Special numerically-controlled machine tool for machining axle type parts

A technology of CNC machine tools and parts, applied in the field of CNC machine tools, can solve problems such as affecting processing efficiency, difficulty in axial measurement, and unguaranteed dimensional accuracy, and achieve the effects of reasonable structure, relative coincidence accuracy, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

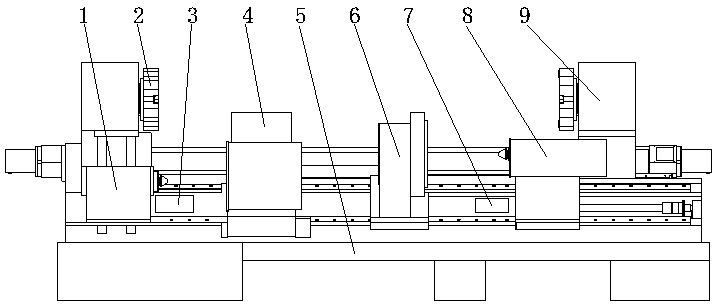

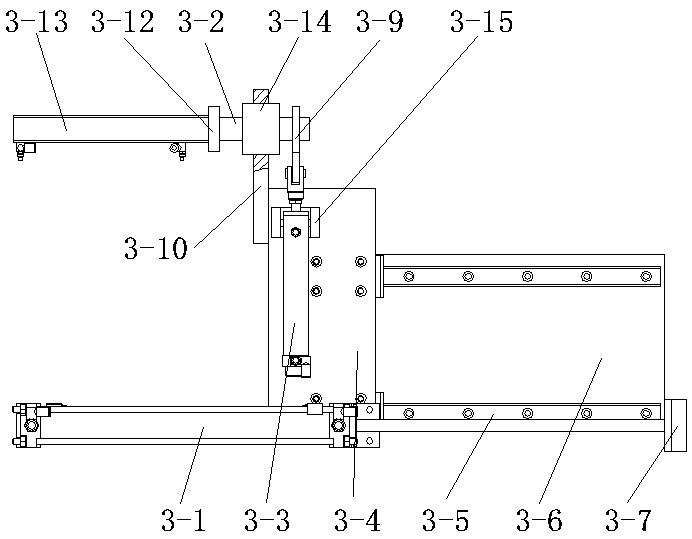

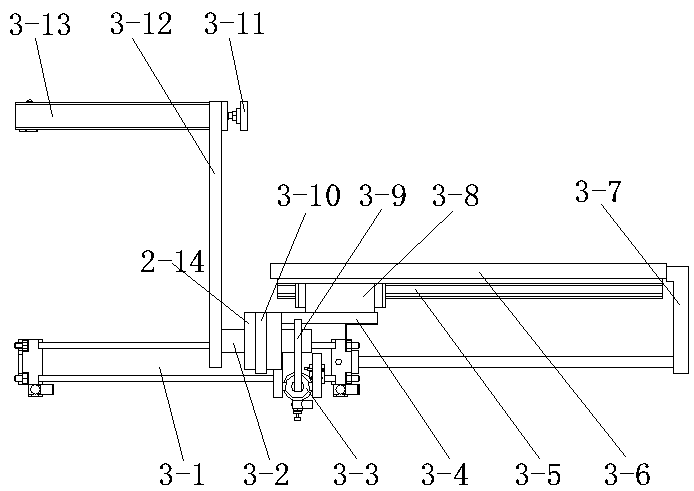

[0031] exist Figures 1 to 15Among them, 1 is the left tailstock, 1-1 is the tailstock body, 1-1-1 is the tailstock sleeve, 1-1-2 is the mandrel, 1-2 is the tailstock sliding body, 1-3 is the base , 1-4 is the guide rail, 1-5 is the tailstock locking device, 1-5-1 is the lower piston rod, 1-5-2 is the piston, 1-5-3 is the reset spring, 1-6 is the pressure plate , 1-7 is the driving device, 1-7-1 is the adjustment plate, 1-7-2 is the end cover, 1-7-3 is the cavity, 1-7-4 is the partition, 1-7-5 is the Piston Ⅰ, 1-7-6 is the sealing flange, 1-7-7 is the adjusting bolt, 1-8 is the sleeve locking device, 1-8-1 is the oil inlet, 1-8-2 is the piston Ⅱ , 1-8-3 is the compression spring, 1-9 is the positioning device of the tailstock slider, 1-9-1 is the piston rod, 1-9-2 is the piston III, 1-9-3 is the positioning pin, 1- 9-4 is the positioning block, 1-10 is the oil cylinder, 1-10-1 is the piston rod I, 2 is the left tool table, 3 is the left axial length measuring device, 3-1 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com