pump device of a double-acting variable vane, comprising a stator, a rotor and a vane. The vane is installed in a vane groove on the rotor. A sliding groove is arranged between every two vane grooves on the rotor. The inside of the sliding groove is equipped with a sliding block. A spring groove is opened within the rotor to mount a single-leaf spring. The single-leaf spring is connected with the sliding block through a long-pole screw. The sliding block is slidable vertically within the groove. The sliding of the sliding block is limited through the sliding groove. By adopting the steering pump of the invention in the technical scheme, a state that the displacement of the steering pump is increased with the increasing of an engine speed is changed through arranging the sliding groove between the two vanes of the rotor, which effectively reduces the output of excess flow within the steering pump, and the energy loss caused by the excess flow generated by throttling an overflow valve.

Owner:SHANGHAI MARITIME UNIVERSITY

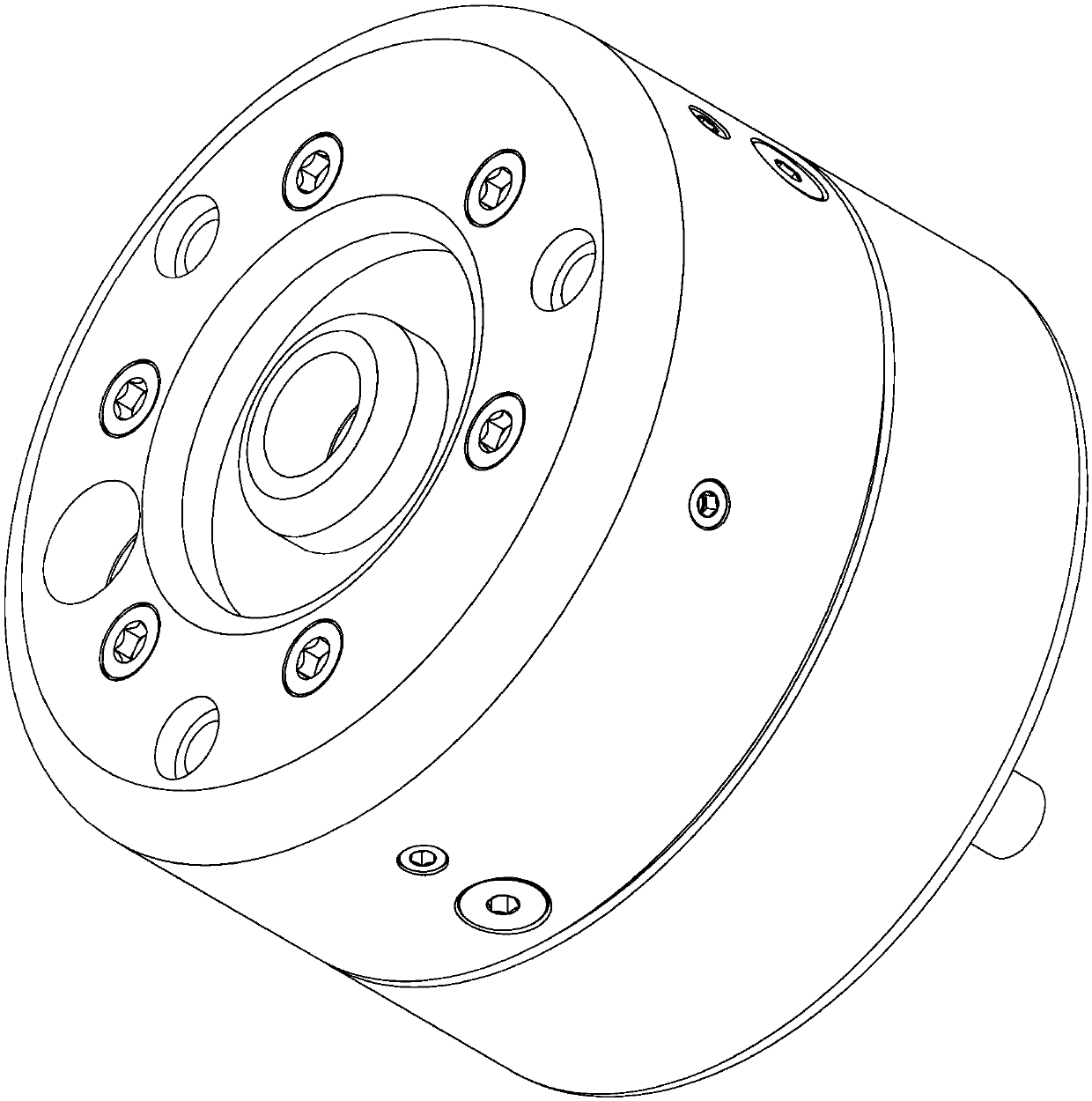

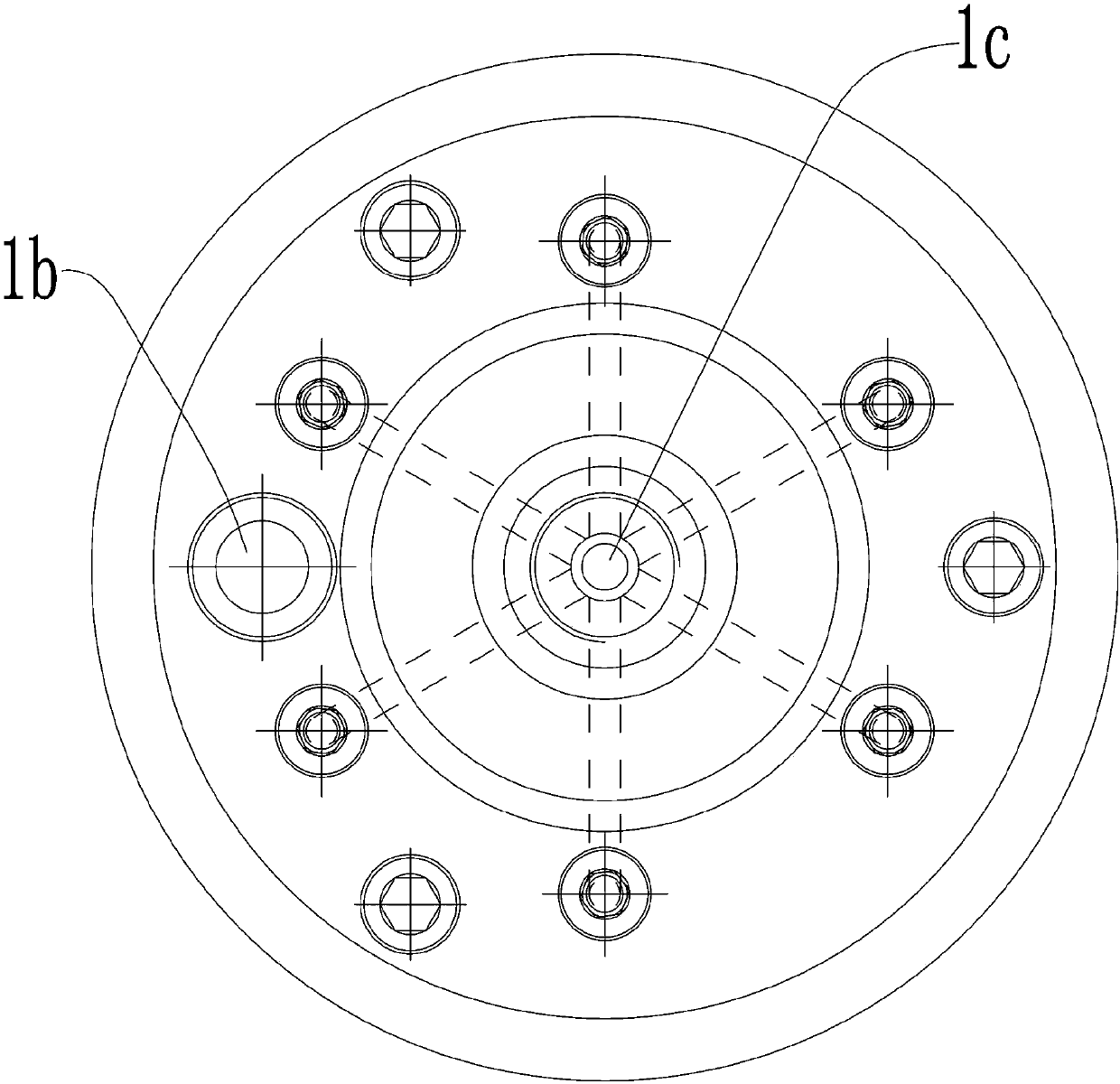

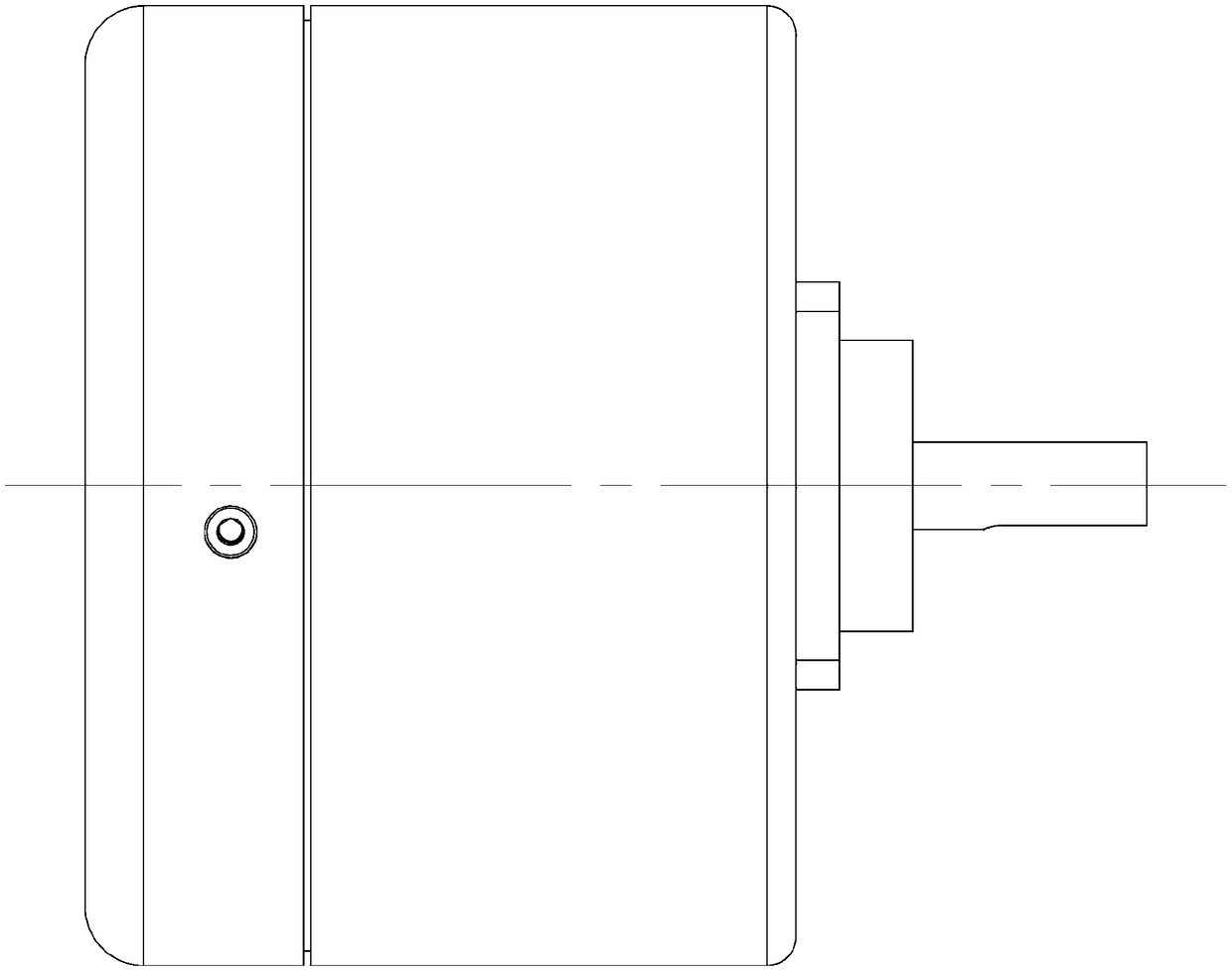

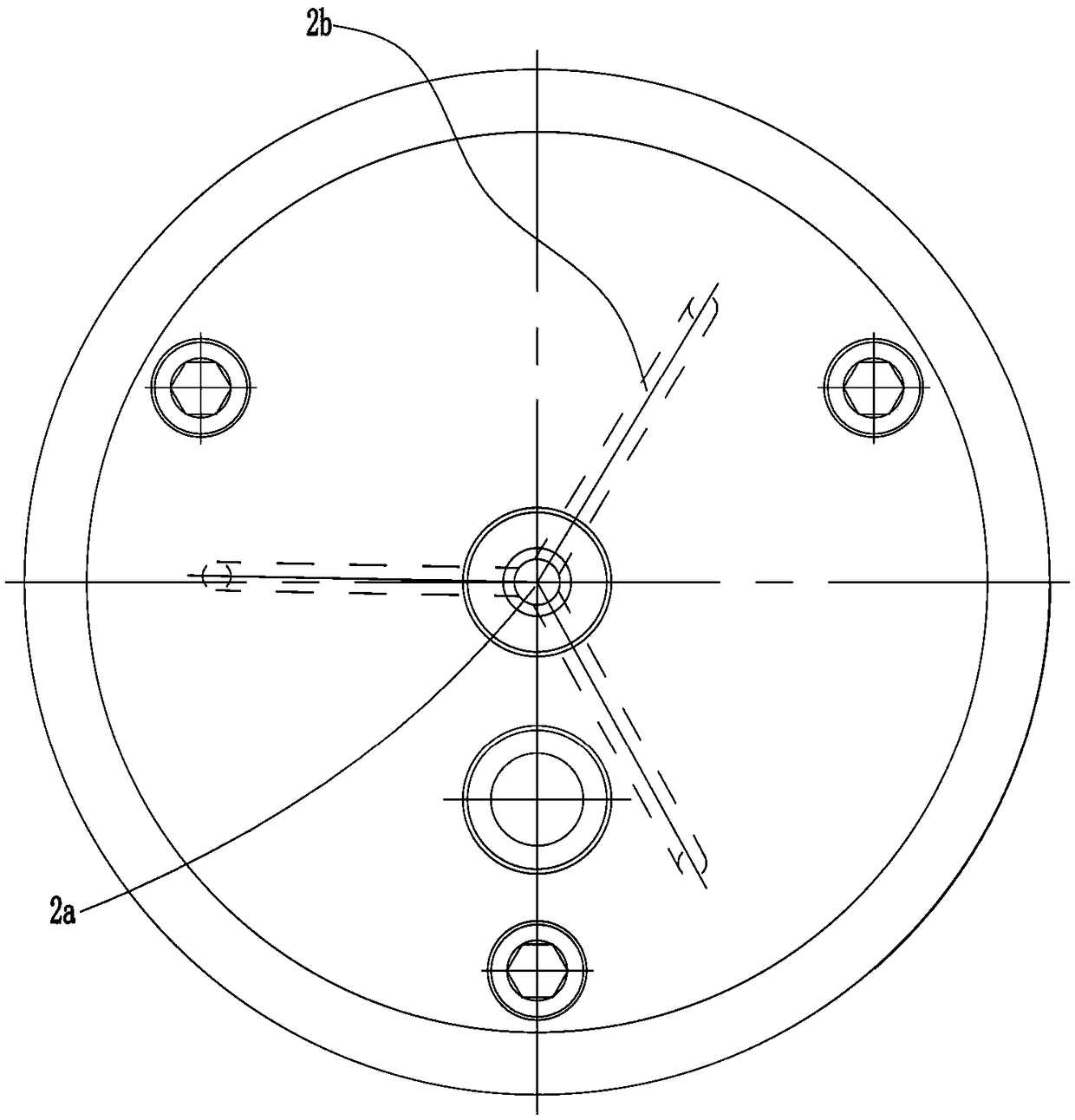

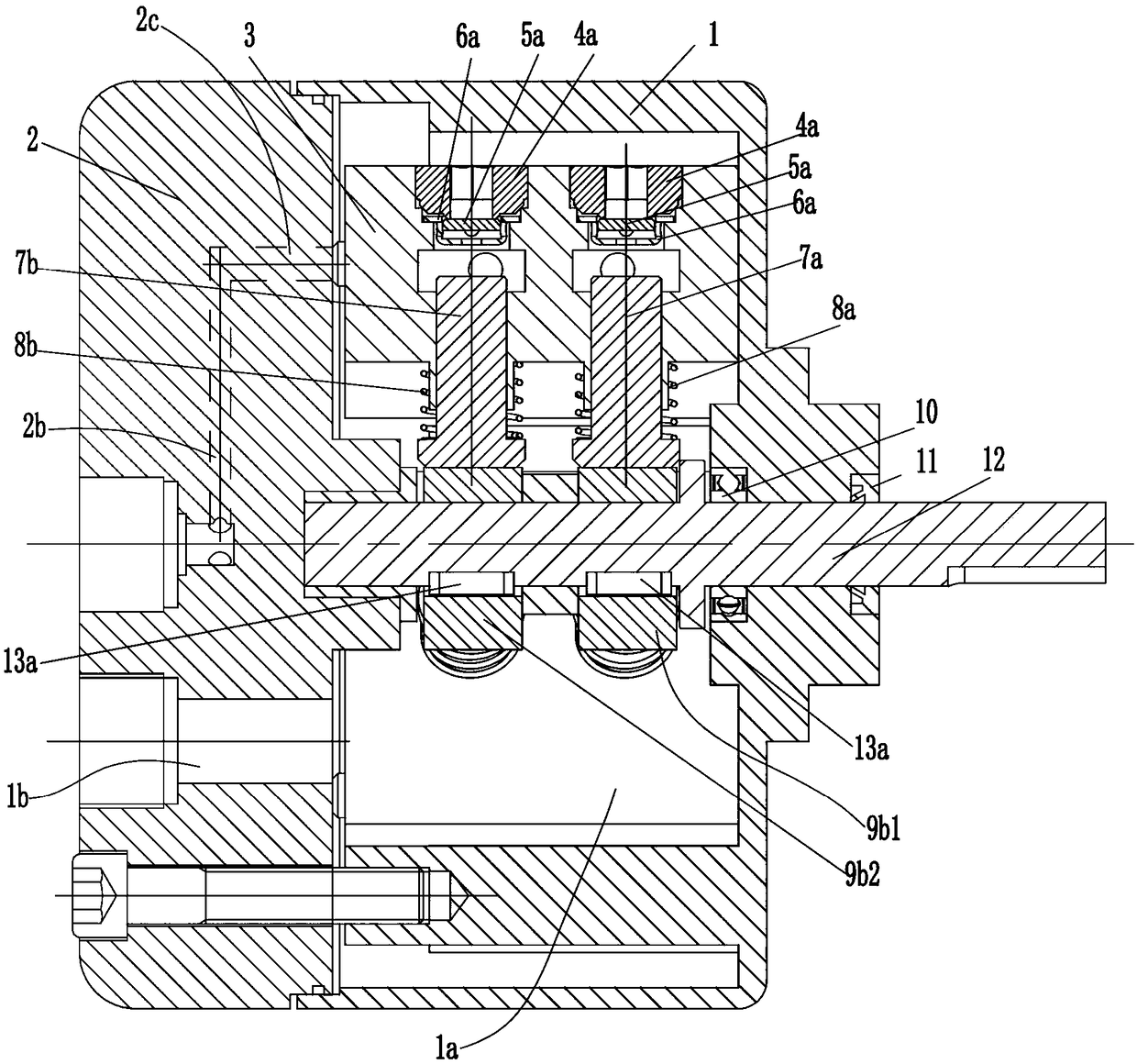

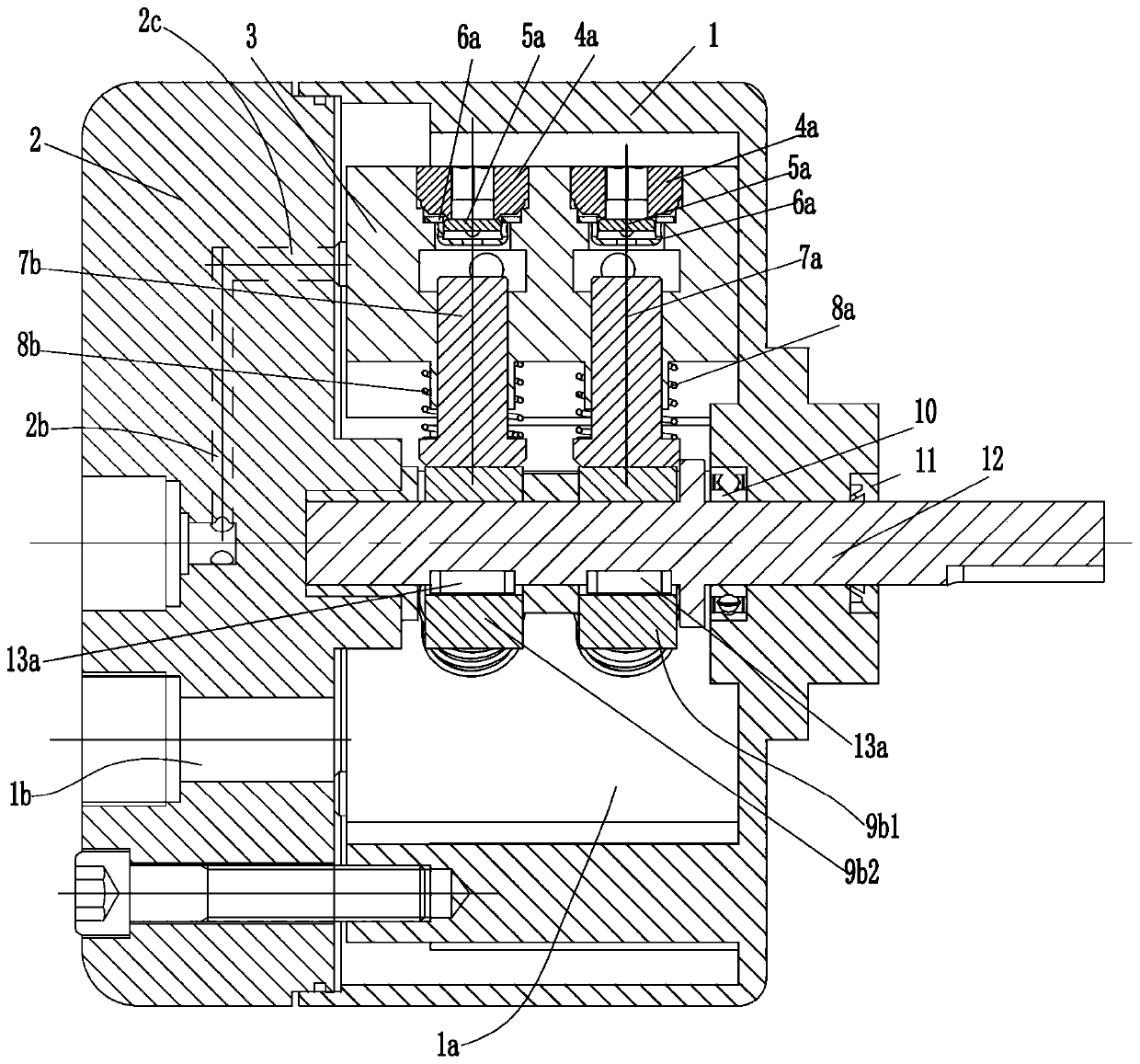

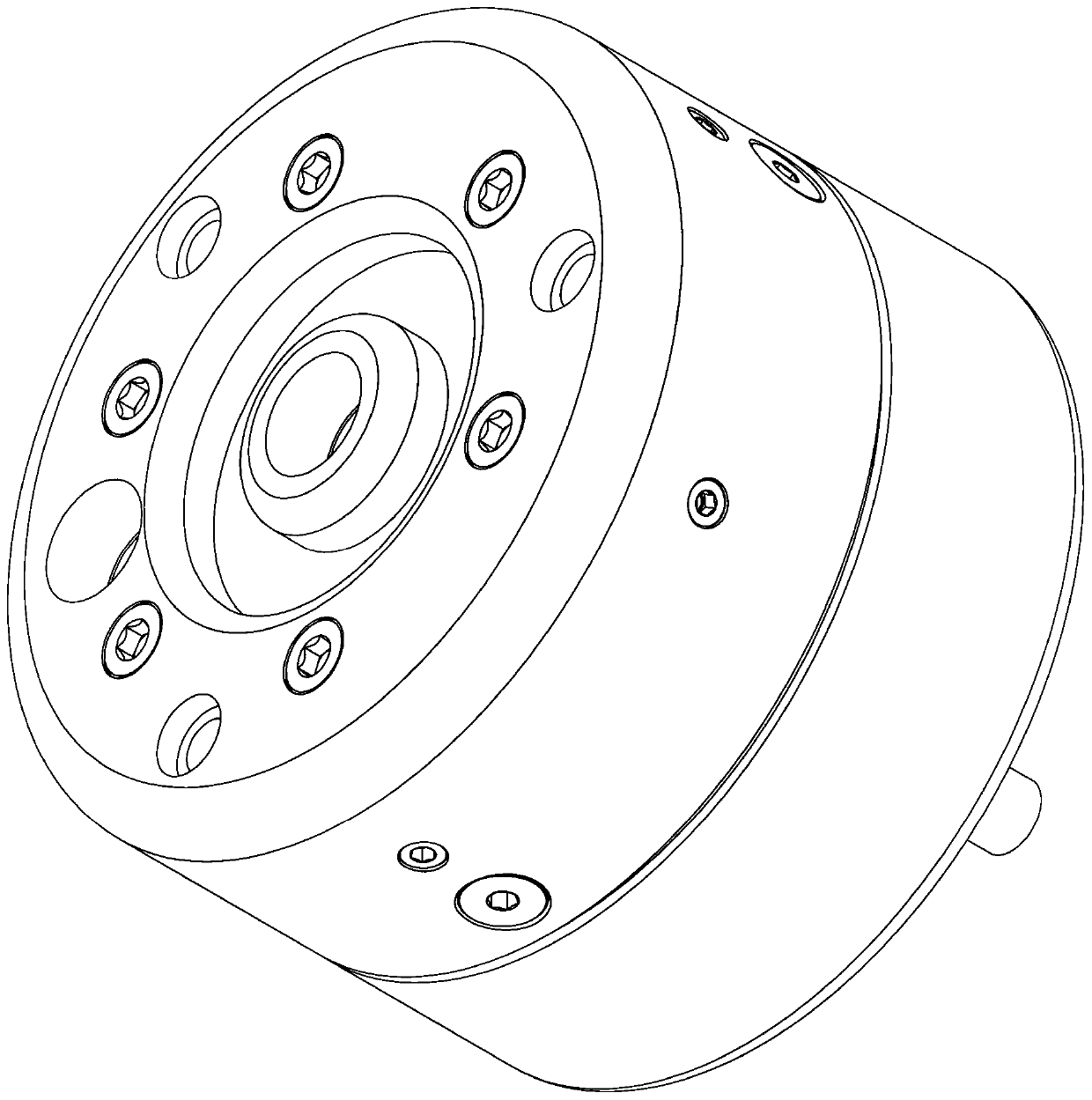

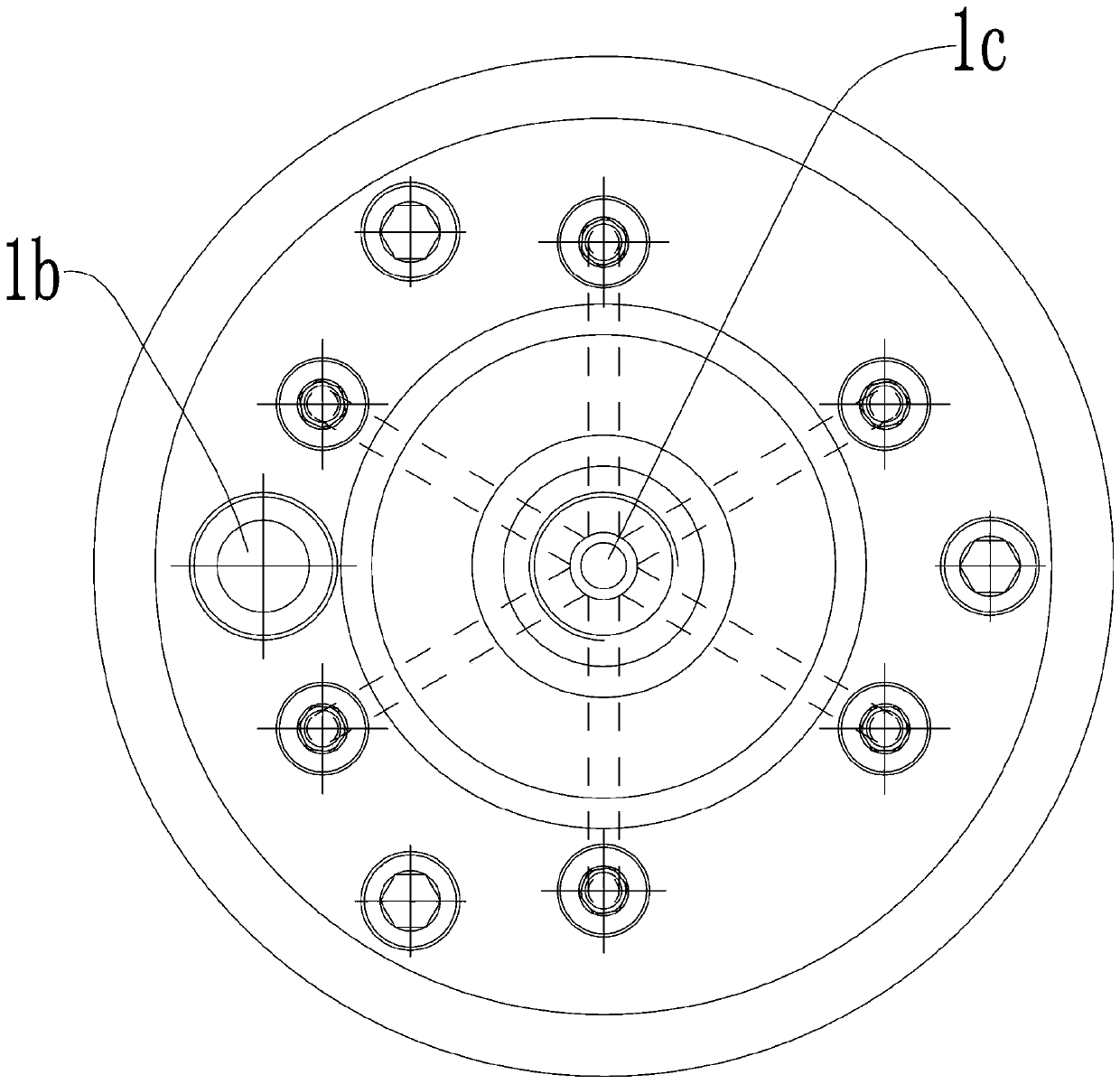

High-pressure variable plunger pump

ActiveCN109611308AImplement variableReduce displacementPositive-displacement liquid enginesMulti-cylinder pumpsHigh pressureControl valves

The invention discloses a high-pressure variable plunger pump. The high-pressure variable plunger pump comprises a pump body and a pump shell arranged on the right end face of the pump body. An oil inlet cavity is formed between the pump shell and the right end face of the pump body, and an oil inlet hole is formed in the left end face of the pump body. The right end face of the pump body is rotationally connected with a rotation shaft, a plurality of plunger modules are arranged in the oil inlet cavity at equal intervals, the part, in the oil inlet cavity, of the rotation shaft is eccentrically provided with a shaft sleeve, and the shaft sleeve is provided with a multi-edge shaft sleeve. A second oil outlet hole is formed in the center position of the left end face of the pump body, a third oil outlet hole is formed in the pump body in the radial direction of the second oil outlet hole, and a plurality of fourth oil outlet holes are formed in the pump body. The communicating positionsof the third oil outlet hole and the fourth oil outlet holes in the pump body are provided with oil outlet one-way valve assemblies. The pump body is internally provided with a variable control valveassembly for controlling the flow of the second oil outlet hole. The high-pressure variable plunger pump is compact in size, low in cost and capable of being applied to the high pressure.

