Patents

Literature

32results about How to "Reduce loading and unloading time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

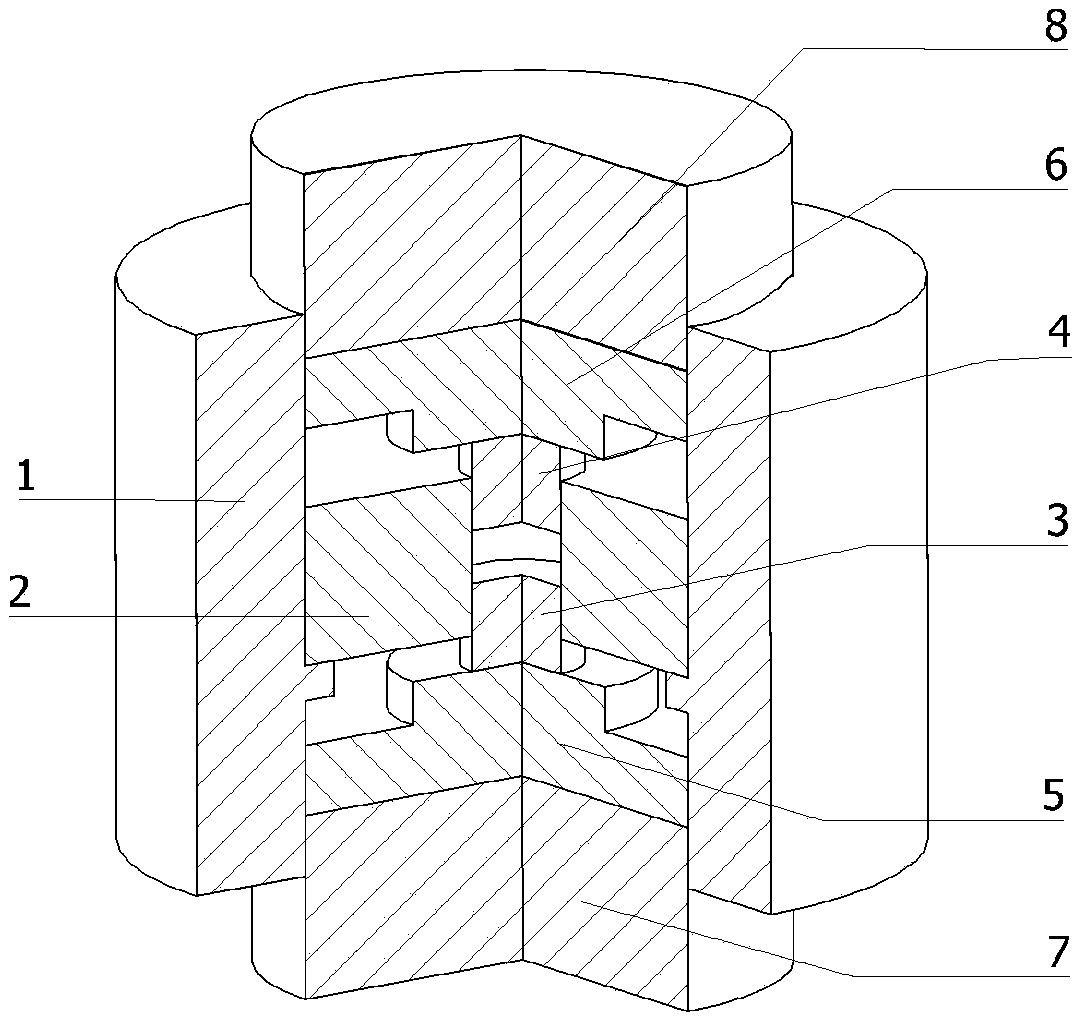

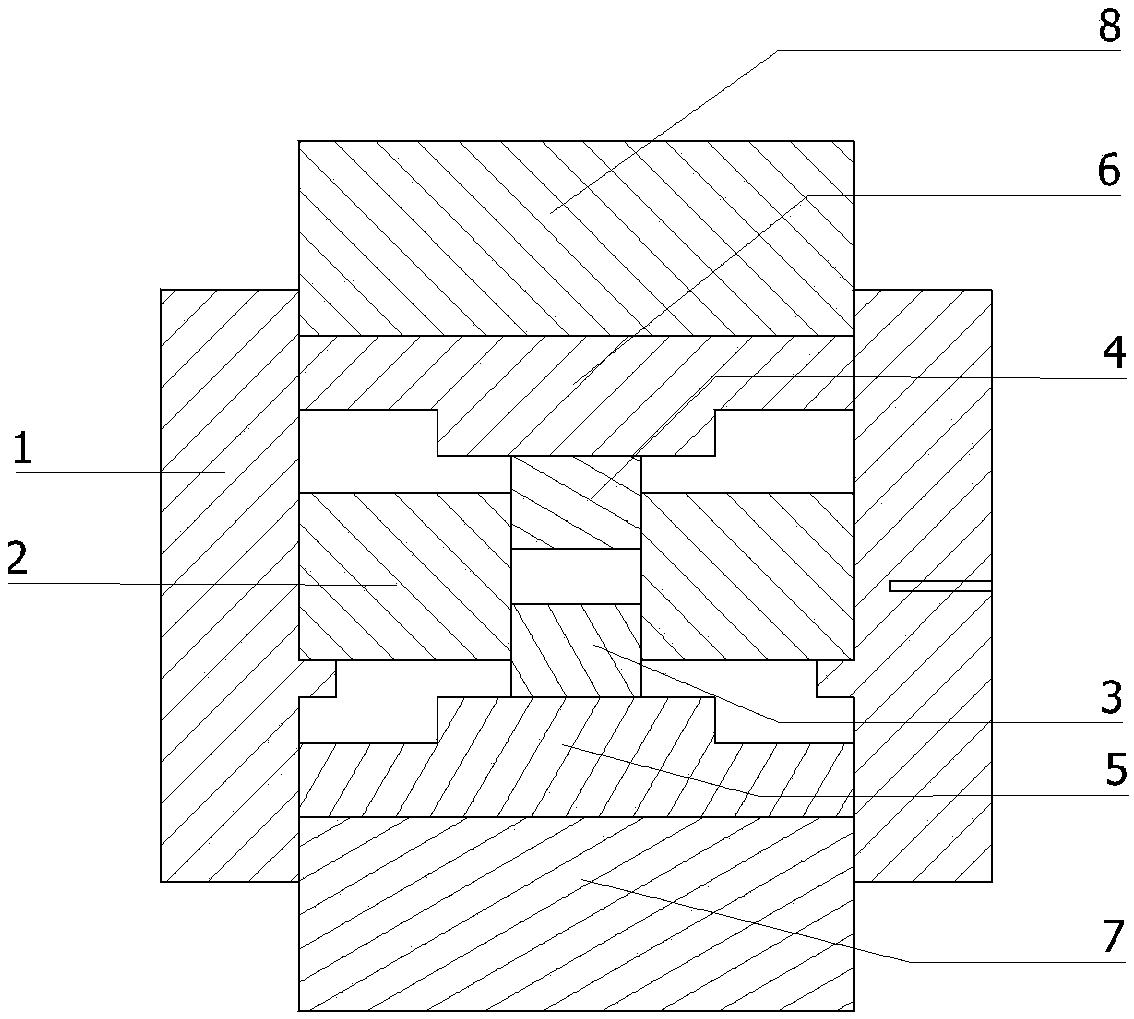

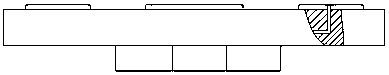

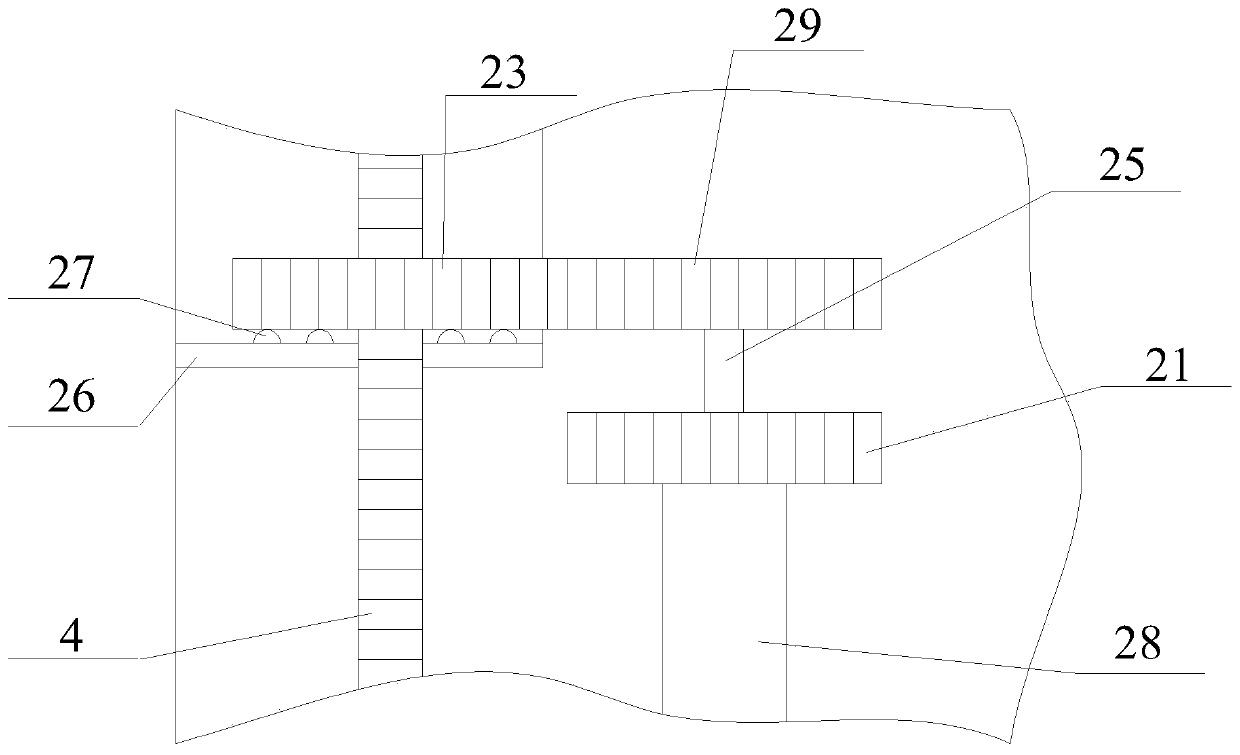

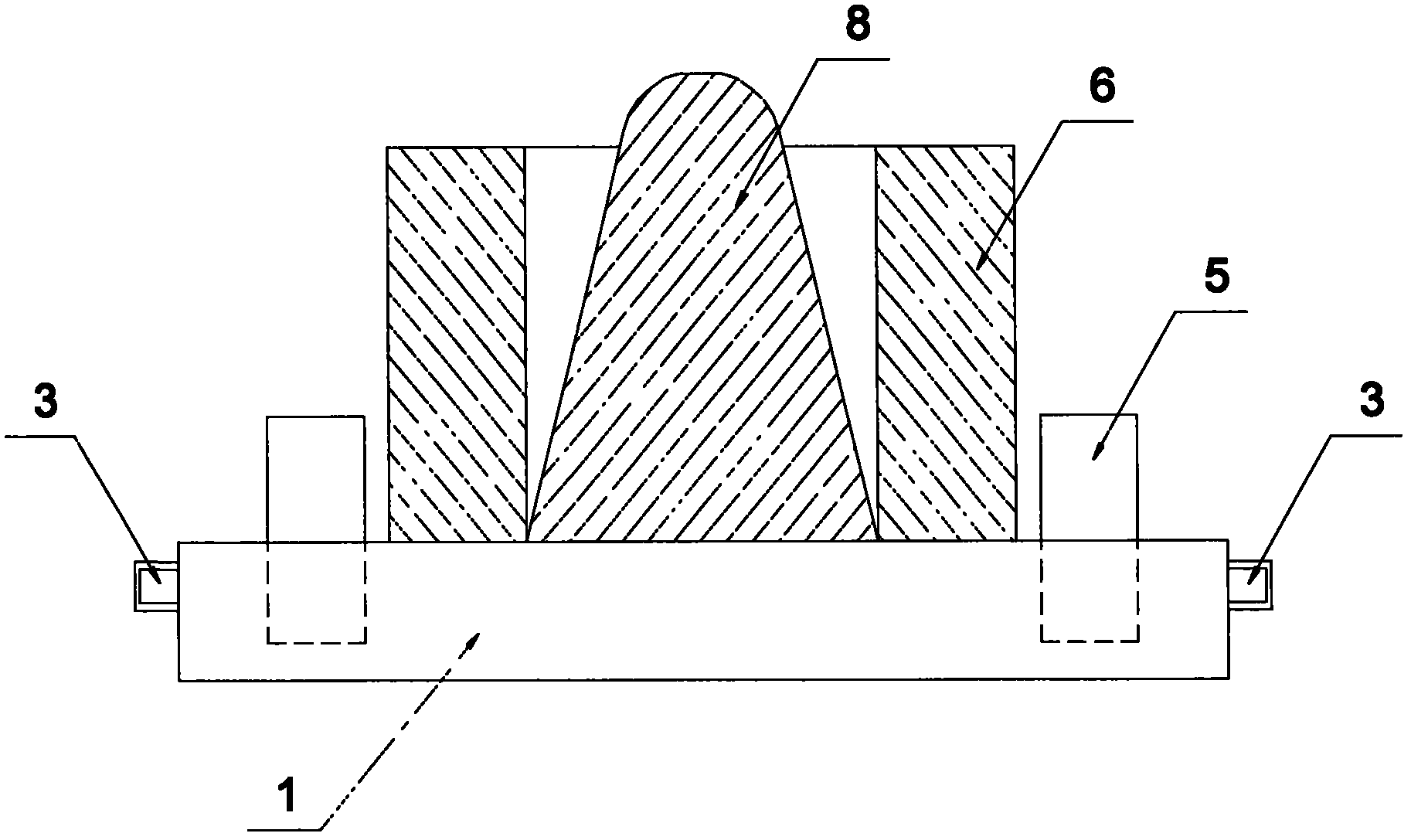

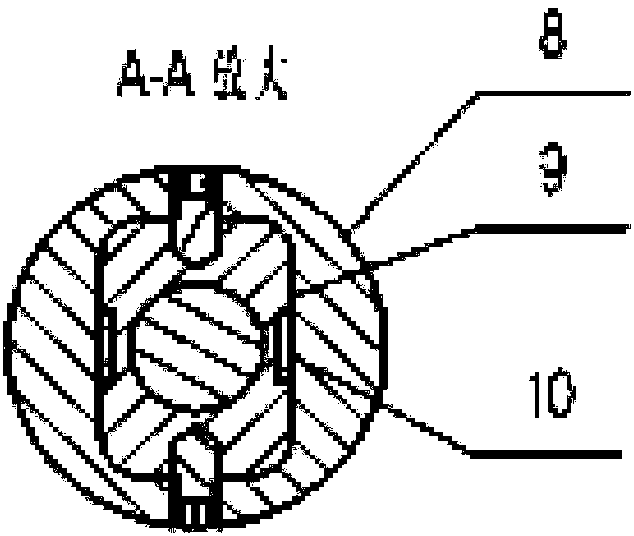

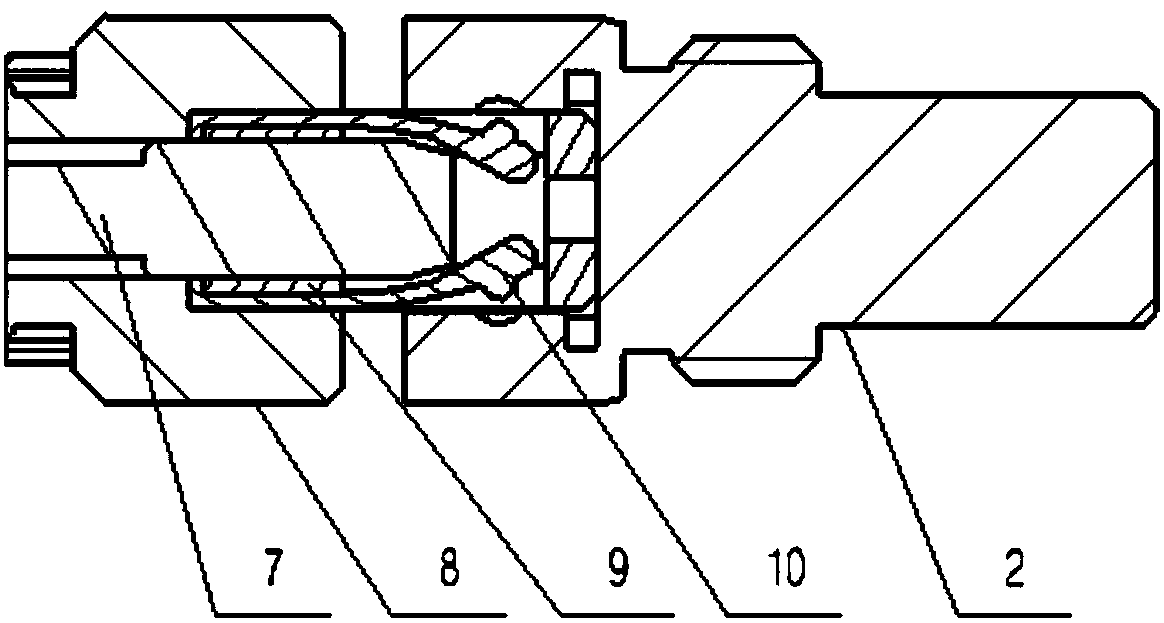

Ultra-high pressure anti-slipping mold for discharging plasma sintering

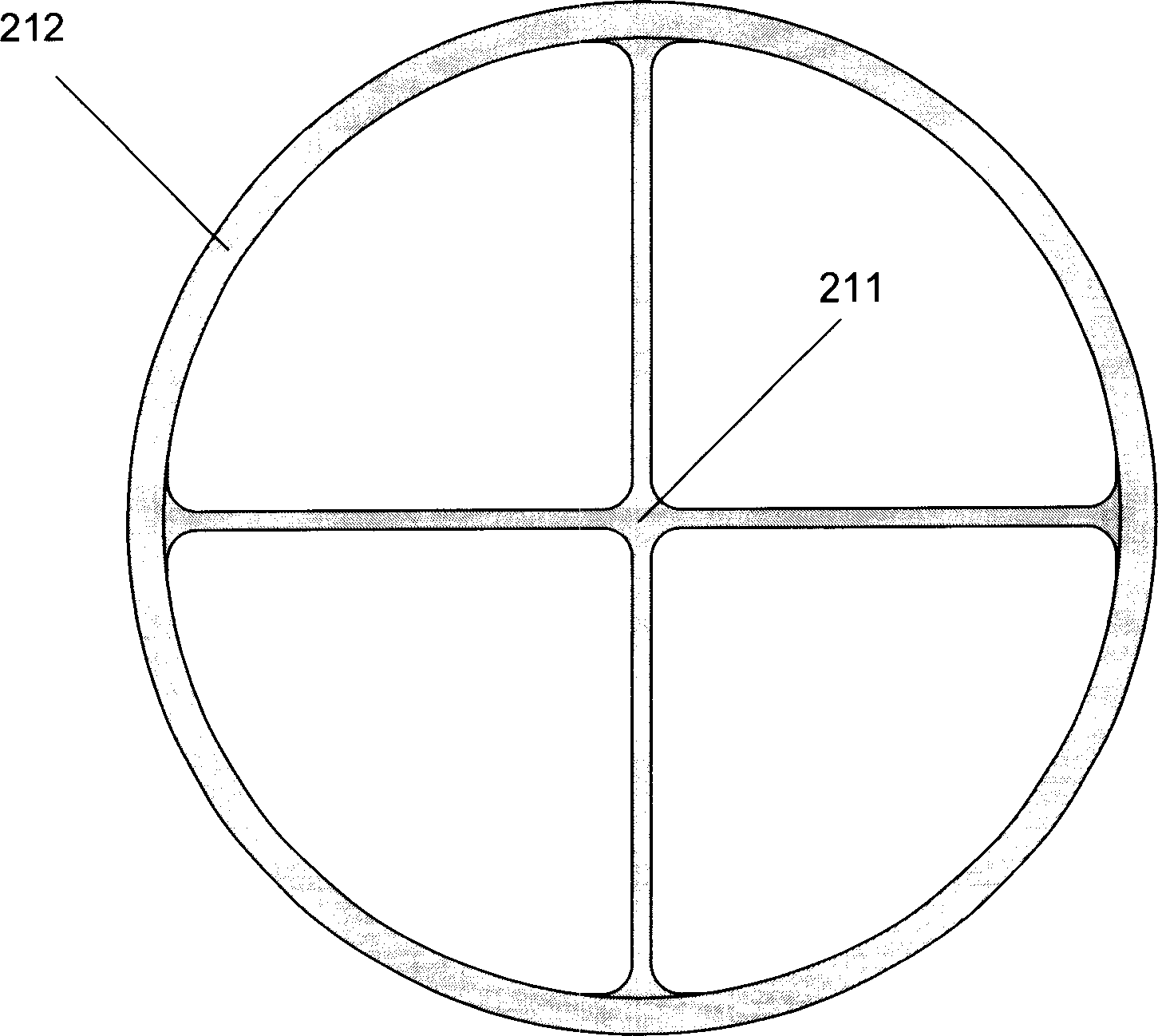

The invention discloses an ultra-high pressure anti-slipping mold for discharging plasma sintering. The ultra-high pressure anti-slipping mold is formed by combining parts formed and processed from high-purity graphite and parts formed and processed from a high-strength tungsten carbide alloy; an inner mold is embedded in the upper portion of a boss of the side wall of an outer mold, and the outermold wall is provided with a radial blind hole which is used for mounting of a thermocouple to monitor the temperature in real time. An upper inner pressure head and a lower inner pressure head are correspondingly embedded in the upper part and the lower part of the inner side wall of the inner mold, and a cavity formed between the upper inner pressure head as well as the lower inner pressure head and the inner mold is a sintering zone which is used for filling powder of a sintering testing piece. One ends of an upper cushion block and a lower cushion block are planes and abut against a lowerouter pressure head and an upper outer pressure head, and the other end faces of the upper cushion block and the lower cushion block are provided with disc-shaped bulges, and the disc-shaped bulges and the lower inner pressure head and the upper inner pressure head are symmetrically mounted in a fit mode. Under the premise that smooth electricity conducting is ensured, the mold can effectively improve the sintering pressure applied on a sample, and prevent relative slipping of the inner mold and the outer mold in the sintering process after the mold is used for a long time; and thus the production cost is reduced, and the production efficiency is improved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

