Transfer robot and handling system and handling method of transfer robot

A handling robot and handling system technology, applied in the field of intelligent storage, can solve the problems of low efficiency and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

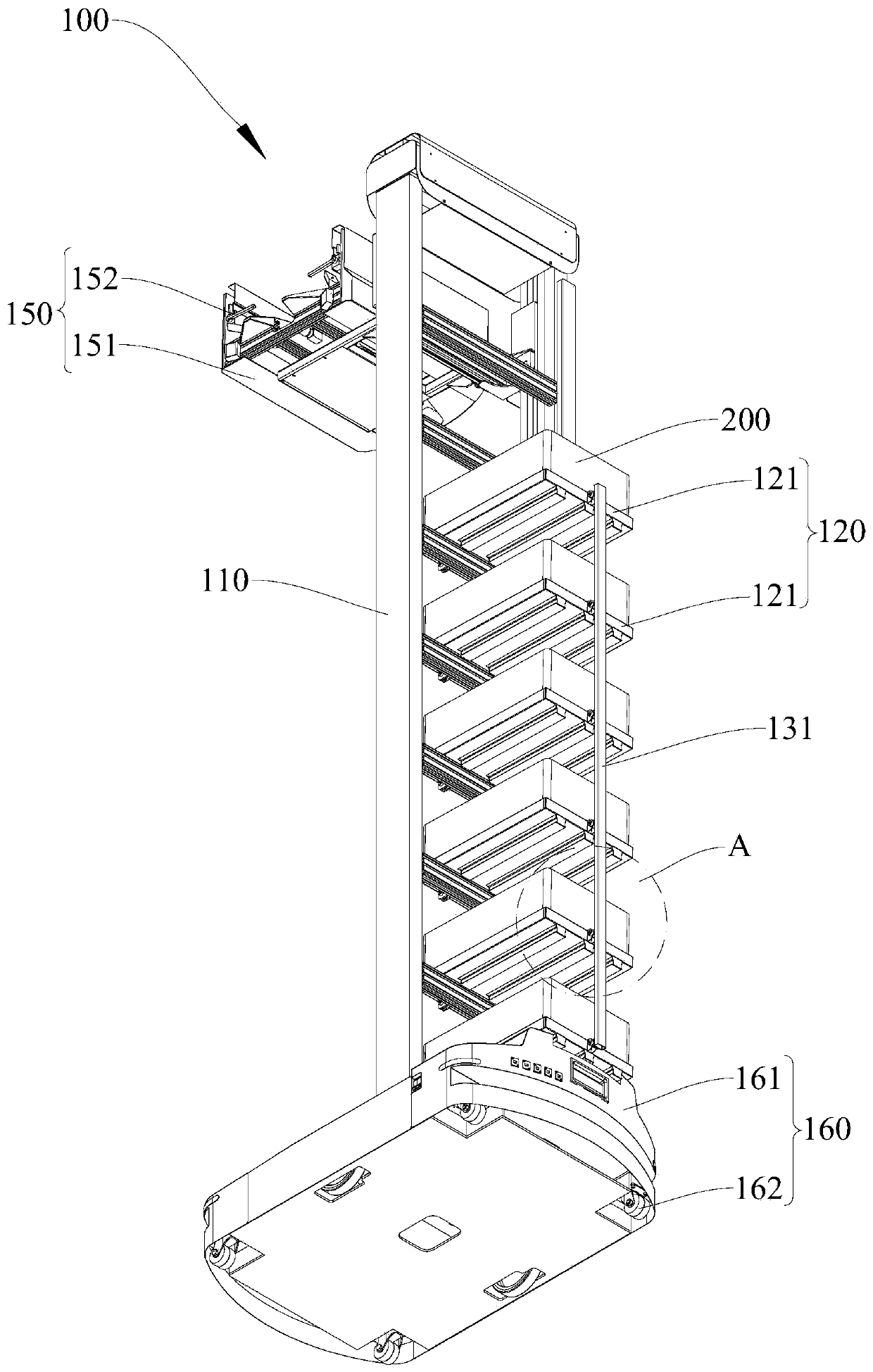

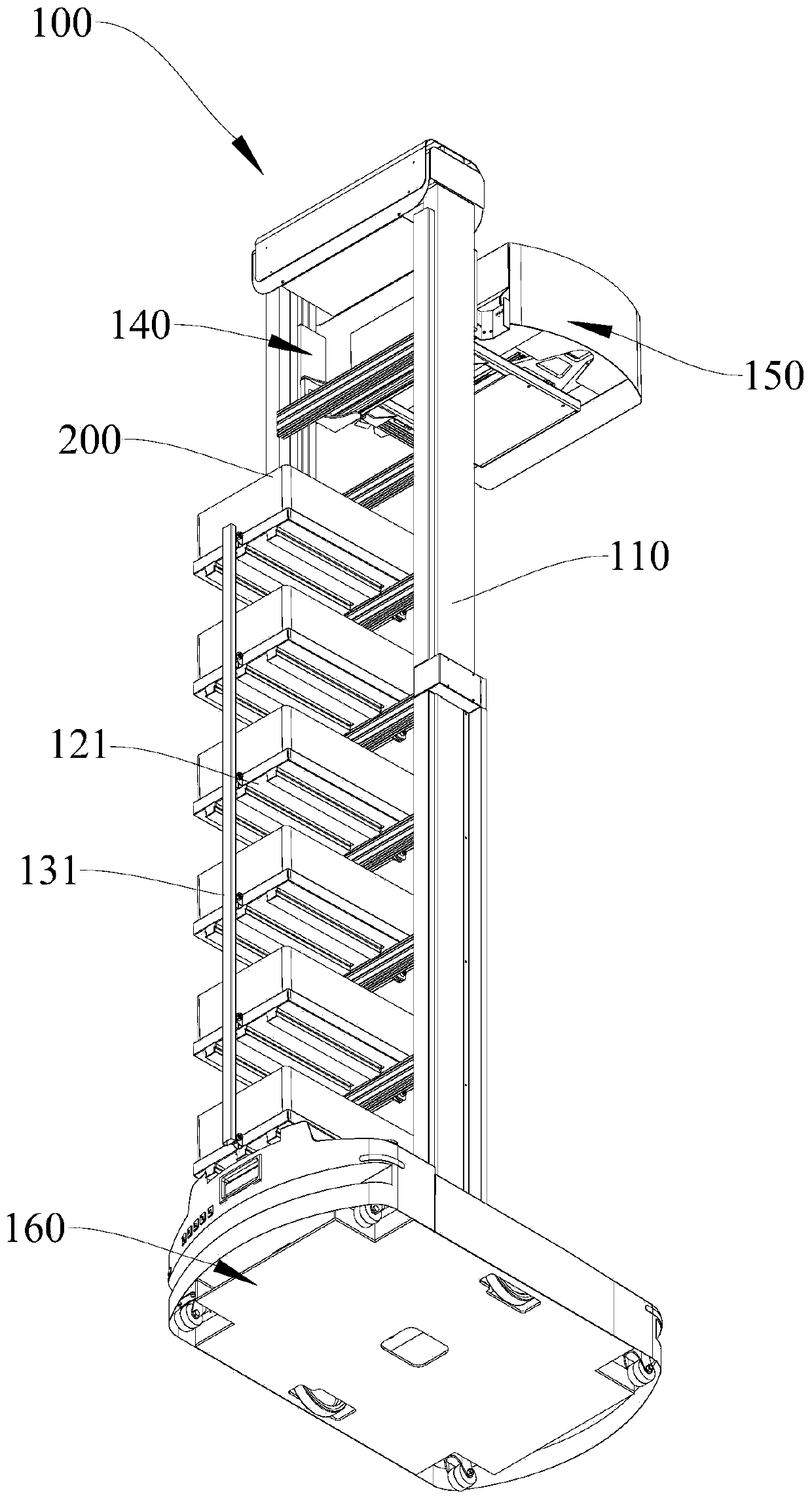

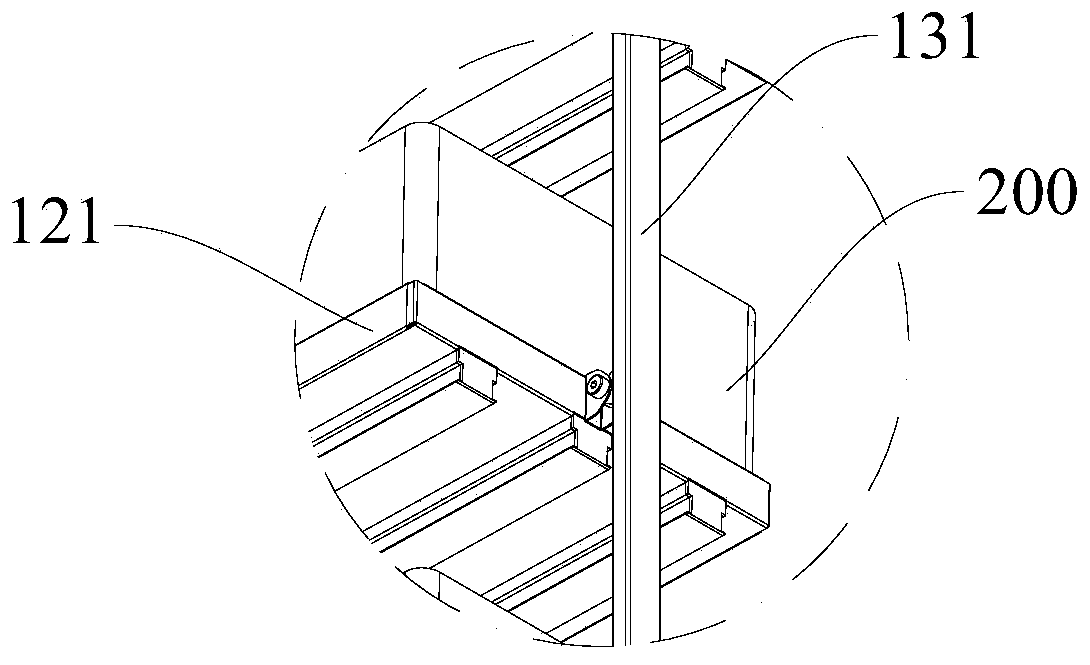

[0142] see Figure 1 to Figure 8 , in the first embodiment of the present invention, when the handling robot 100 is unloading, a plurality of storage components 121 can move synchronously to implement a synchronous unloading action.

[0143] In order to further improve the handling efficiency of the handling robot 100, the handling robot 100 of the present invention can realize synchronous unloading at the unloading position. When specifically unloading, multiple storage components 121 can move synchronously, so that the goods 200 are moved out of the storage components 121, and the unloading action is synchronized in real time. In this way, the goods 200 in each storage module 121 can be unloaded synchronously, which shortens the unloading time and improves the unloading efficiency of the handling robot 100 . After the unloading is completed, the handling robot 100 can return to the loading position to continue loading, which improves the working efficiency of the handling r...

no. 2 example

[0190] see Figure 9 and Figure 17 , in the second embodiment of the present invention, the handling robot 100 also includes a blocking mechanism 170, the blocking mechanism 170 has a blocking position and an avoidance position, when the blocking mechanism 170 is in the blocking position, the blocking mechanism 170 is used to block the goods 200 in the storage assembly 121 When the blocking mechanism 170 is in the avoidance position, the storage assembly 121 can move in or out of the goods 200 .

[0191] It can be understood that after storing the goods 200 to be transported on the storage component 121, during the movement of the transport robot 100 from the loading position to the unloading position, the transport robot 100 will walk a certain distance, and the goods 200 stored in the storage component 121 will exist. Risk of falling. Once the goods 200 in the storage assembly 121 fall, on the one hand, the goods 200 will be damaged, causing economic losses; This will af...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com