Owner:东营盛昶石油机械有限公司

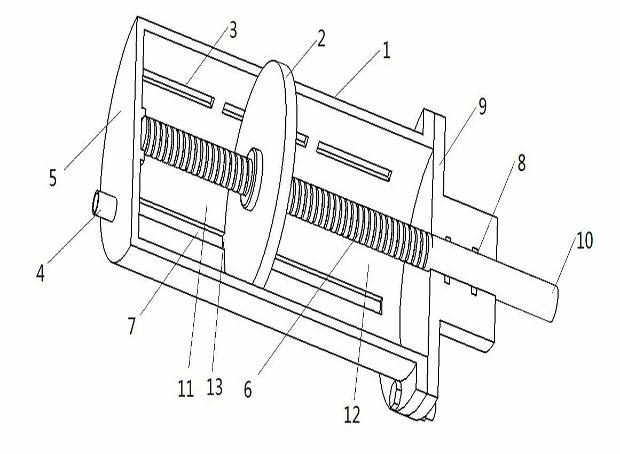

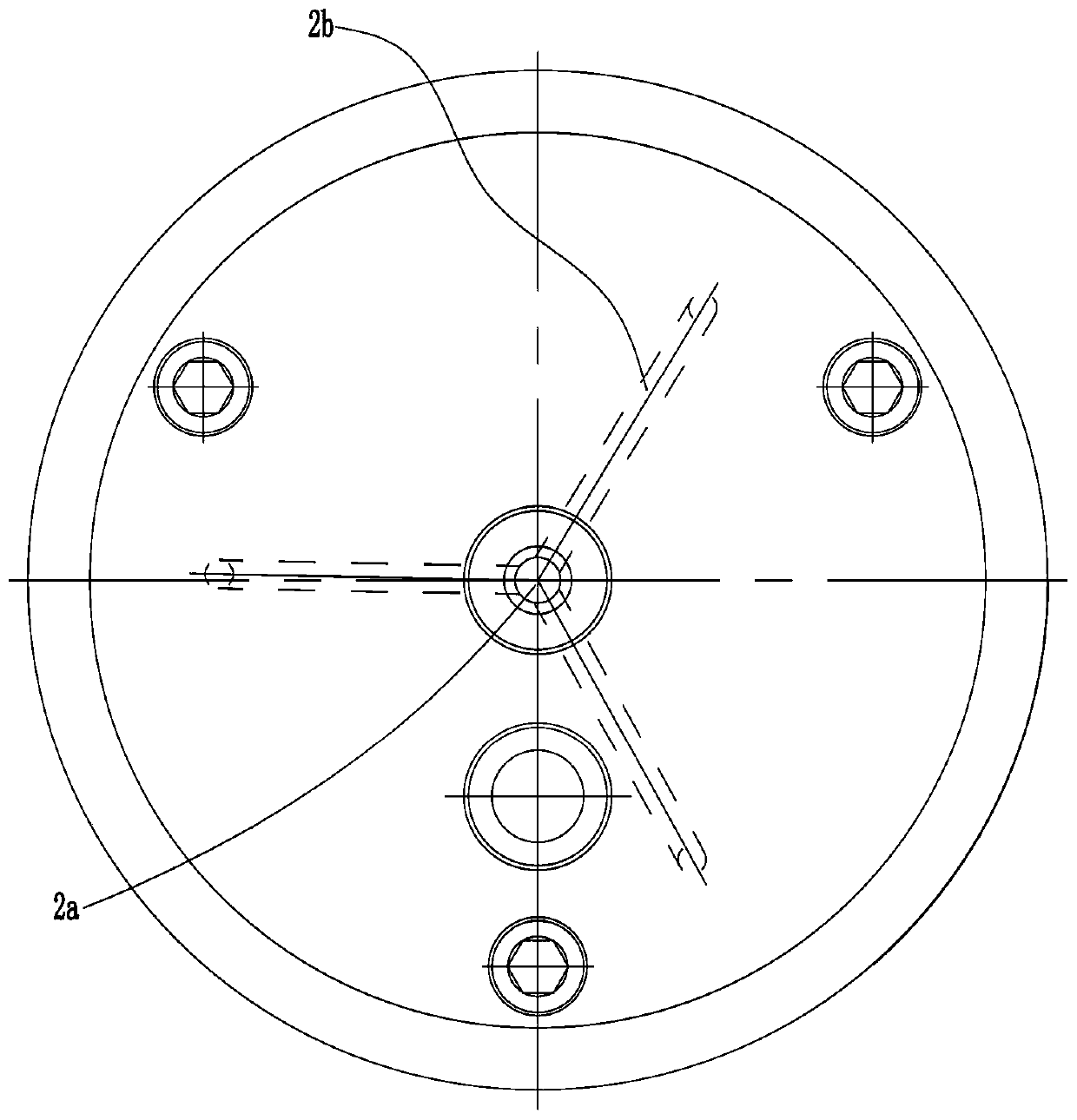

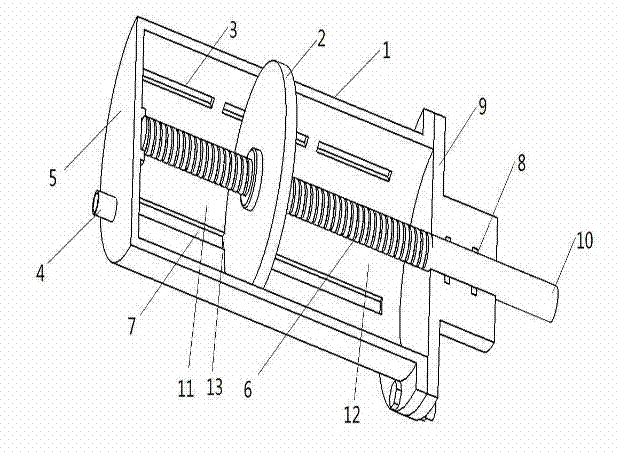

Plunger pump

ActiveCN109340100AReduce displacementImplement variablePositive displacement pump componentsPump controlEngineeringHigh pressure

The invention discloses a plunger pump. The plunger pump comprises a pump body and a pump shell mounted on the right end surface of the pump body. An oil inlet cavity is formed between the pump shelland the right end surface of the pump body, an oil inlet hole is formed in the left end face of the pump body, a rotating shaft is rotatably connected to the right end surface of the pump body, a plurality of variable plunger modules are mounted on the right end surface of the pump body in the oil inlet cavity, and a first shaft sleeve and a second shaft sleeve are eccentrically mounted on the rotating shaft in the oil inlet cavity; the variable plunger modules each include a mounting block, a first plunger, a second plunger, a first spring, a second spring, a first oil suction check valve assembly, a second oil suction check valve assembly and a variable control valve assembly; and a second oil outlet hole is formed in the central position of the left end surface of the pump body, a plurality of third oil outlet holes are formed in the pump body, and the pump body is internally provided with a fourth oil outlet hole. The plunger pump is not only compact in size and low in cost, but also can be applied to high pressure.

Owner:东营盛昶石油机械有限公司

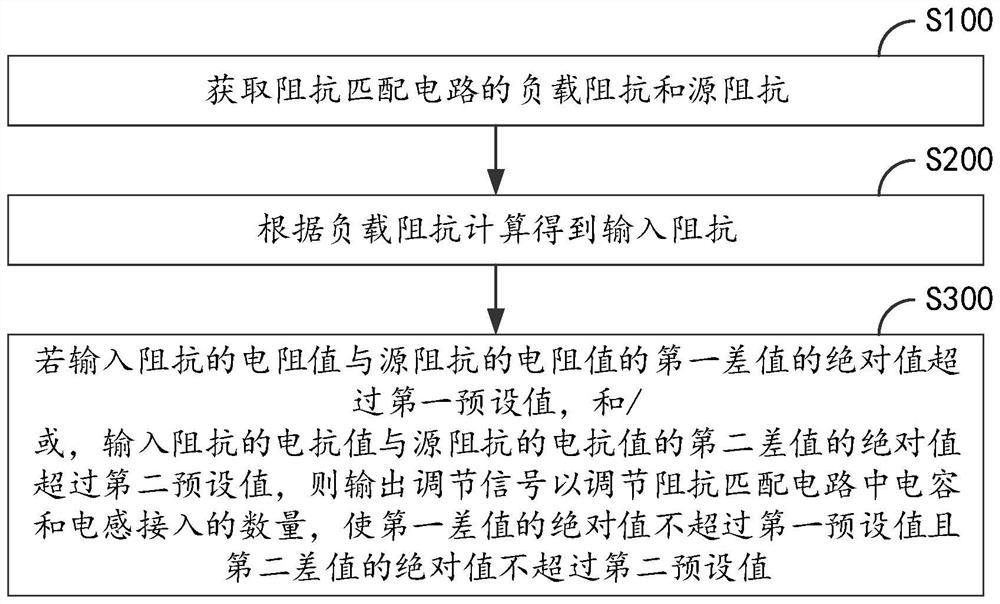

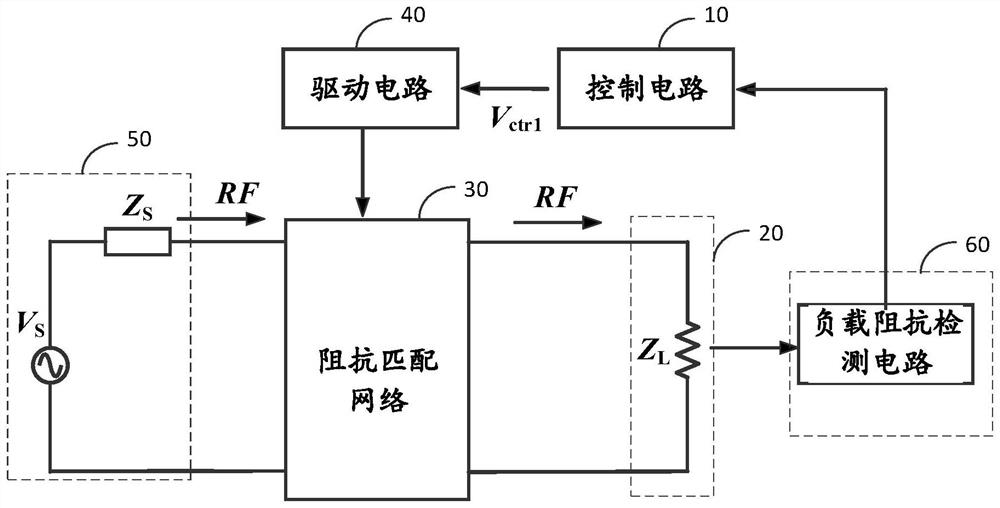

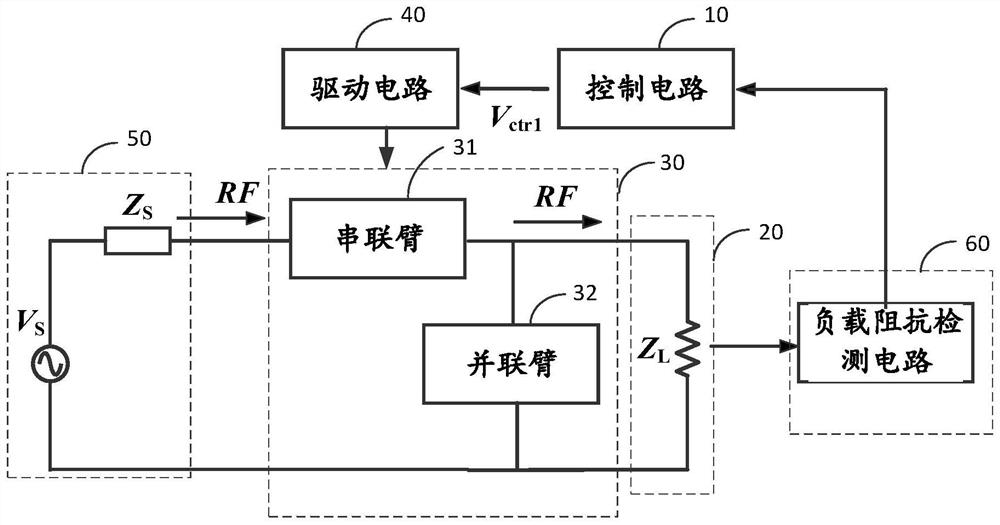

Impedance matching adjusting method and impedance matching circuit

ActiveCN114448387AReduce volumeImplement variableImpedence matching networksCapacitanceInput impedance

The invention provides a method for adjusting impedance matching and an impedance matching circuit. The method comprises the following steps: acquiring load impedance and source impedance of the impedance matching circuit; calculating input impedance according to the load impedance; if the absolute value of a first difference value between the resistance value of the input impedance and the resistance value of the source impedance exceeds a first preset value, and / or the absolute value of a second difference value between the reactance value of the input impedance and the reactance value of the source impedance exceeds a second preset value, outputting an adjusting signal to adjust the number of accessed capacitors and inductors in the impedance matching circuit, the absolute value of the first difference value does not exceed the first preset value, and the absolute value of the second difference value does not exceed the second preset value. According to the impedance matching method and device, the number of the capacitors and the number of the inductors needing to be connected are obtained through calculation, the actual connection of the inductors and the capacitors in the impedance matching network is changed according to the number, impedance matching is achieved, the capacitors and the inductors can be rapidly and accurately changed by changing the connection number of the capacitors and the inductors, and the impedance matching problem is solved.