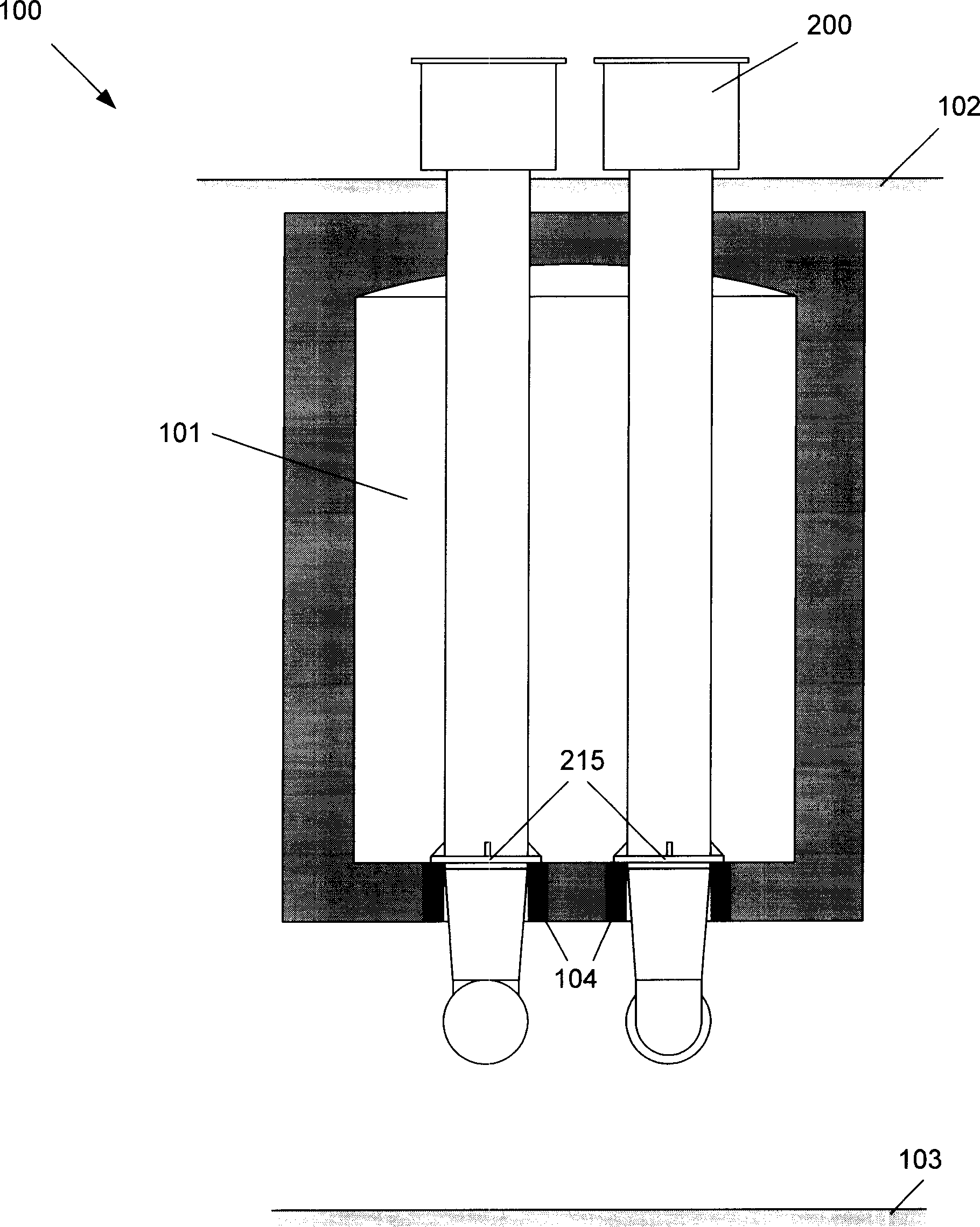

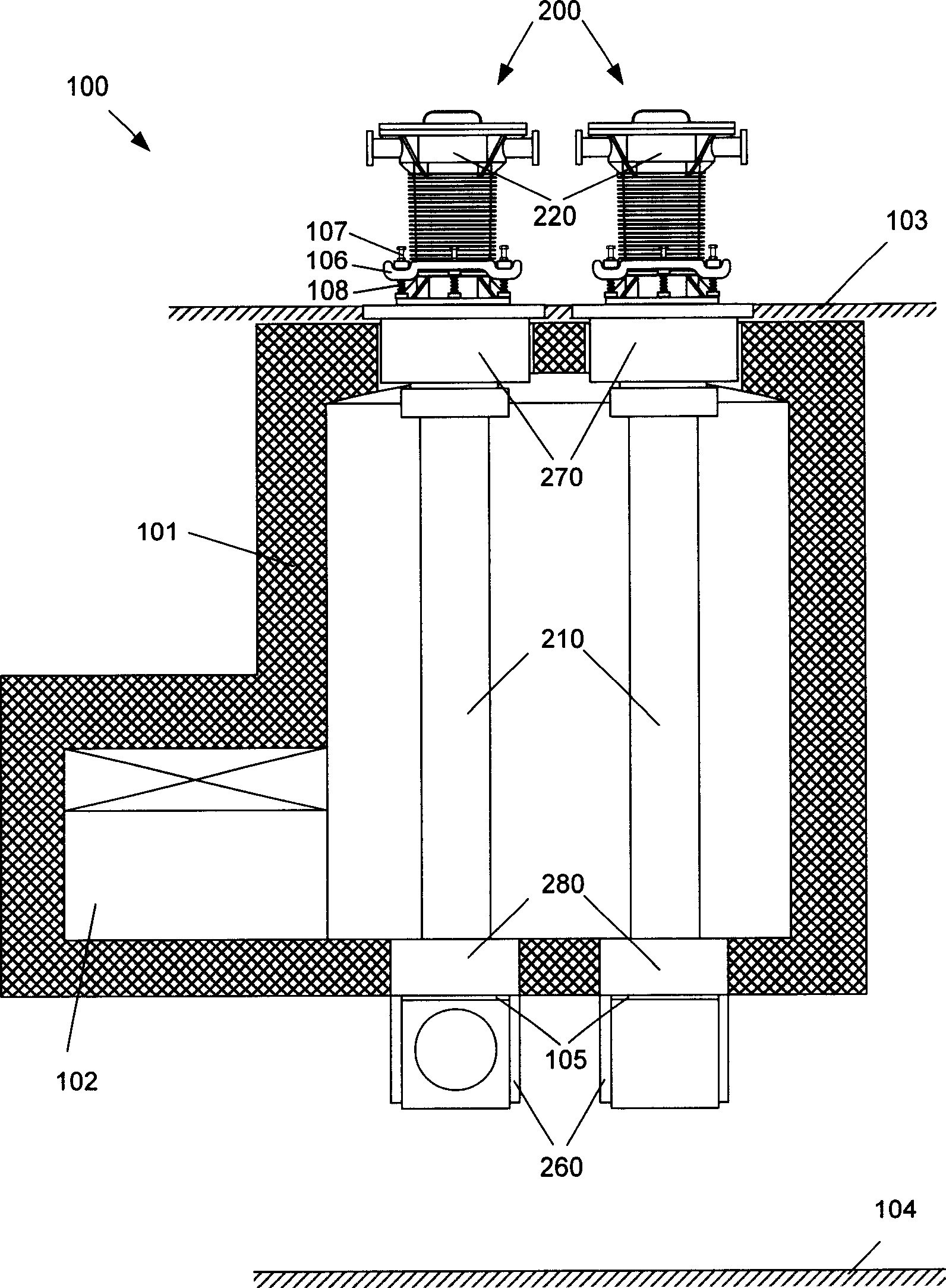

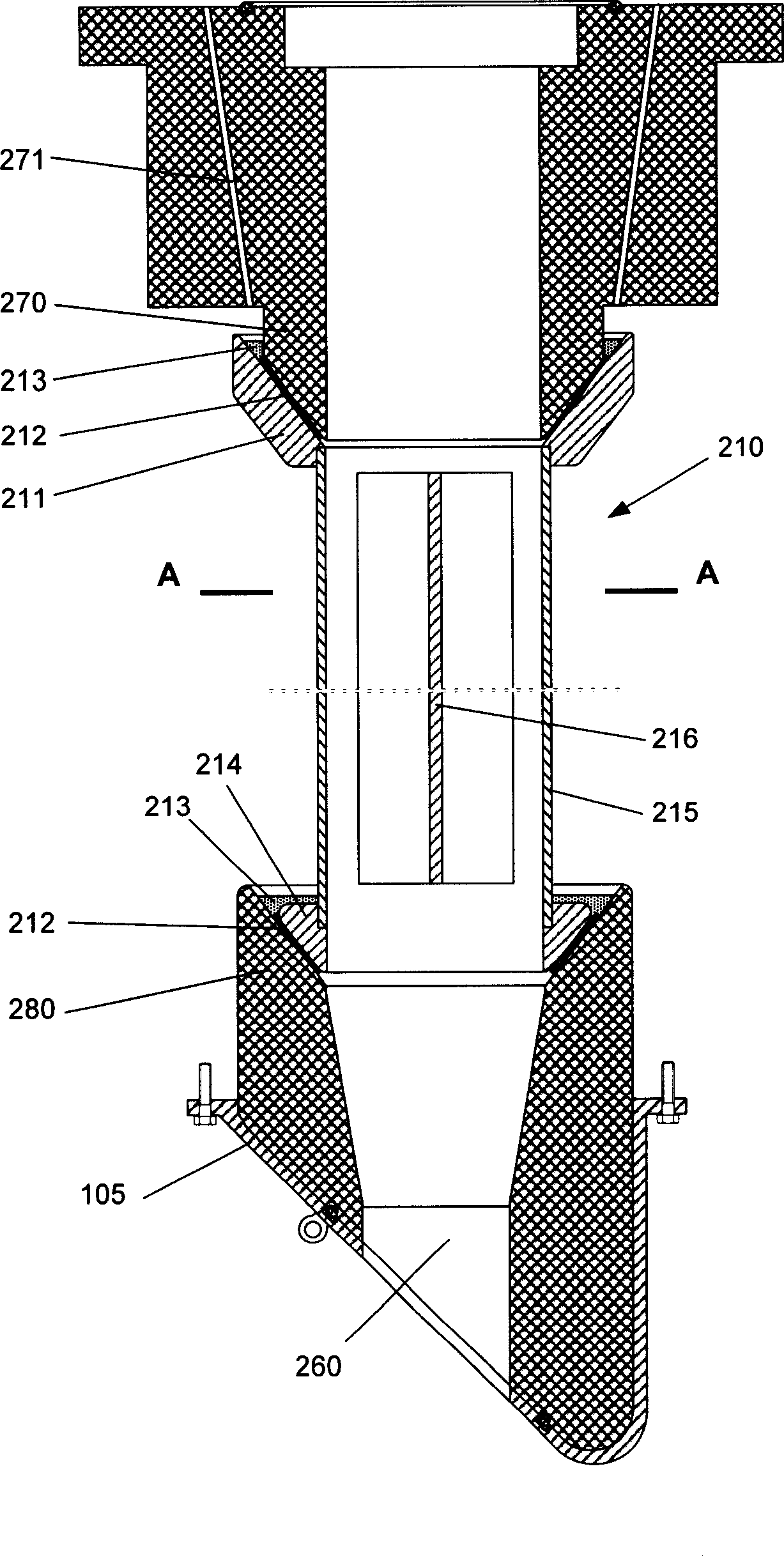

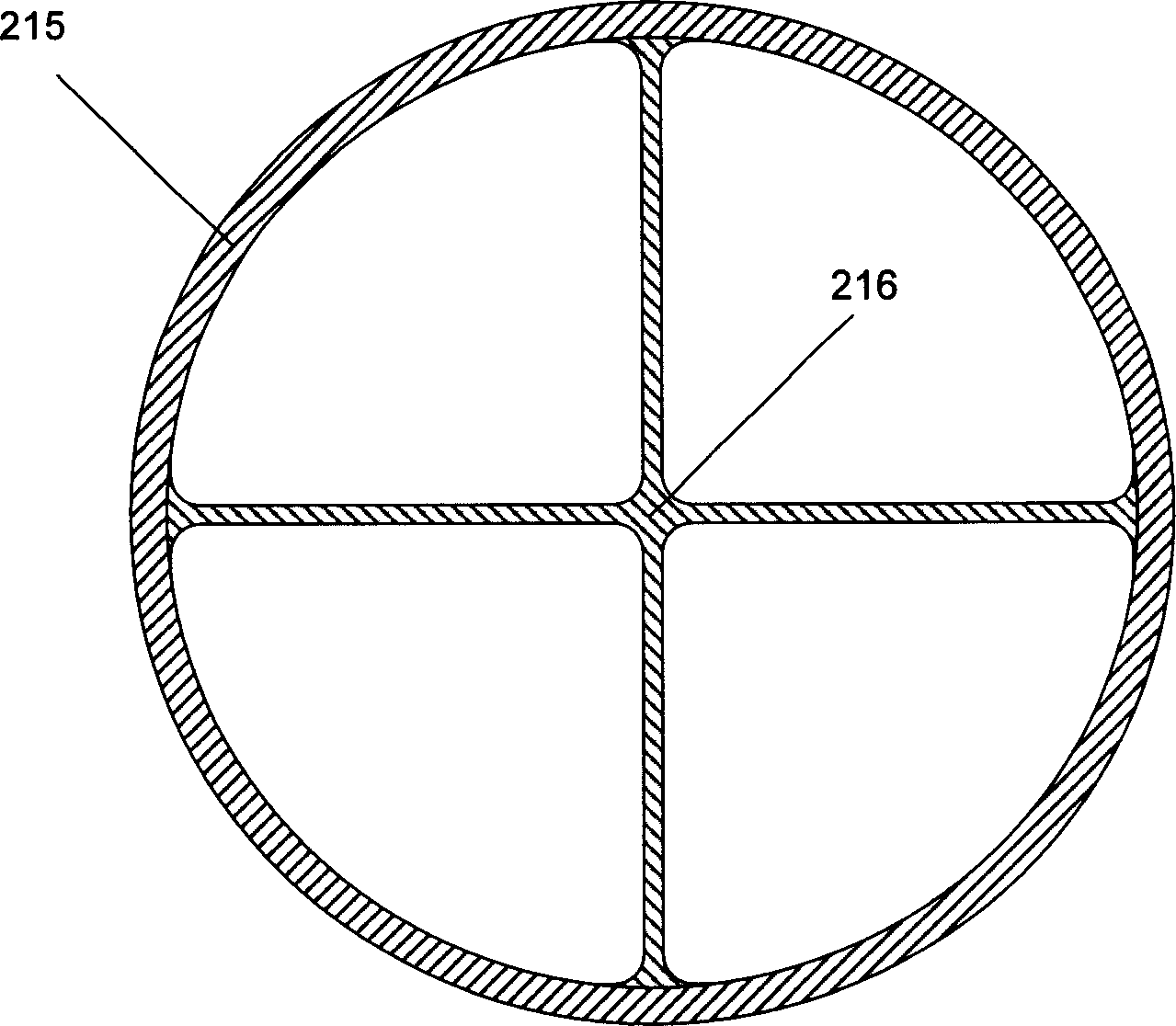

Pijiang metal refining method and device

InactiveCN1704489AImprove creep resistanceExtended service lifeReduction procedureHeat transfer efficiency

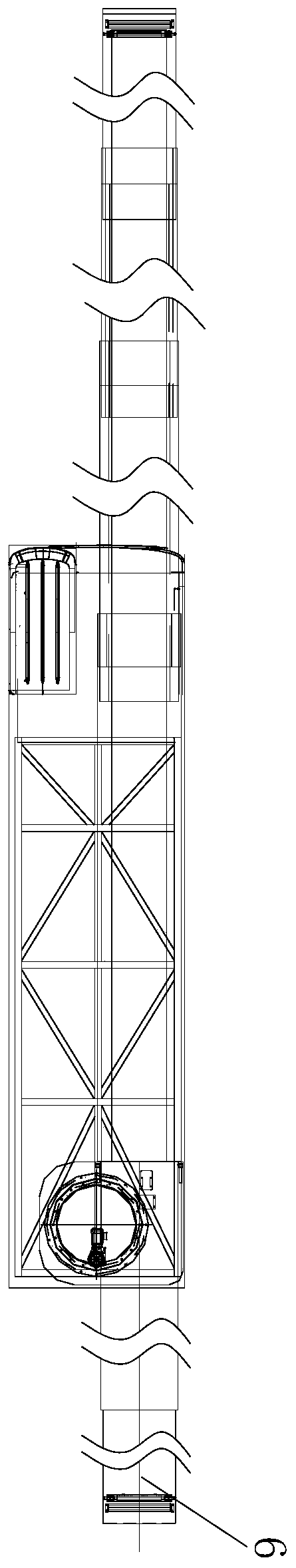

The invention discloses a method for reinforcing the heat transfer efficiency and creep-resistance for pidgeon process reduction tanks, a method for realizing pidgeon process reduction tank automatic charging and discharging, a method for continuous monitoring the pidgeon metal reduction procedure, a method for reclaiming reaction by-product base metals, a vertical reduction tank employing the methods and a pidgeon process reduction furnace constructed by employing the vertical reduction tank.

Owner:刘伟杰

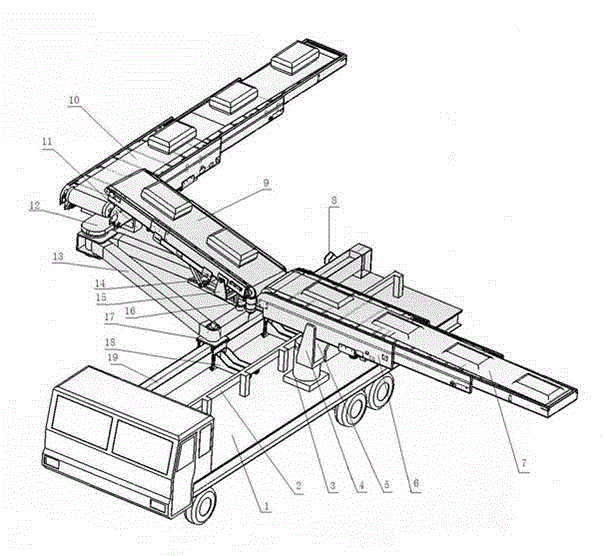

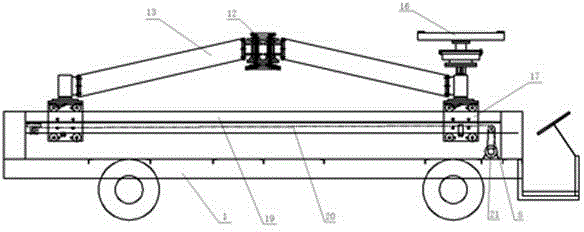

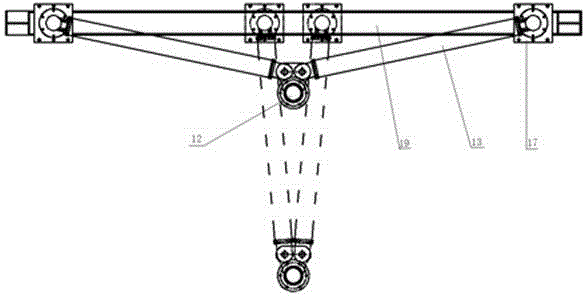

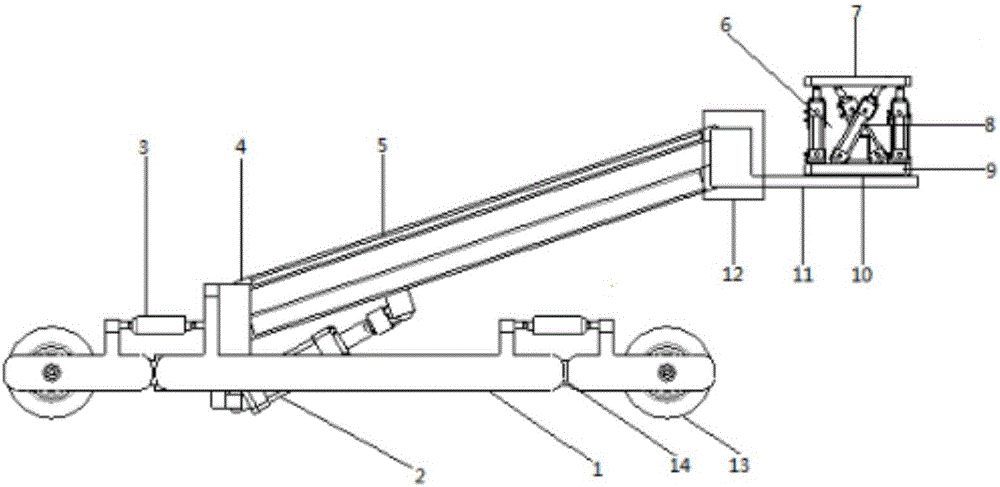

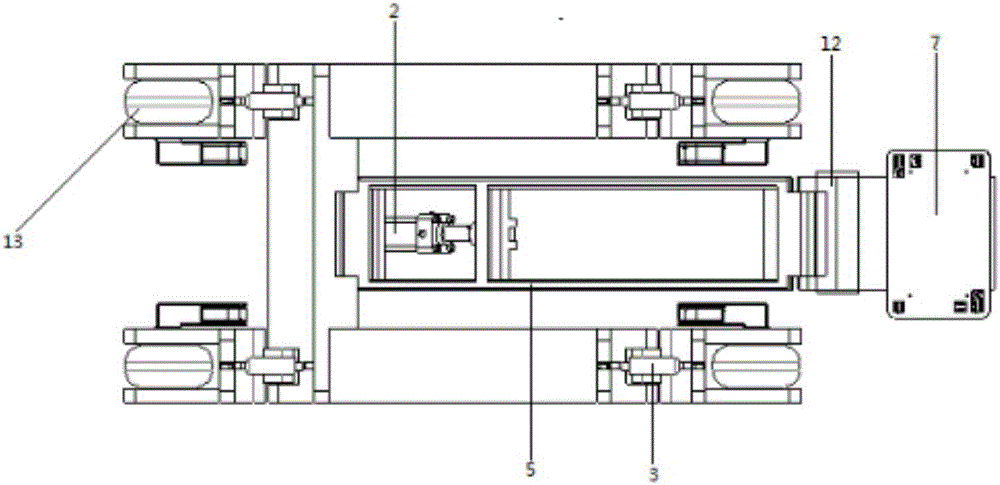

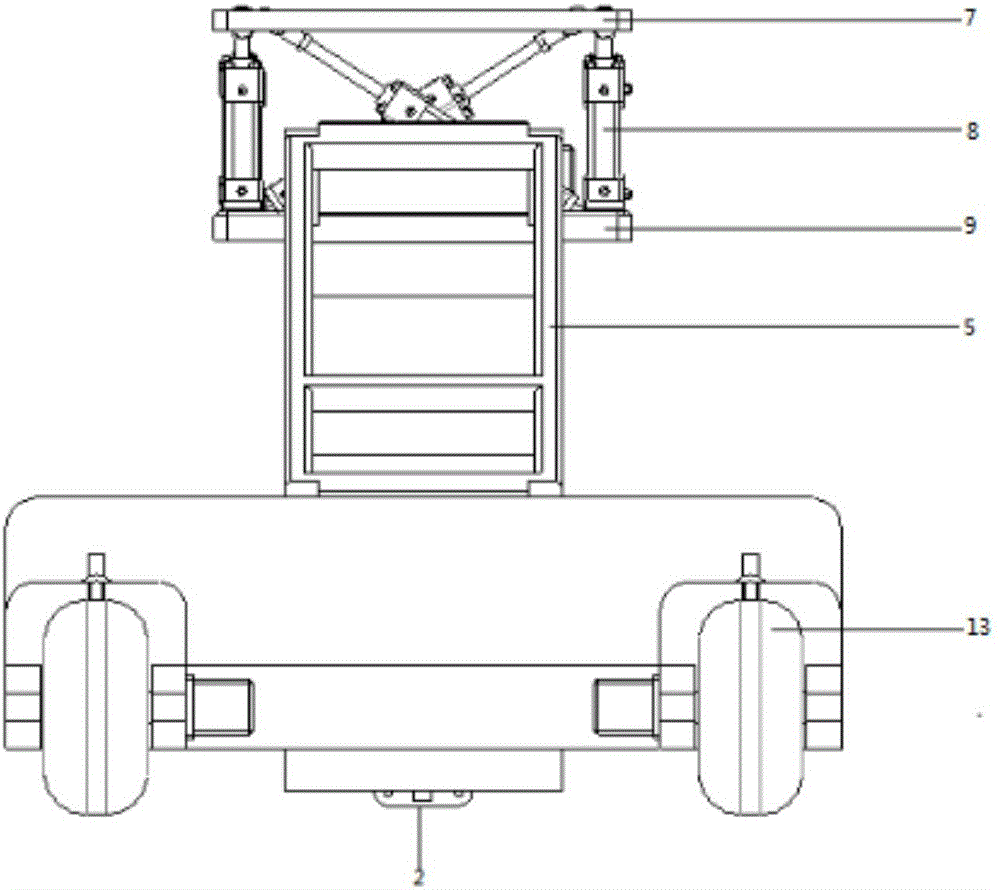

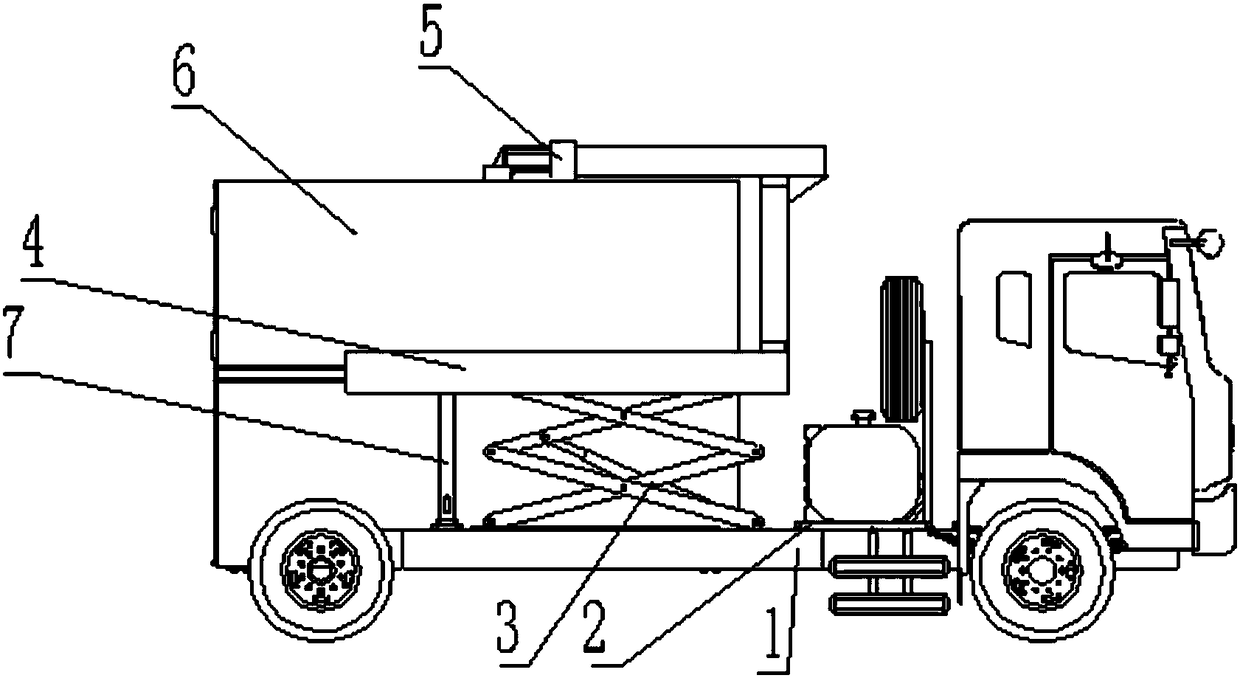

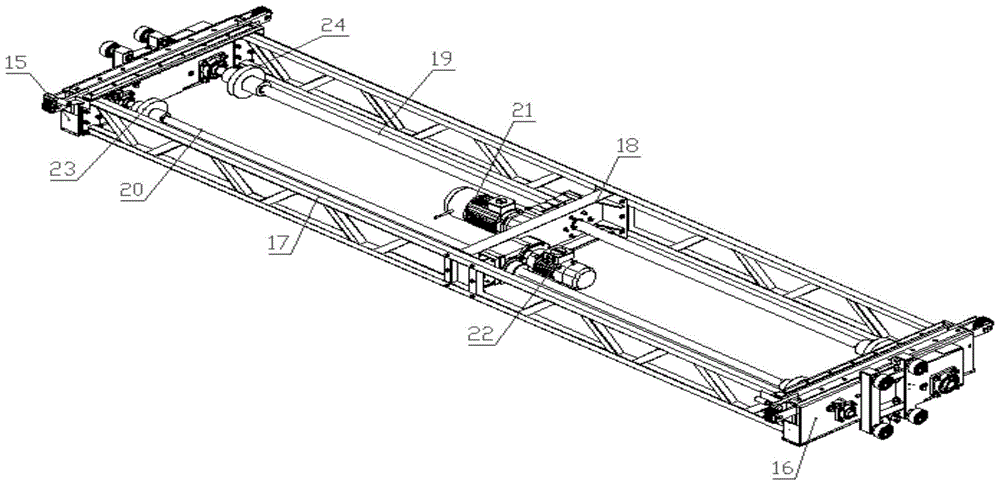

Multifunctional conveying machine

ActiveCN104609203AReduce labor intensityFaster turnaroundLoading/unloadingMechanical conveyorsElectronic control systemElectric control

