Multifunctional conveying machine

A multifunctional conveying and conveyor technology, which is applied in the field of cargo loading and unloading conveying equipment and belt loading and unloading conveyors, can solve the problems of time-consuming and laborious, long preparation time, and single operation, so as to improve economic benefits, reduce loading and unloading operation costs, and reduce The effect of labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

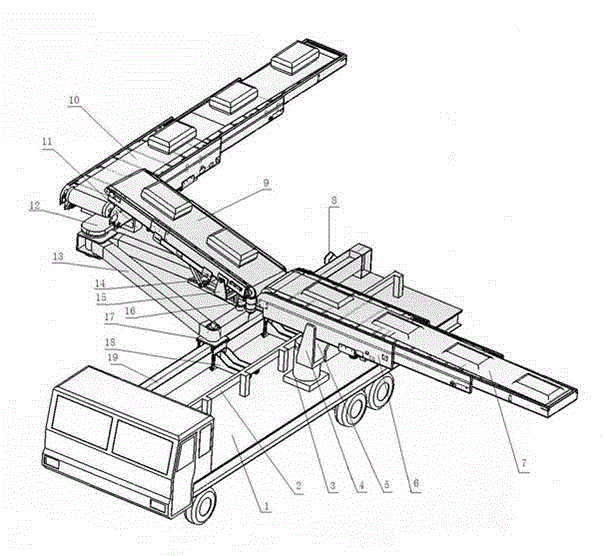

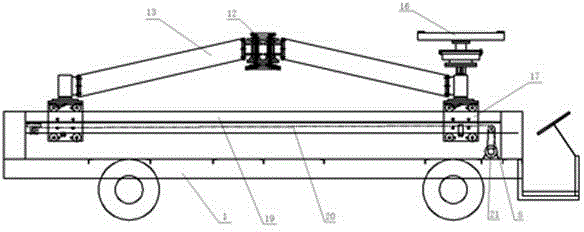

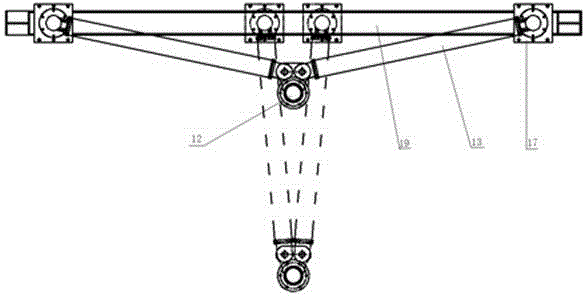

[0012] Embodiment is illustrated below in conjunction with accompanying drawing: select suitable vehicle chassis 1 with corresponding counterweight and hydraulic support leg for selection, and be equipped with hydraulic system, electronically controlled control system, be used to drive the walking, turning, braking and driving of vehicle chassis 1 Driving, lateral extension and vertical height adjustment of hydraulic outriggers, deployment and retraction of loading conveyor 7, discharge conveyor 10, intermediate conveyor 9, position and posture adjustment, loading conveyor 7, discharge conveyor 10 is a multi-stage telescopic conveyor belt; one end of the feeding conveyor 7 is connected to the turntable A5 through the support A4, and a hydraulic telescopic rod for adjusting its pitch angle is installed between the lower part of the support A4 and the first-stage conveying arm A6, and the turntable A5 is located at The chassis 1 is welded on the seat 3 on one side of the middle o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com