Owner:深圳市恒运昌真空技术有限公司

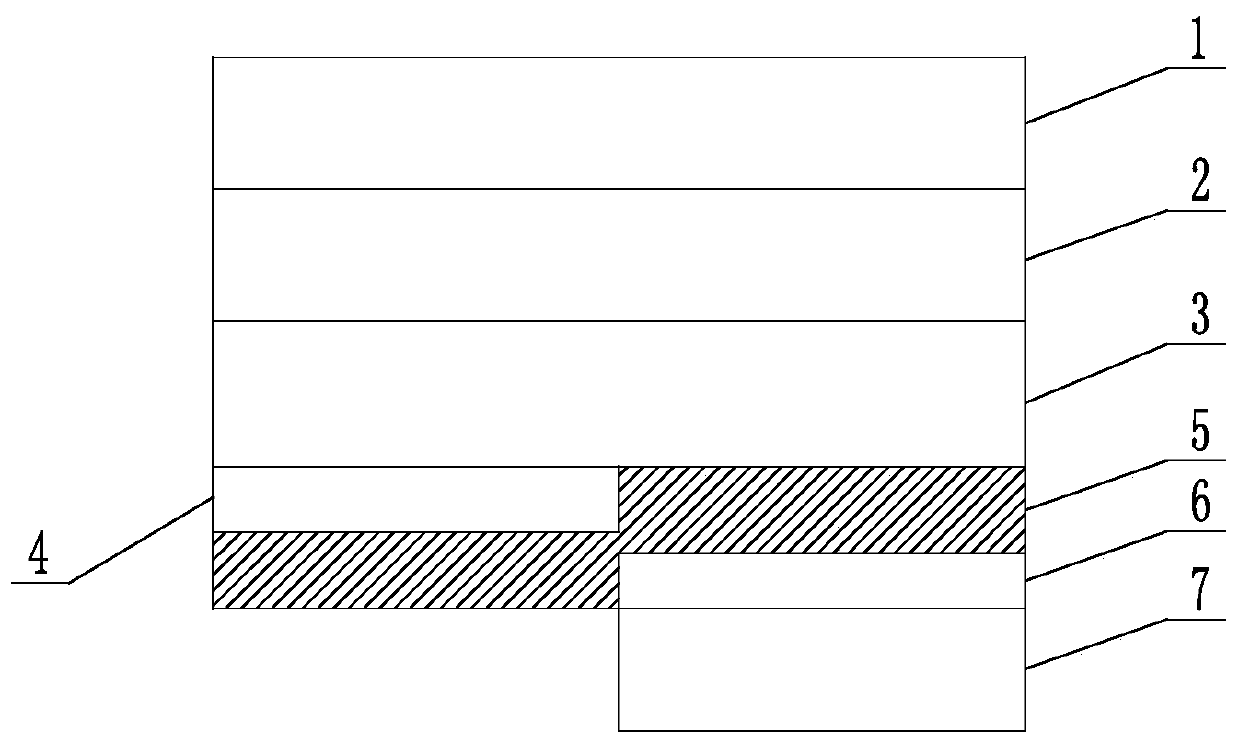

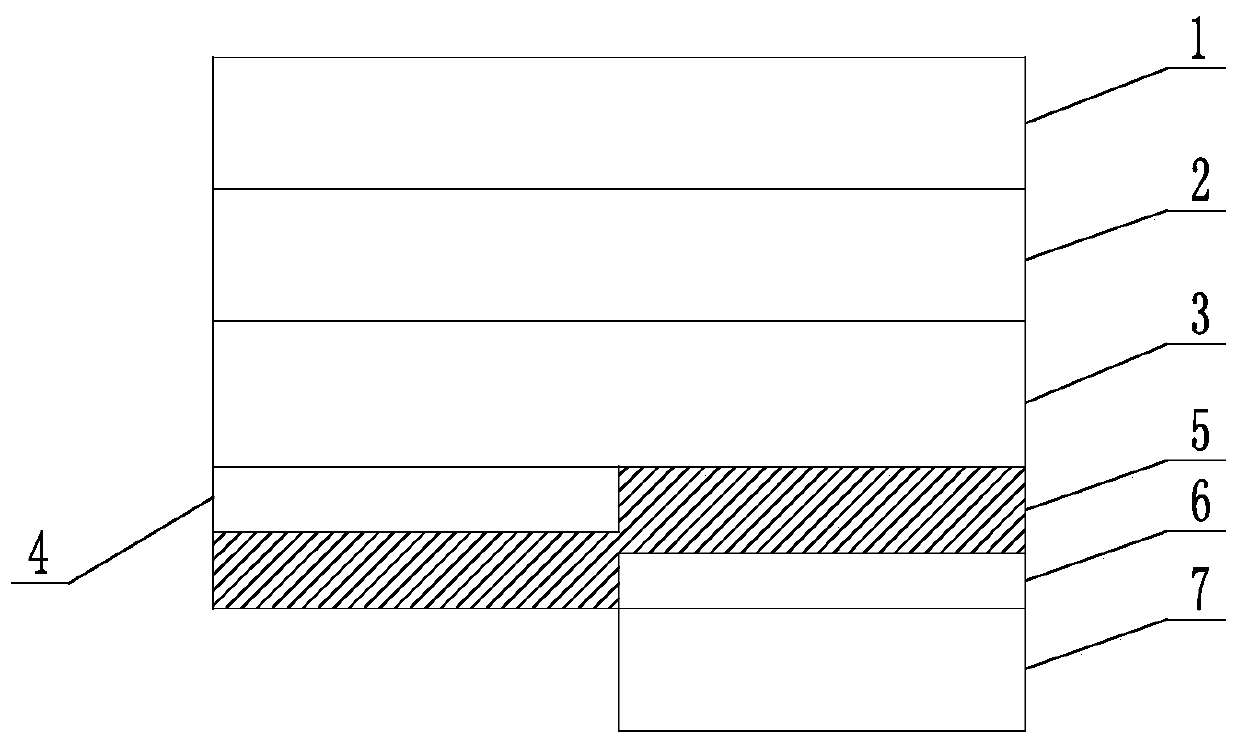

Variable local holographic anti-counterfeiting safety line and preparation method thereof

InactiveCN109979308AWith holographic anodized aluminum effectIntuitive identificationStampsIdentification meansInformation layerSafety wire

The invention relates to an anti-counterfeiting safety line, in particular to a variable local holographic anti-counterfeiting safety line and a preparation method thereof. The variable local holographic anti-counterfeiting safety line includes a plastic film layer, a permanent embossing information layer and a positioning embossing layer which are arranged in sequence from top to bottom; the lower portion of the positioning embossing layer is sequentially provided with a local hollow printing layer and a local aluminum coated layer which contain partial variable information respectively, thepartial variable information is combined to form complete variable information, each piece of partial variable information includes a two-dimensional code, a release layer is arranged between the local hollow printing layer and the local aluminum coated layer, and the lower portion of the corresponding local aluminum coated layer is provided with a hidden ink layer. According to the anti-counterfeiting safety line, a holographic pattern is combined with a printing pattern, the variable information has a holographic alumite effect and is not easy to imitate, identification is simple, the anti-counterfeiting effect is good, the variable information is destroyed when the safety line is taken out from paper, and secondary use can be effectively prevented. The preparation method is scientific,reasonable, simple and easy to perform.

Owner:SHANDONG TAIBAO PREVENTING COUNTERFEIT

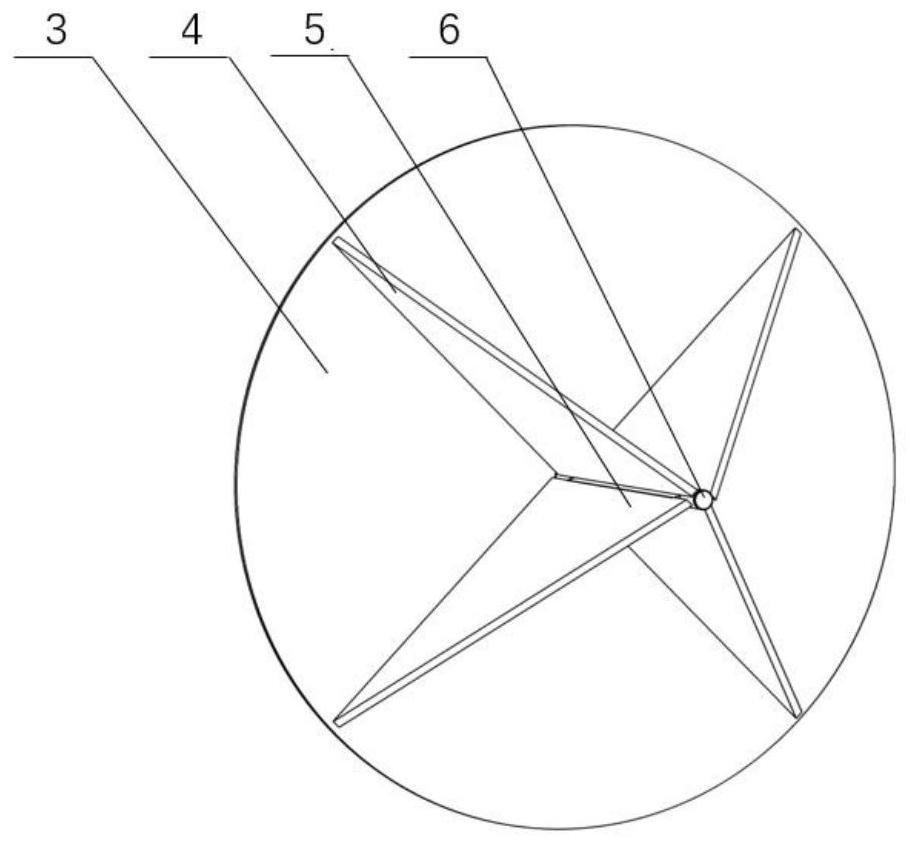

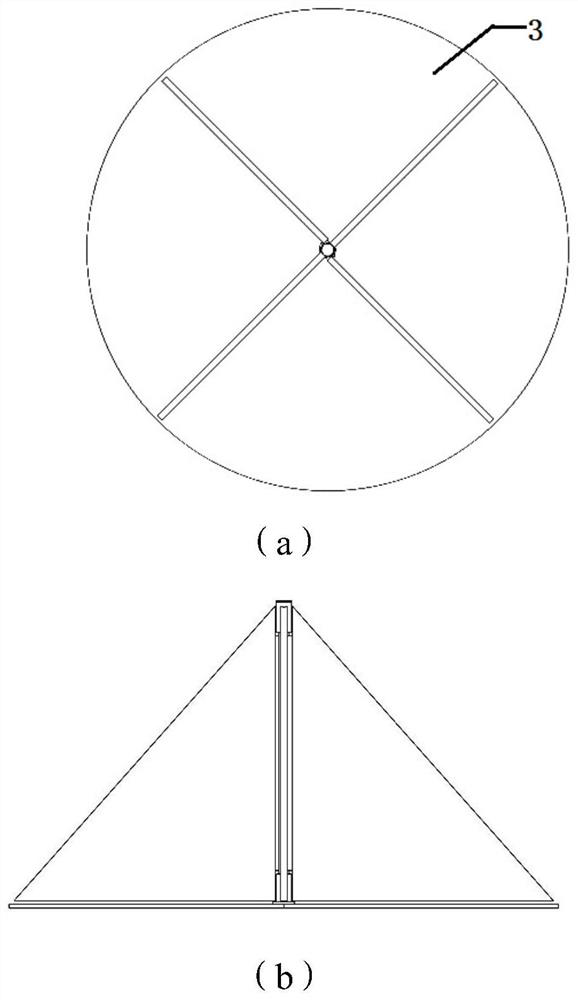

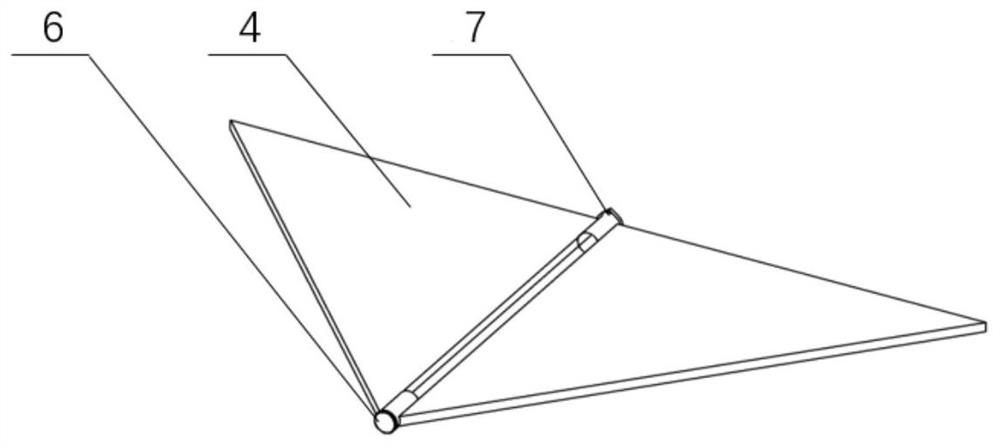

RCS-variable corner reflector and unmanned helicopter target drone

PendingCN112461055AAvoid exposureEnough effective reflective areaMovable targetsStructural engineeringMechanical engineering

The invention discloses an RCS-variable corner reflector and an unmanned helicopter target drone. The reflector comprises a concentric baffle, an eccentric baffle and a fixed connecting part; the concentric baffle is detachably connected with the fixed connecting part; a first corner area is formed between the movable portion of the concentric baffle and the surface of the fixed connecting part; the movable portion of the concentric baffle adjusts the included angle formed with the surface of the fixed connecting part to change the size of the first corner area; the fixed portion of the concentric baffle is detachably connected with the fixed portion of the eccentric baffle; a second corner area is formed by the movable portion of the eccentric baffle and the surface of the fixed connecting part; and the movable portion of the eccentric baffle adjusts the included angle formed with the surface of the fixed connecting part to change the size of the second corner area. By changing the angle between the concentric baffle and the fixed connecting part or changing the angle between the eccentric baffle and the fixed connecting part, the RCS can be variable.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

