Vertical reduction tank and reduction furnace device for metal smelting

A reduction tank and reduction furnace technology, applied in the direction of improving process efficiency, can solve the problems of short life of reduction tank, waste of raw materials, failure to provide safety, etc., to eliminate waste of energy and raw materials, and avoid empty burning" and "" The effect of under-burning and improving the utilization rate of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

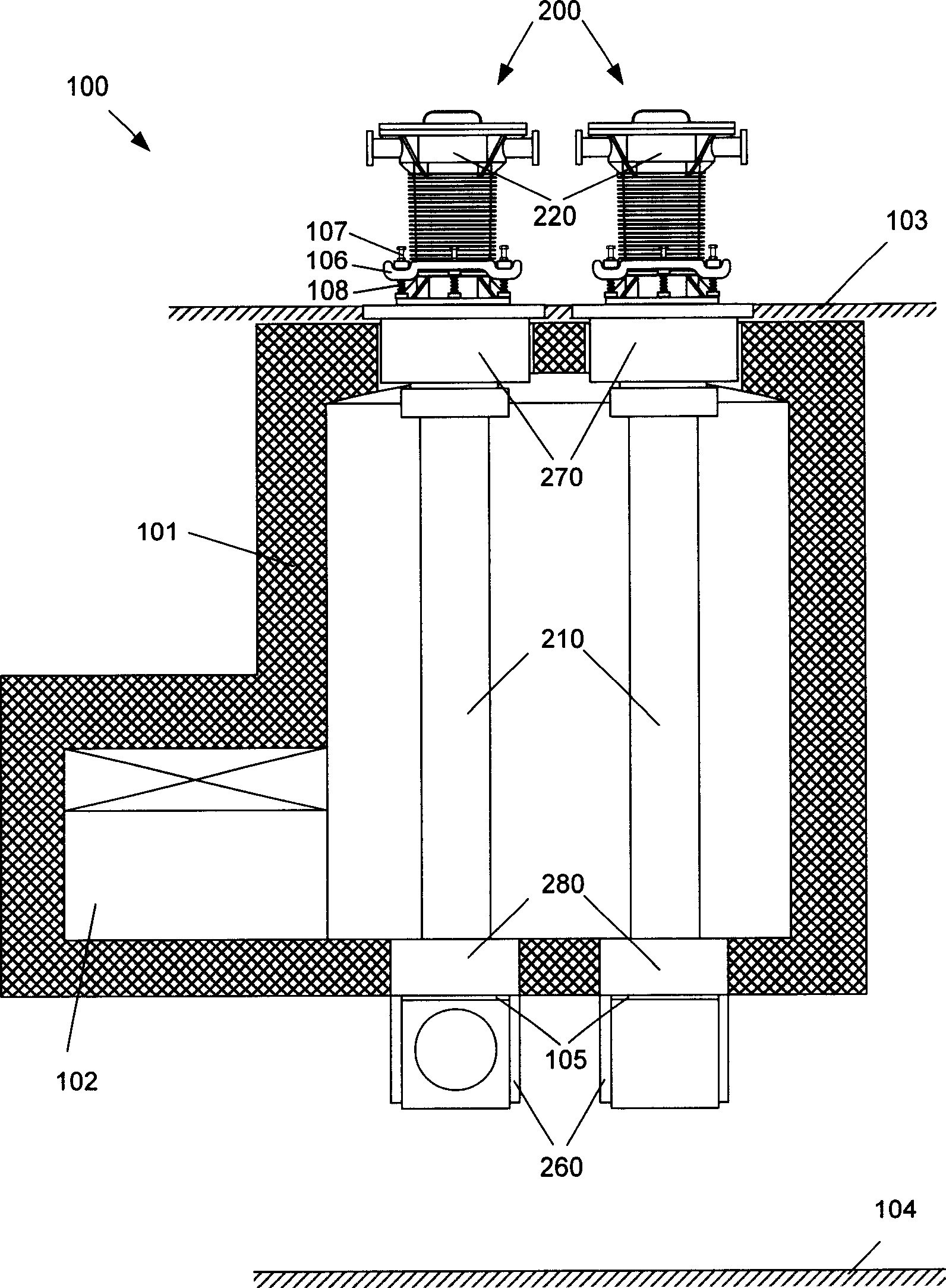