The invention provides a multifunctional conveying machine, and relates to railway freight transportation load and unload in the field of engineering machinery. The multifunctional conveying machine is composed of a vehicle chassis, a hydraulic supporting leg, a load and unload mechanism, a hydraulic system and an electronic control system. The hydraulic system and the electronic control system are adopted for driving the vehicle chassis to walk, turn, brake and drive, the hydraulic supporting leg to transversely stretch and longitudinally adjust a height ,and the load and unload mechanism to unfold, fold, locate, and adjust a posture. The multifunctional conveying machine is used to load and unload cargo in bag among a train, an automobile, a freight house and a railway platform, and has the advantages of reasonably using a load and unload device, being capable of saving the labor force and reducing the labor intensity of a work, improving the efficiency of loading, unloading and carrying, reducing the load and unload operation cost, being beneficial for the cargo integrity and operation safety, and the like.

Owner:大连佳和彩板构件有限公司

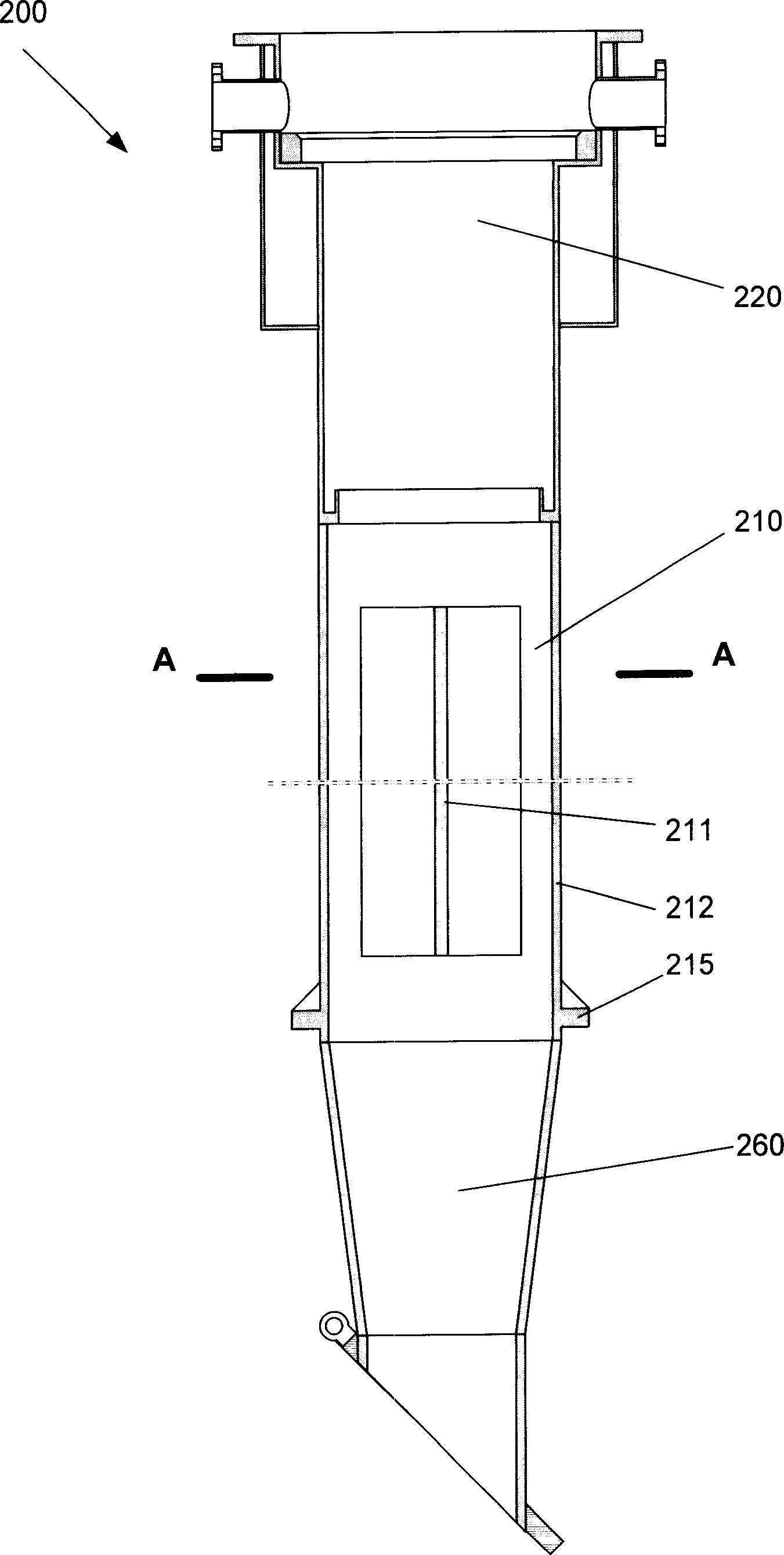

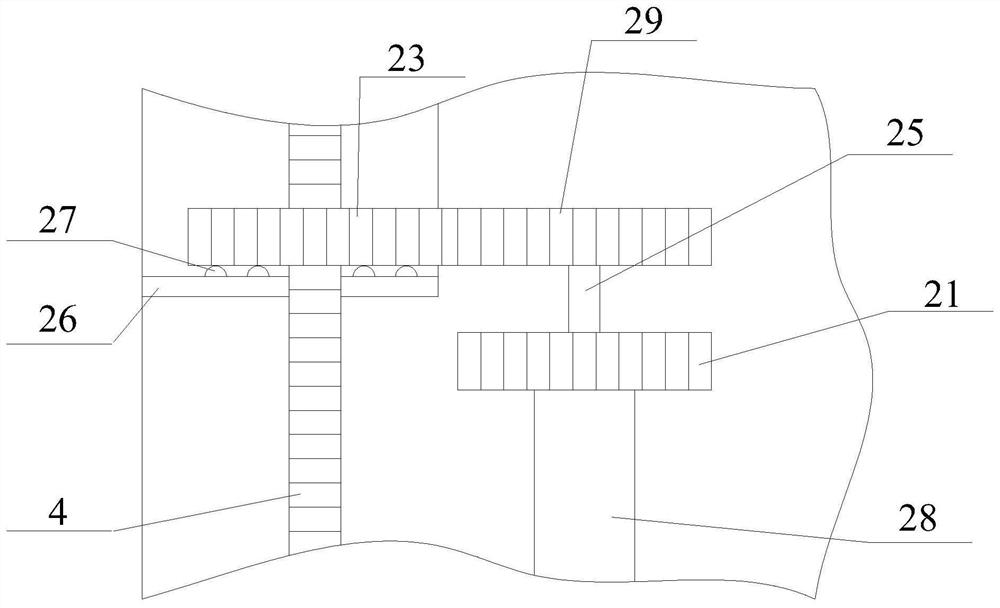

Vertical reduction tank and reduction furnace device for metal smelting

InactiveCN1876856AReduce heat leakageReduce consumptionProcess efficiency improvementHeat transmissionIngot

A leakage method of obstruction reducing furnace intrinsic heat towards the furnace outside along reduction bank; a method which can simultaneously strengthen the coefficient of overall heat transmission and creep resistance of the reduction bank; an air cooling method for metal ingot cylinder of the reduction bank; a method of carrying automatic shipping and delivery of the reduction bank using earth gravity; an on-line continuous monitoring method for matallic reducing process. A vertical reduction bank is built with the said method. A vertical reducing furnace built with the said vertical reduction bank is characterized in that it is of high calorific efficiency, short reduction cycle, long reduction bank age and automatic charge, and can perform on-line observation for reduction process.