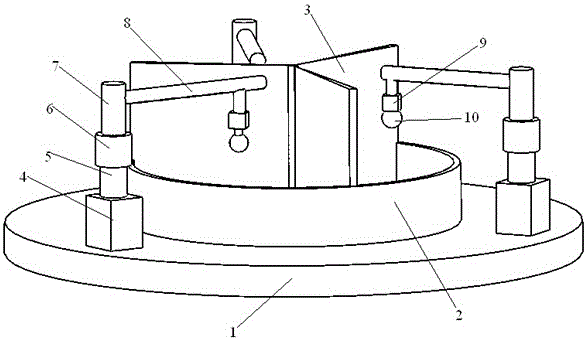

Device for microalgae phototropism research

InactiveCN106190797AWavelength changeChange intensityBioreactor/fermenter combinationsBiological substance pretreatmentsHorizonPhototaxis

The invention discloses a device for microalgae phototropism research. The device comprises a pedestal, a culture dish, shading partitions, a support seat, a support bar 1, an adjusting screw barrel, a regulating lever 2, a horizon bar, a wavelength adjustment assembly and a light source. The influence of lighting on the microalgae distribution can be judged according to the relationship between the algae distribution and light. The device can implement the change of the wavelength of the light source, and can also implement the change of the intensity of the light source, thereby greatly enhancing the accuracy and convenience for microalgae and lighting research. When the wavelength is changed, the wavelength can be regulated only by rotating the gear. The intensity of the light source can be changed by rotating the adjusting screw barrel. The three shading partitions are arranged to well perform change comparison on lighting adjustment, thereby implementing variable and quantitative research on microalgae.

Owner:JILIN JIANZHU UNIVERSITY

Intelligent construction platform for construction of super high-rise building

ActiveCN102839812BMonitor the force conditionEasy to climbBuilding support scaffoldsEngineeringSteel frame

Owner:CHINA CONSTR THIRD ENG BUREAU GRP CO LTD

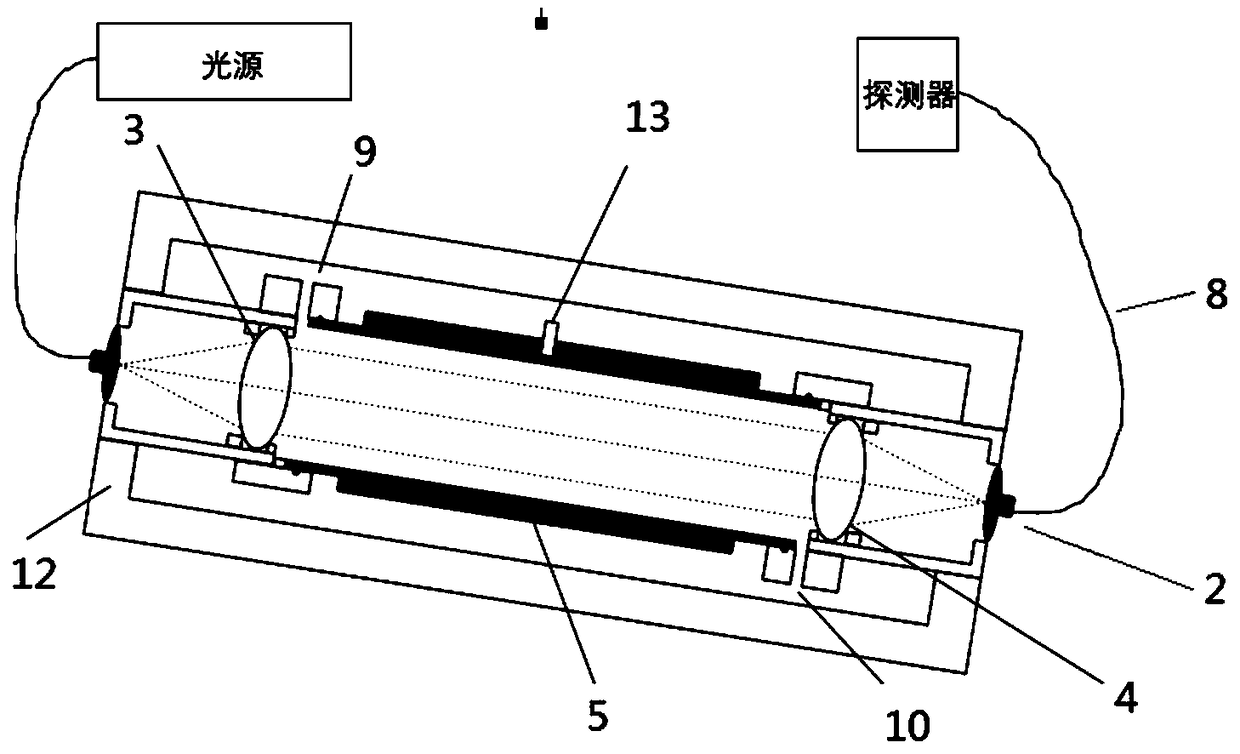

Resolution colorimetric device and equipment

PendingCN109444132AImplement variableImprove maintainability and replaceabilityMaterial analysis by observing effect on chemical indicatorPreparing sample for investigationMaintainabilityOptical pathlength

The invention discloses a resolution colorimetric device and equipment. The reagent quantity required in the embodiment of the invention is much smaller than that of the existing product in the market(such as a vertical pipe structure). Under the condition of small reagent quantity change, the variable and controllable light path is realized. The light path change can be realized only by changinga middle glass pipe; the sensitivity is high if the light path is long. A colorimetric vessel does not need special processing; a used lens and glass pipes are all standard elements; the cost is reduced; the quality controllability and the maintainability and replaceability of the equipment are improved.

Owner:YIWEN ENVIRONMENTAL SCI & TECH GUANGZHOU

A vertical vacuum sputtering coating production line

ActiveCN104004999BSmall footprintHigh economic valueVacuum evaporation coatingSputtering coatingProduction lineSputtering

The invention discloses a vertical vacuum sputtering coating production line, which includes a transfer line and a coating line, the coating line is connected to the transfer line; the transfer line includes a track, at least one transfer car and at least one film loading device, the transfer car Running on the above track, the film loading device is transferred by the transfer car; the coating line includes an inlet chamber, an inlet transition chamber, an inlet buffer chamber, a coating chamber, an outlet buffer chamber, an outlet transition chamber and One exit chamber. Compared with the existing technology, the transmission line and the coating line are connected end to end to form a circular line, which saves floor space. The substrate transmission in the entire coating production line adopts intelligent control, which saves manpower and material resources and improves production efficiency. Each chamber in the coating line is based on Product demand is replaced or increased, and the entire coating production line can adapt to various coating process requirements, prolong the service life, and save resources, so its application prospect is very broad.

Owner:XIANGTAN HONGDA VACUUM TECH CO LTD

Variable partial holographic logic corresponding information anti-fake marker and manufacturing method thereof

InactiveCN109949695AWith holographic anodized aluminum effectIntuitive identificationStampsIdentification meansGraphicsInformation layer

The invention relates to an anti-fake marker and in particular relates to a variable partial holographic logic corresponding information anti-fake marker and a manufacturing method thereof. The anti-fake marker comprises a plastic membrane layer, a two-dimensional code printing layer, a permanent mold pressing information layer, a positioning mold pressing layer, a color layer and an adhesive layer which are arranged in sequence from top to bottom, wherein a partial hollow printing layer and a partial aluminum plating layer are sequentially arranged below the positioning mold pressing layer; the partial hollow printing layer and the partial aluminum plating layer respectively comprise a part of variable information and form complete variable information after being combined; a two-dimensional code of the two-dimensional code printing layer has a corresponding relationship with the variable information; the variable information is a variable graphic diagram and / or variable digits; and an invisible ink layer is arranged below the partial aluminum plating layer correspondingly. With the combination of holographic patterns and printing patterns, the variable information has a holographic alumite effect, the two-dimensional code has the corresponding relationship with the variable information, and is not easy to imitate, simple to identify, good in anti-fake effect and high in anti-transferring property, and the manufacturing method of the anti-fake marker is scientific and reasonable and simple and feasible.

Owner:SHANDONG TAIBAO PREVENTING COUNTERFEIT

Variable jaw protection type helmet

PendingCN112956776AImplement variableAdjustable fitHelmetsHelmet coversStructural engineeringMechanical engineering

The invention discloses a variable jaw protection type helmet. The helmet comprises a helmet shell body and a jaw protection structure hinged to the lower portion of the helmet shell body, the jaw protection structure comprises two jaw protection plates arranged on the left side and the right side of the helmet shell body in pairs and a middle baffle located between the two jaw protection plates, the middle baffle is arranged on the two jaw protection plates in a sliding mode, a flexible jaw protection pad is slidably arranged on at least one jaw protection plate, a linkage flat plate is fixedly arranged on the surface, away from the human face in the helmet shell body, of the flexible jaw protection pad, a connecting rod is fixedly arranged on the linkage flat plate, and a guide blind hole of the connecting rod is formed in the middle baffle; and the jaw protection plate provided with the flexible jaw protection pad is provided with a sliding cavity used for being in linkage with the flat plate and the flexible jaw protection pad to slide. The jaw protector can be changed, the fitting degree of the jaw protector is adjustable, and the effect of protecting the lower jaw of a wearer is good.

Owner:JIANGYIN DAFEIMA AUTOMOBILE TECH CO LTD

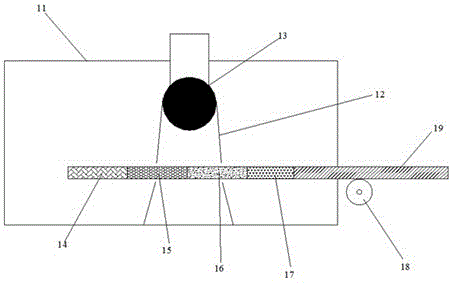

A cathode device for a vacuum coating production line

ActiveCN104018129BIncrease profitReduce wasteVacuum evaporation coatingSputtering coatingProduction lineEngineering

The invention discloses a cathode device for a vacuum coating production line, comprising a cathode assembly and a translation assembly, the cathode assembly is fixedly connected to the translation assembly and moves in translation with the movement of the translation assembly, wherein the cathode in the cathode assembly is a plane Magnetron sputtering cathode. Compared with the prior art, the cathode device provided by the present invention can not only maintain the advantages of low cost and easy maintenance of the planar cathode, but also realize the advantages of variable target and bombardment orbit of the rotating cathode, and realize the additional components of translation The structure is simple, it will not affect the vacuum sealing, and it will not become an uncertain factor in the production line; therefore, the cathode device has great economic value, is environmentally friendly, and reduces the waste of the target, so its application prospect is very good broad.

Owner:XIANGTAN HONGDA VACUUM TECH CO LTD

Cathode device for vacuum coating production line

ActiveCN104018129AIncrease profitReduce wasteVacuum evaporation coatingSputtering coatingProduction lineEngineering

The invention discloses a cathode device for a vacuum coating production line. The device comprises a cathode assembly and a translational assembly, wherein the cathode assembly is fixedly connected with the translational assembly and moves flatwise along the motion of the translational assembly; a cathode of the cathode assembly is a planar magnetic control spluttering cathode. Compared with the prior art, the cathode device has the advantages of low cost and easy maintenance of the planar cathode and variable target materials and bombardment orbits of a rotating cathode; an additional part for realizing translation is in a simple structure, the vacuum sealing property cannot be affected and an uncertain factor in the production line is avoided; therefore, the cathode device has a great economic value and is environmental friendly; the waste of the target materials is reduced, so that the application prospect is very wide.

