Full-automatic loading vehicle

A loading vehicle and fully automatic technology, which is applied in the field of construction machinery, can solve the problems of low work efficiency and high work intensity of operators, and achieve the effects of high work reliability, reduced number of operators, and flexible and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

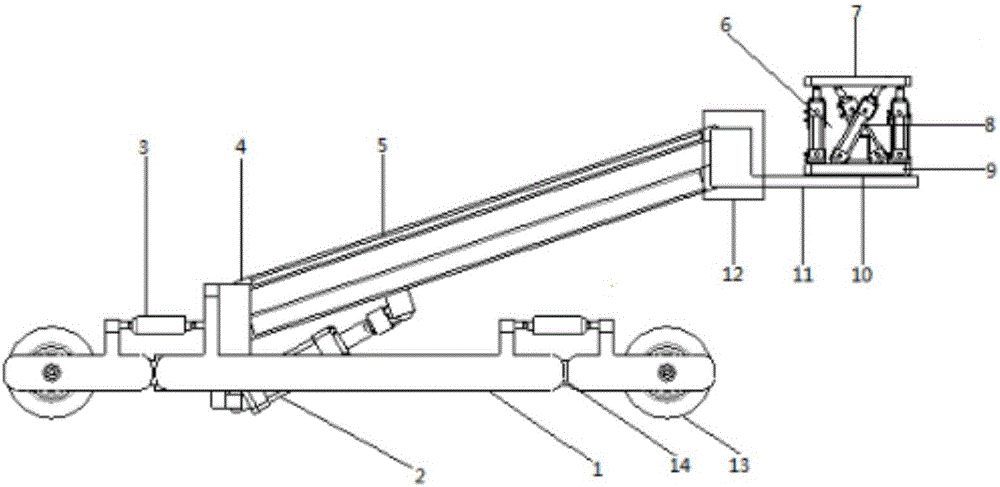

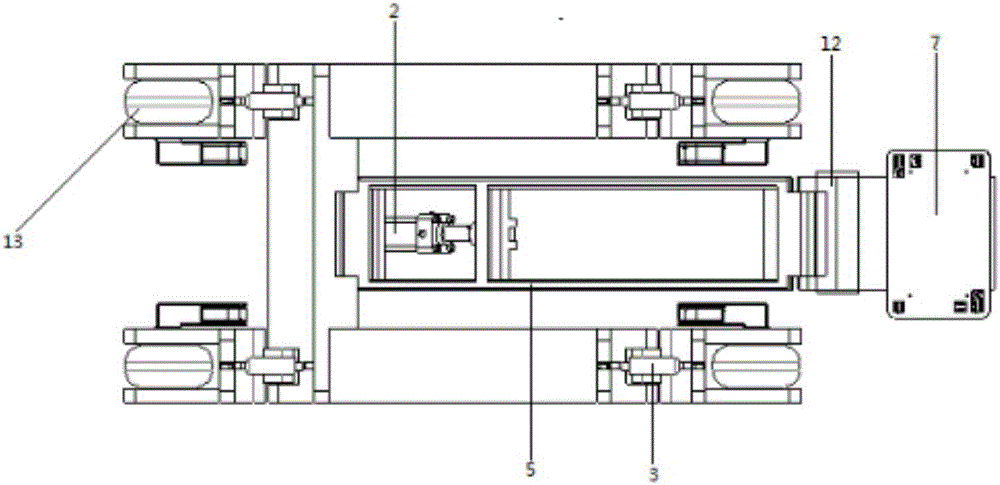

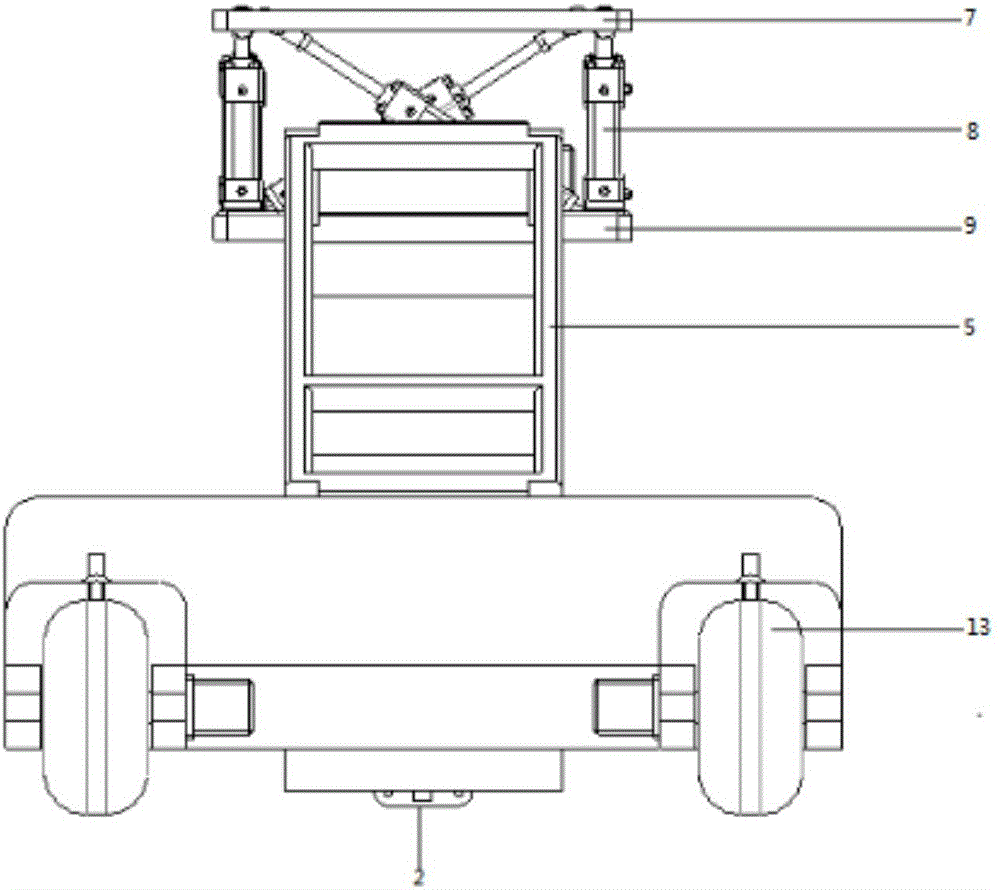

[0018] Such as figure 1 , figure 2 with image 3 In the schematic diagram of the fully automatic loading vehicle shown, the frame 1 of the walking trolley is a metal structure, and its four corners are connected to the mecanum wheel 13 through the damping shock absorber 3 and the hinged rotating shaft 14; one end of the lifting cylinder 2 is connected to the frame The lower end of the middle part of the rear end is fixedly connected, and the other end of the lifting cylinder is connected to a part of the lower part of the parallel lifting rod 5 through a hinged rotating shaft. The other end of the lifting rod is fixedly connected to the bracket platform 11; the visual positioning and guiding device 12 is arranged on the side of the bracket platform close to the parallel lifting rod for loading and unloading positioning identification and guidance. The above-mentioned visual positioning and guiding device is a device for image acquisition The professional industrial camera i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com