Owner:刘伟杰

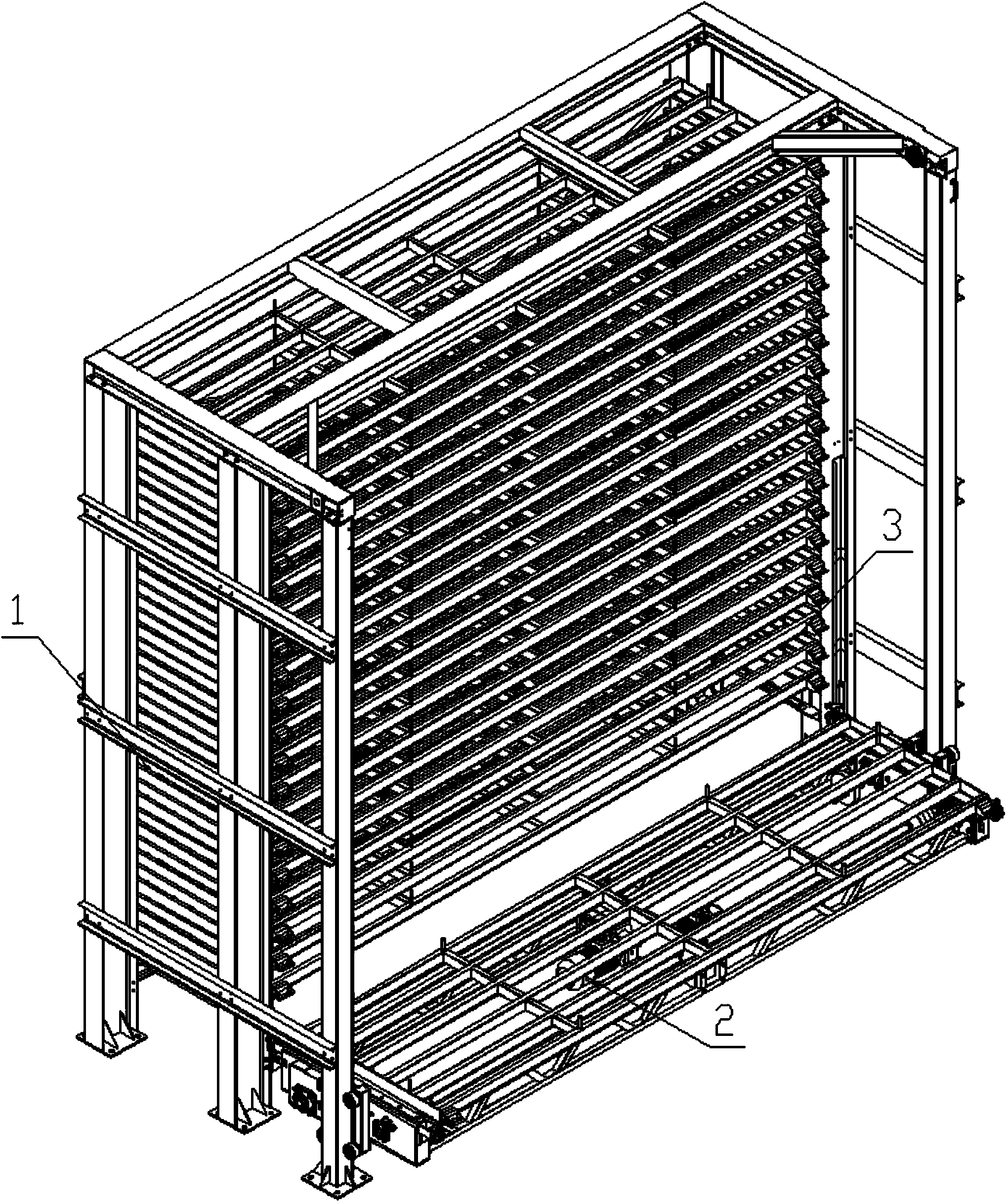

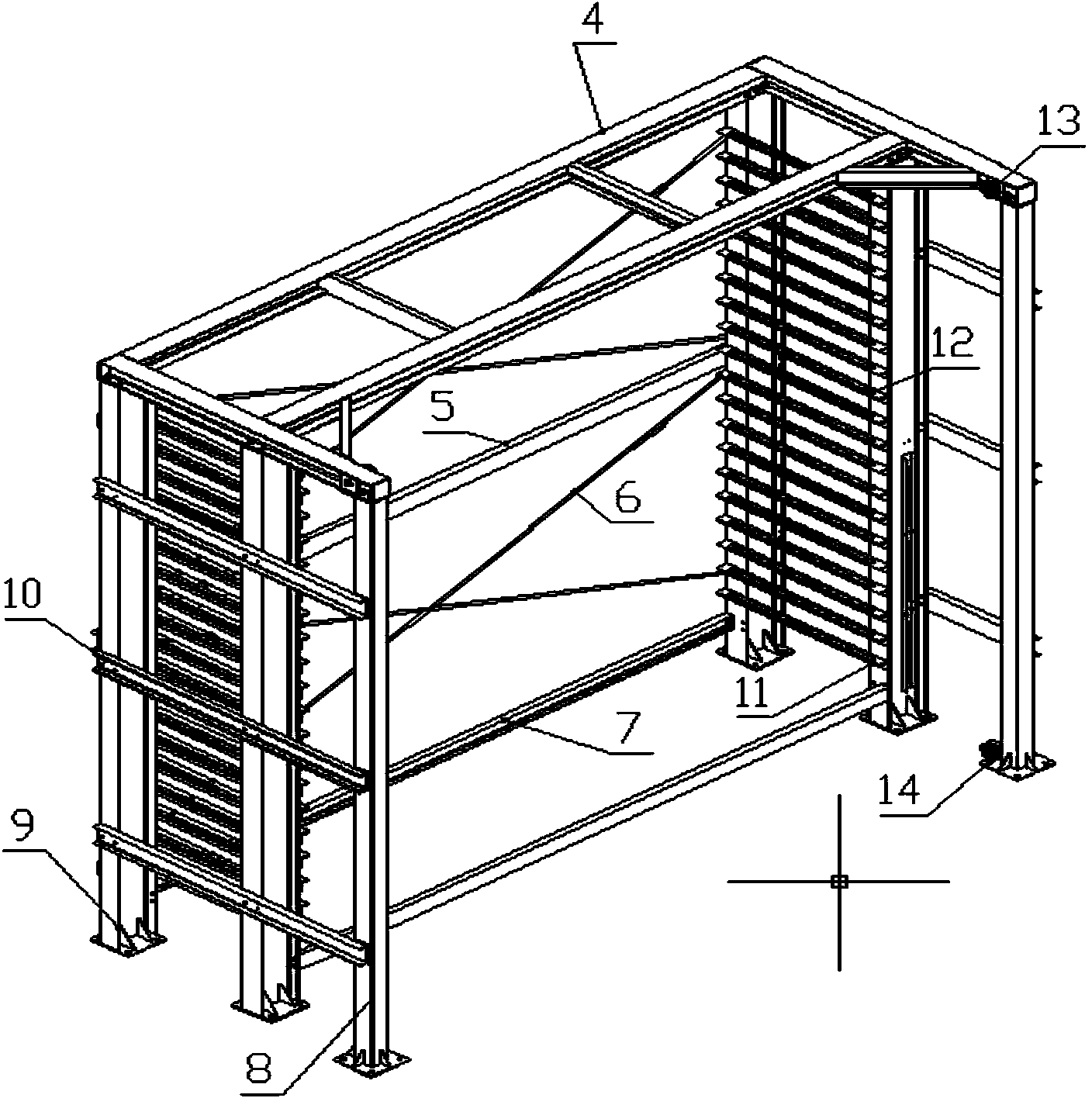

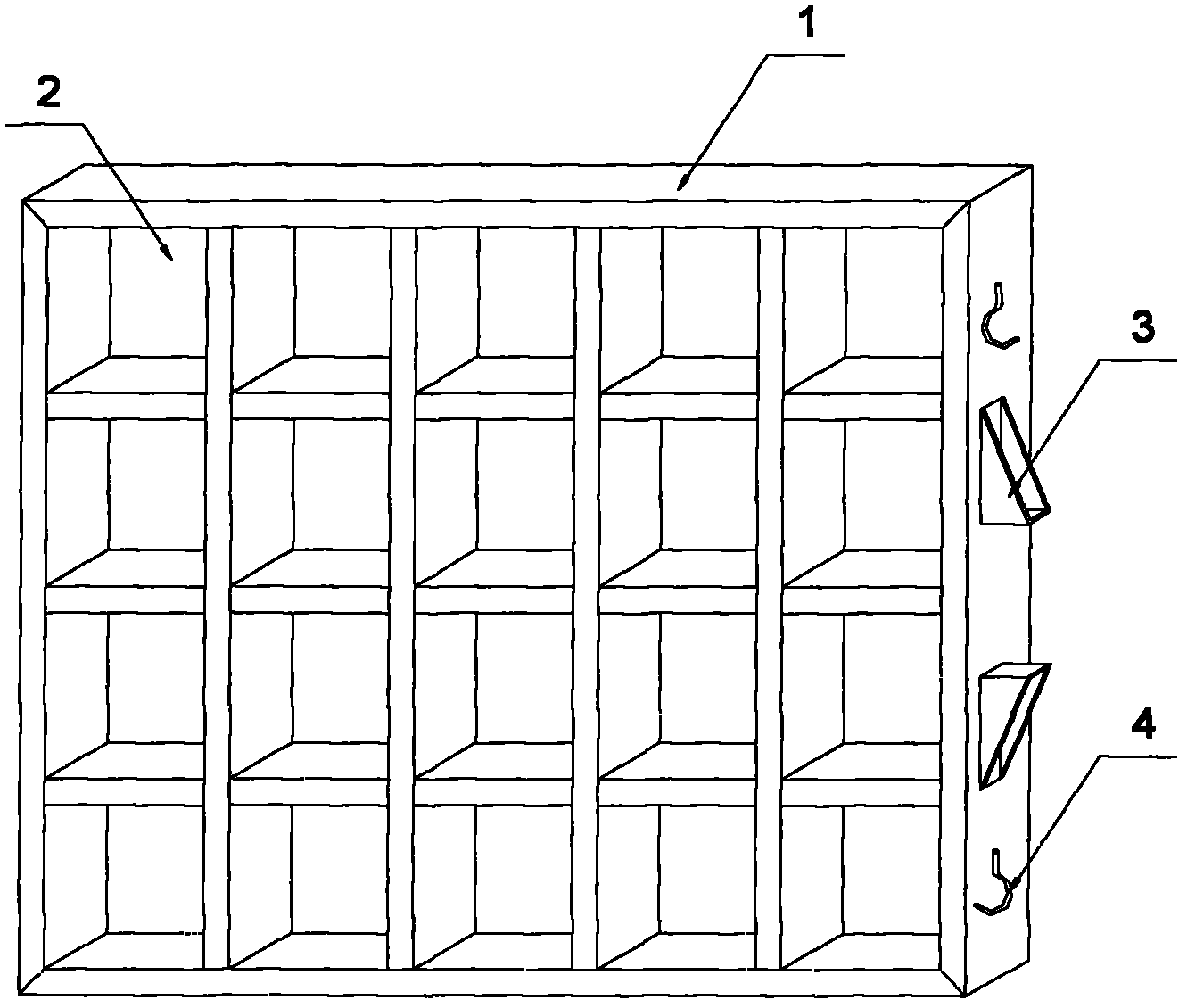

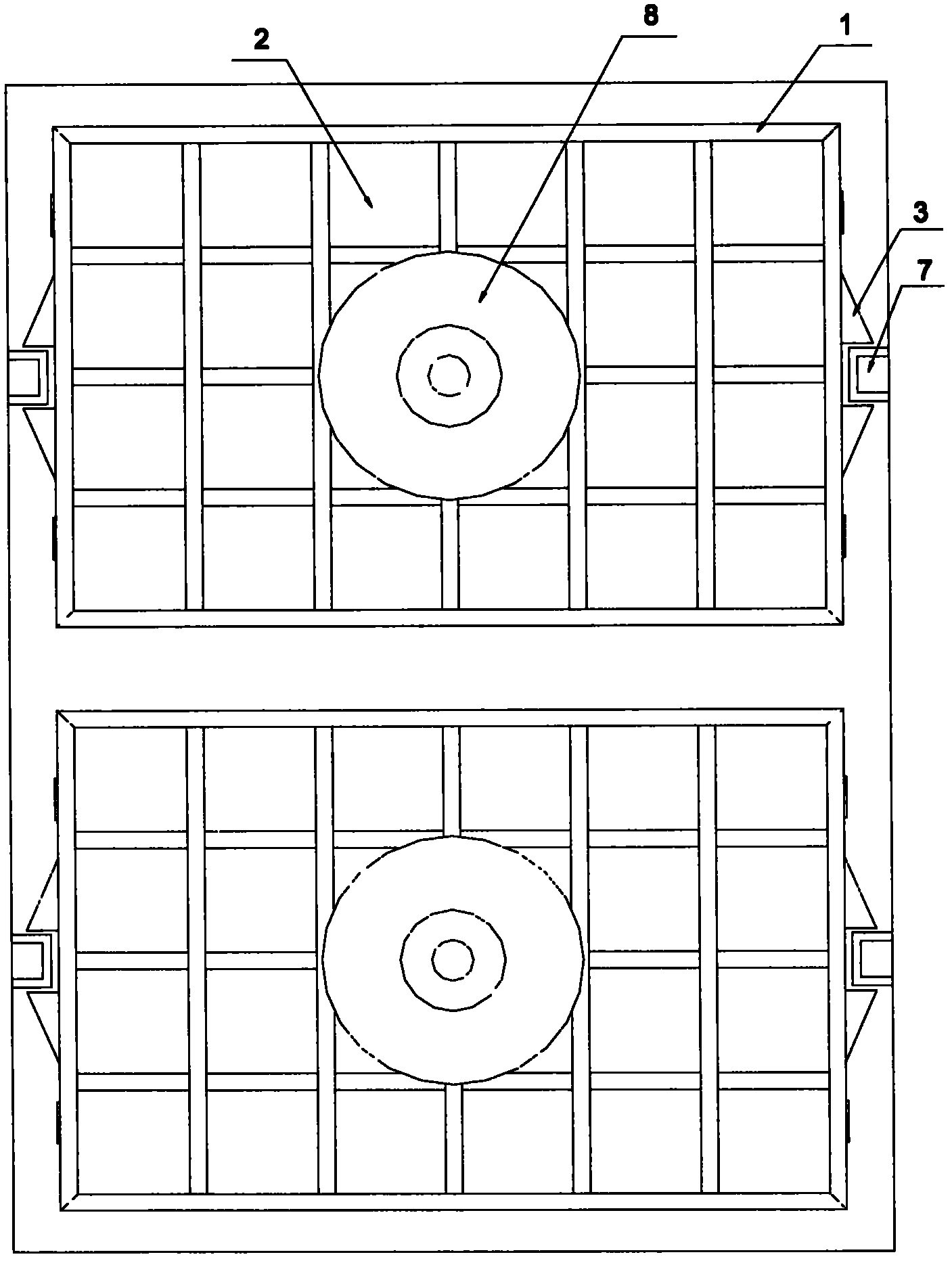

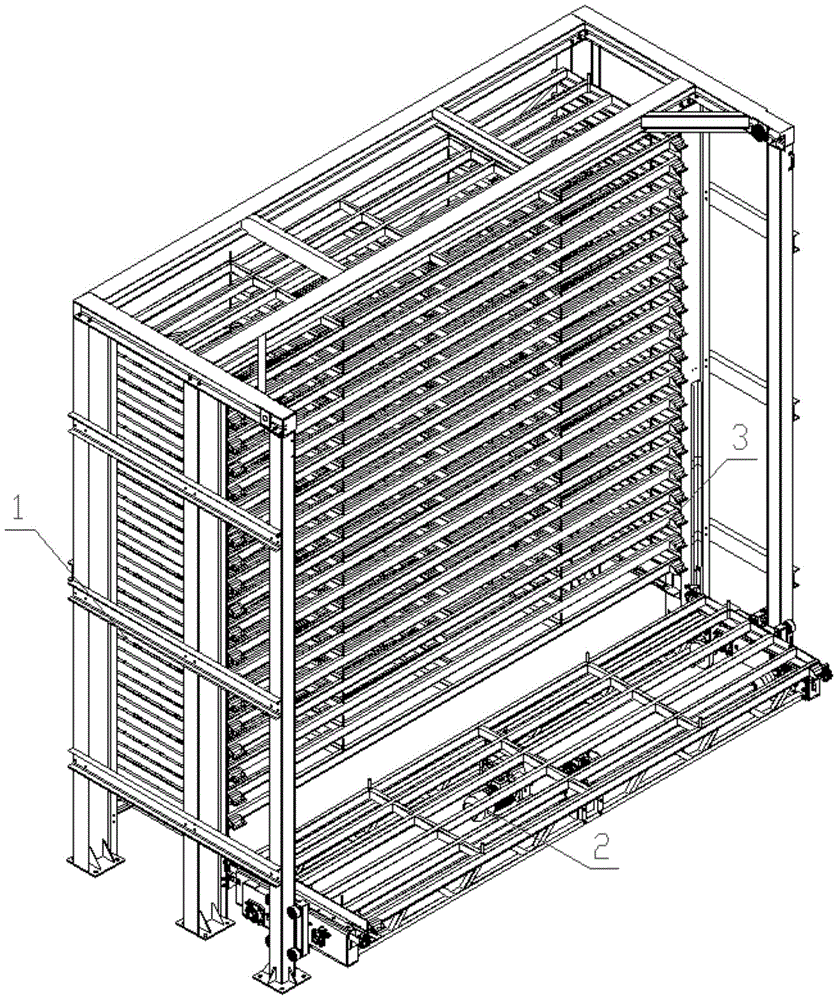

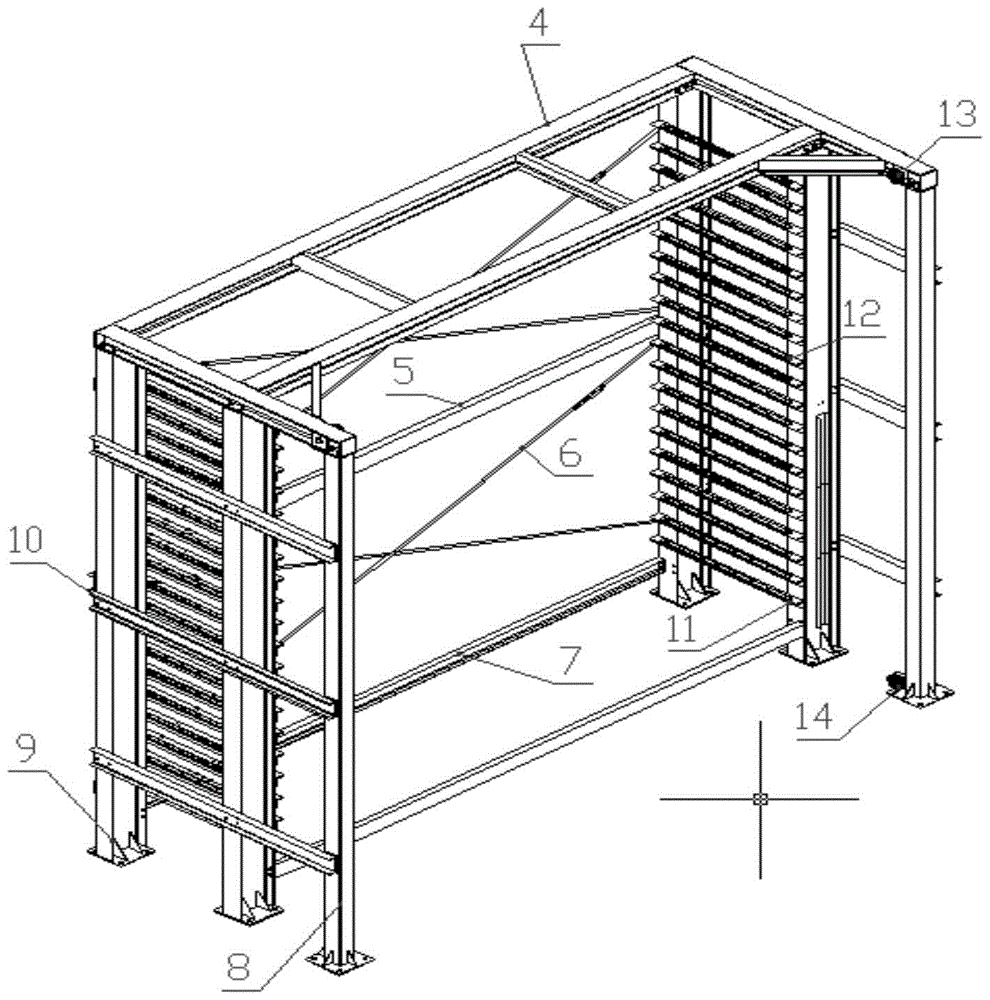

Special-specification vertical goods storing warehouse

ActiveCN104355027AImprove efficiencyCompact structureBuilding constructionsStorage devicesEngineeringUltimate tensile strength

Owner:SHANGDONG TONGLIDA INTELLIGENT MACHINERY

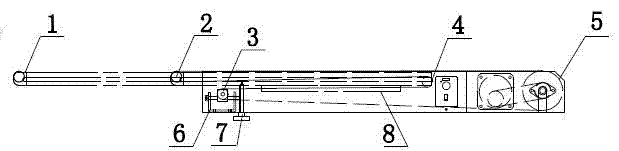

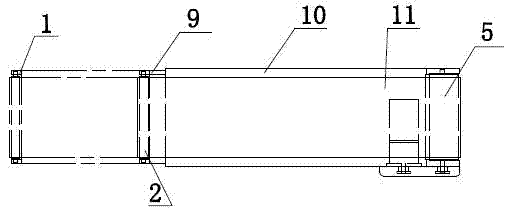

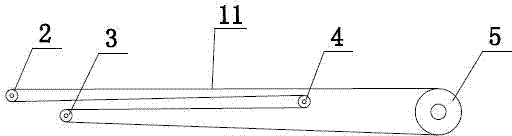

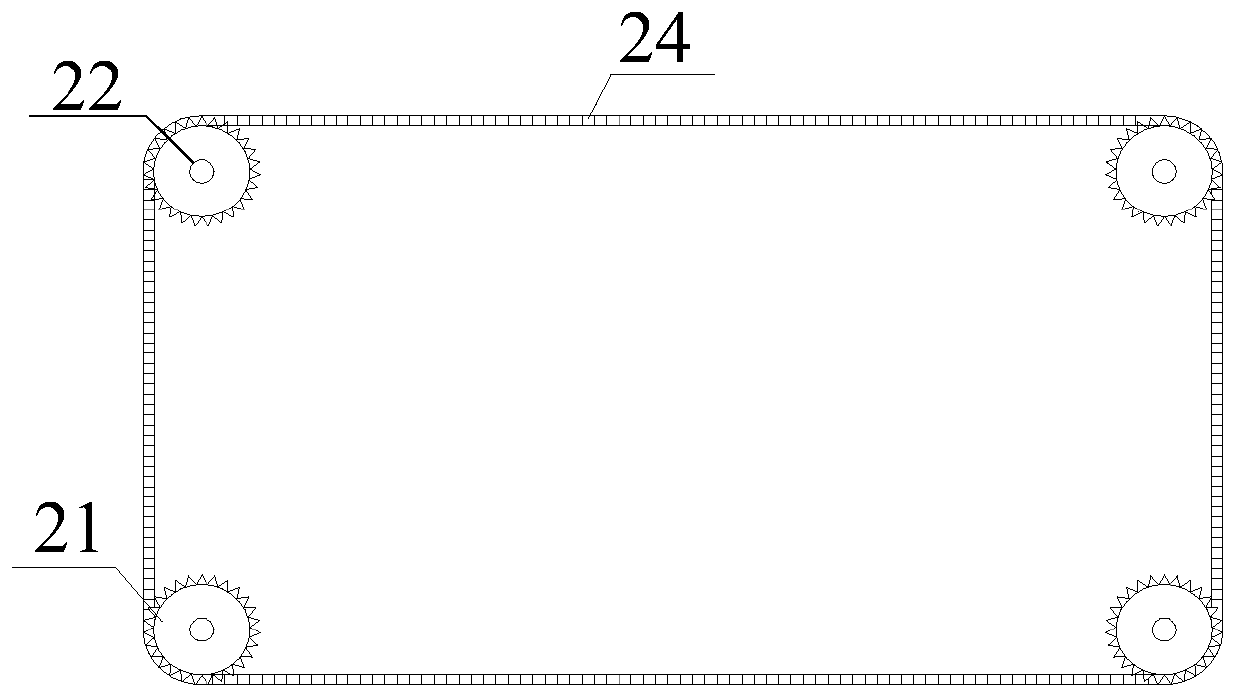

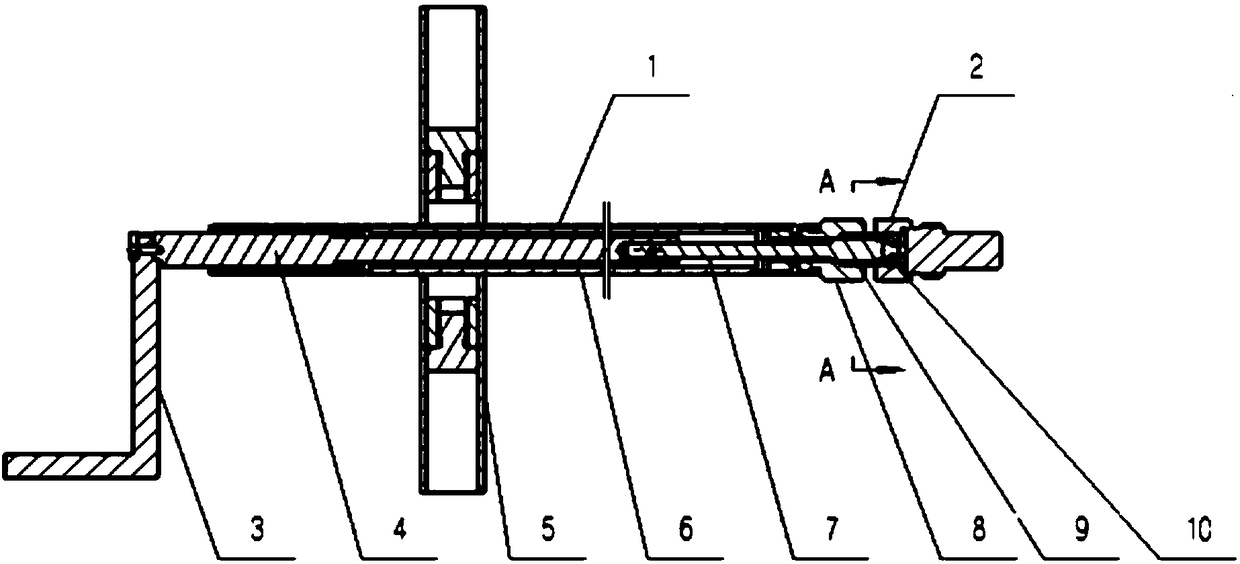

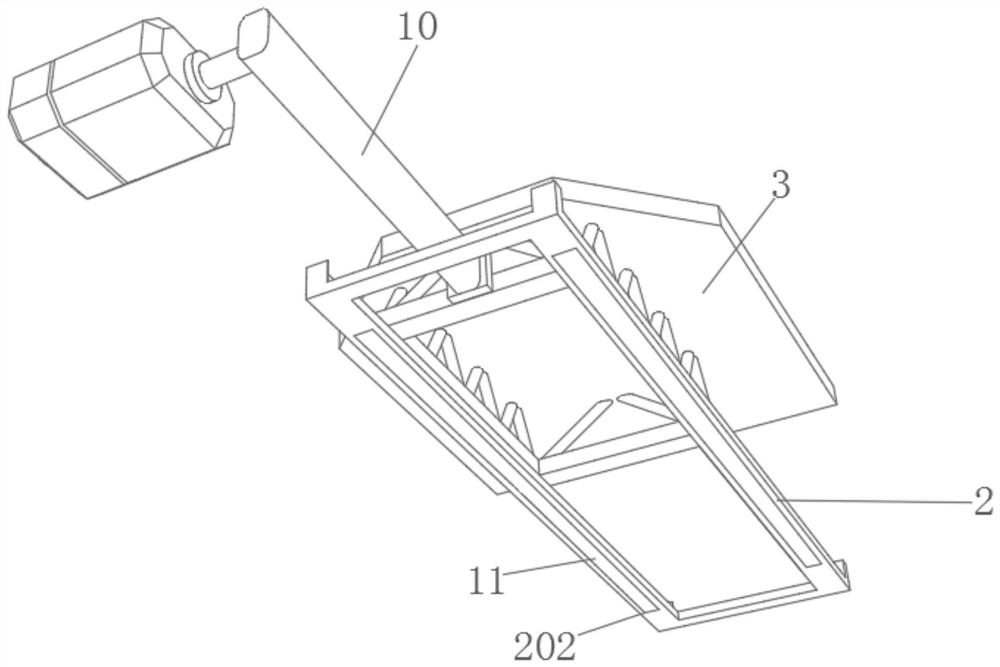

Small telescopic belt conveyer

InactiveCN102234012AReduce distanceReduce loading and unloading timeConveyorsLeather beltEngineering

The invention relates to a small telescopic belt conveyer comprising a fixed rack, rollers, a belt and a movable rack arranged inside the fixed rack, wherein the two ends of a driven roller are fixed on the movable rack by virtue of plugs, the peak of a driving roller and the peak of the driven roller are located in the same horizontal plane, a tensioning roller is arranged on a tightness degree adjusting device, a re-directing roller is arranged between the driven roller and the driving roller, and a guiding bar is arranged between the re-directing roller and the tensioning roller. A telescopic mechanism is adopted, thus the length of a belt can be freely adjusted according to customer requirements, and the problems that a belt conveyer is required to be ordered again as distance of a conveyer is changed and the operating cost of a company is increased can be avoided; and meanwhile, the distance for manually carrying materials in a reciprocating way is shortened, the unloading time is shortened, the operation is stable and easy, the working efficiency is improved, and the labour intensity is reduced.

Owner:WUXI JIESI LOGISTICS EQUIP

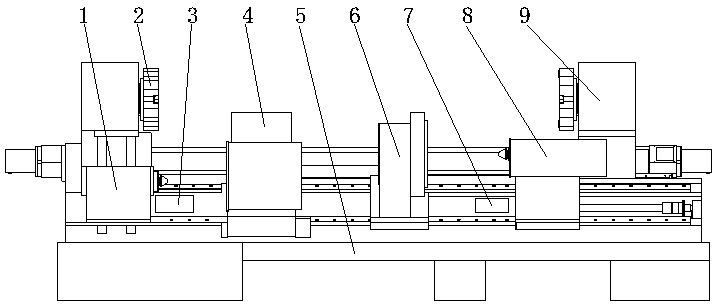

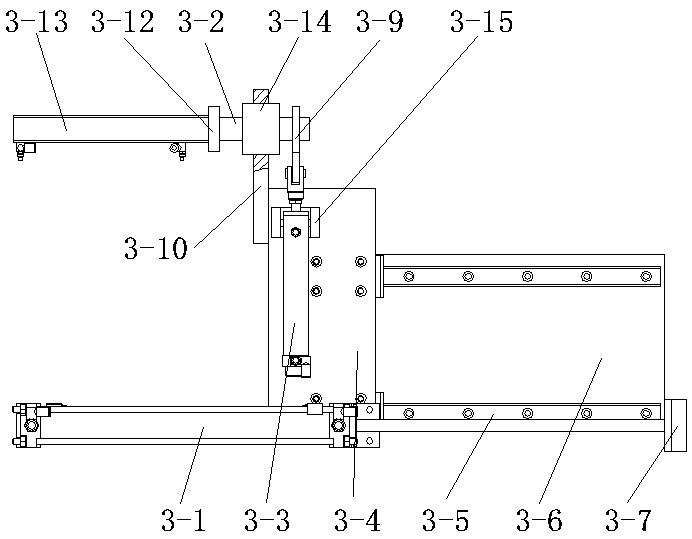

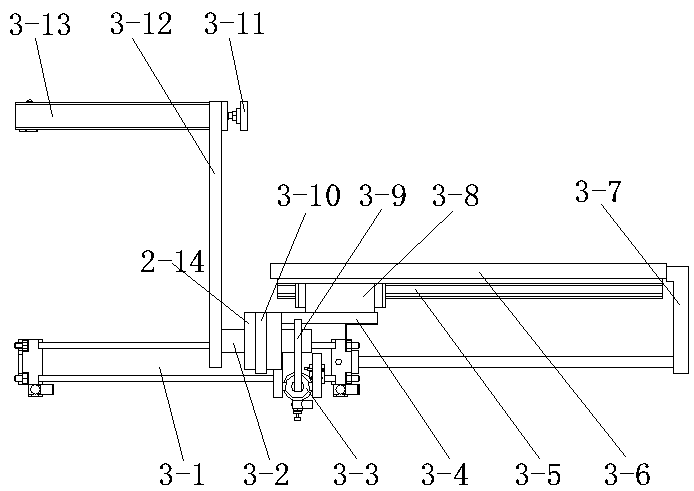

Special numerically-controlled machine tool for machining axle type parts

PendingCN110076351AReasonable structureSimple structureTailstocks/centresAuxillary equipmentNumerical controlMeasurement device

The invention relates to a numerically-controlled machine tool, in particular to a special numerically-controlled machine tool for machining axle type parts. The special numerically-controlled machinetool comprises a tool body, two spindle boxes mounted on the tool body, two tailstocks, two knife posts and a machine tool electrical control device; one of the tailstock can move up and down; supporting barrels are fixedly mounted in spindle holes in the spindle boxes; universal balls are fixed to the inner walls of the supporting barrels; and workpiece axial measurement devices are mounted on two sides of the two spindle boxes. According to the technical scheme, on the basis of an existing two-spindle numerically-controlled machine tool, the structures in the tailstock and the spindle on one side are improved so as to meet the requirements for loading and unloading as well as accurate axial length measurement of long axle type parts relatively large in length-diameter ratio, meanwhile,left-side and right-side axial length measurement devices are added to the machine tool, through the improvement and the addition, the loading and unloading time for the long axle type parts can be shortened effectively, the axial size measurement accuracy can be improved, and automatic loading, unloading, and size measurement can be realized.

Owner:宁夏长兴精密机械有限公司

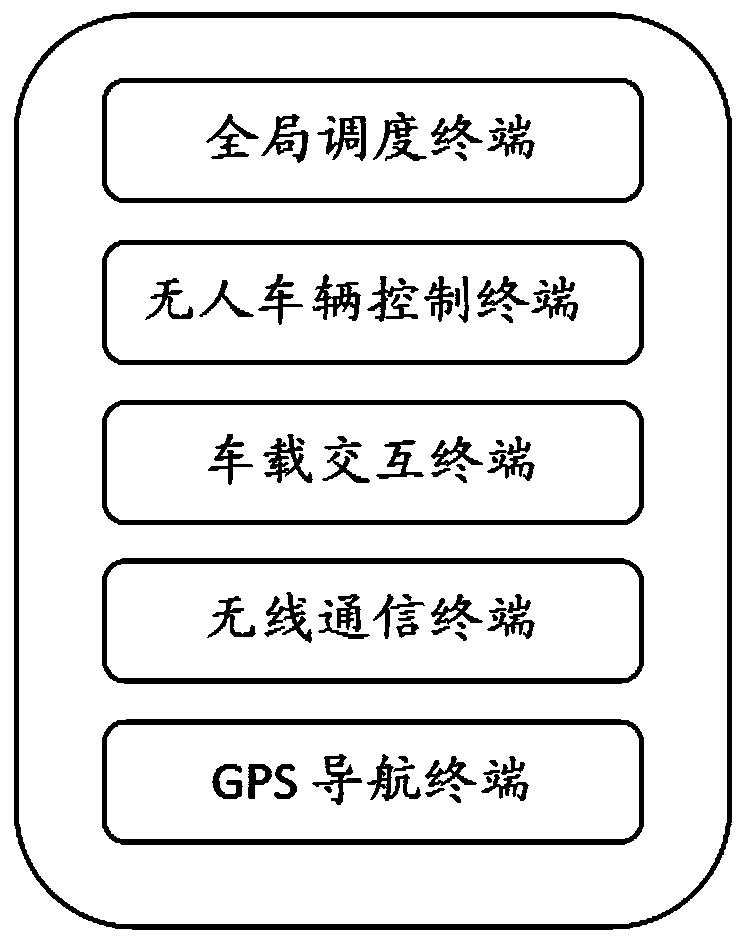

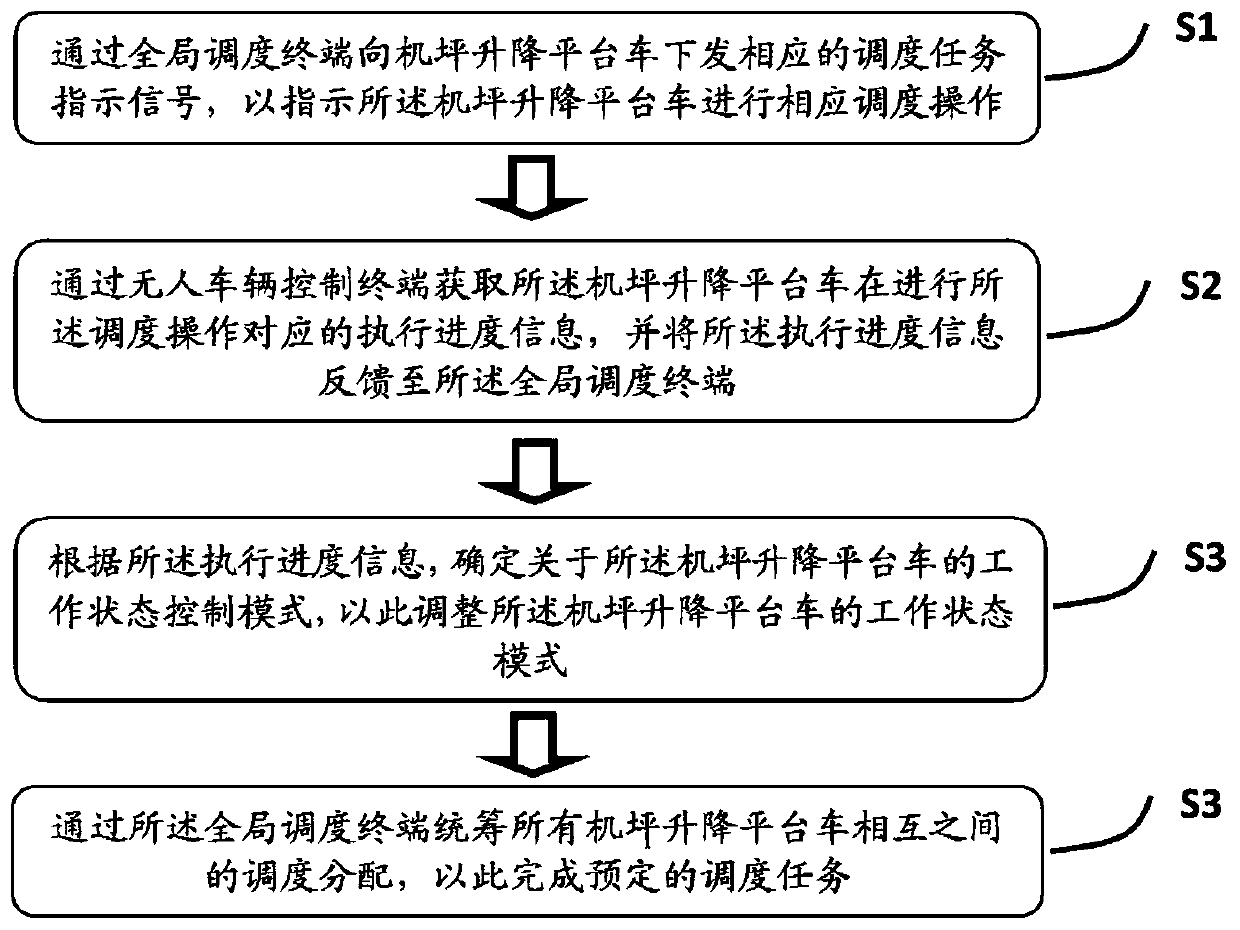

Control system and control method for apron lifting platform car

InactiveCN111290353AImprove work efficiencyImprove safety and reliabilityTotal factory controlProgramme total factory controlGlobal schedulingControl system

The invention provides a control system and control method for an apron lifting platform car. A corresponding scheduling task indication signal is issued to an apron lifting platform vehicle through aglobal scheduling terminal and thus the apron lifting platform vehicle is indicated to perform corresponding scheduling operation; execution progress information corresponding to the scheduling operation is performed by the apron lifting platform vehicle through an unmanned vehicle control terminal; the execution progress information is fed back to a global scheduling terminal; and a working state control mode of the apron lifting platform vehicle is determined based on the execution progress information, so that the working state mode of the apron lifting platform vehicle is adjusted. Scheduling distribution among all apron lifting platform vehicles is planned through the global scheduling terminal and thus a pre-determined scheduling task is completed. Therefore, under the condition that a plurality of unmanned vehicles and a plurality of guarantee operators work in a mixed mode, the apron working efficiency can be improved, the aircraft loading and unloading time can be shortened,the guarantee operators can be reduced, and the safety and reliability under the apron working environment can be improved.