Owner:XIANGTAN HONGDA VACUUM TECH CO LTD

a plunger pump

ActiveCN109340100BReduce displacementImplement variablePositive displacement pump componentsPump controlEngineeringControl valves

The invention discloses a plunger pump. The plunger pump comprises a pump body and a pump shell mounted on the right end surface of the pump body. An oil inlet cavity is formed between the pump shelland the right end surface of the pump body, an oil inlet hole is formed in the left end face of the pump body, a rotating shaft is rotatably connected to the right end surface of the pump body, a plurality of variable plunger modules are mounted on the right end surface of the pump body in the oil inlet cavity, and a first shaft sleeve and a second shaft sleeve are eccentrically mounted on the rotating shaft in the oil inlet cavity; the variable plunger modules each include a mounting block, a first plunger, a second plunger, a first spring, a second spring, a first oil suction check valve assembly, a second oil suction check valve assembly and a variable control valve assembly; and a second oil outlet hole is formed in the central position of the left end surface of the pump body, a plurality of third oil outlet holes are formed in the pump body, and the pump body is internally provided with a fourth oil outlet hole. The plunger pump is not only compact in size and low in cost, but also can be applied to high pressure.

Owner:东营盛昶石油机械有限公司

A high pressure variable displacement plunger pump

ActiveCN109611308BImplement variableReduce displacementPositive-displacement liquid enginesMulti-cylinder pumpsEngineeringHigh pressure

The invention discloses a high-pressure variable plunger pump. The high-pressure variable plunger pump comprises a pump body and a pump shell arranged on the right end face of the pump body. An oil inlet cavity is formed between the pump shell and the right end face of the pump body, and an oil inlet hole is formed in the left end face of the pump body. The right end face of the pump body is rotationally connected with a rotation shaft, a plurality of plunger modules are arranged in the oil inlet cavity at equal intervals, the part, in the oil inlet cavity, of the rotation shaft is eccentrically provided with a shaft sleeve, and the shaft sleeve is provided with a multi-edge shaft sleeve. A second oil outlet hole is formed in the center position of the left end face of the pump body, a third oil outlet hole is formed in the pump body in the radial direction of the second oil outlet hole, and a plurality of fourth oil outlet holes are formed in the pump body. The communicating positionsof the third oil outlet hole and the fourth oil outlet holes in the pump body are provided with oil outlet one-way valve assemblies. The pump body is internally provided with a variable control valveassembly for controlling the flow of the second oil outlet hole. The high-pressure variable plunger pump is compact in size, low in cost and capable of being applied to the high pressure.

Owner:东营盛昶石油机械有限公司

Cavity-variable cherry tomato slicing device

ActiveCN104325492BAvoid cumbersomeImprove the pressing effectMetal working apparatusEngineeringMechanical engineering

The invention relates to the technical field of cutting devices of cherry tomatoes, in particular to a variable-cavity cherry tomato slicing device. The slicing device comprises a bottom disk, a disk cover and a cutter, wherein the bottom disk is used for accommodating the cherry tomatoes, and is provided with a concave part; the disk cover is used for pressing the cherry tomatoes, and is provided with a concave part; the cutter is used for cutting the cherry tomatoes; a lower connecting part extends from one side of the bottom disk; an upper connecting part which corresponds to the lower connecting part extends from one side, which corresponds to the lower connecting part, of the disk cover; the lower connecting part is hinged to the upper connecting part; a spring is further arranged between the lower connecting part and the upper connecting part; an accommodating space for accommodating the cherry tomatoes is formed between the bottom disk and the disk cover; a gap between one side, which is far away from the lower connecting part, of the bottom disk and one side, which is far away from the upper connecting part, of the disk cover is greater than the thickness of the cutter. The variable-cavity cherry tomato slicing device has the advantages of high cutting safety, high efficiency, good pressing effect, and easiness and convenience in operation.

Owner:王远志

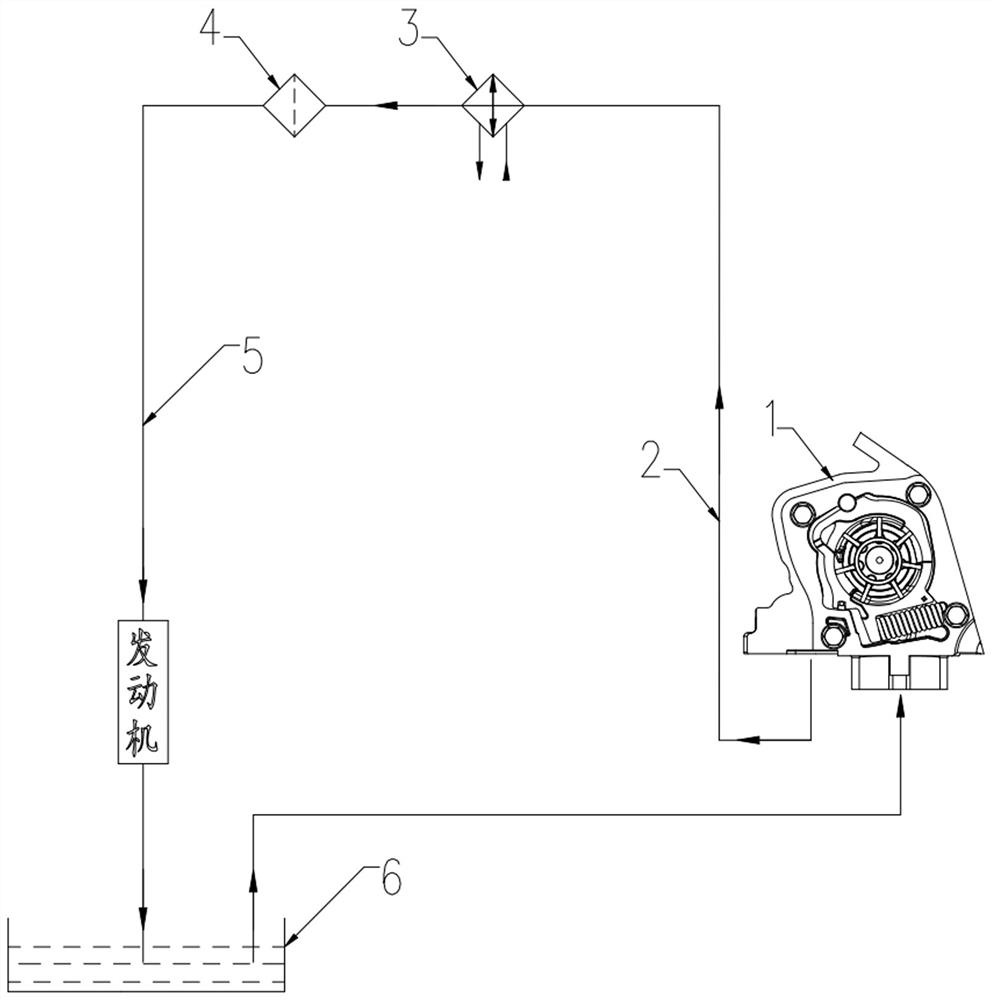

First-stage variable pump control system with simplified structure

PendingCN111963271AImplement variableReduce power consumptionMachines/enginesPressure lubrication with lubrication pumpOil pressureEngineering

The invention discloses a first-stage variable pump control system with a simplified structure. The system comprises an oil pump, a pump outlet, a main oil passage and an oil sump, the oil pump comprises a pump body, a feedback pressure control cavity, a variable sliding block, a variable spring, an oil inlet and an oil outlet, the oil sump is connected to the oil inlet through an oil path, and the oil outlet communicates with the oil sump through the pump outlet and the main oil passage; an oil through groove or an oil through hole is formed in the position, close to the oil outlet, of the variable sliding block and used for introducing pressure oil of the oil outlet into the feedback pressure control cavity; when the oil pressure of the oil outlet is increased, the oil pressure in the feedback pressure control cavity is correspondingly increased; and when the oil pressure reaches a set variable pressure point, the oil pressure in the feedback pressure control cavity can push the variable sliding block to overcome the elastic force of the variable spring to deflect, so that the output displacement of the oil pump is reduced, the first-stage displacement is variable, the variable response is more sensitive, an oil circuit can be actively protected if the oil circuit pressure is too high, and therefore a safety valve mechanism does not need to be designed.

Owner:HUNAN OIL PUMP

Air spring appending air chamber structure with variable volume

InactiveCN102305261BImplement variableStable pressureSpringsResilient suspensionsAir springEngineering

The invention discloses an air spring appending air chamber structure with variable volume for a vehicle, and the structure comprises a cylindrical appending air chamber cavity body of which the two ends are provided with openings, wherein the middle axle of the inner cavity of the appending air chamber cavity body is provided with a screw rod of which the upper end is connected with an external driving device; the screw rod in the appending air chamber cavity body is sheathed with a piston by a screw rod pair, the outer wall of the piston is tightly matched with the inner wall of the appending air chamber cavity body, and the appending air chamber cavity body is divided into an effective volume cavity and a spare volume cavity; the whole inner wall of the appending air chamber cavity body is provided with a piston rotation-limiting groove along the axial direction, and the edge of the piston is provided with a protruding part which is clamped in the piston rotation-limiting groove; the inner wall of the appending air chamber cavity body is provided with three vent grooves at interval along the axial direction; and a gap between every two vent grooves and the thickness of the piston are equal. The air chamber structure provided by the invention has the advantages of simple structure and small volume, and can be used for effectively and reliably achieving the variable volume ofthe appending air chamber.

Owner:JIANGSU UNIV

One-hand operation type variable discharging bottle cap

The invention discloses a one-hand operation type variable discharging bottle cap which comprises a bottle cap body. A side body of the bottle cap body is provided with a discharging outlet. A discharging control mechanism used for controlling the discharging outlet to be connected or disconnected is installed in a hollow chamber. The discharging control mechanism comprises rotating parts with first arms and second arms, and the number of the rotating parts is two. The two rotating parts are installed on a top cover plate in a rotating mode, and the first arms of the two rotating parts are arranged in an attached mode and further block the discharging outlet. The second arms of the two rotating parts are arranged in a separated mode. The discharging control mechanism further comprises a control part used for controlling the second arms of the two rotating parts to move in opposite directions and a restoring force generating mechanism used for generating restoring force along with opposite-direction movement of the second arms of the two rotating parts. The control end of the control part extends out of the side body. By means of the one-hand operation type variable discharging bottle cap, materials in a bottle body can fall off from the inside of the bottle cap through one-hand operation, operation is convenient, the materials in a bottle cannot be affected with damp easily, the moistureproof effect is excellent, and the discharging amount can further be controlled.

