Variable local holographic anti-counterfeiting safety line and preparation method thereof

A holographic anti-counterfeiting and security thread technology, applied in the field of variable partial holographic anti-counterfeiting security thread and its preparation, can solve the problem of inconvenience in product logistics management and digital management of anti-counterfeiting inquiry, holographic pattern and printed pattern are not integrated together, and safety cannot be eliminated. problems such as secondary use of the line, to achieve the effect of convenient digital management of anti-counterfeiting inquiry, convenient logistics management, and good holographic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

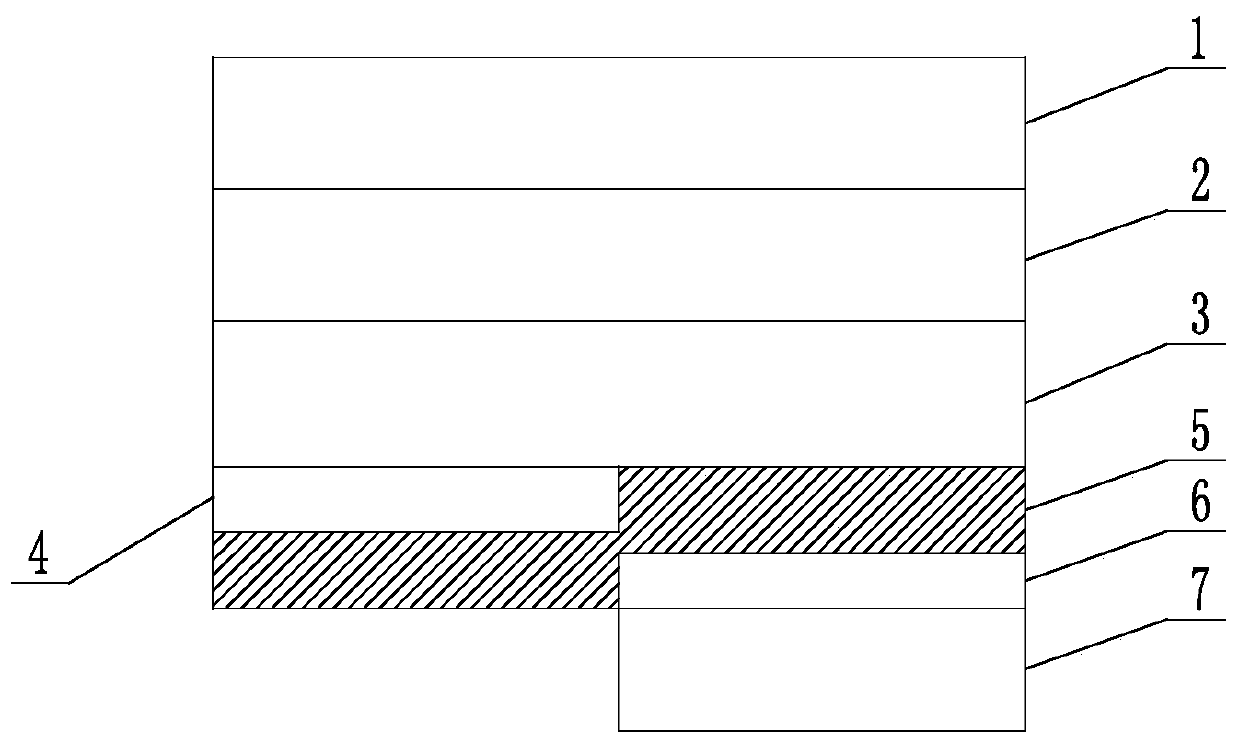

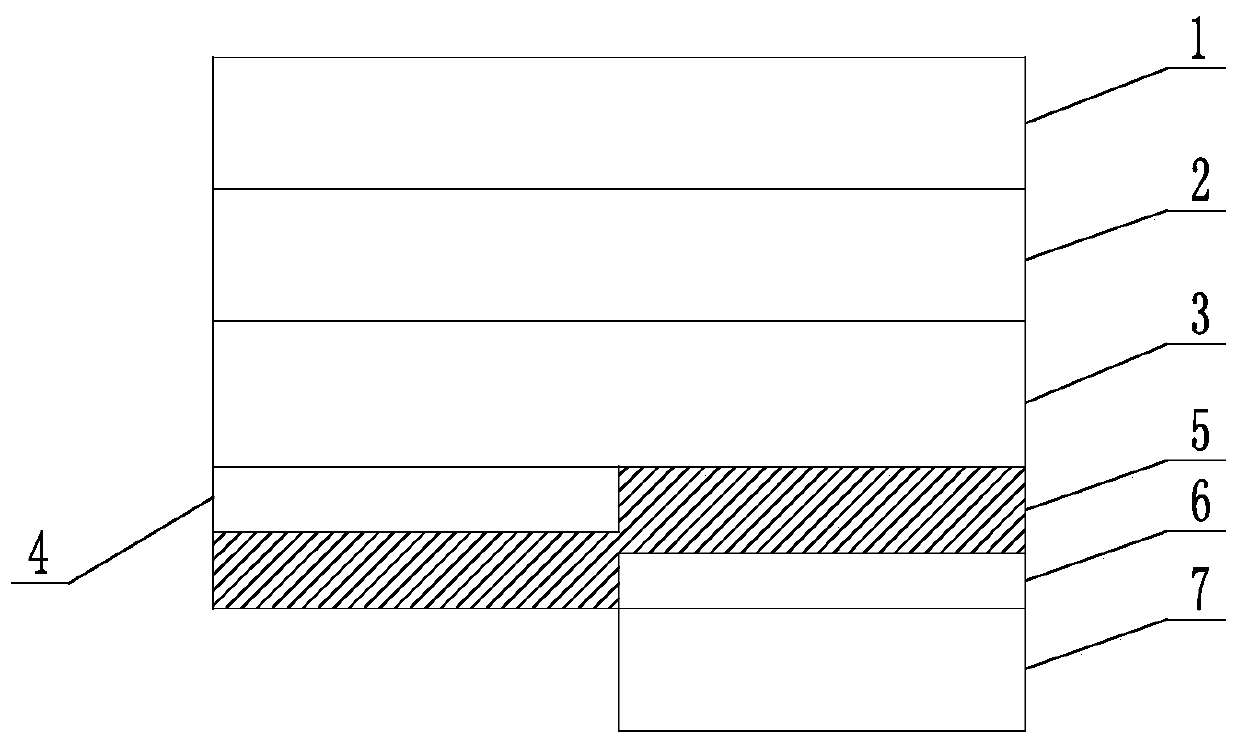

[0039] Such as figure 1 As shown, the variable local holographic anti-counterfeiting security thread includes a plastic film layer 1, a permanent molded information layer 2 and a positioning molded layer 3 arranged in sequence from top to bottom, and a partial hollow printing layer is arranged in sequence below the positioning molded layer 3 4 and the partial aluminum plating layer 6, the partial hollow printing layer 4 and the partial aluminum plating layer 6 contain part of variable information respectively, and form complete variable information after being combined, the variable information includes a two-dimensional code, and the partial hollow printing layer 4 A release layer 5 is arranged between the partial aluminum plating layer 6 , and an invisible ink layer 7 is arranged below the partial aluminum plating layer 6 .

[0040] in:

[0041] The width of the variable partial holographic anti-counterfeiting security thread is 3mm.

[0042] The plastic film layer 1 is a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com