Steel coil carrier

A seat frame and coil steel technology, which is applied in the external frame, sustainable manufacturing/processing, sustainable packaging industry, etc., can solve the problems of time-consuming reinforcement methods or loading and unloading procedures, inconvenient access to the seat frame, and high cost of reinforcement devices. Achieve the effect of reducing loading and unloading time and transportation costs, fixing coils easily, and solving time-consuming and laborious effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

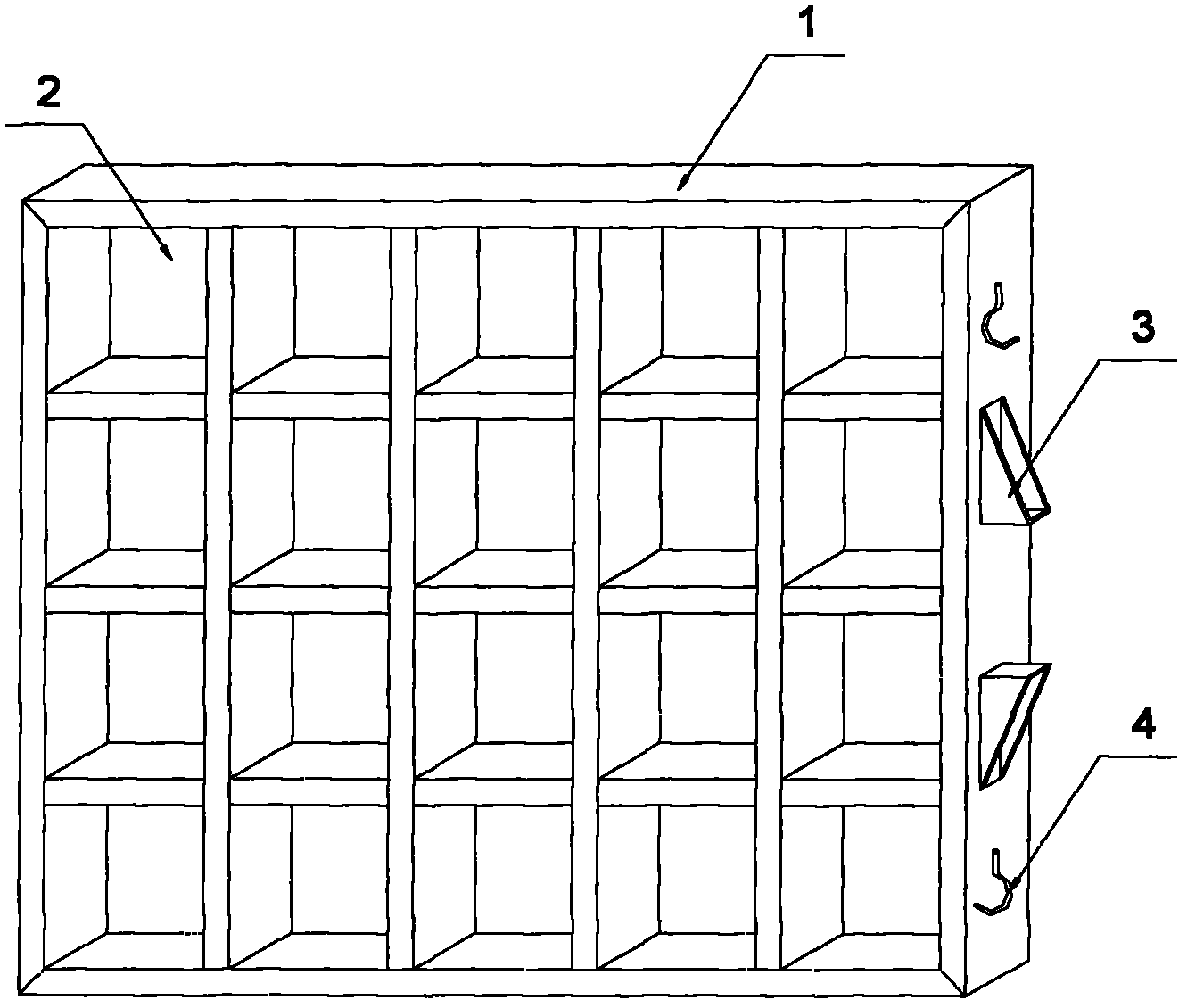

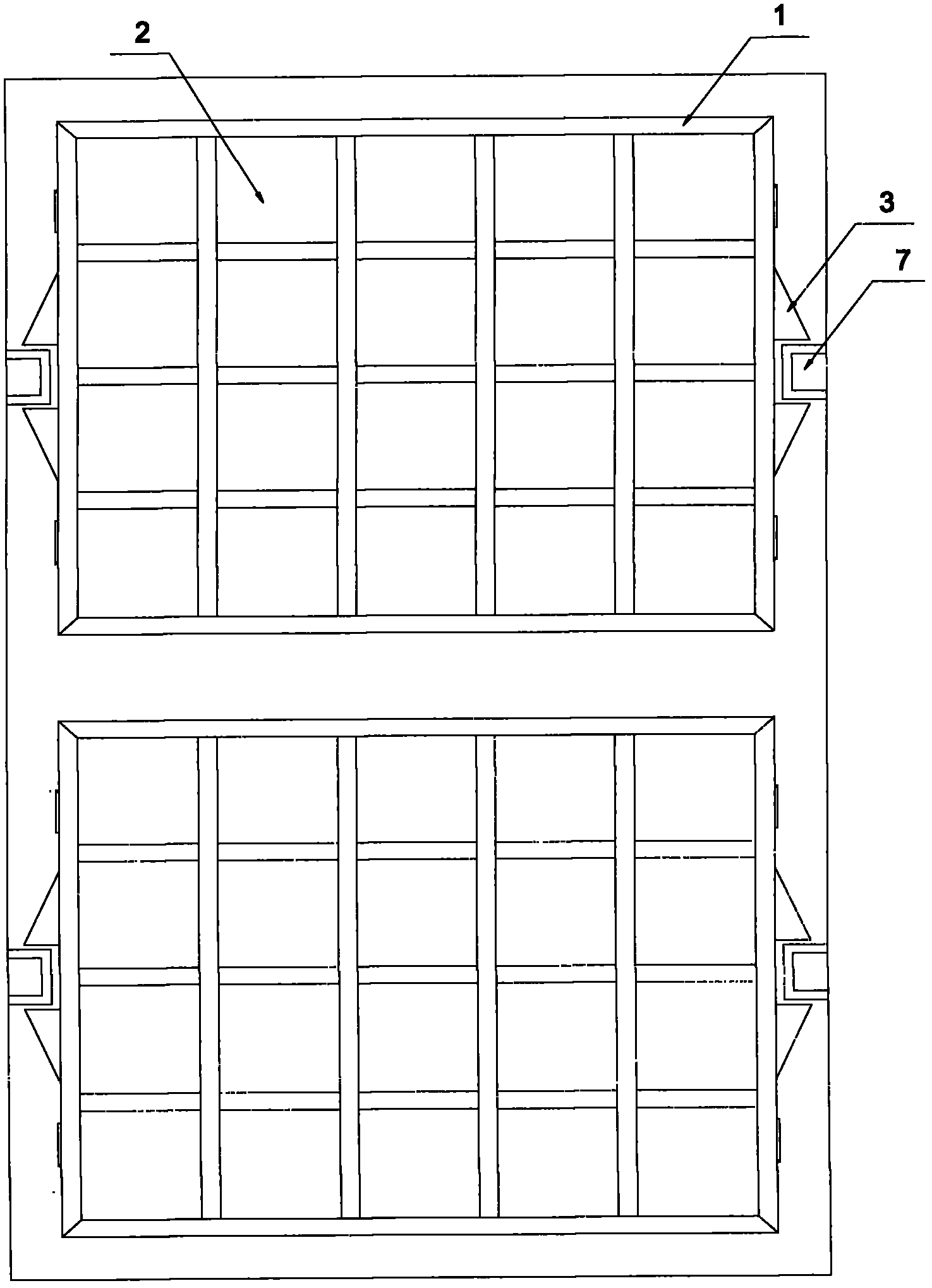

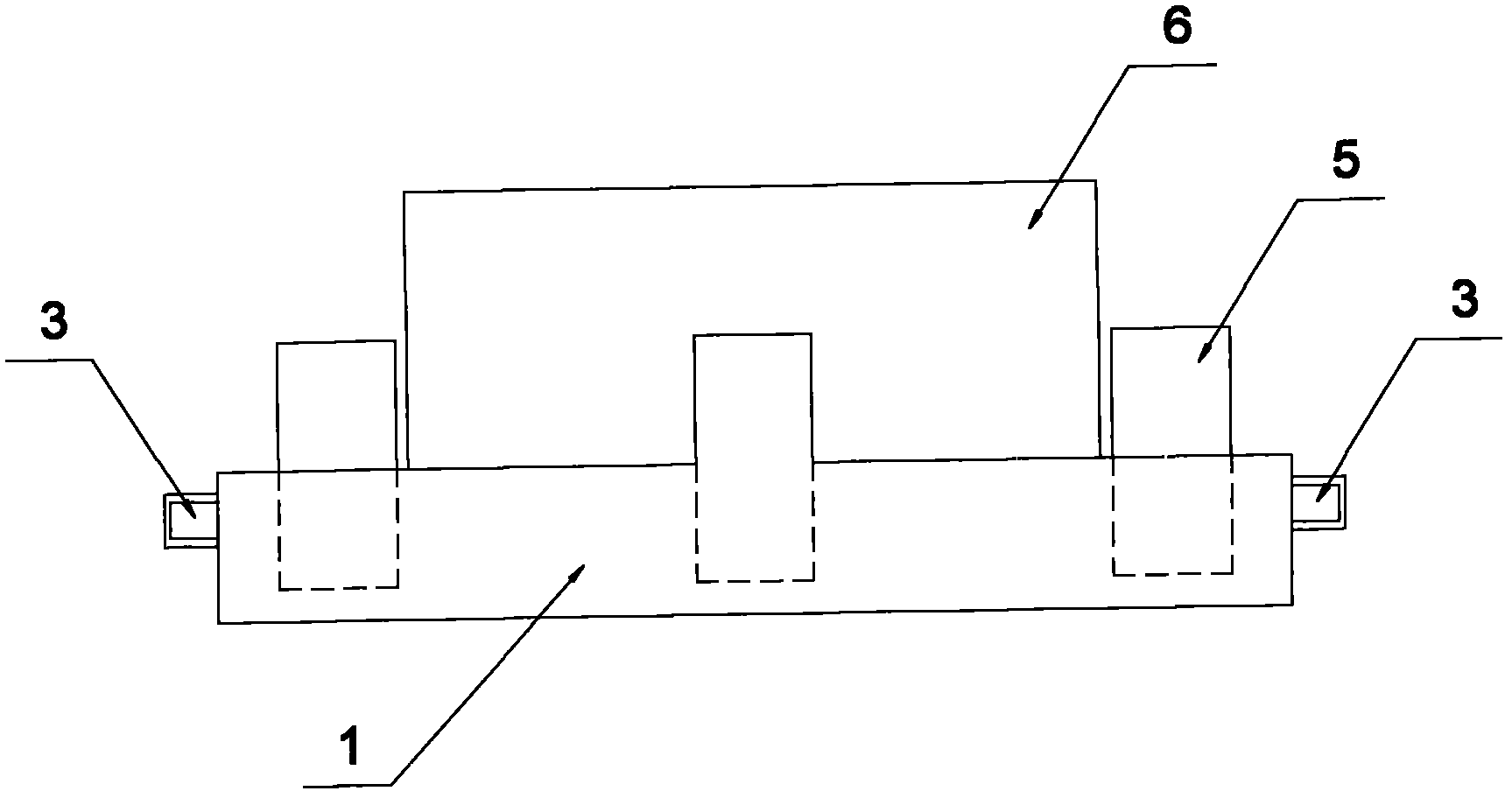

[0015] The coiled steel seat frame 1 of the present invention is made by welding channel steel and square pipes arranged vertically and horizontally. The coiled steel seat frame 1 is provided with a square hole 2, and a baffle pin 5 is inserted in the square hole 2. The coiled steel seat There are triangular baffles 3 on both sides of the frame 1, and a pair of triangular baffles 3 on each side form a card slot, and a hook 4 is provided on the outside of the triangular baffle 3, and two pairs of hooks are welded on both sides of the coiled steel seat frame 1. 4. The above-mentioned hooks 4 are arranged diagonally in the same direction, and the hooks 4 on the same side are arranged in opposite directions. The hooks 4 arranged diagonally in the same direction can be used to lift and lower the coiled steel frame 1, and the coiled steel frame 1 has no Front and back, both sides can be used, and it is convenient for hoisting, lifting and landing. In order to prevent the coiled stee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com