Air spring appending air chamber structure with variable volume

An additional air chamber and air spring technology, applied in the direction of springs, springs/shock absorbers, gas shock absorbers, etc., can solve the problems of complicated changes, improve ride comfort and ride comfort, and reduce the space occupied. The effect of small, widened variation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

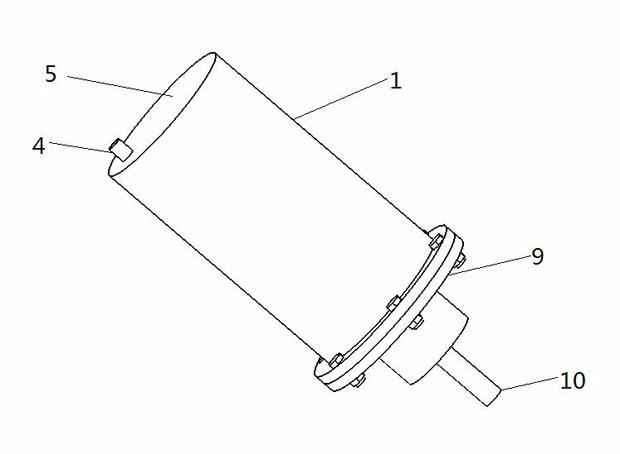

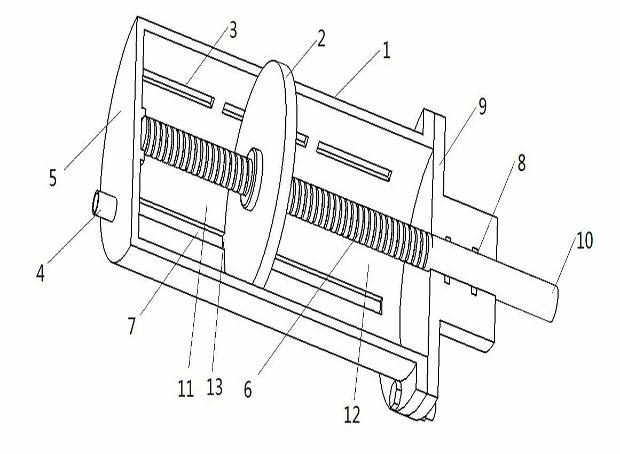

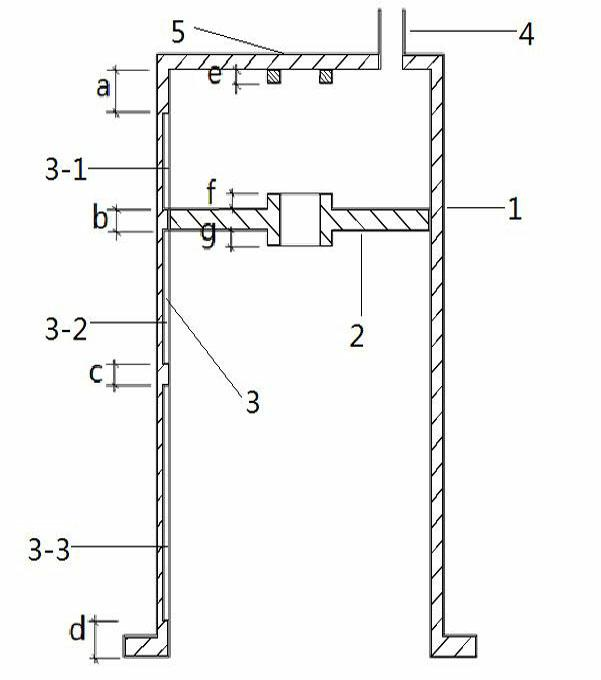

[0013] see Figure 1-2 , the present invention includes a cylindrical additional air chamber cavity 1, the two ends of the additional air chamber cavity 1 are open, the lower opening is sealed and connected to the lower sealing cover plate 5, and the upper opening is sealed and connected to the upper sealing cover plate 9 to ensure that the additional air chamber The airtightness of chamber cavity 1. The lower sealing cover plate 5 is connected to one end of the connecting pipeline 4, so that one end of the connecting pipeline 4 communicates with the additional air chamber cavity 1, and the other end of the connecting pipeline 4 communicates with the air spring body.

[0014] A lead screw 6 is arranged at the central axis of the inner cavity of the additional air chamber cavity 1, the lower end of the lead screw 6 is fixedly connected to the lower sealing cover 5, the upper end of the lead screw 6 passes through the hole on the sealing cover 9, and extends Out of the addition...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com