Owner:JINJIANG CHUANGYOU NETWORK TECH CO LTD

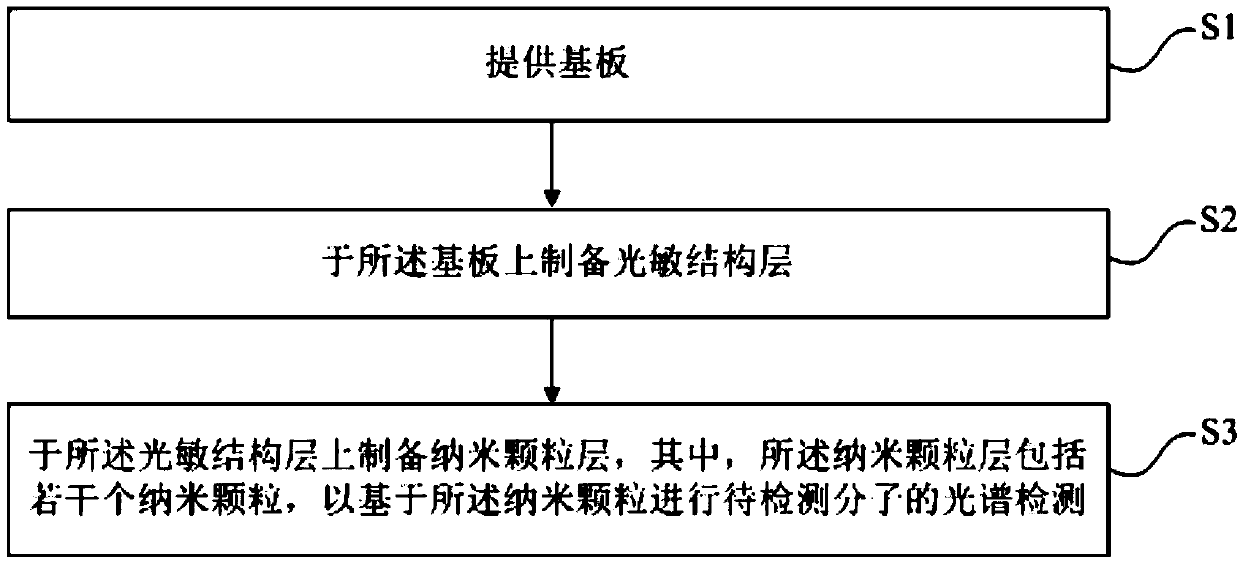

SERS (Surface Enhanced Raman Scattering) substrate structure, preparation method and detection method

ActiveCN109557072AImplement variableImprove SERS capabilityRaman scatteringRaman scatteringLight wave

The invention provides an SERS (Surface Enhanced Raman Scattering) substrate structure, a preparation method and a detection method. The SERS substrate structure comprises a base plate; a photosensitive structure layer and a nano-particle layer, wherein the photosensitive structure layer is located on the base plate; and the nano-particle layer is located on the photosensitive structure layer; thenanoparticle layer comprises a plurality of nano-particles, the nano-particles are subjected to spectral detection of a to-be-detected molecule under irradiation of a detection light wave. Through the above scheme, the variable structure of the SERS substrate is implemented through the design of the SERS substrate structure and the photosensitive structure layer, thereby realizing the variation of the SERS capability; the SERS capability can be improved under the condition of larger initial nanoparticle gaps through the design; the intrusion capability of the to-be-detected molecule and the SERS capability of the SERS substrate can be simultaneously improved, and the recycling of the SERS substrate can be also achieved.

Owner:NINGBO UNIV

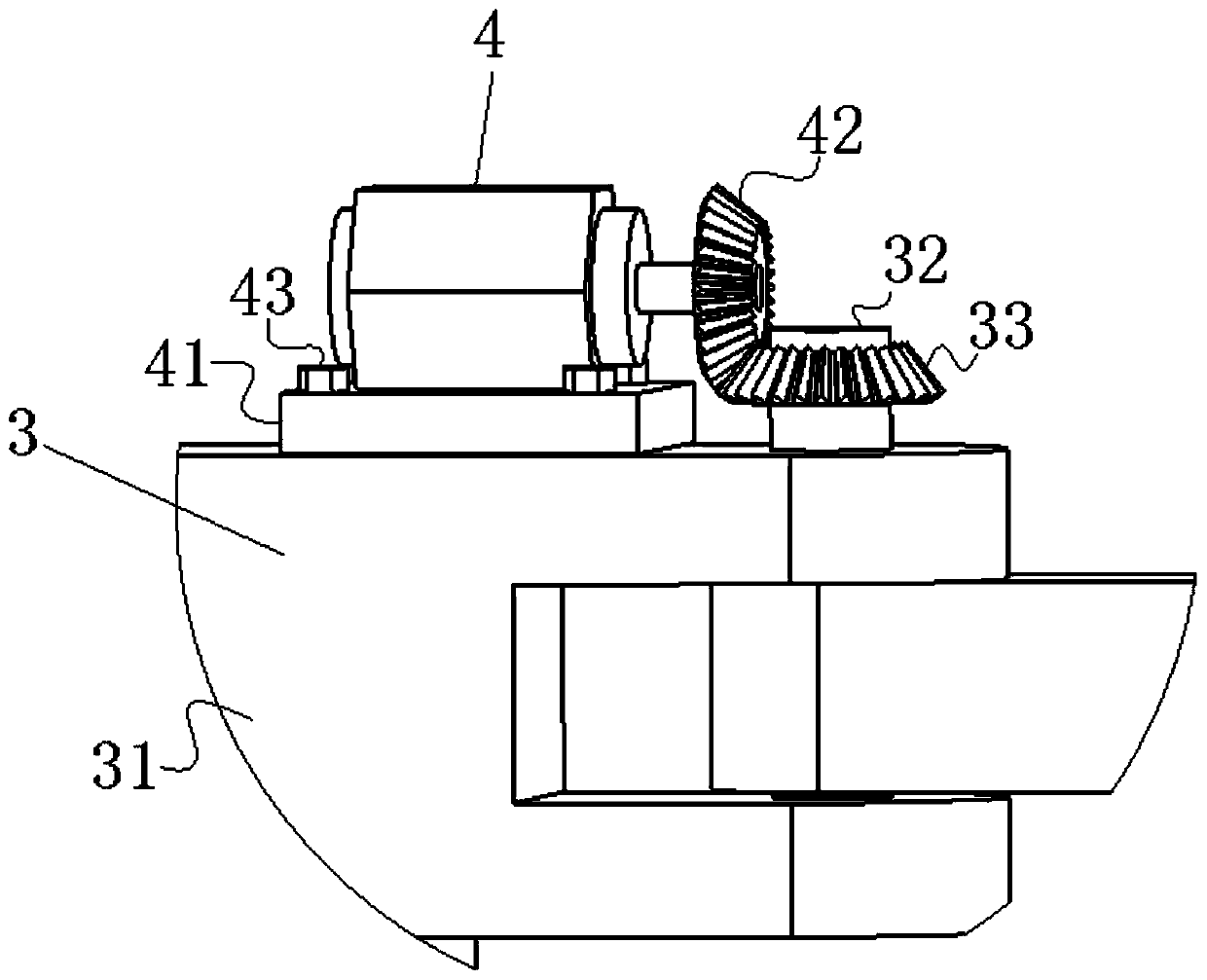

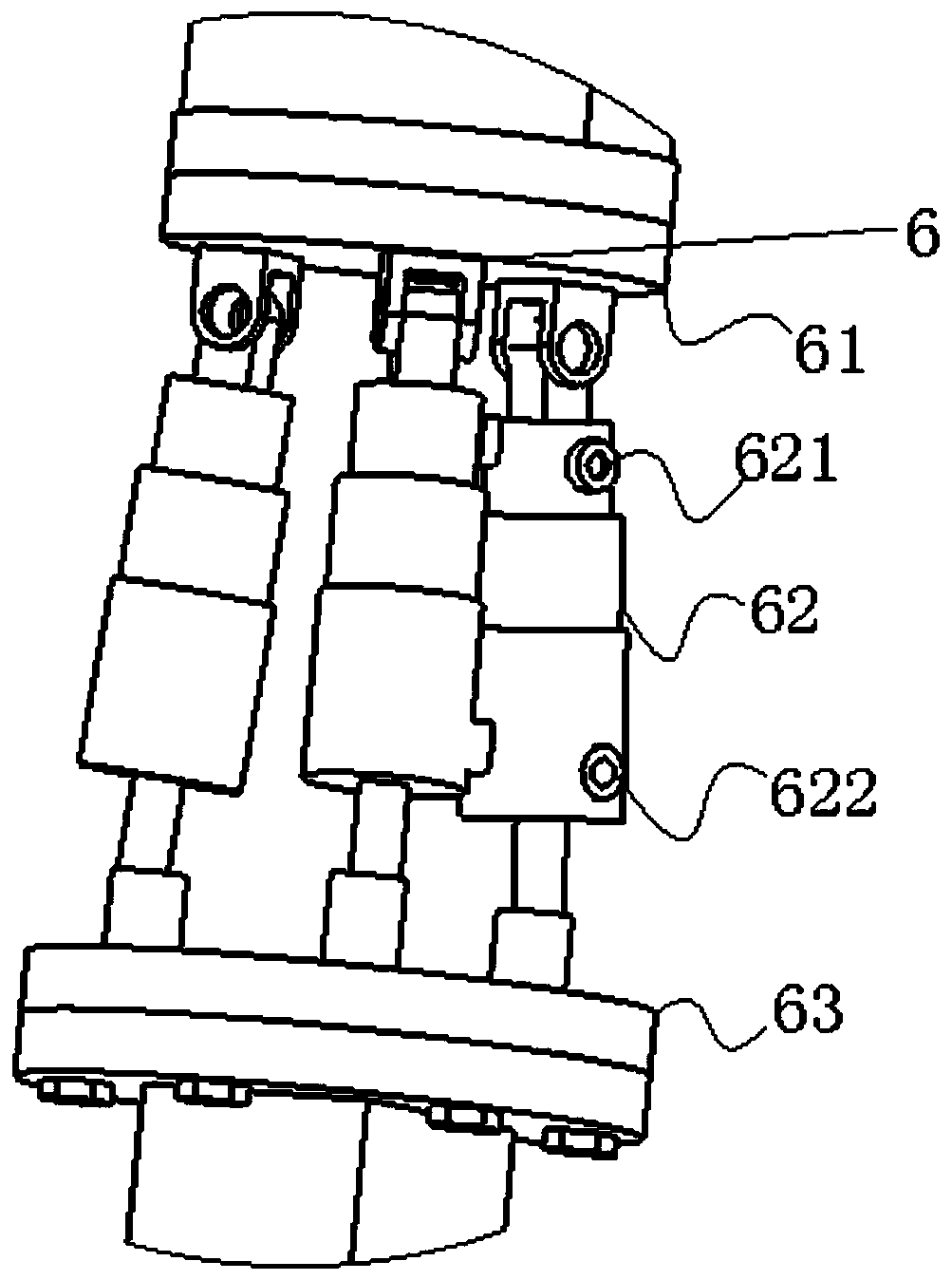

Upper limb rehabilitation mechanical arm capable of changing shoulder center

PendingCN109875845AImplement variableNo strainProgramme-controlled manipulatorChiropractic devicesHand armDrive motor

The invention discloses an upper limb rehabilitation mechanical arm capable of changing the shoulder center. The upper limb rehabilitation mechanical arm comprises a base, a supporting frame, a shoulder joint, a shoulder motor, a shoulder connecting rod, a 3-DOF parallel hydraulic platform, a big arm connecting rod, a big arm, an elbow joint and a wrist joint, and the shoulder joint comprises a transverse beam and a rotary shaft; the shoulder motor comprises a motor, a fixed base and a bevel gear; the 3-DOF parallel hydraulic platform comprises an upper bottom plate, three telescopic hydrauliccylinders and a lower bottom plate; the big arm comprises a holder, a driving motor, an upper connecting plate and a rotating shaft; the elbow joint comprises a small driving motor, a big driving motor, a small holder, a large holder and a lower connecting plate; the wrist joint comprises a driving motor, a holder, a wrist baffle, a belt pulley, a wrist connecting rod, a bolt connecting rod and abolt. According to the upper limb rehabilitation mechanical arm, the shoulder center can be changed so that the shoulder joint can move in any direction no matter where the big arm and the forearm ofthe arm are, and the upper limb rehabilitation mechanical arm has the advantages of being compact in structure, high in practicability and the like.

Owner:ANHUI UNIV OF SCI & TECH

A vacuum coating production line

ActiveCN104018130BSmall footprintHigh economic valueVacuum evaporation coatingSputtering coatingProduction lineEngineering

The invention discloses a vacuum coating production line, which includes a transfer line and a coating line, the coating line is connected to the transfer line; the transfer line includes a track, at least one transfer car and at least one film loading device, and the transfer car runs on the track , convey the film loading device through the transfer car; the coating line includes an inlet chamber, an inlet transition chamber, an inlet buffer chamber, a coating chamber, an outlet buffer chamber, an outlet transition chamber and an outlet chamber . Compared with the existing technology, the transmission line and the coating line are connected end to end to form a circular line, which saves floor space. The substrate transmission in the entire coating production line adopts intelligent control, which saves manpower and material resources and improves production efficiency. Each chamber in the coating line is based on Product demand is replaced or increased, and the entire coating production line adapts to various coating process requirements, prolongs the service life, and saves resources, so its application prospects are very broad.

Owner:XIANGTAN HONGDA VACUUM TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com