Packed material large-slope lifting device

A technology with large slopes and materials, applied in the direction of transportation, packaging, conveyors, etc., can solve the problems of low operating reliability, occupying effective storage capacity, easy bag jamming at the tape interface, etc., to improve conveying speed and reliability, and improve work Efficiency, the effect of improving labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

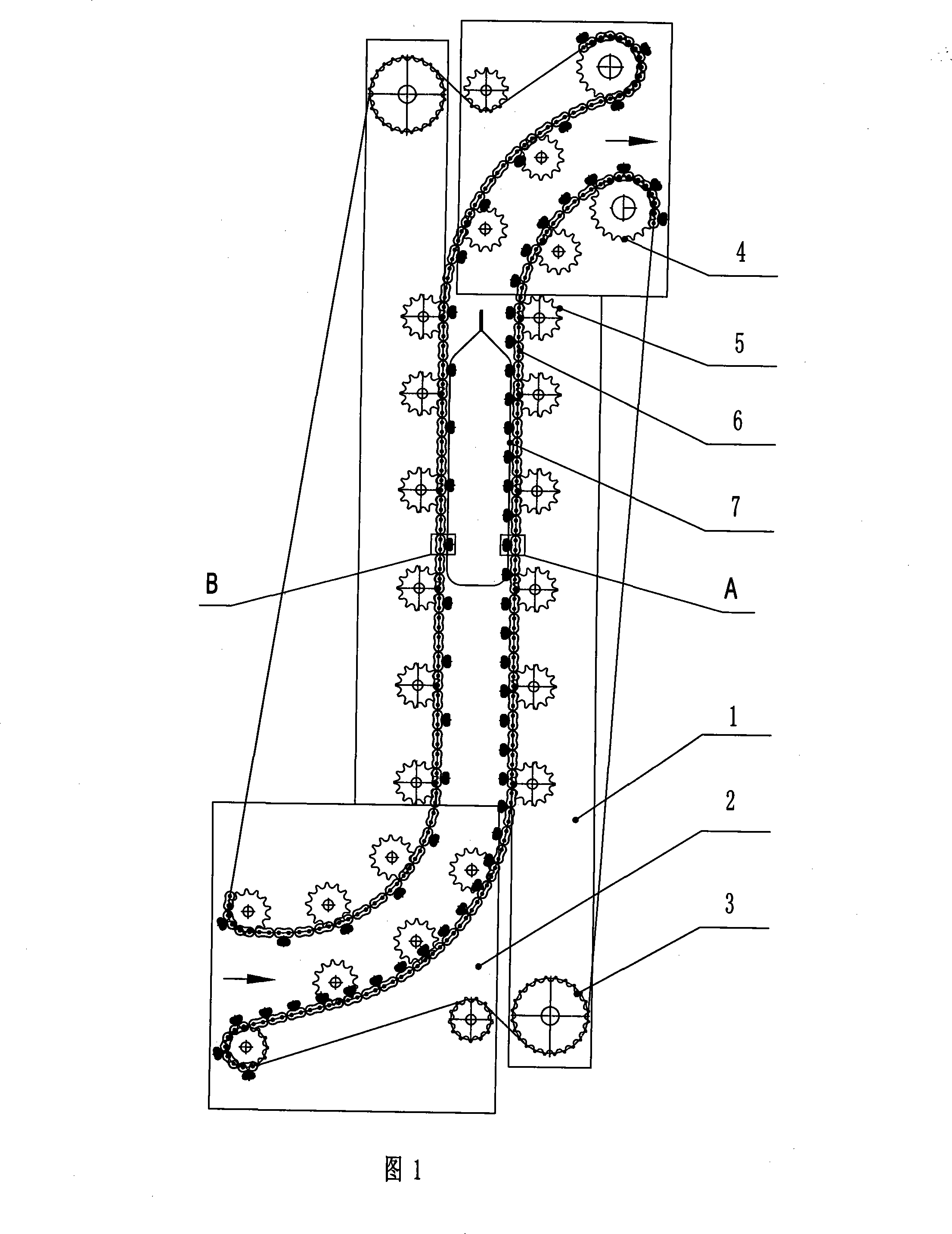

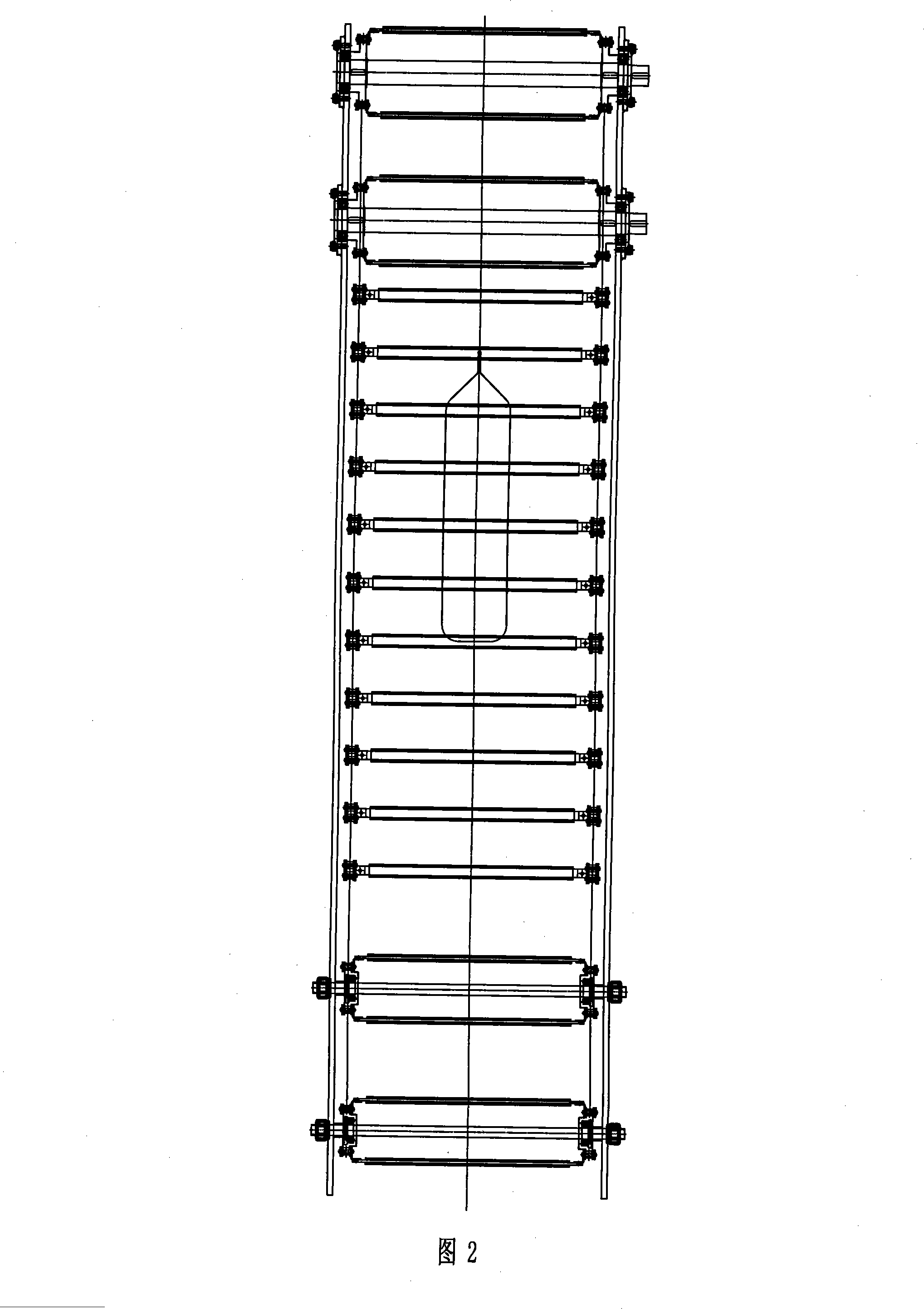

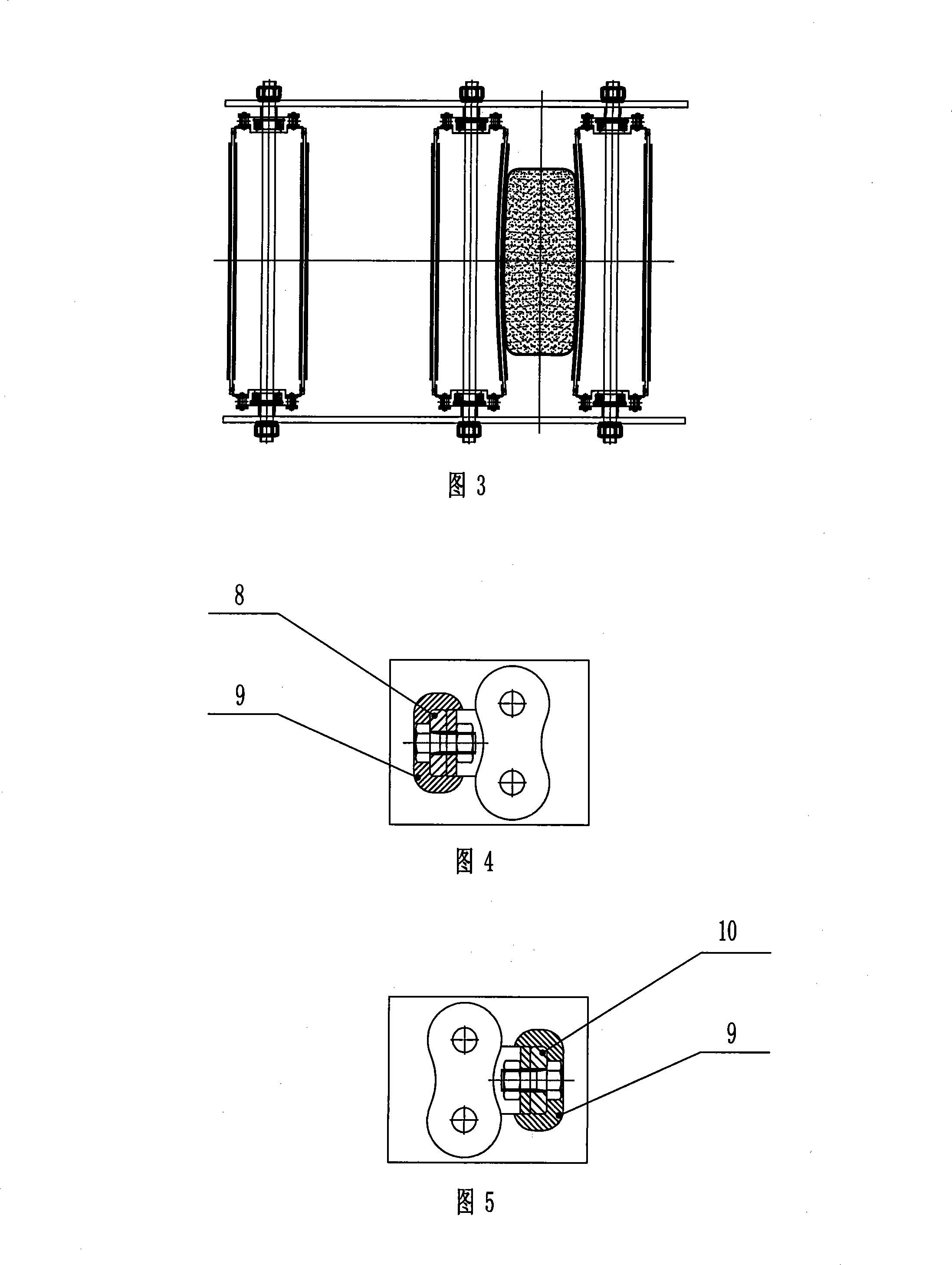

[0022] As shown in Figures 1-5, a large-slope lifting device for bagged materials includes a left frame 1, a right frame 2, drive sprockets, support sprockets and Tensioning sprocket, two sets of short-pitch conveying chains 6 are respectively engaged with the drive sprocket 4, supporting sprocket 5 and tensioning sprocket 3 provided on the left frame and the right frame to move in a circular motion. 6 are respectively hinged with a lower supporting plate 8 and an upper pressing plate 10 to form a lower supporting plate group and an upper pressing plate group, and the lower supporting plate group constitutes the supporting surface of the material bag. 60 mm, the distance between two adjacent upper platens of the upper platen group is relatively large, generally 80-160 mm, its function is to clamp the material bag in sections, so that the material bag is lifted synchronously with the upper platen and the lower supporting plate, and at the same time avoids bagging The inner mate...

Embodiment 2

[0026] The distance between two adjacent lower supporting plates is 50 mm, the distance between two adjacent upper pressing plates of the upper pressing plate group is 120 mm, the length of the hinged fulcrum at both ends of the upper pressing plate and the lower supporting plate is 1.8 times the width of the material bag, and the rest are the same Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com