A high pressure variable displacement plunger pump

A variable plunger and high pressure technology, applied in the field of high pressure variable plunger pumps, can solve the problems of large installed power, large floor space, and increased use costs, and achieve the effect of reducing displacement and realizing variable displacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

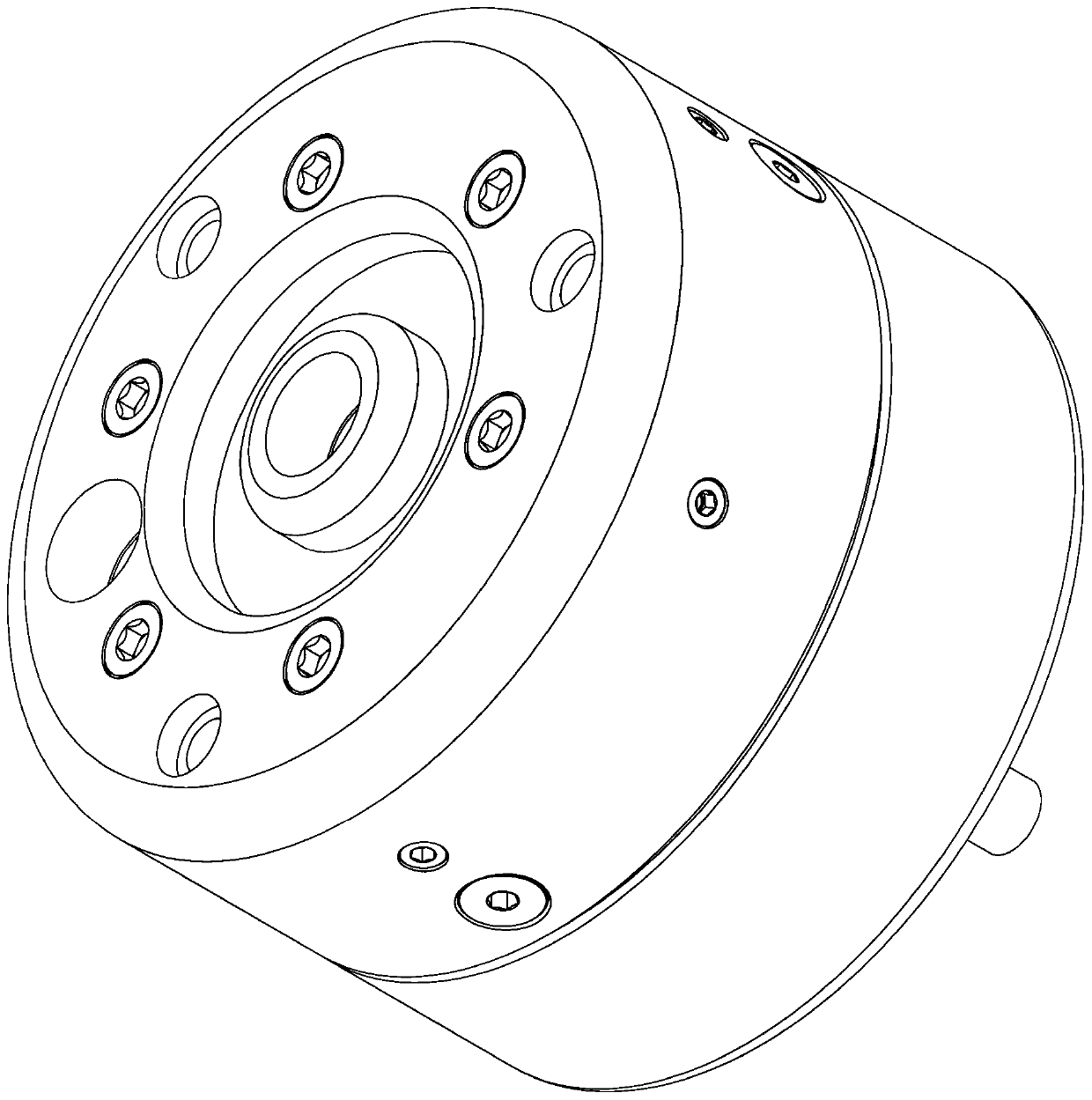

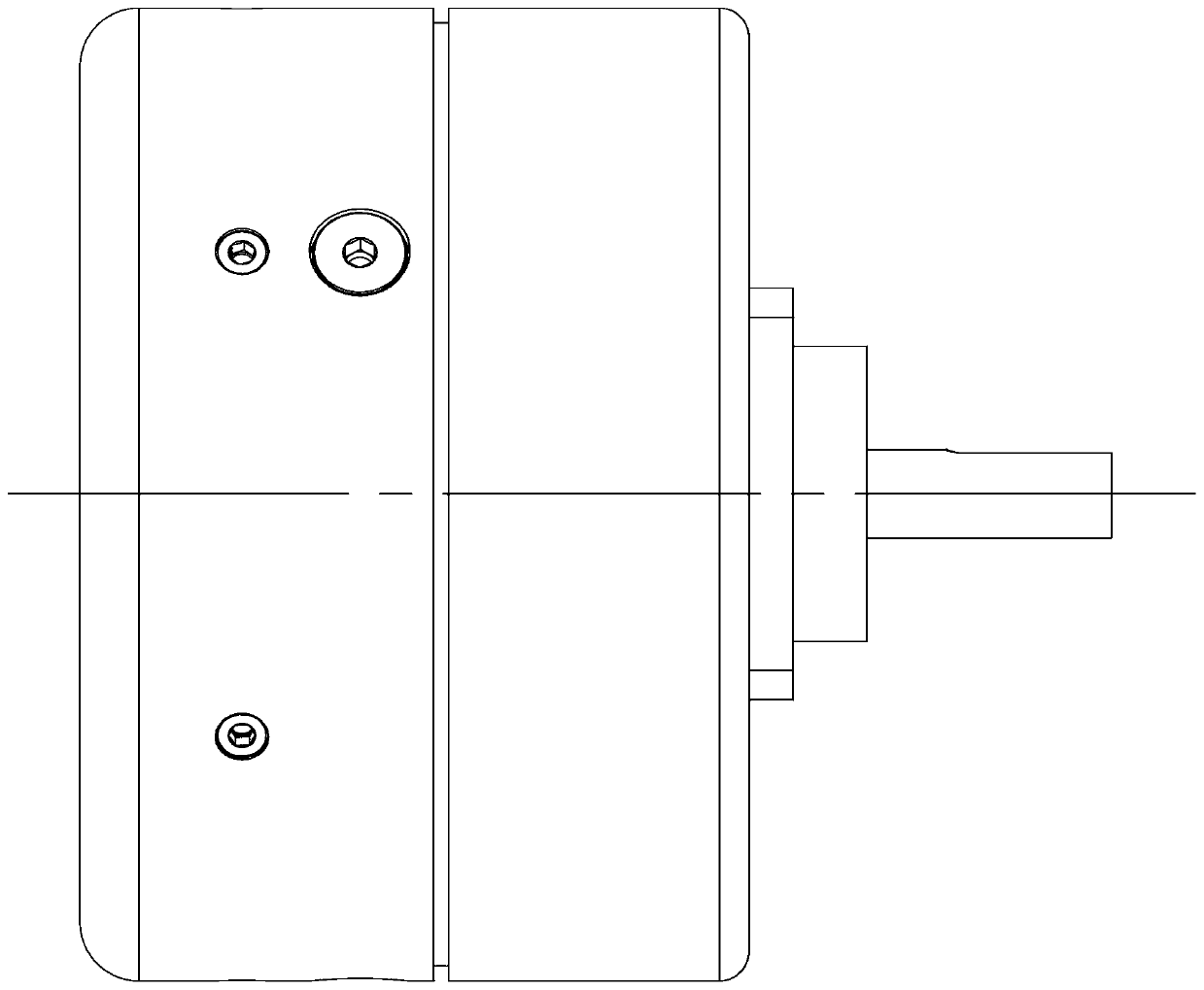

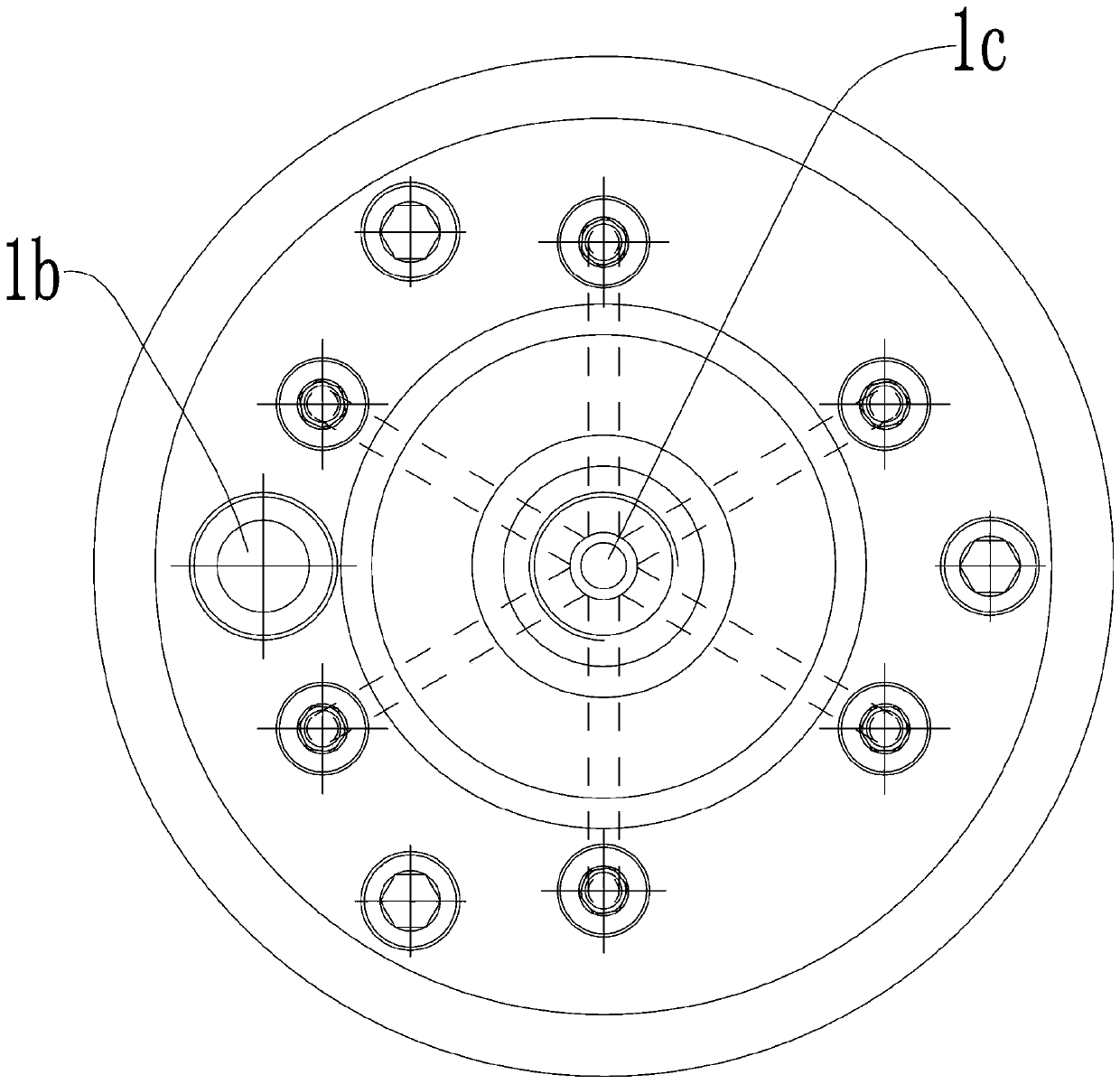

[0028] see Figure 1-10 As shown, a high-pressure variable displacement plunger pump includes a pump body 1 and a pump casing 19 installed on the right end surface of the pump body 1, an oil inlet chamber 1a is formed between the pump casing 19 and the right end surface of the pump body 1, The left end surface of the pump body 1 is provided with an oil inlet hole 1b communicating with the oil inlet chamber 1a; the right end surface of the pump body 1 is rotatably connected with a rotating shaft 17 protruding from the pump casing 19, and the oil inlet chamber 1a is internally On the right end surface of the pump body 1, six plunger modules are evenly installed with the rotating shaft 17 as the center. In the oil inlet chamber 1a, a shaft sleeve 21 is eccentrically installed on the shaft 17 through a pin key. On the shaft sleeve 21 A polygonal axle sleeve 22 with a regular hexagonal cross section is installed on it.

[0029] The plunger module includes a mounting block 13, a pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com