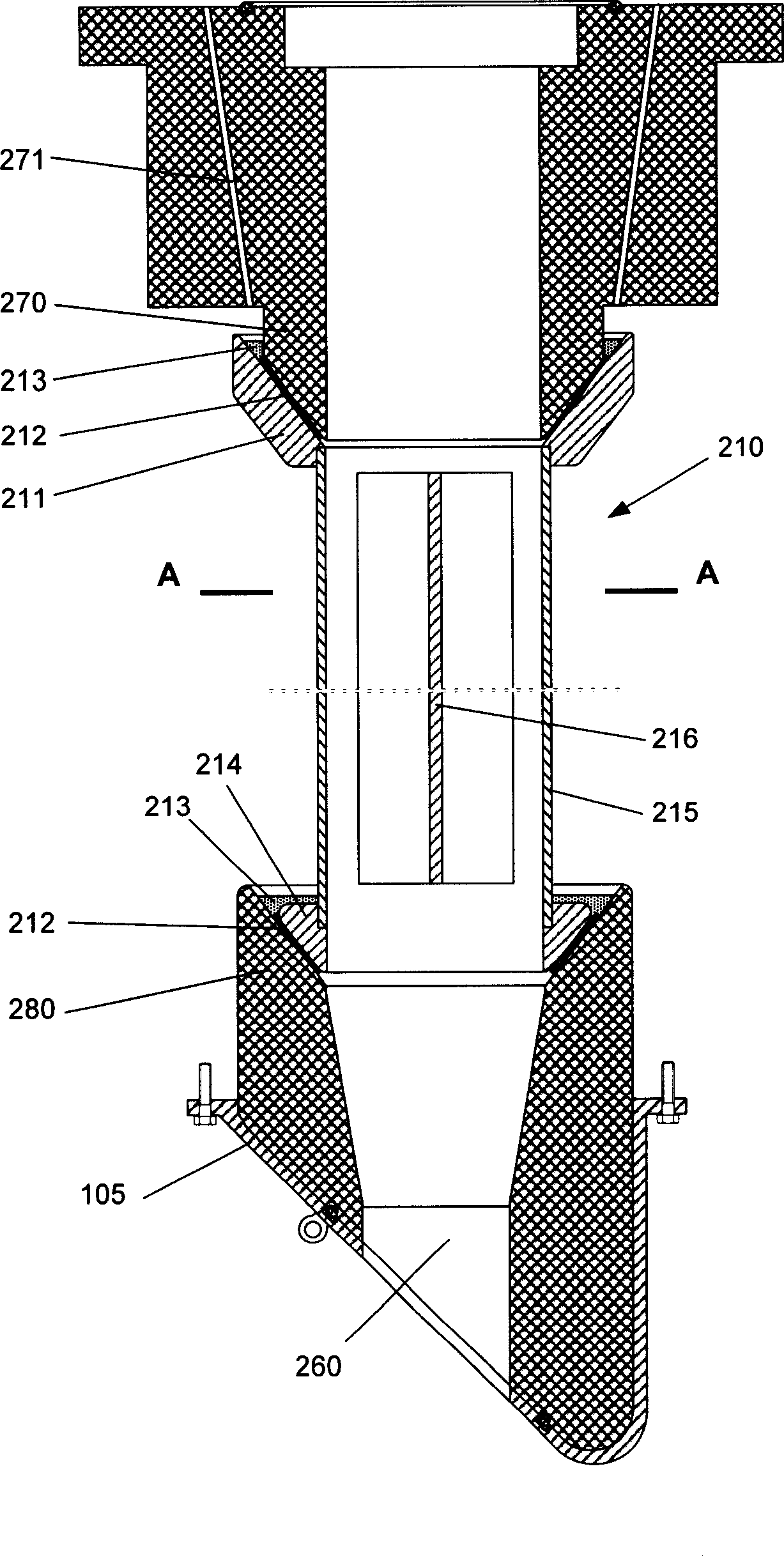

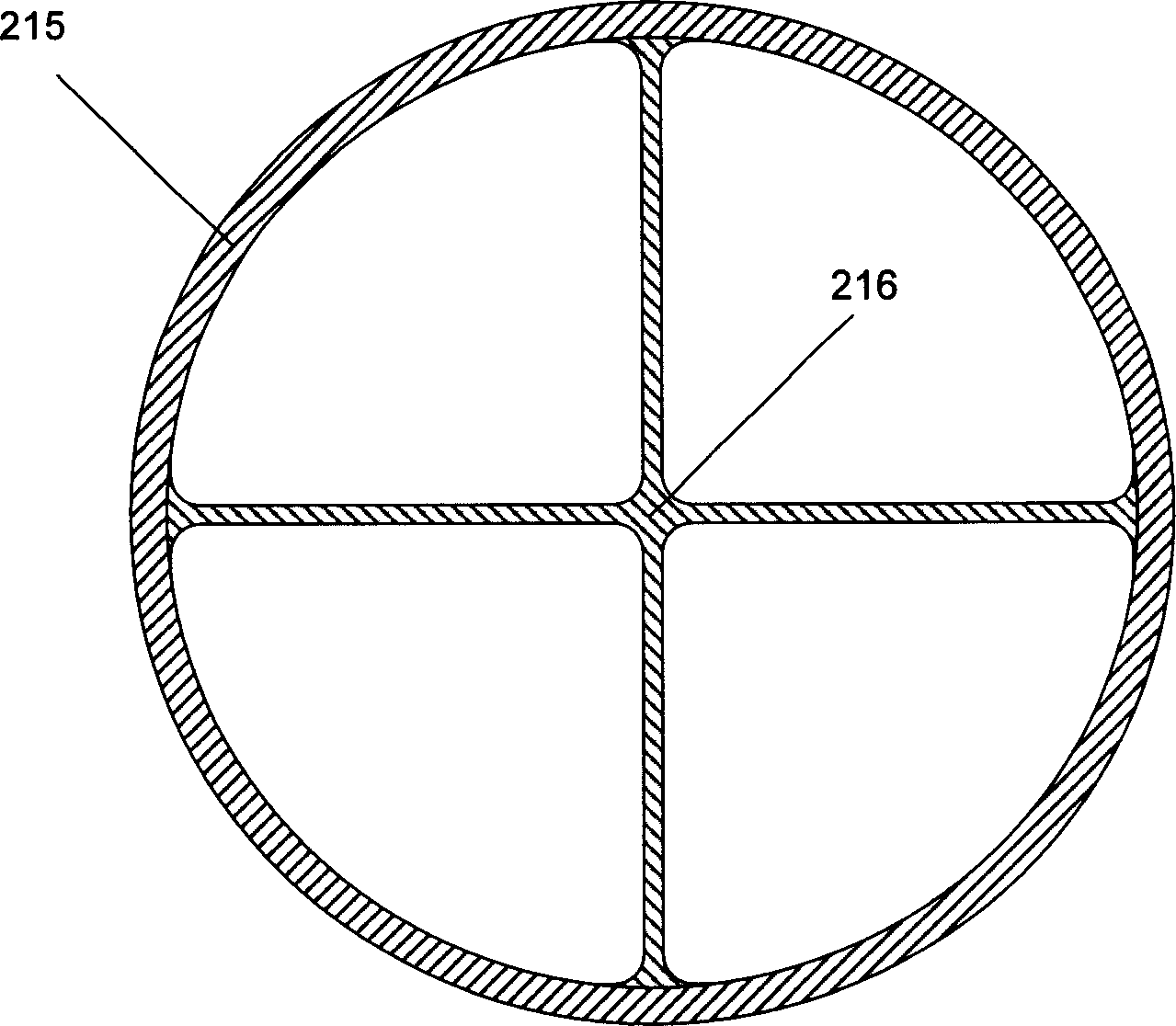

[0043] figure 1 Shown is a schematic cross-sectional view of a vertical reduction furnace (100) constructed using the vertical reduction tank of the present invention (one embodiment). The vertical reduction furnace (100) consists of a furnace body (101), a combustion chamber (102), a plurality of vertical reduction tanks (200) installed therein, an upper working platform (103) and a lower working platform (104). Heating of the reduction furnace (100) can be accomplished using any suitable heat source. Appropriate lifting and conveying devices (not shown) are installed on the upper working platform (103) for taking out reduced metal lumps and loading raw material balls. Appropriate conveying devices (not shown) are installed on the lower working platform (104) for unloading and conveying the reaction residues. The number and arrangement of the vertical reduction tanks (200) installed in the reduction furnace (100) can be flexibly changed according to factors such as design o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com