Detonation type synthesis device

A synthesis device and detonation technology, which is applied in the field of new material synthesis, can solve problems such as low conversion rate and difficult recovery, and achieve the effects of improving conversion rate and recovery rate, reducing costs, and simplifying the connection structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

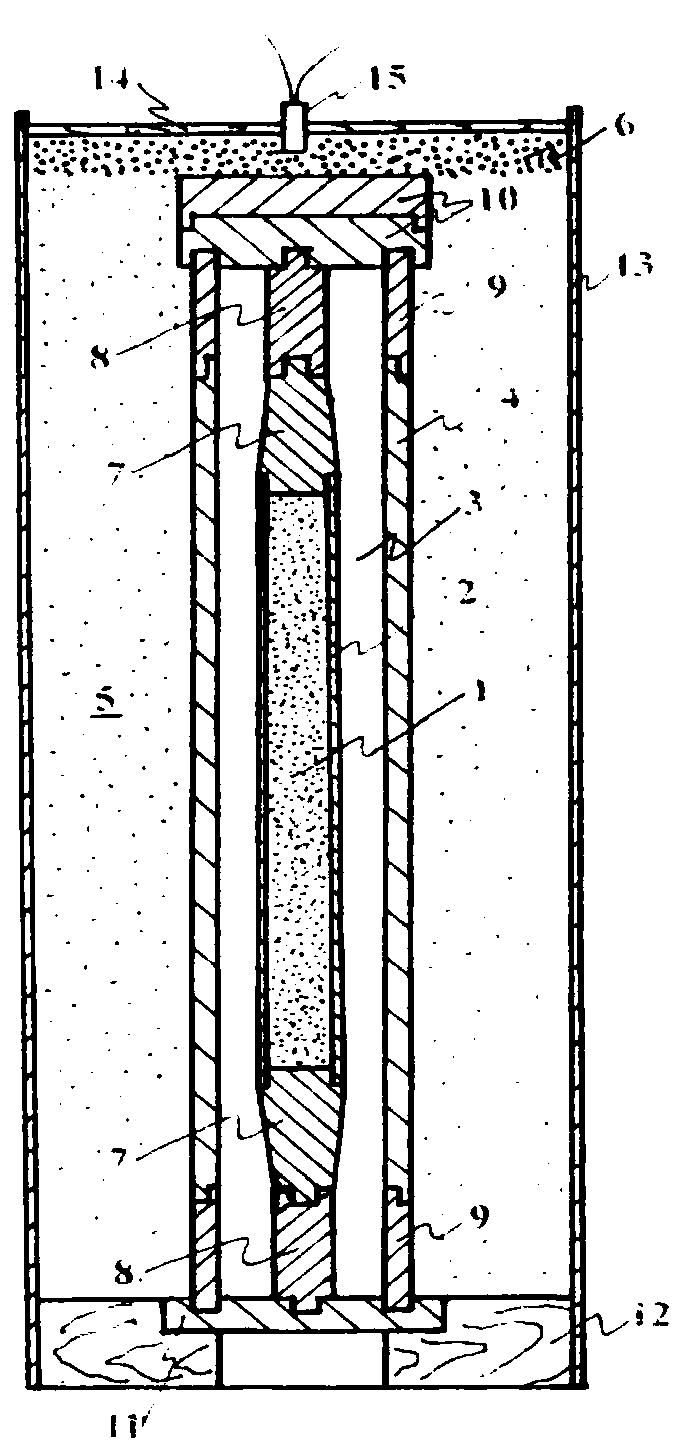

[0051] This embodiment provides a double-tube connection structure for detonation synthesis, including a drive tube 4 and a sample tube 2. Both the drive tube 4 and the sample tube 2 are circular tube structures, and the drive tube 4 is coaxially sleeved outside the sample tube 2. , the annular gap between the inner wall of the driving tube 4 and the outer wall of the sample tube 2 is used as a cavity 3; the top port and the bottom port of the sample tube 2 are provided with sealing end plugs 7, and the top port and the bottom port of the sample tube 2 are both located at the drive Inside tube 4. It also includes fixing parts, which are covered with fixing parts at the top port and the bottom port of the driving tube 4, which can prevent the main explosive from entering the cavity 3; The drive tube 4 moves toward the axis of the sample tube 2 from top to bottom, so that the drive tube 4 covers the top end plug 7 of the sample tube 2, the sample tube 2 and the bottom of the sam...

Embodiment 2

[0053] Further improvement on the basis of Example 1, the outer diameter of the portion of the end plug 7 that is in contact with the drive tube 4 is smaller than the outer diameter of the sample tube 2; further preferably, the end plug 7 is a frustum of a conical structure, and The large-diameter end of the frustum-conical structure is plugged into the port of the sample tube 2, and the small-diameter end of the frustum-conical structure is connected with the fixing piece.

Embodiment 3

[0055] Further improvement on the basis of Embodiment 1 or 2, when the detonation wave of the fixing part is transmitted to the connection between the end of the drive tube 4 and the fixing part after the detonation, the end of the driving tube 4 and the connection part of the fixing part are disconnected , the fixing part is scattered outward by the action of the stretching wave; As a preferred solution, the fixing member installed on the top of the drive tube 4 includes a fixing ring 9 and two layers of cover plates 10; one end of the fixing ring 9 is connected with the top of the drive tube 4, and the other end is connected with the cover plate 10; the cover plate 10 is used In the sealed cavity 3 , an annular groove is opened on the lower surface of the cover plate 10 , and the end of the fixing ring 9 can be inserted into the annular groove for fixing. The fixing member installed on the bottom of the driving tube 4 includes a fixing ring 9 and a base 11, one end of the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com