Owner:BEIJING NAVAGRAHA INTELLIGENT TECH CO LTD

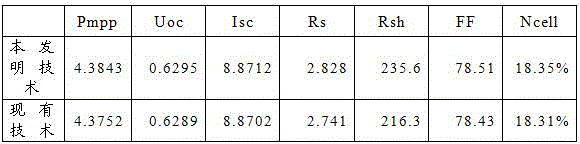

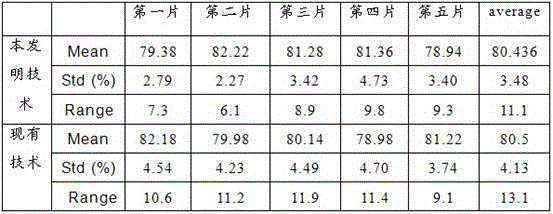

Stackable high-temperature annealing technology

ActiveCN106257625AEasy to operateShort time consumingSemiconductor/solid-state device manufacturingQuartzMaterials science

The invention discloses a stackable high-temperature annealing technology. The technology comprises the following specific operation steps that 1, etched silicon wafers are stacked in order and put into a quartz sheet frame for annealing; 2, the silicon wafers on the quartz sheet frame are covered with a quartz cover plate and pressed, and the quartz sheet frame is fed into a high-temperature diffusion-oxidation furnace; 3, annealing is conducted by increasing and stabilizing the temperature of a furnace tube of the high-temperature diffusion-oxidation furnace; 4, temperature decreasing and discharging from the furnace are conducted, wherein the temperature of the furnace tube of the high-temperature diffusion-oxidation furnace is decreased, and the quartz sheet frame is discharged from the furnace. The stackable high-temperature annealing technology has the advantages that the surfaces of the stacked silicon wafers are isolated from air, and therefore the problems existing in a thermal oxidation technology are effectively solved; operation is easy, the consumed time is short, and quantity production is easy to achieve; meanwhile, the yield is high, the battery piece efficiency is significantly improved, the problems such as edge breakage, corner faults, hidden cracks and fragments in the loading and unloading process of the silicon wafers can be effectively solved, the loading and unloading time is shortened, the quality of battery pieces is improved, and the qualified rate of the battery pieces is increased.

Owner:HENGDIAN GRP DMEGC MAGNETICS CO LTD

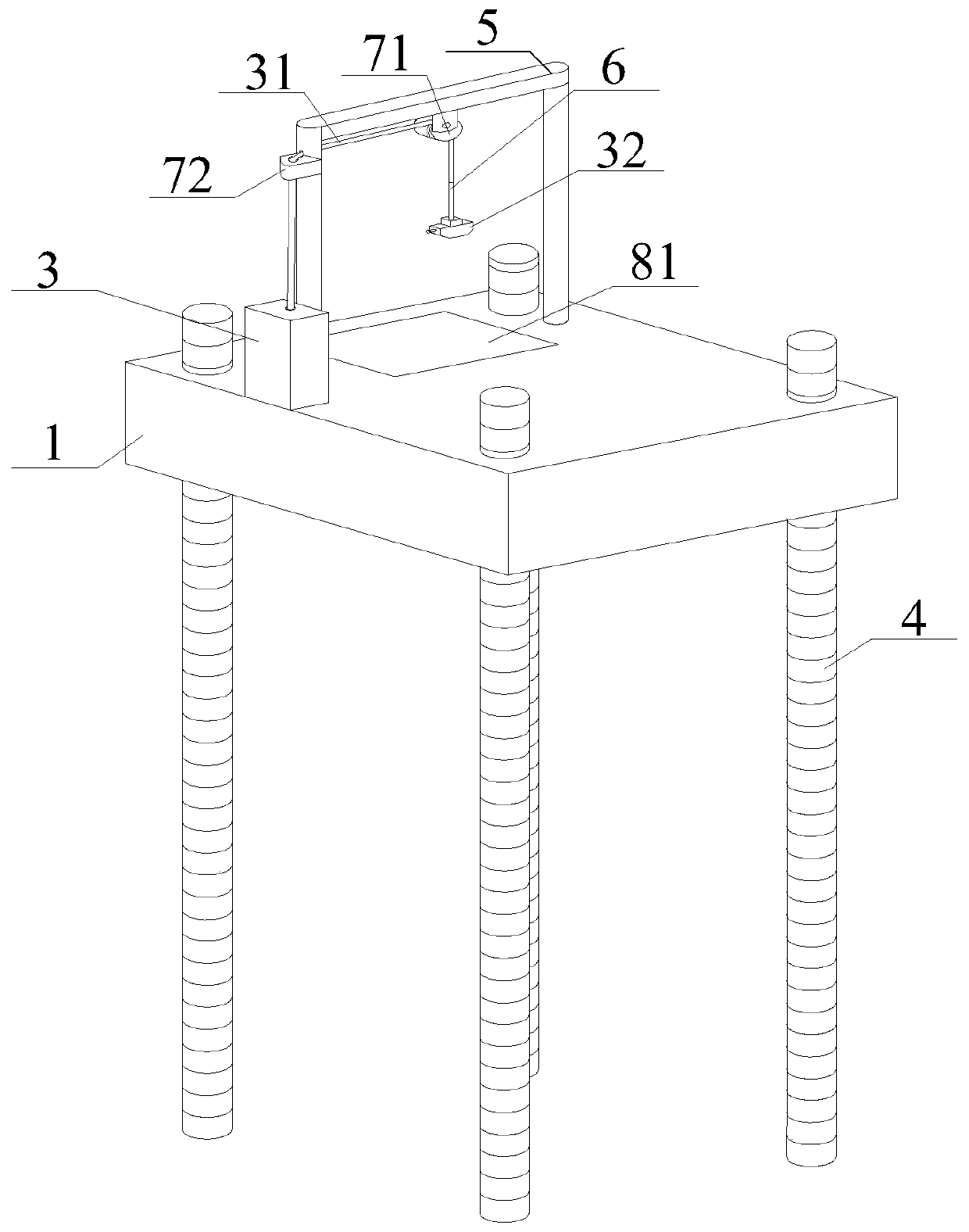

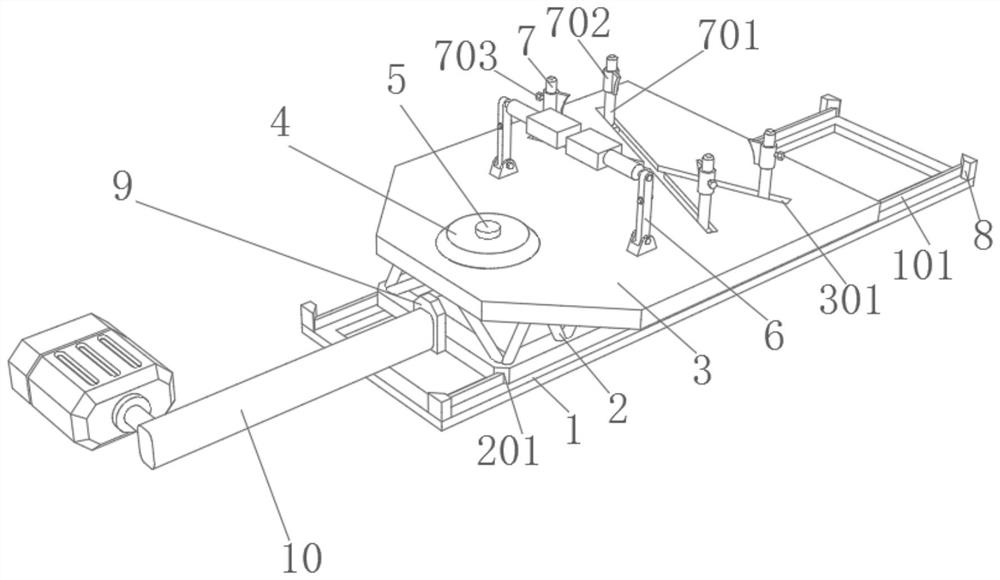

Full-automatic loading vehicle

InactiveCN106185357AReduce in quantityReduce loading and unloading timeLoading/unloadingVehicle frameMecanum wheel

The invention discloses a full-automatic loading vehicle comprising a travelling trolley, a lifting device, a visual locating and guiding device and an abutting and loading device; the travelling trolley comprises a frame and four mecanum wheels arranged in the front and at the rear of the frame; the lifting device comprises a lifting cylinder, parallel lifting rods and a bracket platform; the visual locating and guiding device is a special industrial camera for acquiring an image; and the abutting and loading device comprises a rotary supporting and fixing device, an upper platform, a lower platform and electric servo cylinders. By using the full-automatic loading vehicle, full-automatic operation can be performed; due to the adoption of a six-degree-of-freedom platform, multidirectional movement is realized, the height and inclination angle of workpiece equipment are regulated precisely, and the loading or unloading work of workpieces on the equipment is finished; meanwhile, all-dimensional movement in a way such as advancing, transversely moving, obliquely moving, rotating and a combination thereof can be realized; and the full-automatic loading vehicle is flexible and convenient in operation in a limited and narrow space and high in working reliability.

Owner:YANSHAN UNIV

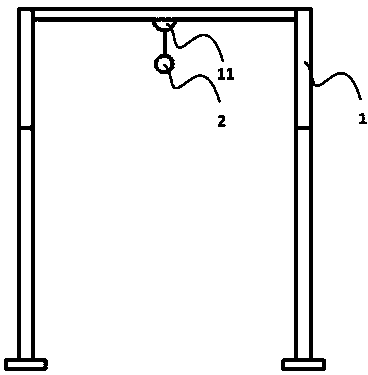

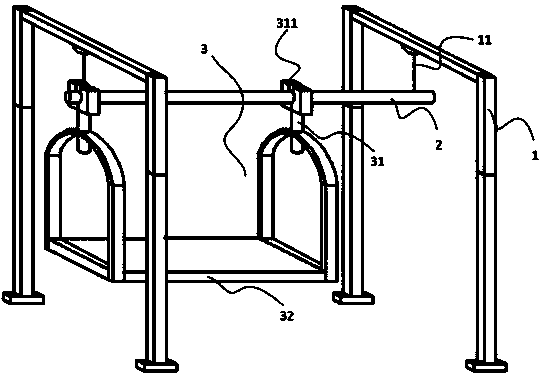

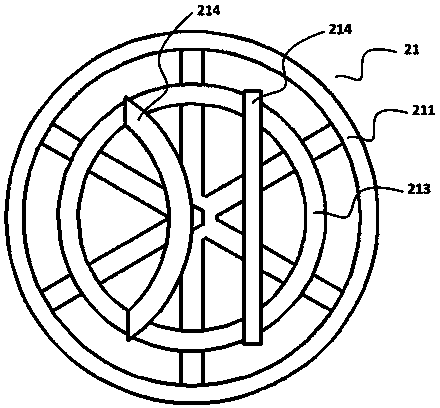

Automatic steering greenhouse suspension type rail transport vehicle system and working method thereof

ActiveCN111532697AAvoid occupyingEasy to cleanControl devices for conveyorsElevated railway with suspended vehicleSteering wheelAutomatic steering

The invention discloses an automatic steering greenhouse suspension type rail transport vehicle system and a working method thereof. The automatic steering greenhouse suspension type rail transport vehicle system comprises support columns, rail beams, a transport vehicle and a software central control device, wherein the support columns are distributed on a transportation rail; suspension structures are arranged at the tops of the support columns; the transport vehicle comprises suspension single rods, a vehicle body and a moving driving motor; moving mechanisms are arranged at the upper endsof the suspension single rods; the rail beams are connected with the moving mechanisms; the moving driving motor drives the moving mechanisms; the vehicle body is fixedly connected with the lower endsof the suspension single rods; a steering mechanism is further arranged at the joint of the rail beams and comprises a steering wheel, a rotary driving motor, a rotary base and steering guide rails;the rotary base is connected with the steering wheel; the rotary driving motor drives the rotary base to rotate; the steering guide rails are fixed on the rotary base; the steering guide rails and therail beams are on the same horizontal plane; the steering guide rails are used for connecting the two rail beams; and the moving driving motor and the rotary driving motor are respectively connectedwith the software central control device.

Owner:江苏侬盛泰格农业科技(集团)有限公司

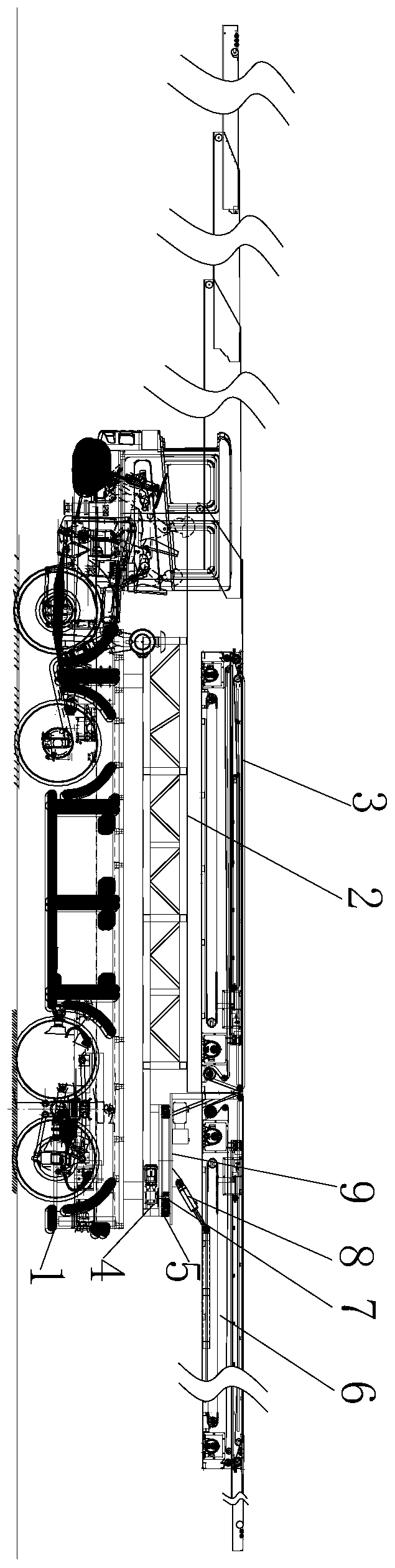

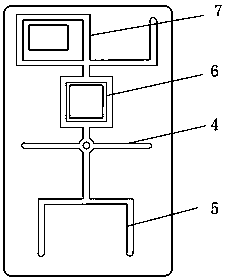

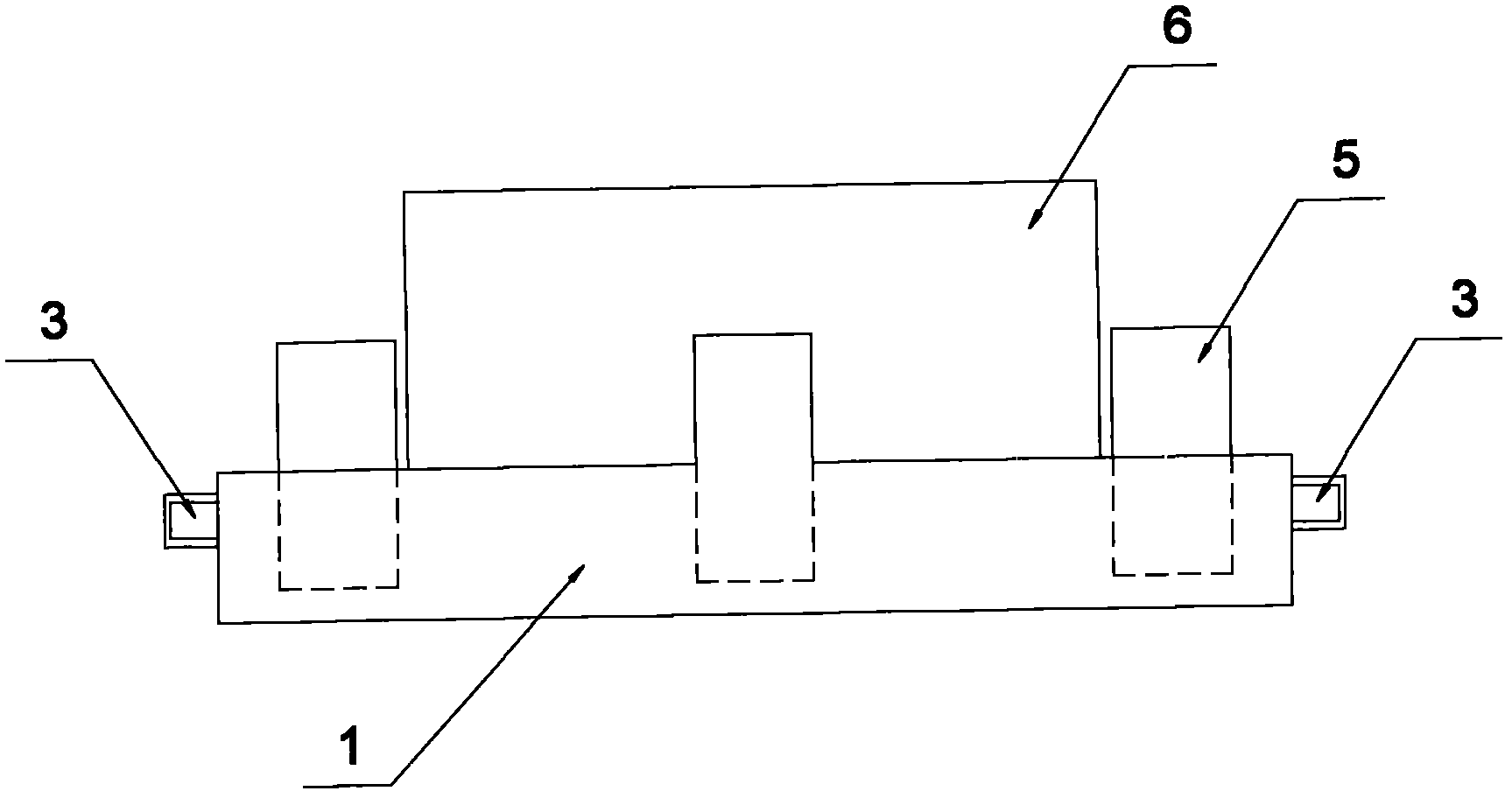

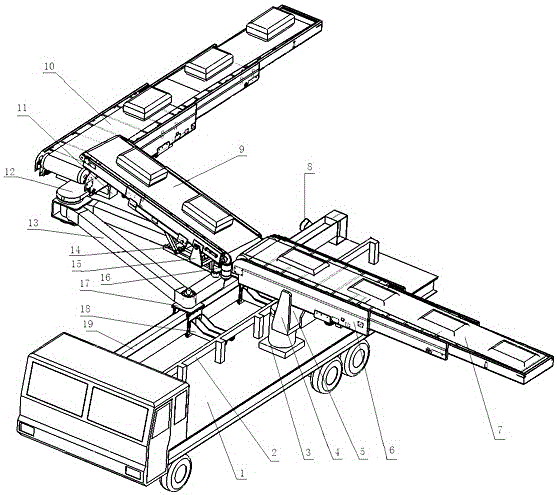

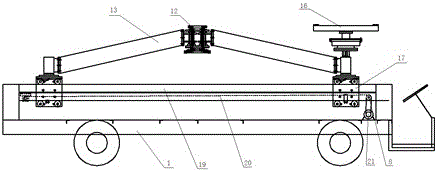

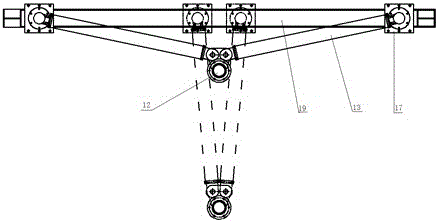

Vehicle-mounted telescopic conveyor for airport

PendingCN109808912ASolve the problem that the loading and unloading time is too longReduce loading and unloading timeFreight handling installationsItem transportation vehiclesNatural disasterSprocket

The invention discloses a vehicle-mounted telescopic conveyor for an airport. The vehicle-mounted telescopic conveyor comprises an automobile, an underframe, a fixed telescopic conveyor, a gear reducer, a slewing supporting mechanism, a rotary telescopic conveyor, a motor gear, an oil cylinder and an oil cylinder fixing base, wherein the underframe is fixed to the automobile; the fixed telescopicconveyor and the rotary telescopic conveyor are fixed to the underframe; the gear reducer and the slewing supporting mechanism are in engaged transmission through the motor gear; the slewing supporting mechanism is connected with the underframe; the oil cylinder fixing base is connected to the upper side of the slewing supporting mechanism; the oil cylinder fixing base is connected with the oil cylinder; a fixed telescopic belt line on the fixed telescopic conveyor drives chain wheels and a chain through a gear reducing motor to complete expansion and retraction of a machine body and a belt; the rotary telescopic conveyor drives the slewing supporting mechanism through the gear reducing motor to complete rotation of a line body. The invention solves the problem that in the airport and a disaster relief area where the a natural disaster occurs, a conveying and transporting machine costs too long time for loading or unloading materials, the vehicle-mounted telescopic conveyor quickly leaves after loading or unloading, and can be quickly docked with a cargo plane for conveying.

