Aircraft engine mounting vehicle

An aero-engine and installation vehicle technology, applied in aircraft assembly, aircraft parts, ground installations, etc., can solve the problems of high engine loading and unloading costs, low degree of automation, low efficiency, etc., to reduce loading and unloading costs, improve efficiency, and positioning accuracy. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

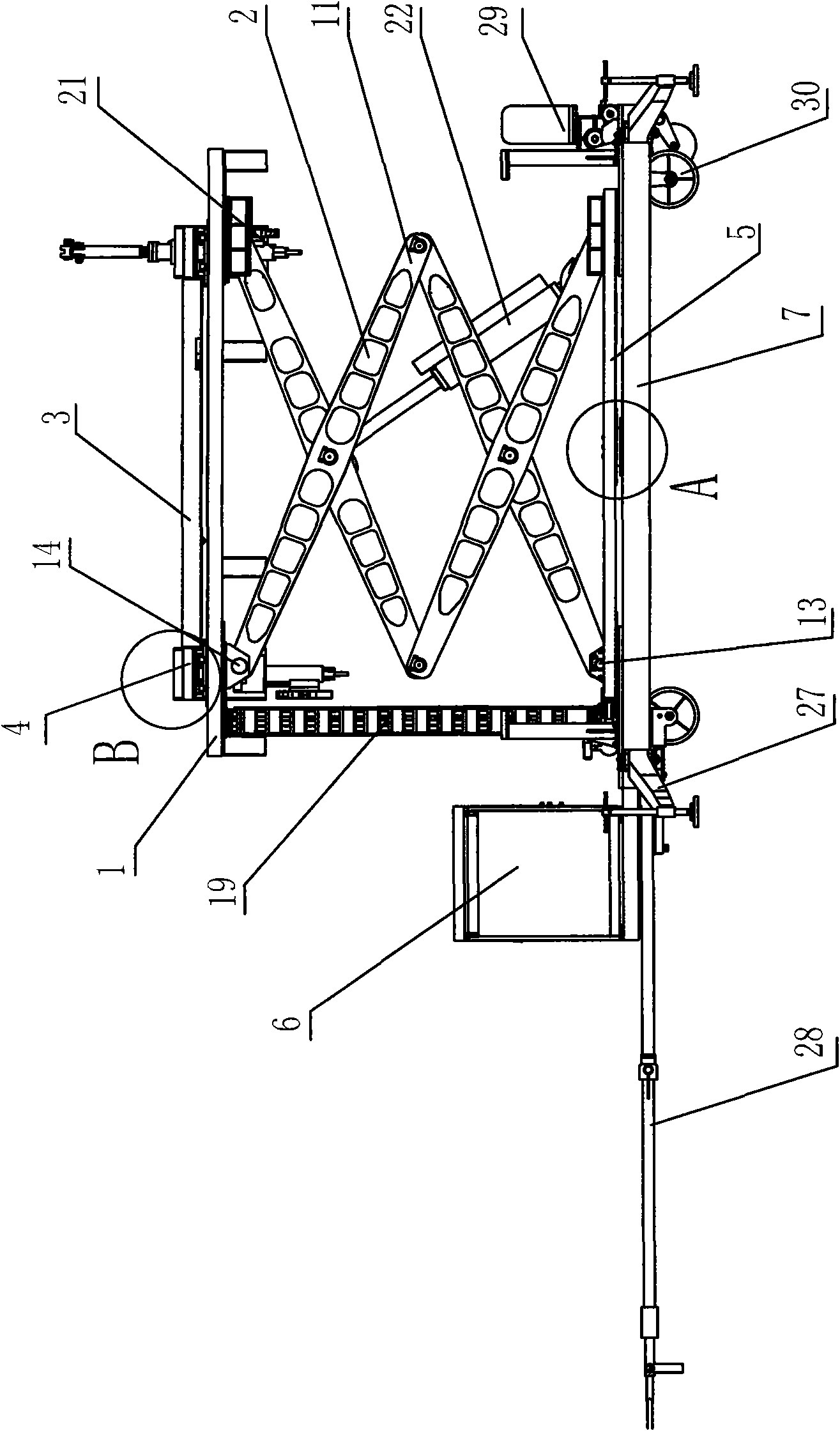

[0025] Below in conjunction with accompanying drawing, the present invention will be further described: as figure 1 , Figure 4 , an aero-engine installation vehicle, comprising a lifting bracket 1, a scissor lift mechanism 2, a front and rear moving frame 3, a left and right moving frame 4, a turntable mechanism 5, an electro-hydraulic servo control system 6 and a car body 7, wherein:

