Framework of conveying system on backlight module production line and method thereof

A backlight module and handling system technology, applied in optics, nonlinear optics, instruments, etc., can solve problems such as product damage, waste, and inability to grasp test results in real time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

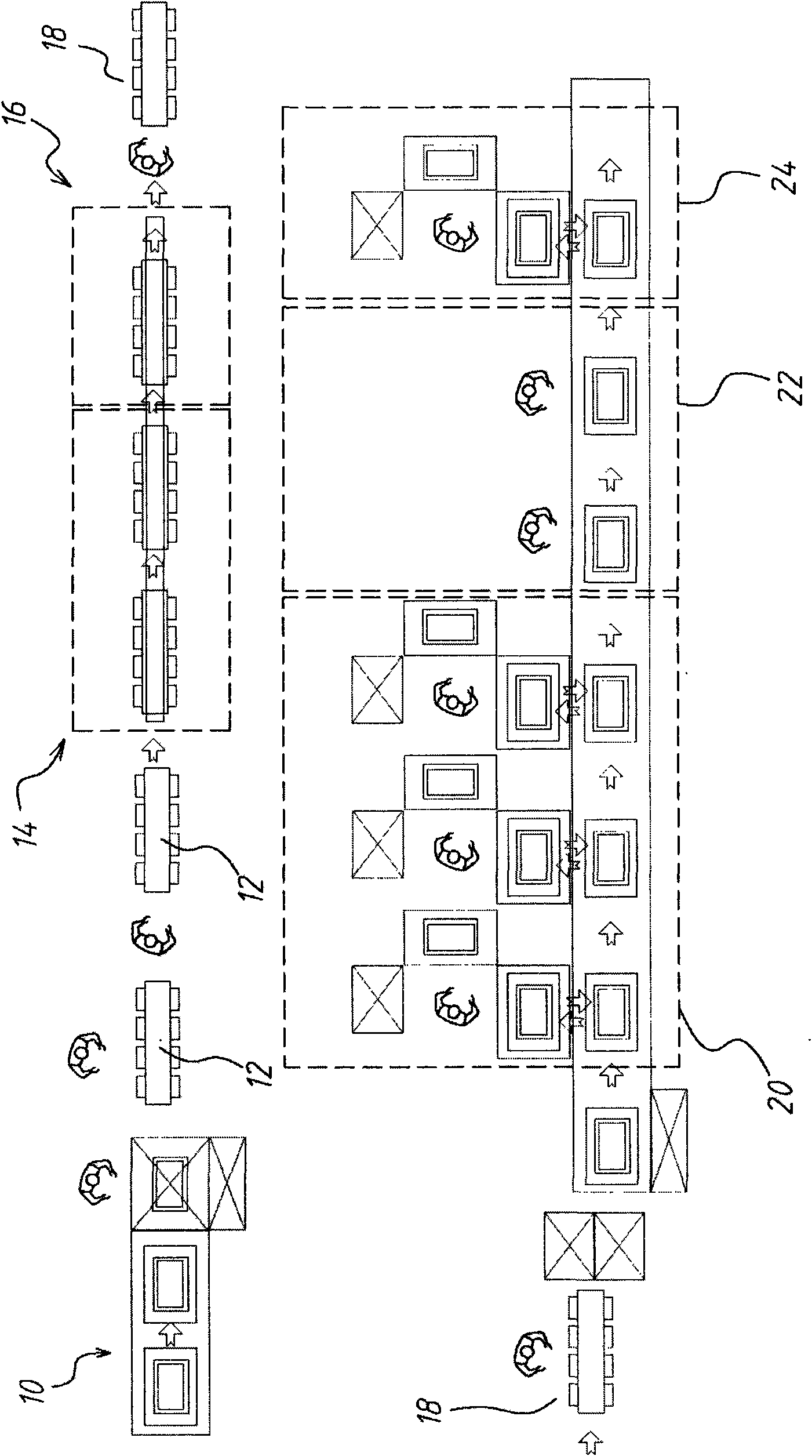

[0014] The present invention provides a structure and method of a transport system on a backlight module production line, which is applied to the test of the backlight module of a liquid crystal display after assembly, and integrates the structure of various test process machines to save manpower and material costs.