Owner:上海睦祥自动化股份有限公司

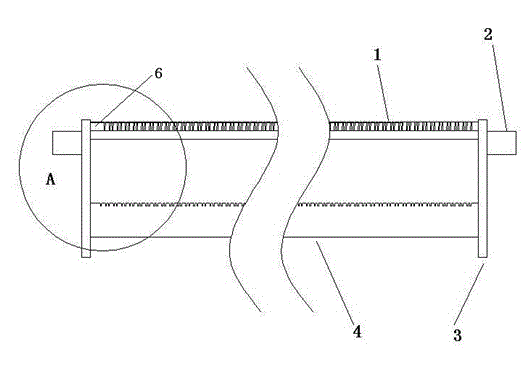

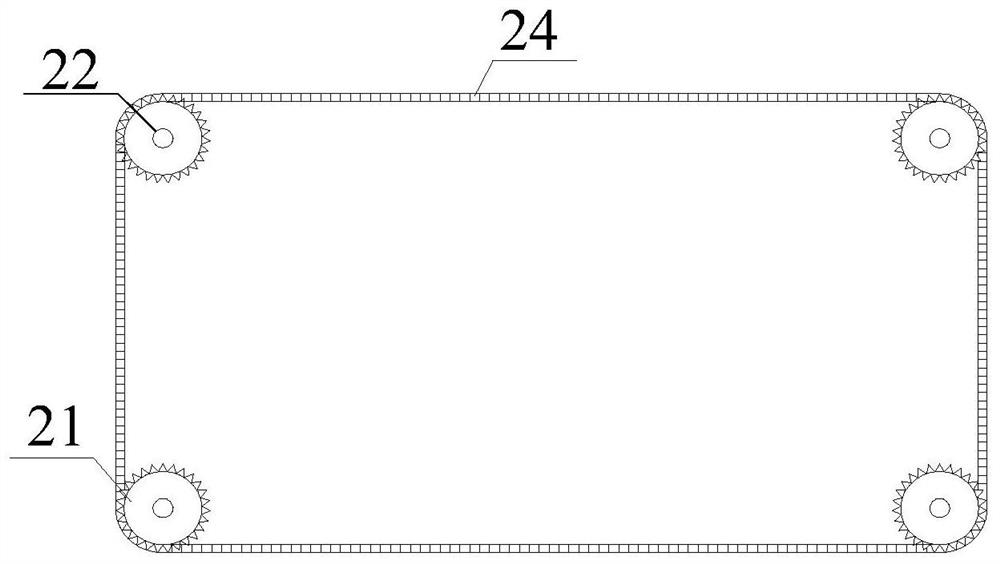

Quartz boat for diffusion

InactiveCN102723301AImprove high temperature gettering effectImprove conversion efficiencySemiconductor/solid-state device manufacturingPhysicsSilicon chip

The invention relates to the technical field of production of solar cells, in particular to a quartz boat for diffusion. The quartz boat for diffusion comprises a side connecting piece and brackets, wherein the brackets comprise a pair of upper brackets and a pair of lower brackets; the pair of upper brackets is symmetrically fixed on the inner side walls at the upper end of the side connecting piece; the pair of lower brackets is symmetrically fixed on the inner side walls at the bottom of the side connecting piece; a plane where the pair of upper brackets is arranged on is mutually parallel to that where the pair of lower brackets is arranged on; the distance between the pair of upper brackets is longer than that between the pair of lower brackets; and grooves at different intervals are formed in the inner side surfaces of the pair of upper brackets and the upper side surfaces of the pair of lower brackets. Through the adoption of the quartz boat for diffusion, the open-circuit voltage and the short-circuit current of the solar cells can be improved, the conversion efficiency is further improved, the square resistance of the cells can be controlled easily, the uniformity is enhanced, the method is feasible, and the operation is simple and convenient.

Owner:山东力诺太阳能电力股份有限公司

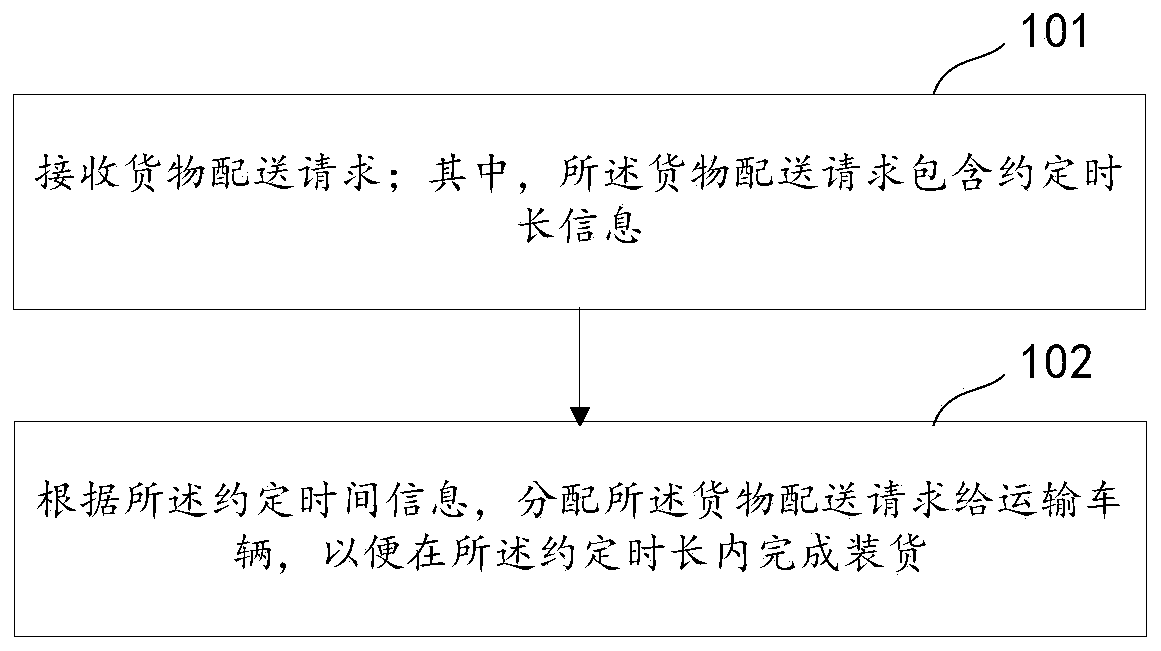

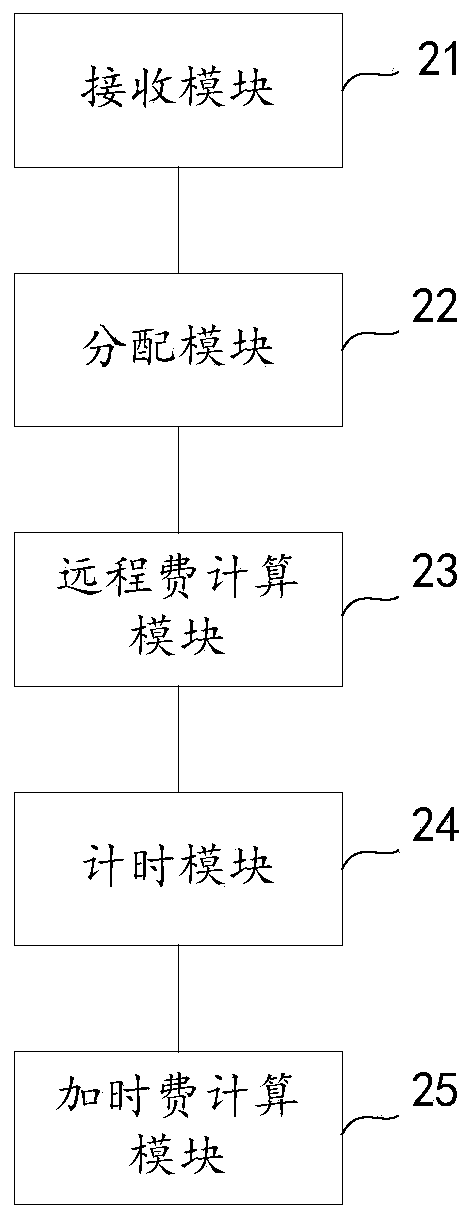

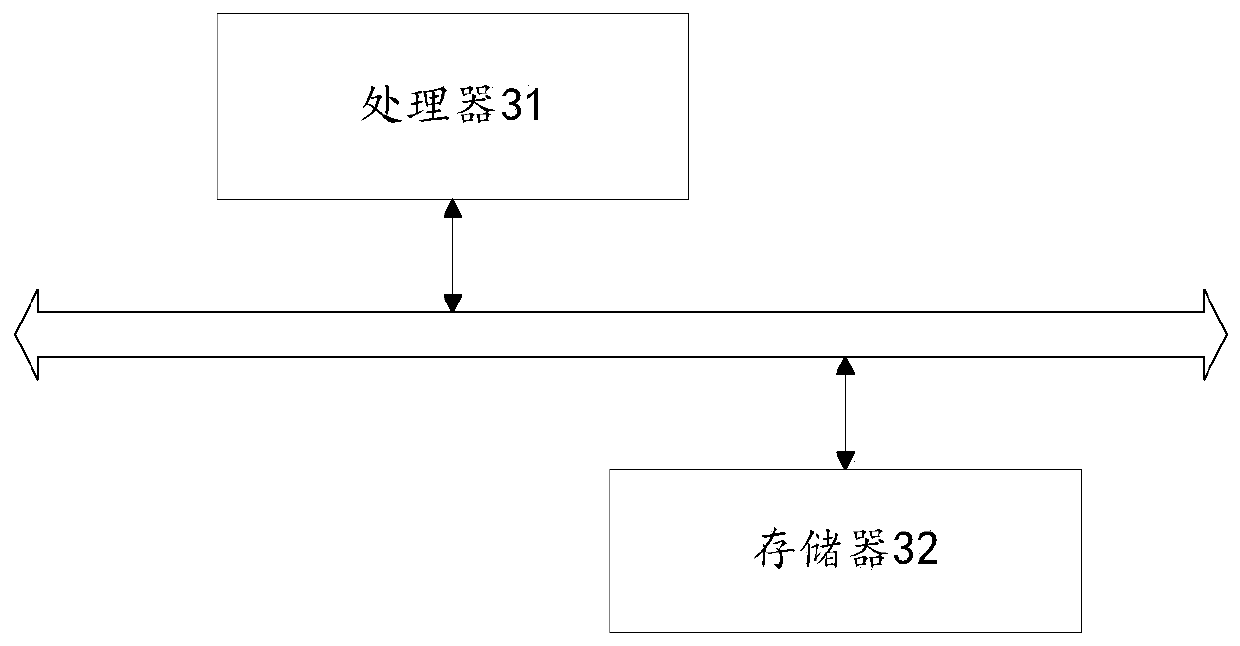

Distribution request distribution method and device, equipment and storage medium

InactiveCN109948818AMeet fast freight needsReduce loading and unloading timeReservationsLogisticsUser needsTime information

The invention discloses a distribution request distribution method and device and equipment. The method comprises the following steps: receiving a cargo distribution request, Wherein the cargo distribution request comprises agreed time length information; And according to the agreed time information, distributing the cargo distribution request to a transport vehicle so as to complete loading within the agreed time length. By means of the technical scheme, when the user needs to transport goods with a small quantity of to-be-transported goods, the user can select the rapid freight transport mode according to the actual situation, the loading and unloading time can be saved, the freight transport cost can be reduced, and the rapid freight transport requirement of the user can be met.

Owner:天津五八到家科技有限公司

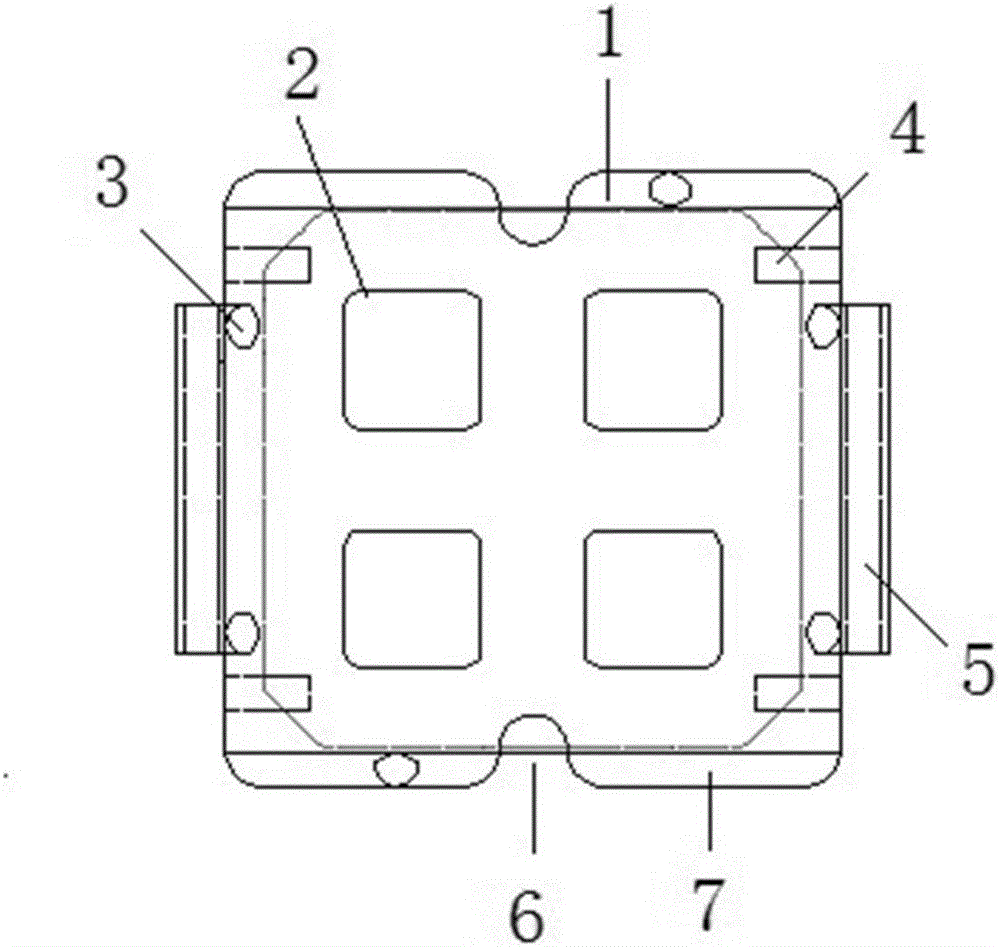

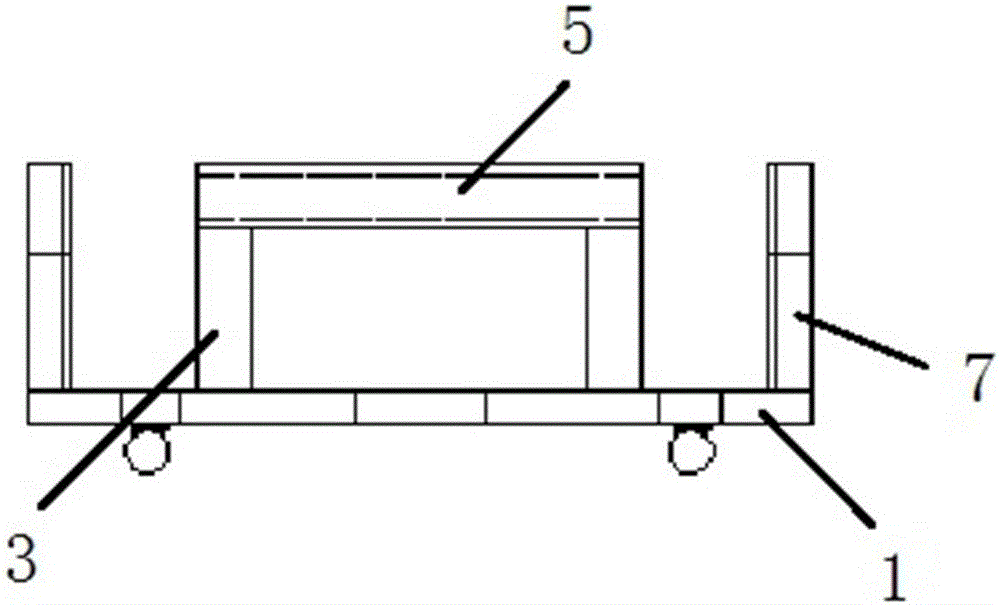

Tool for polishing ceramic mobile phone back plate

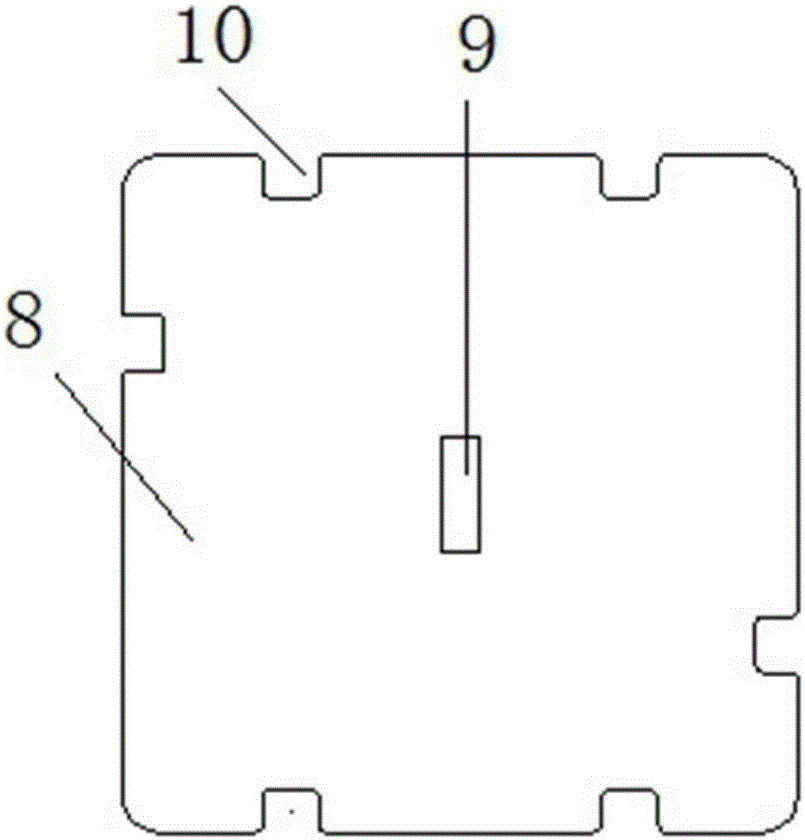

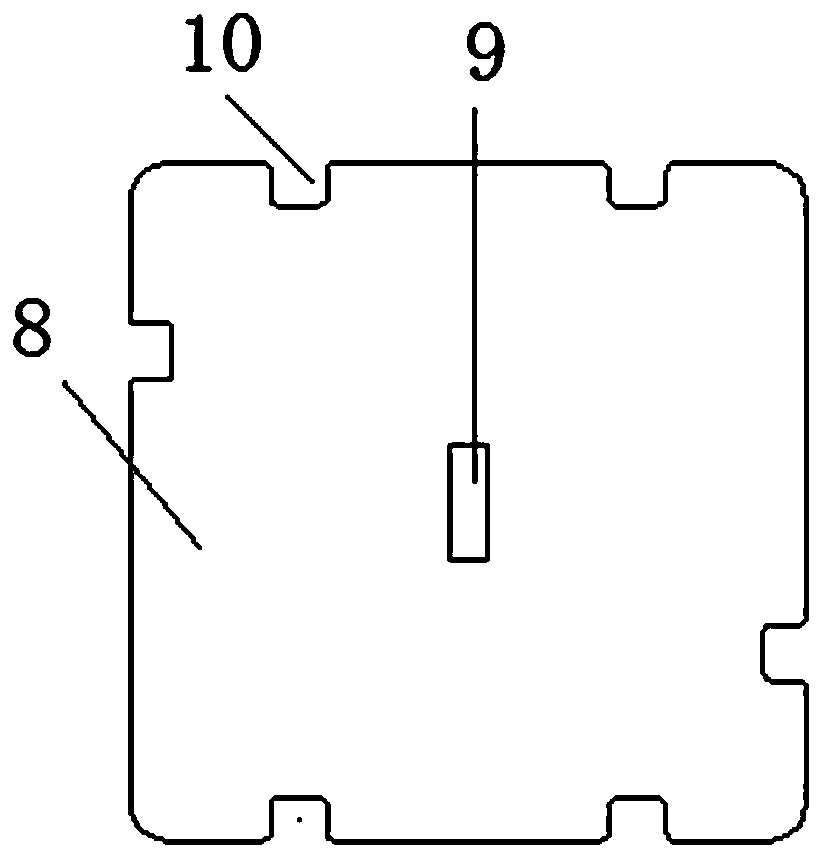

PendingCN108527070AReduce loading and unloading timeReduce scratching effectPolishing machinesGrinding machinesBackplaneMachining process

The invention relates to a tool for polishing a ceramic mobile phone back plate. The tool comprises a bottom surface, vacuum adsorption tool bodies and vacuum adsorption holes. The tool adopts a special groove type and a special material, in the mobile phone back plate machining process, the clamping precision of the mobile phone back plate can be guaranteed, the machining precision of the mobilephone back plate can be improved, the yield of the mobile phone back plate can be increased, in addition, the scratching effect of an acrylic material or an aluminum alloy material on the ceramic mobile phone back plate can be reduced by using the material, and secondary damage in the machining process can be reduced. The tool has the advantages that the adsorption force is strong, the number of the vacuum air grooves can be decreased, and meanwhile the comprehensive cost of the tool can be lowered.

Owner:HARBIN AURORA OPTOELECTRONICS TECH

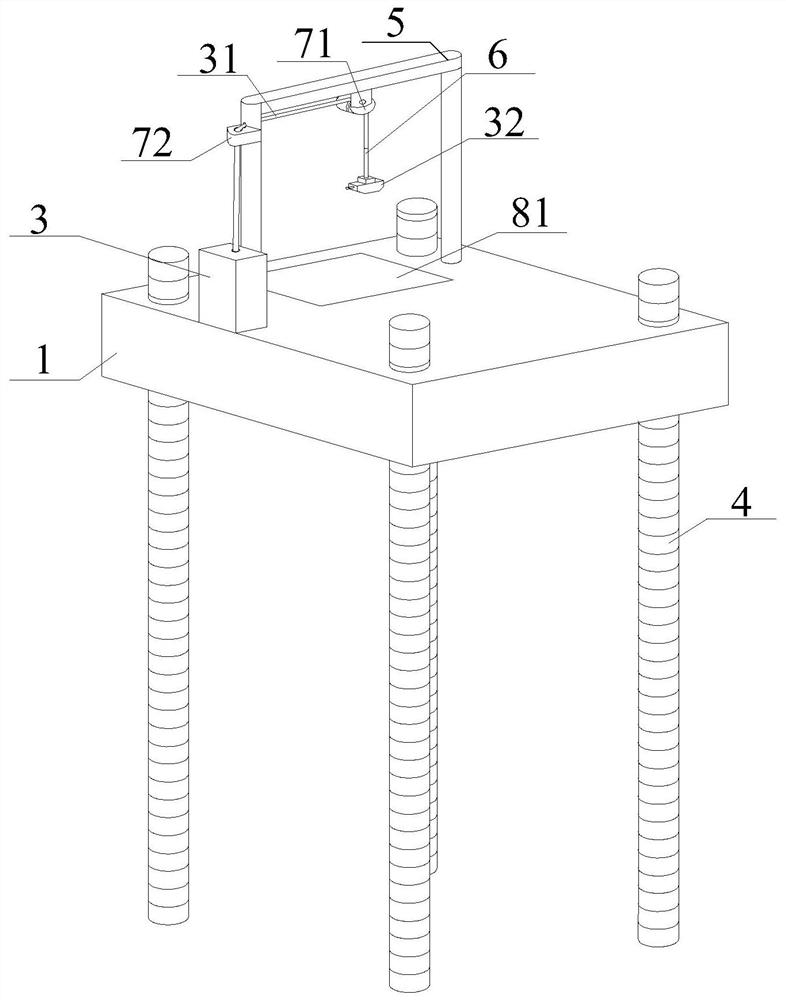

Attached scaffold for construction

ActiveCN110565935ARealize automatic liftingRealize opening and closingScaffold accessoriesBuilding support scaffoldsDrive wheelEngineering

The invention belongs to the technical field of construction, and provides an attached scaffold for construction. The attached scaffold comprises a base, a hoisting device and a threaded column; a lifting device is arranged in the base and comprises a driving wheel, a driven wheel and a lifting wheel; the driving wheel is fixedly connected with a synchronizing wheel, and the lifting wheel is connected with a threaded column in a sleeving mode; the hoisting device comprises a winding device, a hoisting rope and a fixing device, and the fixing device comprises a hoisting rod, a driven rod, a limiting ring and jacking rods; a moving space is formed in the driven rod, and the limiting ring moves in the moving space; the jacking rods are connected with the hoisting rod through elastic pieces, the ends of the jacking rods are each arranged in an arc shape, and the arc-shaped ends of the jacking rods move in the moving space; and a feeding space is formed in the base, and an automatic flipping device is arranged on the feeding space and comprises a cover plate, a rotating plate, a fixing seat and a rotating shaft. Thus, quick assembling, automatic lifting and material transporting can beachieved, the working efficiency is improved, and workers can be effectively protected.

