Small telescopic belt conveyer

A belt conveyor and telescopic technology, applied in the field of small telescopic belt conveyors, can solve the problems of increasing the company's operating costs and affecting the production cycle of products, and achieve the effects of shortening the loading and unloading time, convenient work and stable operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

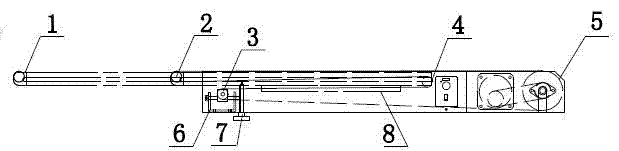

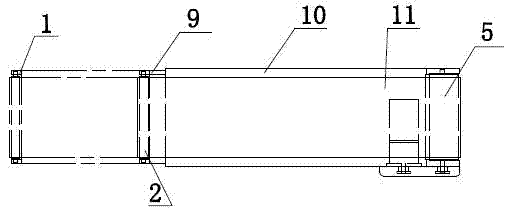

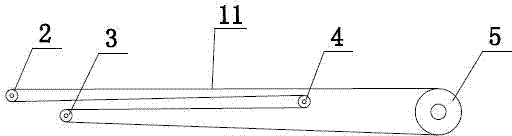

[0013] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

[0014] The small telescopic belt conveyor of the present invention comprises a fixed frame 10, a drum, and a belt 11. One end of the belt 11 is wound around the drum and fixed on the frame 10, and the movable frame 9 is placed inside the fixed frame 10. The two ends of the driven roller 2 are fixed on the movable frame 9 through plugs 1, the driving roller 5 and the driven roller 2 are on the same level, the tension roller 3 is arranged on the elastic adjustment device 6, and the driven roller 2 and the A redirecting roller 4 is arranged between the driving rollers 5 , and a guide bar 8 is arranged between the redirecting roller 4 and the tension roller 3 .

[0015] When the telescopic belt needs to be freely telescopic, loosen the telescopic fixed rod 7 at the bottom of the fixed frame 10, and the movable frame 9 is formed along the guide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com