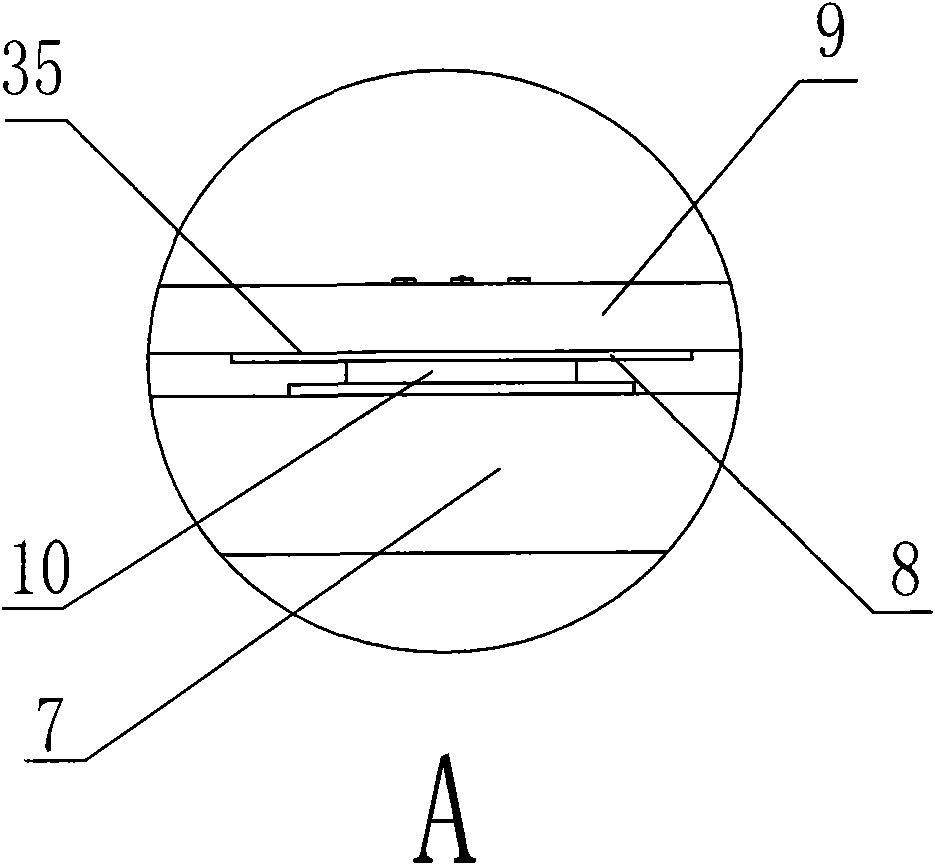

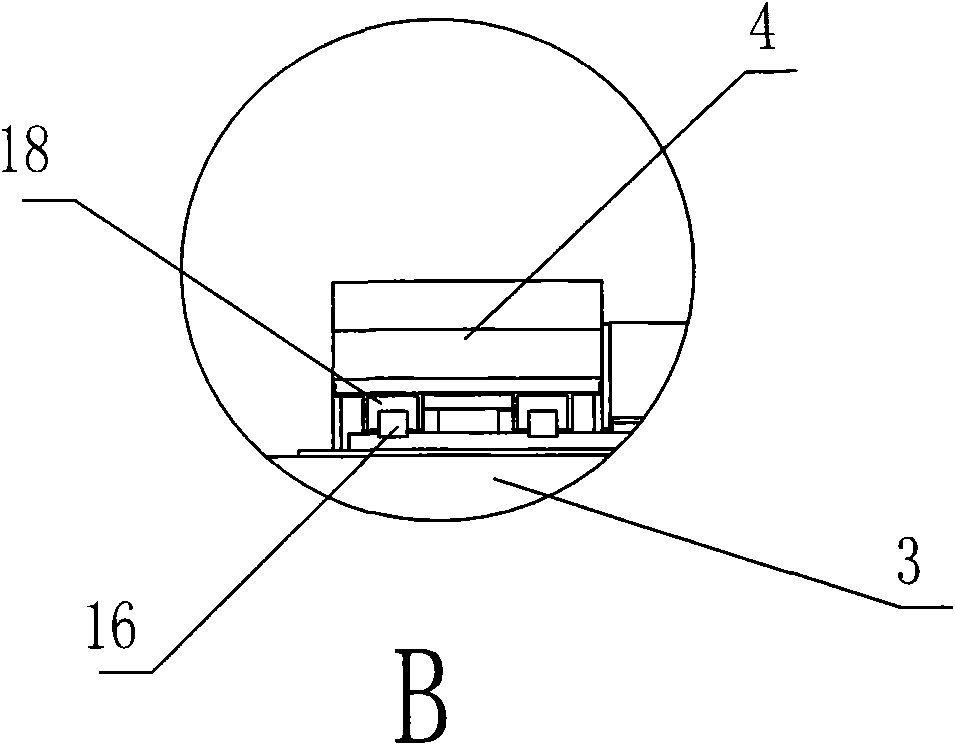

[0026] like image 3 , Figure 5 , the lifting bracket 1 is provided with eight longitudinal linear guide rails 15, the front and rear moving frame 3 is provided with eight transverse linear guide rails 16 and longitudinal sliders 17, the left and right moving frame 4 is provided with horizontal sliders 18, and the longitudinal sliders 17 is located in the longitudinal linear guide rail 15, and the transverse slider 18 is located in the transverse linear guide rail 16. The longitudinal linear guide rail 15 and the transverse linear guide rail 16 are respectively fixed on the front and rear m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com