Owner:WEIFANG CHANGDA CONSTR GROUP

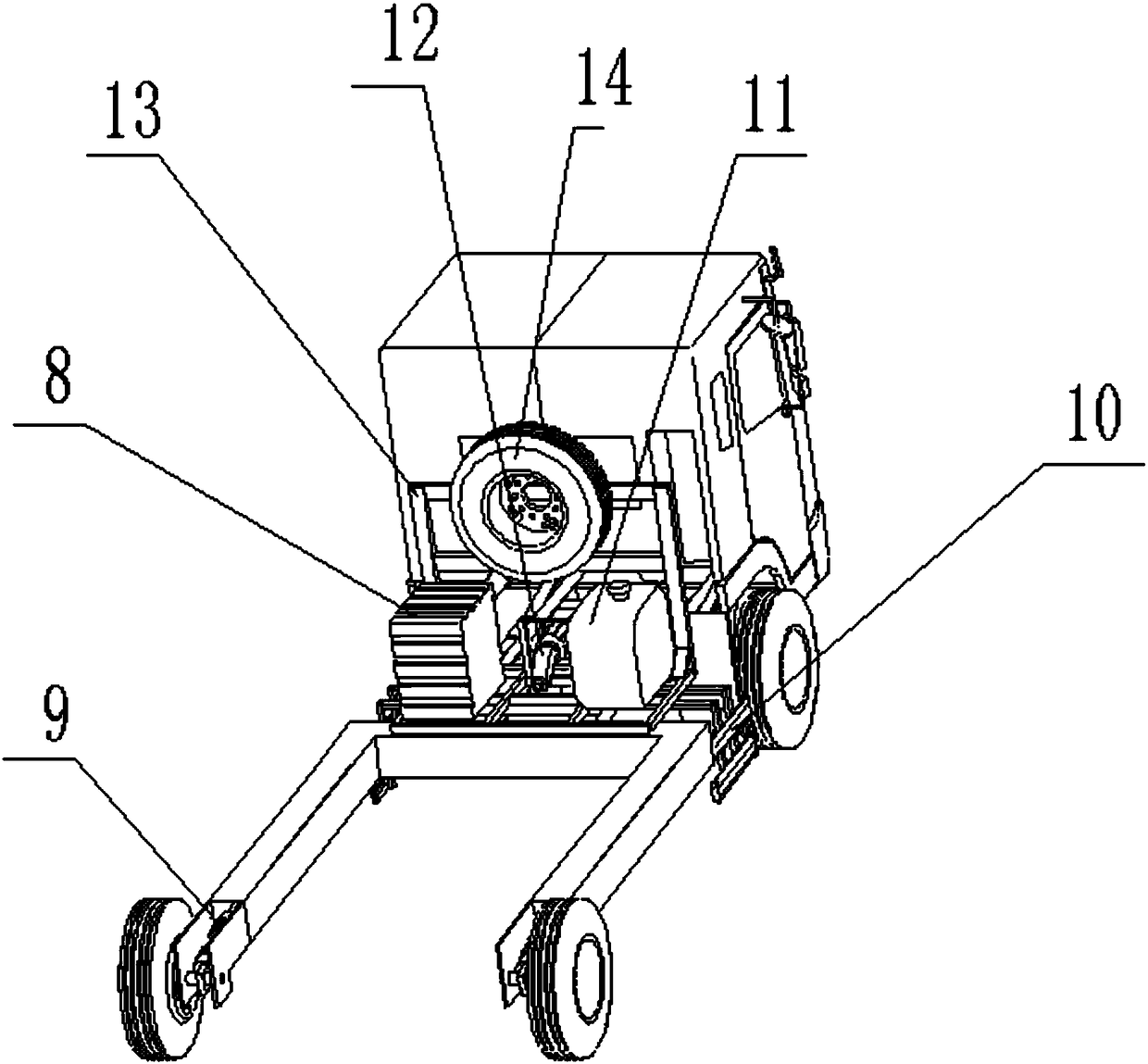

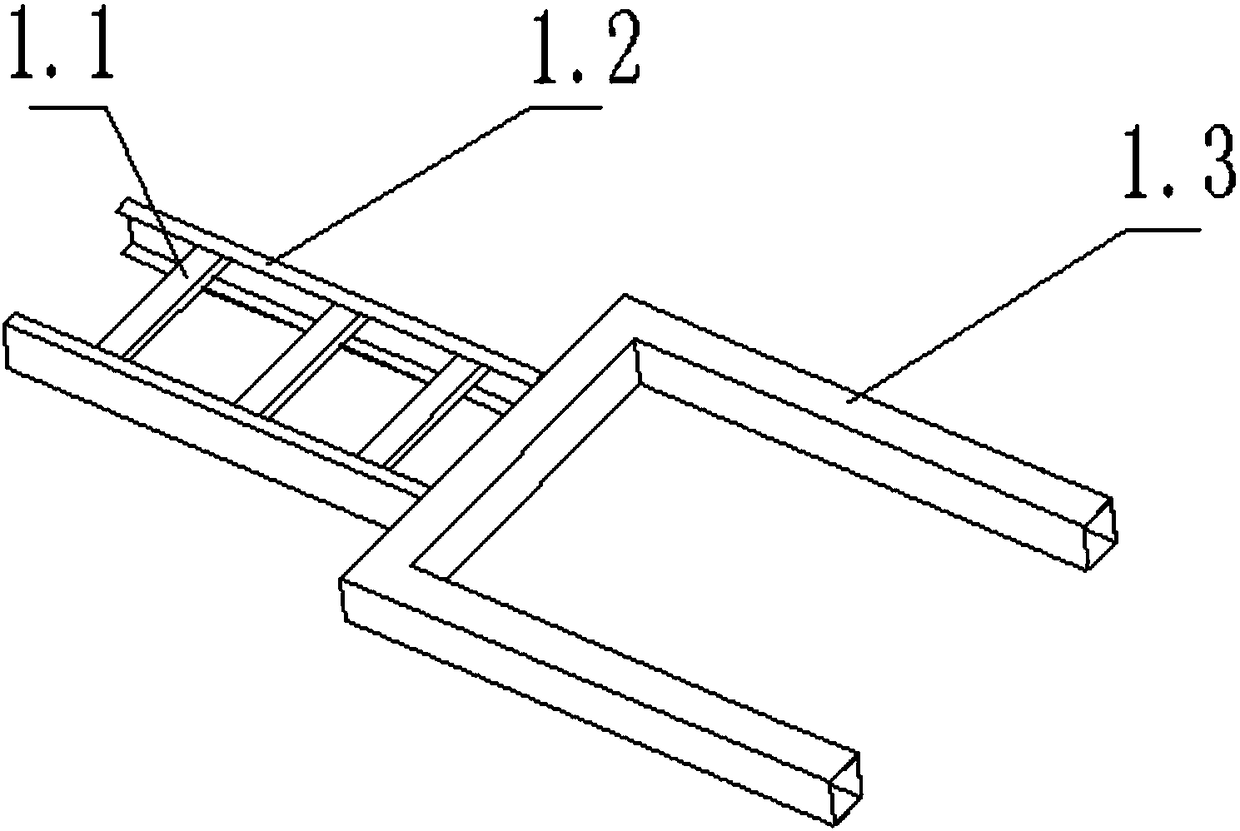

Carriage type transport vehicle with movable and replaceable carriage

ActiveCN108407903AShorten the timeImprove convenienceItem transportation vehiclesVehicle with parallel load movementVehicle frameBraced frame

The invention discloses a carriage type transport vehicle with a movable and replaceable carriage. The transport vehicle comprises a main vehicle frame, a supporting platform, a lifting mechanism, a carriage supporting frame, a telescopic locking mechanism, a carriage mechanism and a supporting mechanism; the supporting platform is installed on the main vehicle frame; vehicle frame rear longitudinal beams of the main vehicle frame are each of a hollow structure and used for lifting the carriage mechanism; the lifting mechanism is installed on the vehicle frame rear longitudinal beams; the carriage supporting frame is installed on the lifting mechanism; the telescopic locking mechanism is installed on the carriage supporting frame; the carriage mechanism is installed in rails of the carriage supporting frame; and the supporting mechanism is installed on the main vehicle frame. The carriage type transport vehicle can lower the carriage to the ground to be loaded and unloaded, and meanwhile, the carriage can be lifted on certain high platforms to be loaded and unloaded. When the vehicle encounters a place with stairs, through the telescopic locking mechanism, the carriage can be lifted and move forwards and backwards at the same time, and therefore goods are loaded and unloaded on the stairs.

Owner:HEBEI UNIV OF TECH

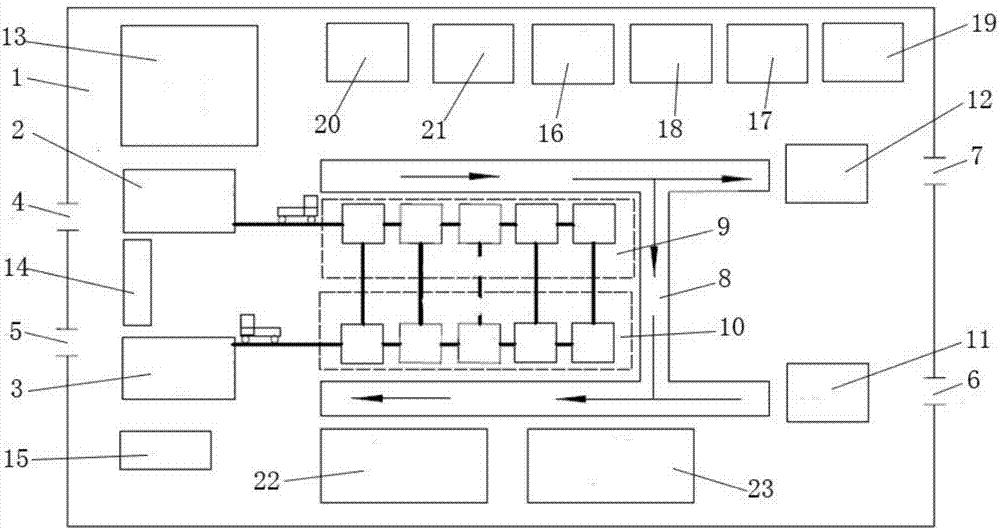

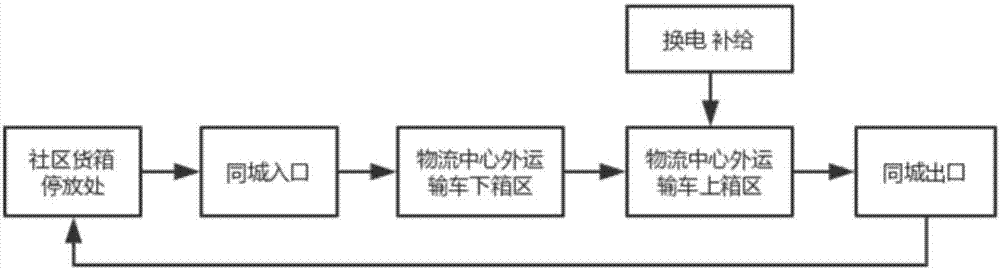

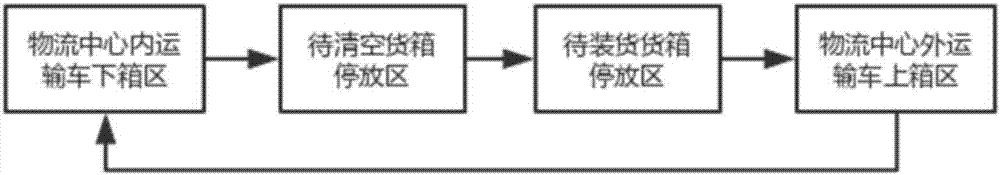

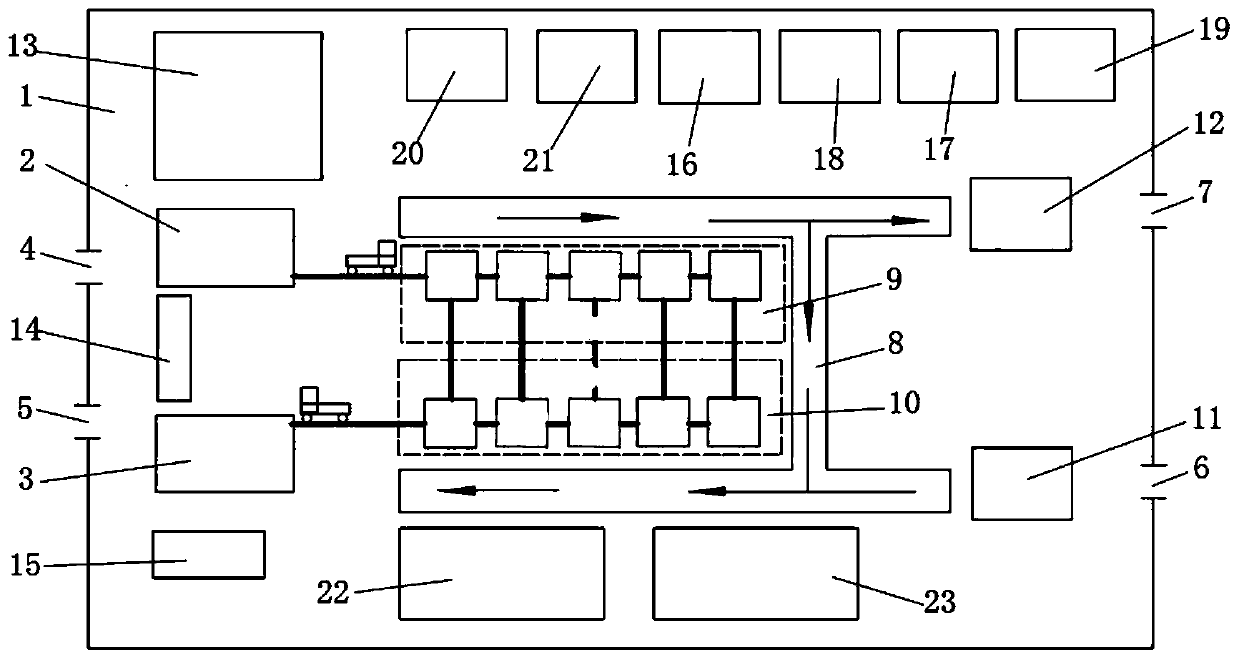

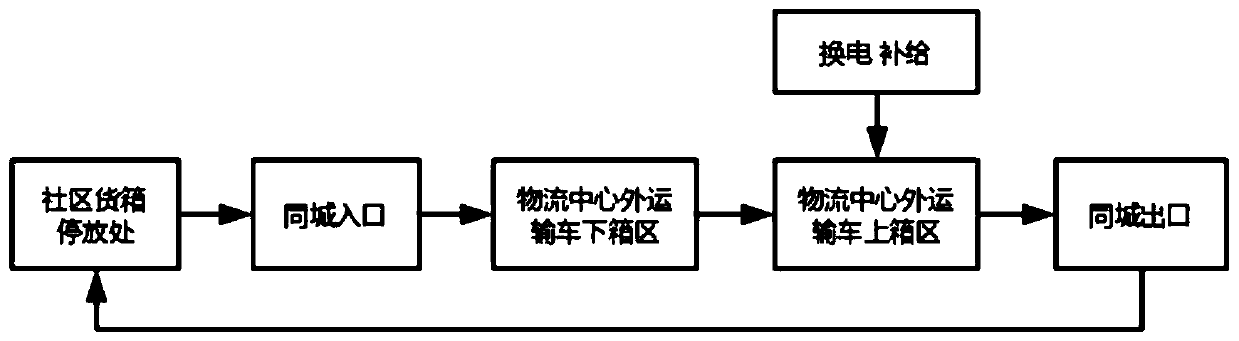

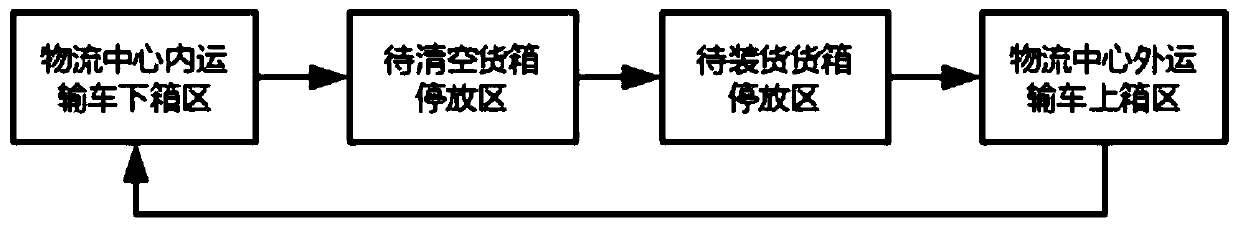

Circular operation intra-city logistics system

ActiveCN107285050AImprove continuityImprove fluencyConveyorsStorage devicesContinuous/uninterruptedCity logistics

The invention provides a circular operation intra-city logistics system comprising a logistics center, intra-city outward transportation vehicles and logistics center internal transportation vehicles. The logistics center is provided with a packing box treatment area, an intra-city vehicle entrance, an intra-city vehicle exit, an entrance for vehicles entering the city and an exit for vehicles leaving the city. The packing box treatment area is provided with a goods sorting flow line, a to-be-emptied packing box placing station and a to-be-charged packing box placing station. An intra-city outward transportation vehicle box unloading station, an intra-city outward transportation vehicle box loading station, an entering-city vehicle goods treatment station and a leaving-city vehicle goods treatment station are arranged at corresponding positions on the goods sorting flow line. The logistics center internal transportation vehicles transport to-be-emptied packing boxes on the intra-city outward transportation vehicle box unloading station to the to-be-emptied packing box placing station and then transport the emptied packing box to the to-be-charged packing box placing station. The circular operation intra-city logistics system can achieve continuous circular operation in the logistics center, save labor cost and time cost and improve the use frequency of the vehicles and the work efficiency of the express industry.

Owner:WUHAN UNIV OF TECH

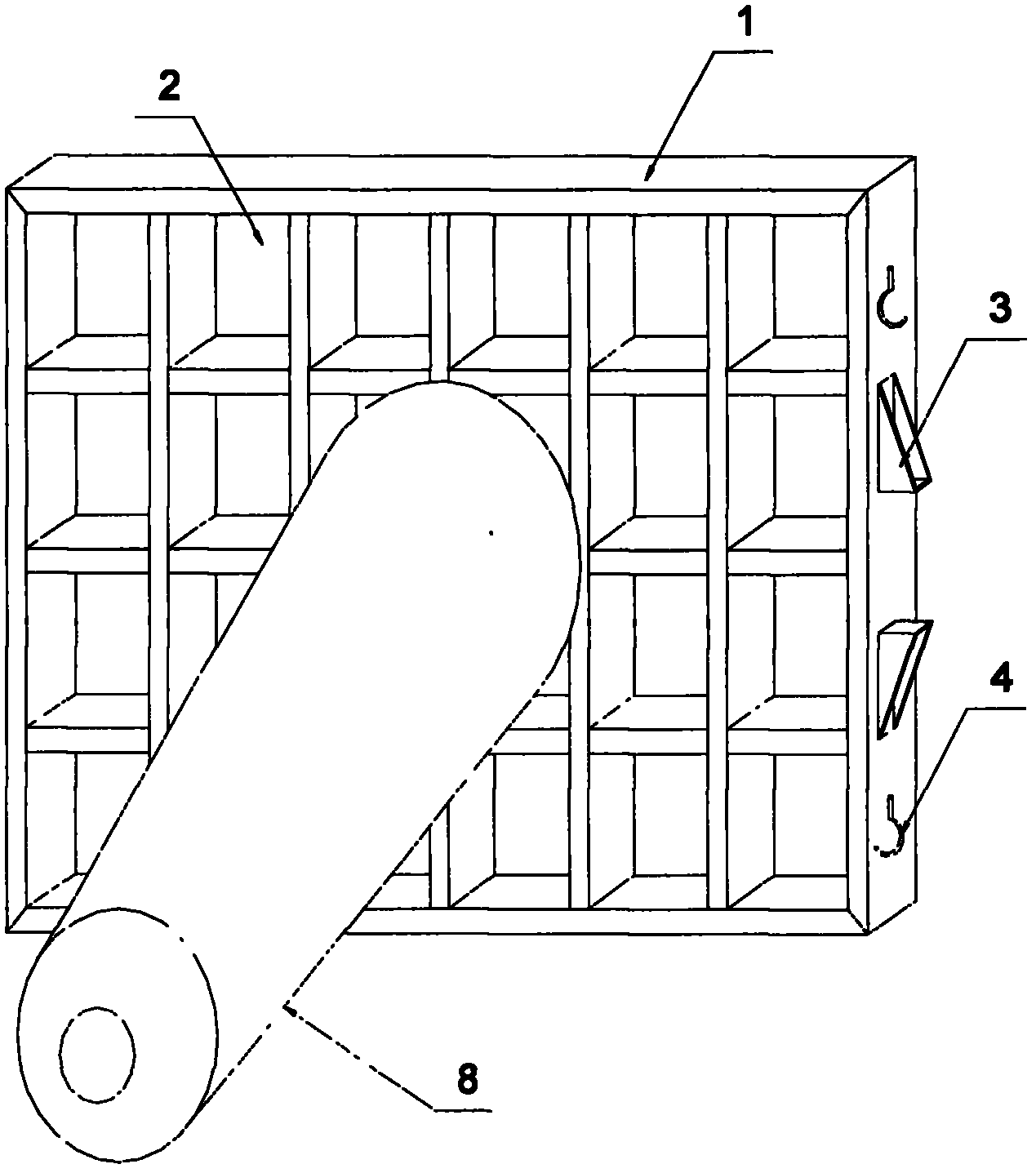

Steel coil carrier

InactiveCN102556493AEasy to fixTime-consuming and laborious to solvePackage recyclingExternal framesMechanical engineering

The invention relates to an anti-slip reinforcement device for cargo transport, in particular to a steel coil carrier for reinforcing vertical loading and transport of steel for a train, which belongs to auxiliary devices for transport and loading reinforcement business for the train and the like. The steel coil carrier is formed by welding channel steel and square pipes which are vertically and horizontally arranged, square holes are arranged on the steel coil carrier, triangular barrier plates are arranged on two sides of the steel coil carrier, lifting hooks are arranged on the outer sides of the triangular barrier plates, and baffle plate pins are inserted into the square holes. The steel coil carrier is formed by welding the high-quality channel steel and the high-quality square pipes, thereby being safe in operation, convenient in use, high in safety and universality and reusable. The steel coil carrier is applicable to vertical loading and reinforcement of steel coils of different coiling diameters, convenient in flexibility, simple in fixation of coiled plates and fast in loading without reinforcement, loading and unloading time are shortened, and transport cost is reduced.

Owner:蒋恩泉

Attached scaffolding for construction

ActiveCN110565935BRealize automatic liftingRealize opening and closingScaffold accessoriesBuilding support scaffoldsRotational axisDrive wheel

The invention is applicable to the technical field of construction, and provides an attached scaffold for construction, comprising a base, a lifting device and a threaded column, a lifting device is arranged in the base, and the lifting device includes a driving wheel, a driven wheel and a lifting wheel, and the driving wheel is fixedly connected The synchronizing wheel, the lifting wheel is sleeved with the threaded column; the lifting device includes a winding device, a lifting rope and a fixing device, and the fixing device includes a lifting rod, a driven rod, a limit ring and a top rod. The driven rod is provided with a moving space, and the limit The ring is movable in the moving space, the top rod is connected to the lifting rod through an elastic piece, and the end of the top rod is arranged in an arc shape, and the arc-shaped end of the top rod is movable in the moving space. The base is provided with a feeding space, and the feeding space is provided with an automatic flipping device. The automatic flipping device includes a cover plate, a rotating plate, a fixed seat and a rotating shaft. Thereby, the present invention can realize rapid grouping, automatic lifting and transportation of materials, improve work efficiency, and can effectively protect workers.