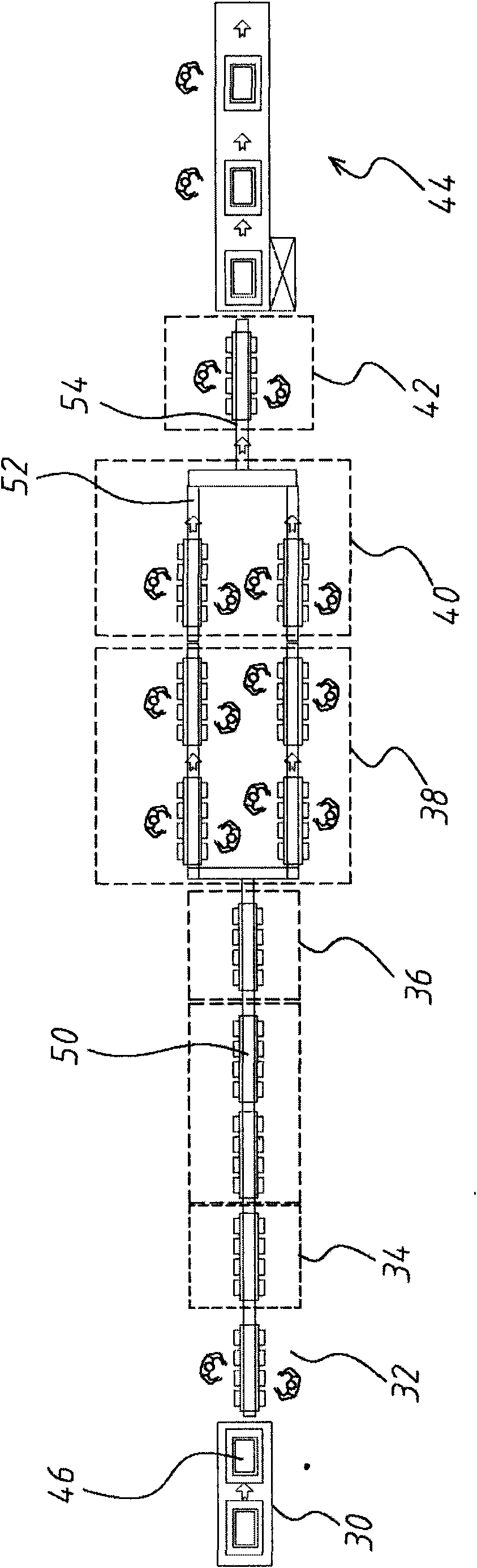

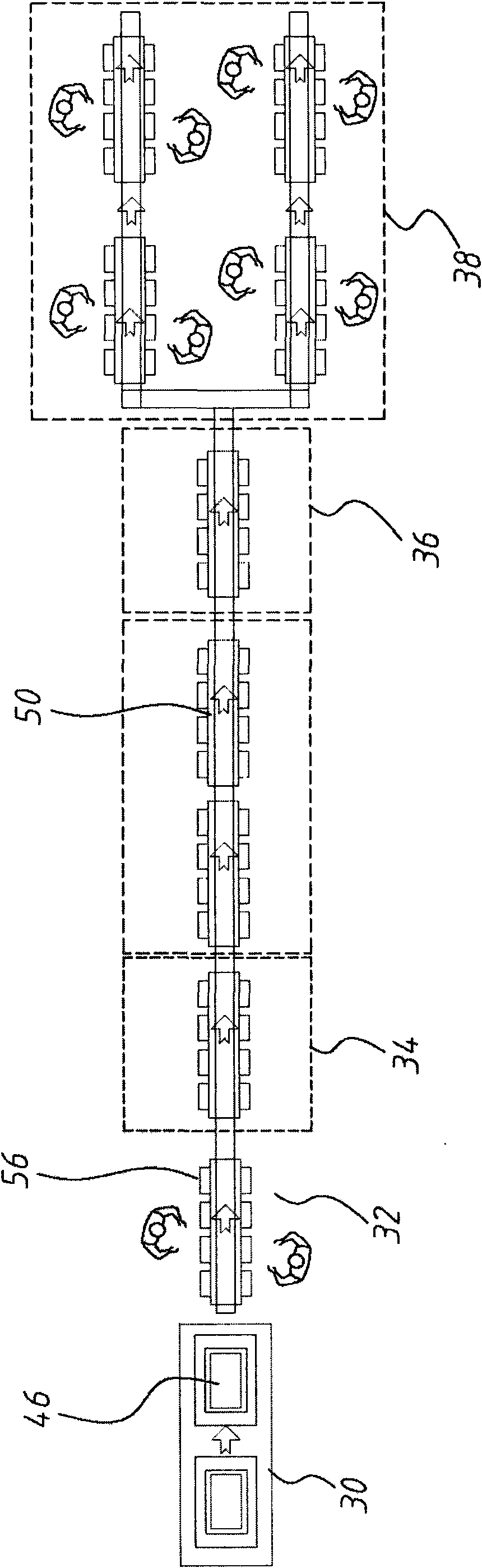

[0015] Such as figure 2 As shown, a structure of a handling system on a backlight module production line includes a plurality of test areas and a plurality of conveyor belts; wherein, the test area includes an assembly completion test area 32, a heat resistance test area 34, and a cooling test area 36 , a product testing area 38, a sampling area 40, an unloading area 42 and a visual inspection area 44, wherein the assembled testing area 32 is used to test the assembled products, and the heat resistance testing area 34 is The product is heated to carry out the aging test and to test whether the product can be started smoothly. Then, the cooling test area 36 is us...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com