Intelligent construction platform for construction of super high-rise building

A technology for building construction and construction platform, which is applied in the direction of building, building structure, scaffolding supported by house structure, etc., can solve the problem that the force and deformation of the formwork are difficult to control, the formwork is not equipped with a stress monitoring system, and it is difficult to support columns. Find support points and other issues to achieve the effect of facilitating safety monitoring, improving cross-section changes, and saving construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

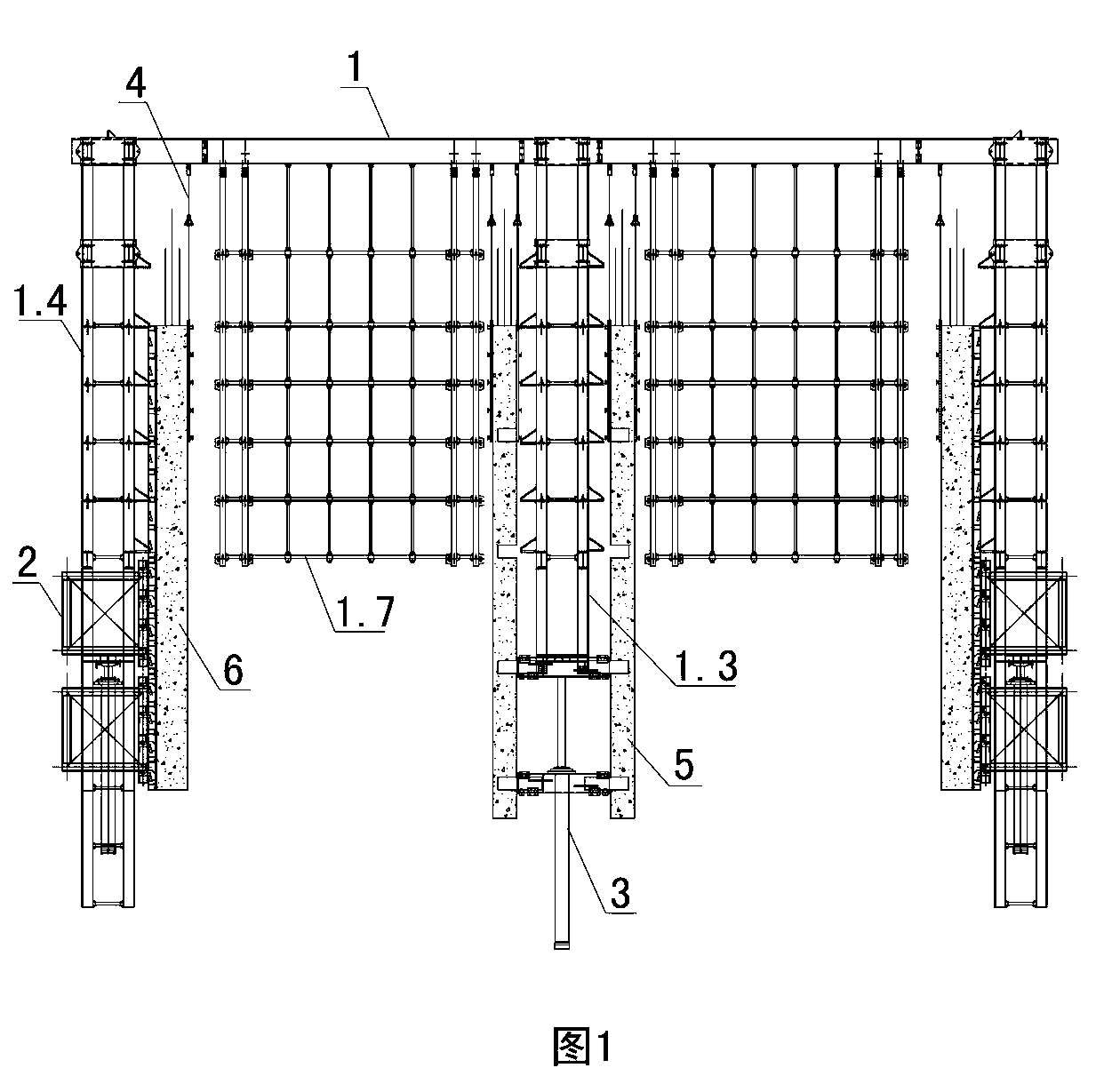

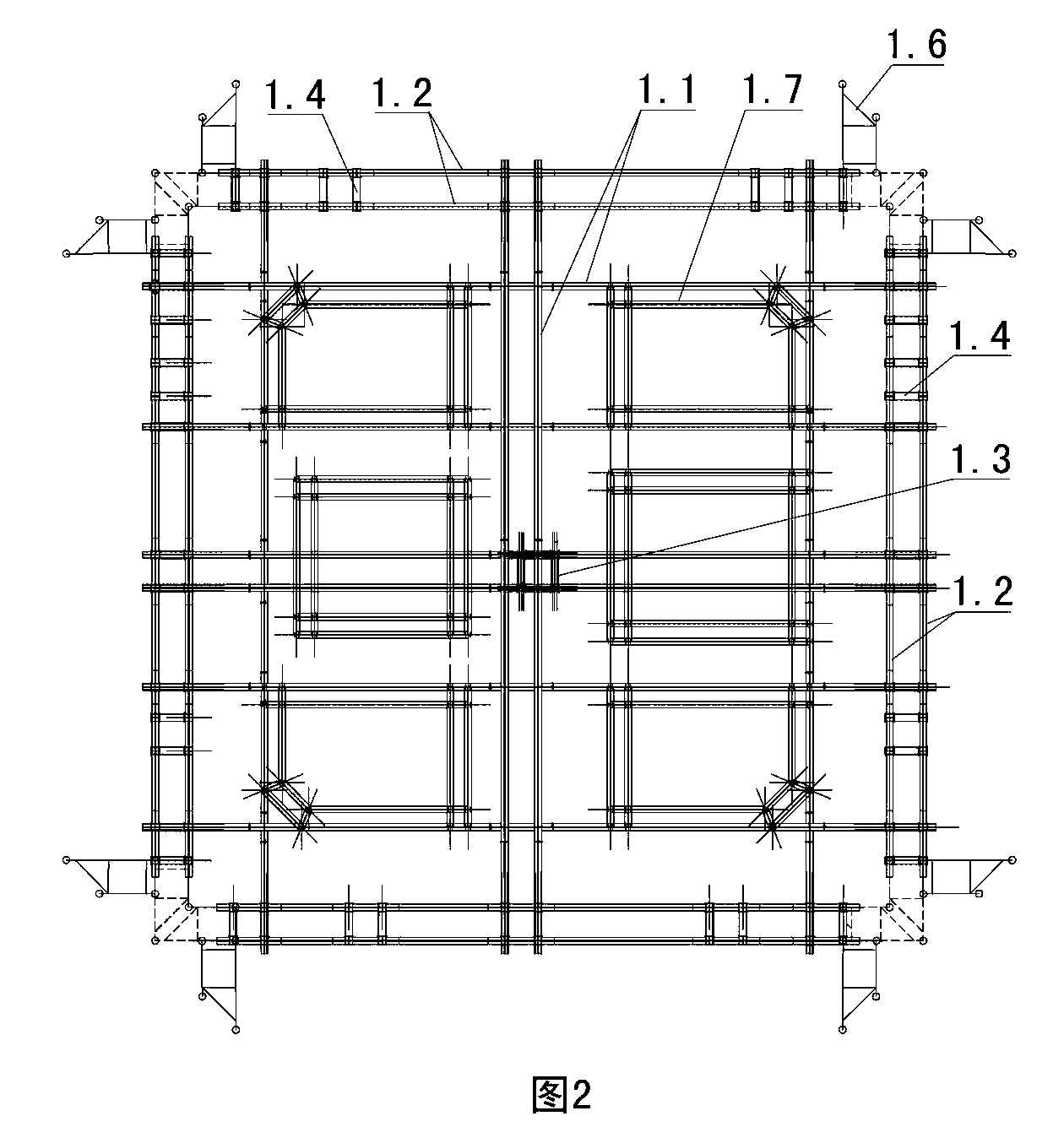

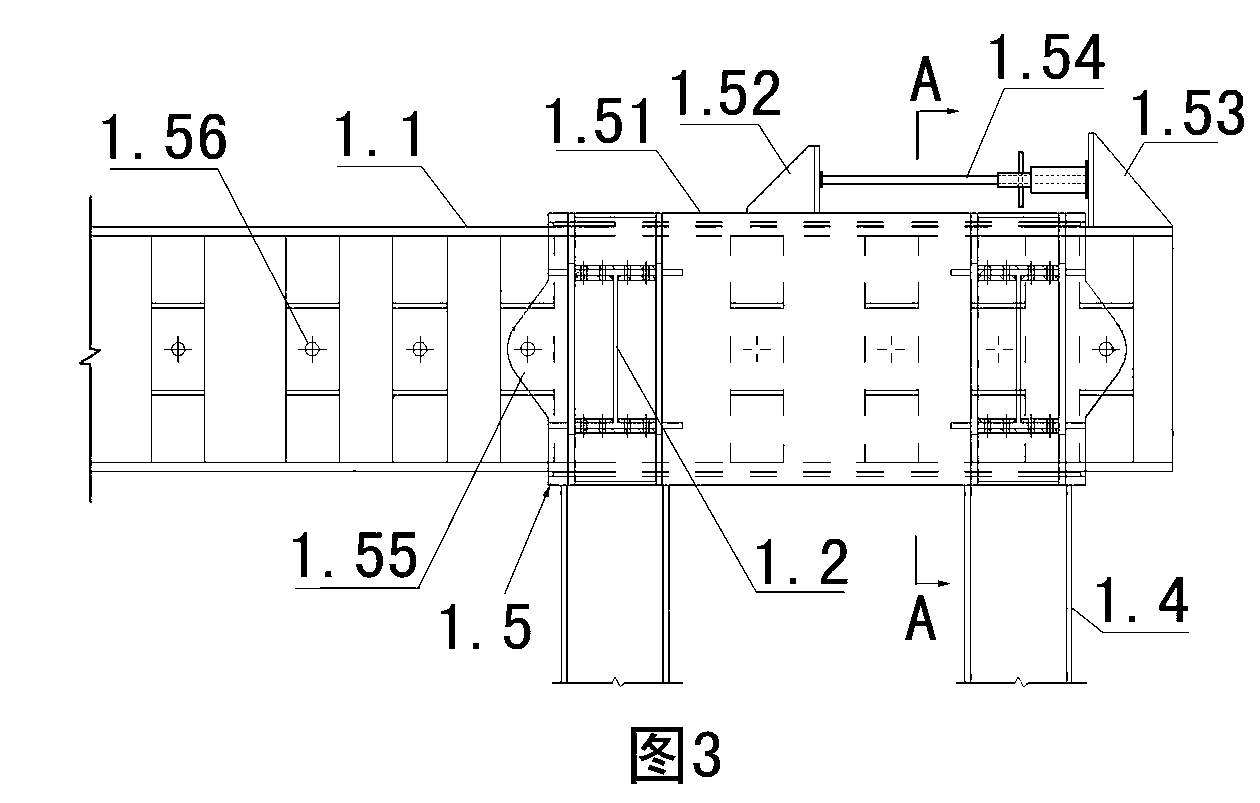

[0044] Examples see figure 1 , figure 2, this intelligent construction platform for the construction of super high-rise buildings, including support and jacking system connected to the shear wall, steel frame system 1 connected to the support and jacking system, and hanging on the steel frame Template System 4 on System 1. The steel frame system 1 includes a main platform frame 1.1 with a rectangular platform surface, an outer frame 1.2 at the four sides of the main platform frame, a hanger 1.7 and an inner supporting column 1.3 arranged at the lower part of the main platform frame, and an outer The outer support column 1.4 of frame bottom. The support and jacking system is composed of an inner frame support and jacking system 3 and an outer frame support and jacking system 2, and the inner support column 1.3 is connected to the inner shear wall 5 through the support of the inner frame support and the jacking system 3 Above, the outer support column 1.4 is connected to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com