Owner:WEIFANG CHANGDA CONSTR GROUP

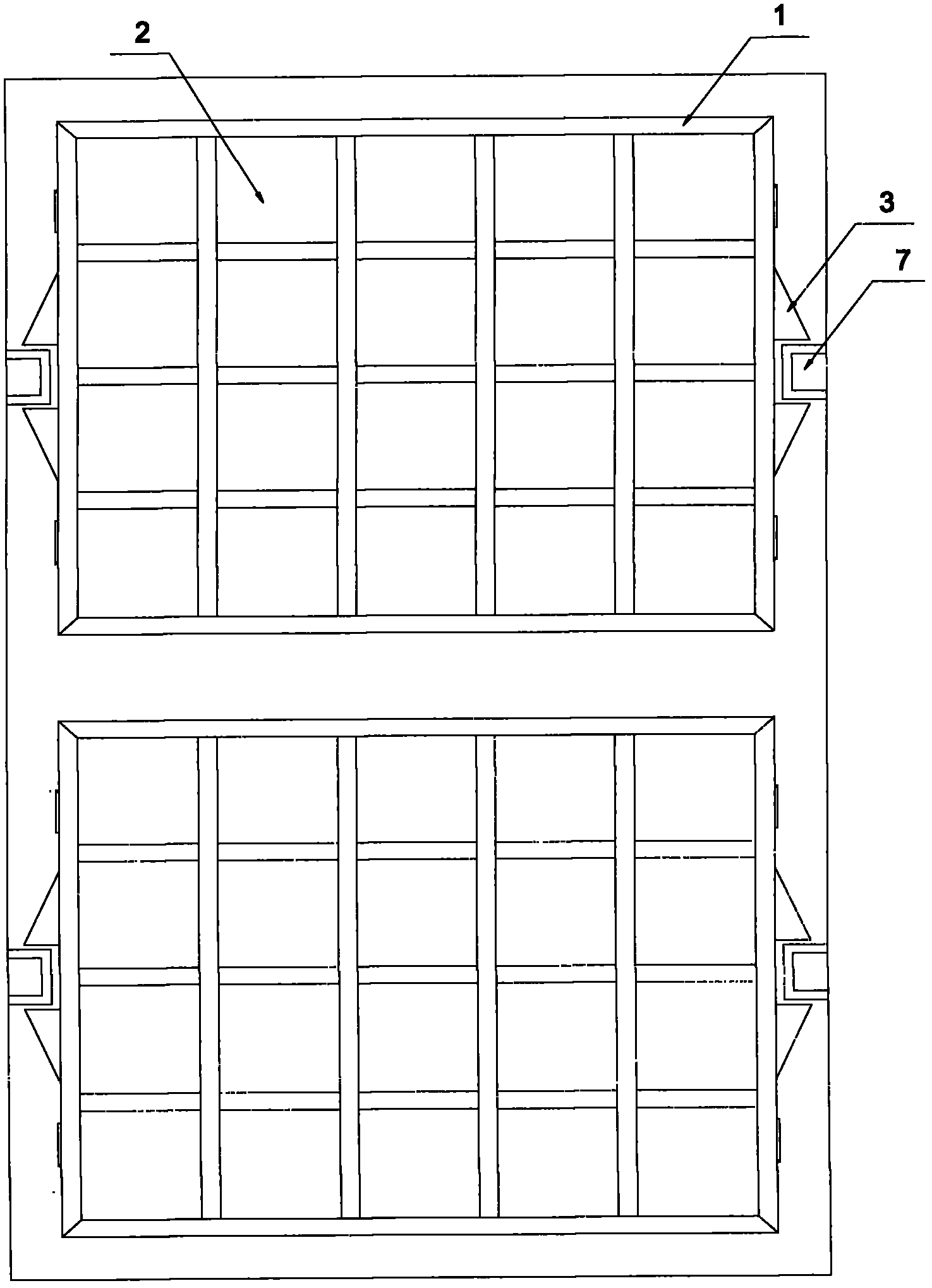

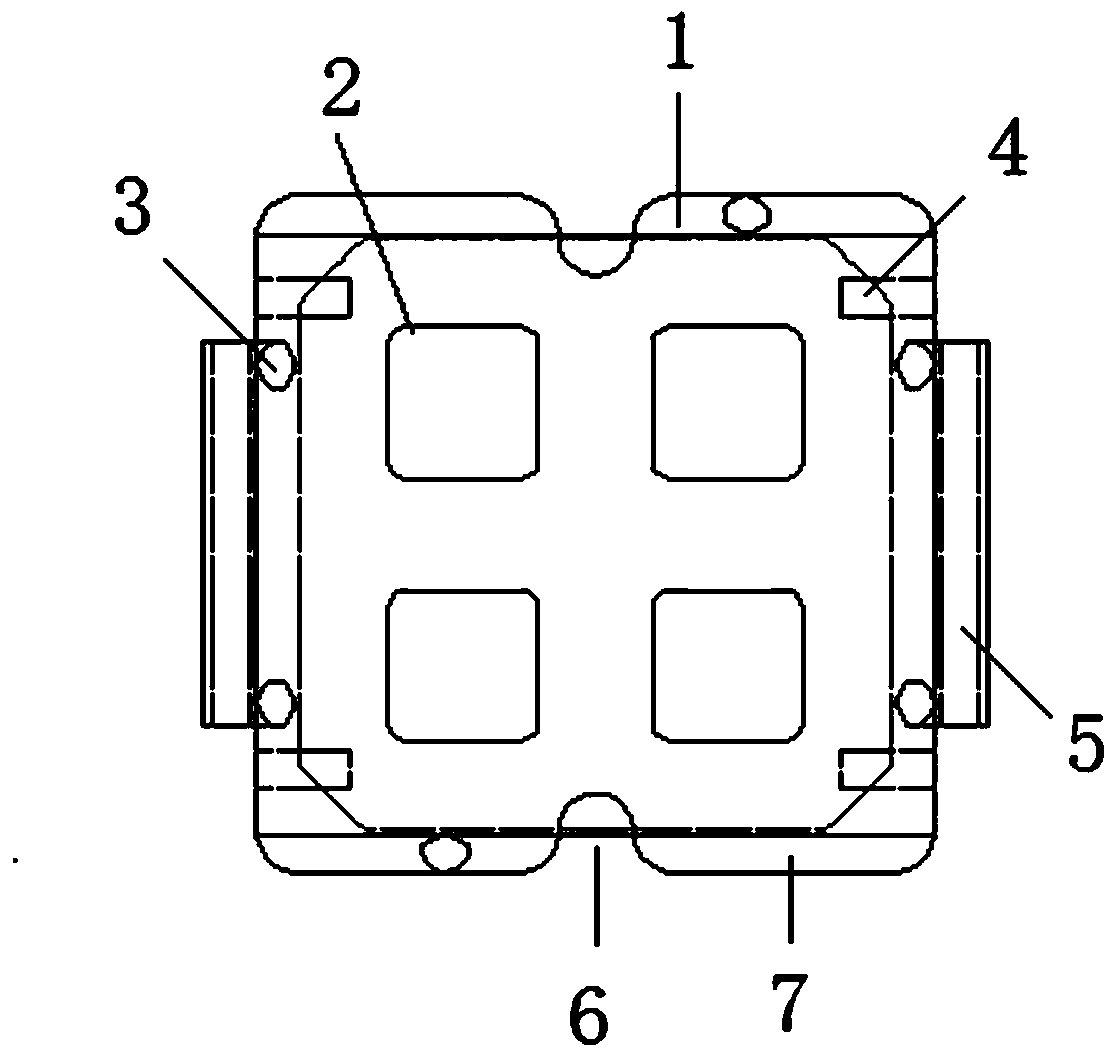

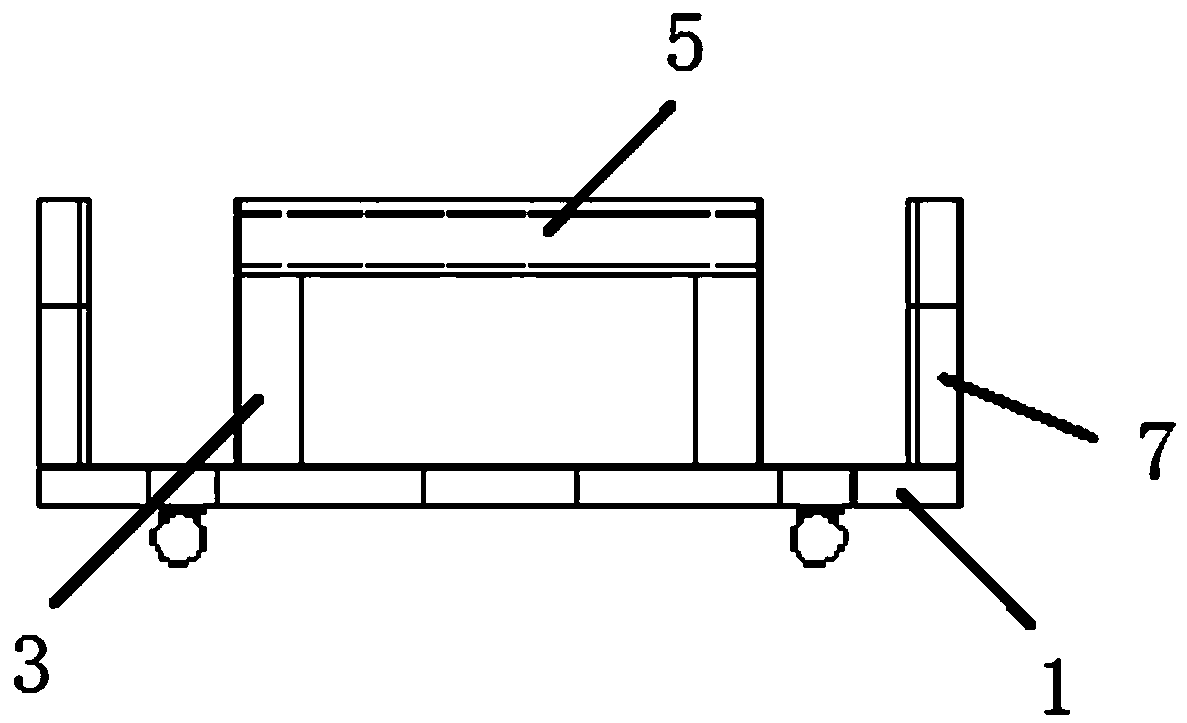

Vertically-loaded coil steel seat frame

InactiveCN102582644AEasy to fixEffectively fixedCargo supporting/securing componentsEngineeringMechanical engineering

The invention relates to an anti-skidding reinforcing device for cargo transportation, belonging to an auxiliary device for the transportation loading reinforcement service such as train, in particular to a vertically-loaded coil steel seat frame for vertically-loaded coil steel train transportation reinforcement. The coil steel seat frame is formed by welding channel steel and square tubes arranged longitudinally and transversely; a square hole is arranged on the coil steel seat frame; triangular baffles are arranged on the two sides of the coil steel seat frame; a lifting hook is arranged on the outer side of the triangular baffle; a baffle pin is inserted into the square hole; and a fixing sleeve is welded on the coil steel seat frame. The vertically-loaded coil steel seat frame provided by the invention is formed by welding high-quality channel steel and square tubes, has the advantages of high safety and strong generality, is simple to operate and convenient to use, and can be recycled. The vertically-loaded coil steel transported by train can be effectively fixed, and the slide or swing of the coil steel caused by railway acceleration or start or stop of a vehicle is avoided.

Owner:蒋恩泉

Multifunctional Conveyor

ActiveCN104609203BReduce labor intensityFaster turnaroundLoading/unloadingMechanical conveyorsElectronic control systemOperation safety

The invention provides a multifunctional conveying machine, and relates to railway freight transportation load and unload in the field of engineering machinery. The multifunctional conveying machine is composed of a vehicle chassis, a hydraulic supporting leg, a load and unload mechanism, a hydraulic system and an electronic control system. The hydraulic system and the electronic control system are adopted for driving the vehicle chassis to walk, turn, brake and drive, the hydraulic supporting leg to transversely stretch and longitudinally adjust a height ,and the load and unload mechanism to unfold, fold, locate, and adjust a posture. The multifunctional conveying machine is used to load and unload cargo in bag among a train, an automobile, a freight house and a railway platform, and has the advantages of reasonably using a load and unload device, being capable of saving the labor force and reducing the labor intensity of a work, improving the efficiency of loading, unloading and carrying, reducing the load and unload operation cost, being beneficial for the cargo integrity and operation safety, and the like.

Owner:大连佳和彩板构件有限公司

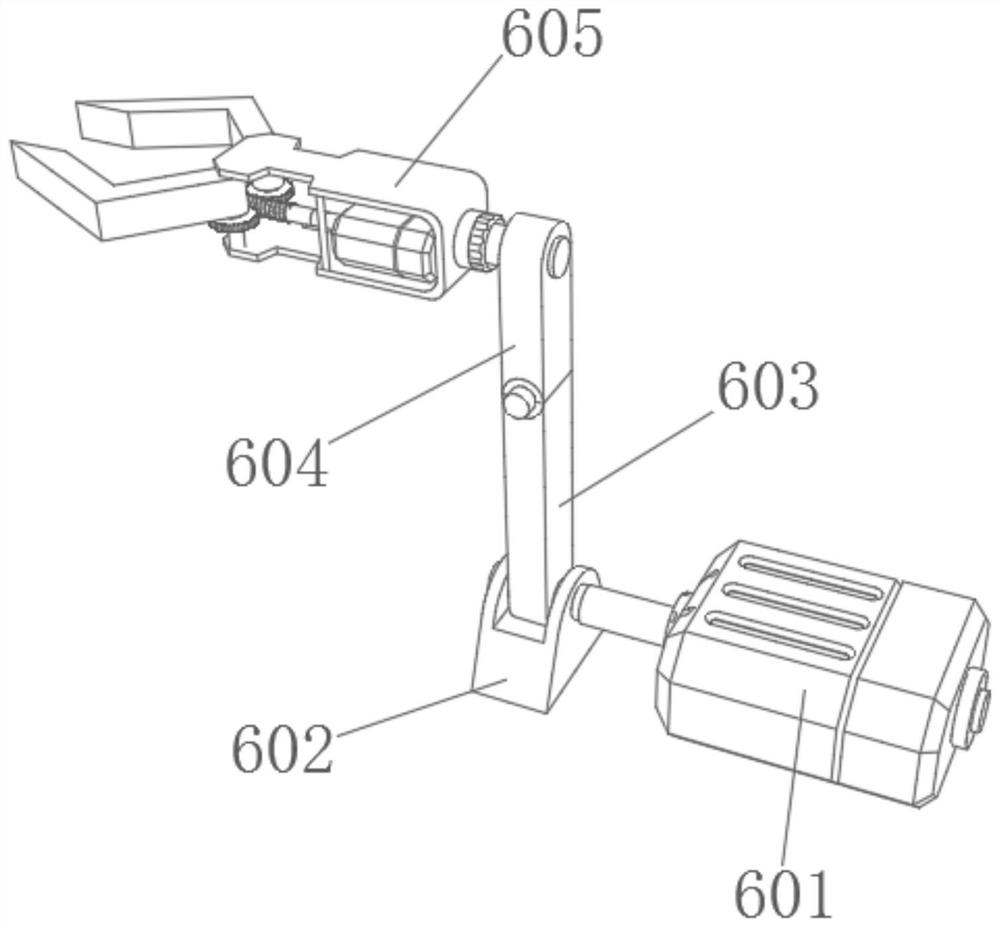

Tool and method for loading and unloading source of pump-out lithology density logging tool

ActiveCN106363578BReduce harmSolve the loading and unloading source problemMetal-working hand toolsEngineeringRadioactive source

Owner:718TH RES INST OF CHINA SHIPBUILDING INDAL CORP

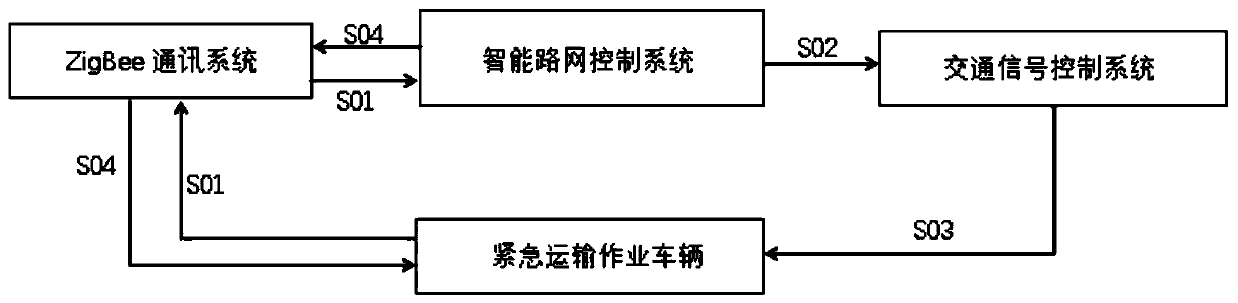

Intelligent road network control system of iron and steel plant based on ZigBee communication network and control method

InactiveCN110428607ARealize information interactionReduce power consumptionControlling traffic signalsParticular environment based servicesCommunications systemControl signal

The invention discloses an intelligent road network control system of an iron and steel plant based on a ZigBee communication network, and relates to the field of control over a road network of the iron and steel plant. The defects are overcome that at present, a traffic crossing signal light mainly adopts a single phase control mode, the traffic jam or waiting phenomenon can occur on emergency transportation operation vehicles, and efficient operation cannot be easily conducted. According to the technical scheme, the intelligent road network control system is characterized by outputting operation path planning information to the emergency transportation operation vehicles through a ZigBee communication system, and the emergency transportation operation vehicles conduct transportation operation; the intelligent road network control system outputs a signal light control signal to a traffic signal control system, the traffic signal control system adjusts phases of signal lights of traffic crossings in an emergency transportation operation traffic path, and passing green wave bands are formed for the emergency transportation operation vehicles. The intelligent road network control system of the iron and steel plant based on the ZigBee communication network can plan an optimum transportation operation route according to intelligent road network vehicle information and an emergencytransportation operation plan, and ensures efficient completion of transportation tasks.

Owner:SHANGHAI MEISHAN IND CIVIL ENG DESIGN & RES INST CO LTD

A kind of antistatic heat-resistant silicone skin and its manufacturing process

ActiveCN106893131BImprove thermal conductivityUniform heat conductionCoatingsManufacturing technologyPolymer science

The invention relates to the technical field of liquid crystal display screens, in particular to anti-static heatproof silicone rubber and a manufacturing technology thereof. The anti-static heatproof silicone rubber comprises a base material layer and an anti-static heatproof silicone rubber layer coating on the upper surface of the base material layer, wherein the base material layer is a PI film, and the anti-static heatproof silicone rubber layer comprises, by weight, 96-100 parts of silicone rubber, 0.5-1.5 parts of coloring agent and 0.5-1.5 parts of vulcanizing agent. The anti-static heatproof silicone rubber has the advantages that the anti-static heatproof silicone rubber is faster and more uniform in heat conduction and capable of avoiding the defects of static residues and static puncture; lamination times reach 60-80 times, feeding and discharging time is shortened, and production capacity is increased; without silicone oil precipitation, UV glue edge sealing cannot be affected.

Owner:东莞市亚马电子有限公司

Installation method of double-circular-track system of super high-rise unit type curtain wall

PendingCN113309363AReduce time spent running up and downReduce loading and unloading timeBuilding material handlingArchitectural engineeringHanging basket

The invention provides an installation method of a double-circular-track system of a super high-rise unit type curtain wall. The installation method comprises the following steps of S1, erecting a hanging basket stopping platform for operating a hanging basket to stop on a stopping face; S2, assembling an operation hanging basket on the ground; S3, determining the installation position of circular tracks, and installing the circular tracks; S4, installing a hoisting device and the operation hanging basket for a curtain wall on the circular tracks; S5, debugging the circular tracks, the hoisting device and the operation hanging basket for acceptance; S6, installing the curtain wall unit; and S7, dismounting the circular tracks. According to the installation method of the double-circular-track system of the super high-rise unit type curtain wall provided by the invention, the circular tracks are installed through the method, the unit curtain wall is installed through the circular rails, multiple lifting points can be provided in a narrow construction site, and multi-gradient curtain wall installation can be carried out by installing the circular tracks with multiple gradients, so that the up-down transportation time of the hanging basket and materials is shortened, the indoor decoration operation is not affected, and the construction progress is accelerated.

Owner:CONSTR DEV OF CHINA CONSTR SIXTH ENG DIV +1

Bracket device for automobile bumper punching and welding all-in-one machine

InactiveCN112537045AReduce loading and unloading timeReduce participationDomestic articlesElectric machineryEngineering

The invention relates to the technical field of machining tools, and discloses a bracket device for an automobile bumper punching and welding all-in-one machine. The bracket device comprises a supporting base, a connecting block is fixedly connected to the middle part of the front surface of the supporting base, and the output end of a push rod motor is fixedly connected to the front surface of the connecting block; and the bottom face of the push rod motor is fixedly connected with the bottom face of the inner wall of the automobile bumper punching and welding all-in-one machine, a placing groove is formed in the bottom face of the supporting base, and an electromagnet is arranged in the placing groove. According to the bracket device for the automobile bumper punching and welding all-in-one machine, the push rod motor is started to drive a bracket structure to move backwards to pass through a punching device and a welding device of the punching and welding all-in-one machine, and punched workpieces are transferred to the rear part to be fixed through the fixing device under the work of a conveying device; and the push rod motor is matched with the conveying device, so that the feeding and discharging time in the workpiece machining process is shortened, the participation of people is reduced, the production efficiency is greatly improved, and the production cost is reduced.

Owner:苏州力朗瑞西智能科技有限公司

A stacked high temperature annealing process

ActiveCN106257625BSimple structureEasy to operateSemiconductor/solid-state device manufacturingElectrical batterySilicon chip

The invention discloses a stackable high-temperature annealing technology. The technology comprises the following specific operation steps that 1, etched silicon wafers are stacked in order and put into a quartz sheet frame for annealing; 2, the silicon wafers on the quartz sheet frame are covered with a quartz cover plate and pressed, and the quartz sheet frame is fed into a high-temperature diffusion-oxidation furnace; 3, annealing is conducted by increasing and stabilizing the temperature of a furnace tube of the high-temperature diffusion-oxidation furnace; 4, temperature decreasing and discharging from the furnace are conducted, wherein the temperature of the furnace tube of the high-temperature diffusion-oxidation furnace is decreased, and the quartz sheet frame is discharged from the furnace. The stackable high-temperature annealing technology has the advantages that the surfaces of the stacked silicon wafers are isolated from air, and therefore the problems existing in a thermal oxidation technology are effectively solved; operation is easy, the consumed time is short, and quantity production is easy to achieve; meanwhile, the yield is high, the battery piece efficiency is significantly improved, the problems such as edge breakage, corner faults, hidden cracks and fragments in the loading and unloading process of the silicon wafers can be effectively solved, the loading and unloading time is shortened, the quality of battery pieces is improved, and the qualified rate of the battery pieces is increased.

Owner:HENGDIAN GRP DMEGC MAGNETICS CO LTD

Standing warehouse for special specification items

ActiveCN104355027BImprove efficiencyCompact structureBuilding constructionsStorage devicesEngineeringUltimate tensile strength

Owner:SHANGDONG TONGLIDA INTELLIGENT MACHINERY

A cyclic operation intra-city logistics system

ActiveCN107285050BImprove continuityImprove fluencyConveyorsStorage devicesContinuous/uninterruptedLogistics management

The invention provides a circular operation intra-city logistics system comprising a logistics center, intra-city outward transportation vehicles and logistics center internal transportation vehicles. The logistics center is provided with a packing box treatment area, an intra-city vehicle entrance, an intra-city vehicle exit, an entrance for vehicles entering the city and an exit for vehicles leaving the city. The packing box treatment area is provided with a goods sorting flow line, a to-be-emptied packing box placing station and a to-be-charged packing box placing station. An intra-city outward transportation vehicle box unloading station, an intra-city outward transportation vehicle box loading station, an entering-city vehicle goods treatment station and a leaving-city vehicle goods treatment station are arranged at corresponding positions on the goods sorting flow line. The logistics center internal transportation vehicles transport to-be-emptied packing boxes on the intra-city outward transportation vehicle box unloading station to the to-be-emptied packing box placing station and then transport the emptied packing box to the to-be-charged packing box placing station. The circular operation intra-city logistics system can achieve continuous circular operation in the logistics center, save labor cost and time cost and improve the use frequency of the vehicles and the work efficiency of the express industry.

Owner:WUHAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com