Tool for polishing ceramic mobile phone back plate

A technology for tooling and mobile phones, which is applied in the field of polishing and processing tooling using vacuum adsorption ceramic mobile phone backplanes, can solve the problems that the edge integrity of the backplane is greatly affected, the processing efficiency and yield are affected, and the loading and unloading time is increased. Scratch effect, reduce loading and unloading time, reduce quantity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

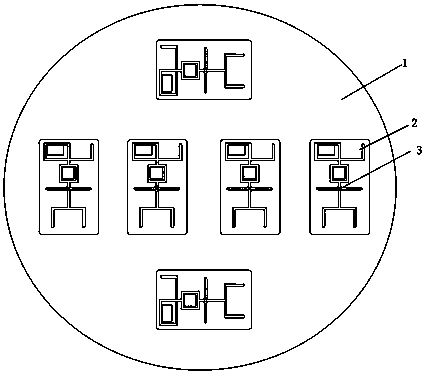

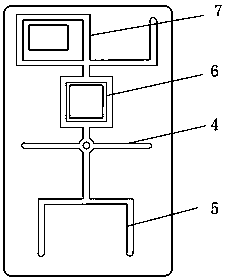

[0027] combine Figure 1-2 , this embodiment includes a bottom surface 1 , a vacuum adsorption tooling 2 and a vacuum adsorption hole 3 . image 3 It is a schematic diagram of the structure of the vacuum adsorption tooling. The middle part of the tooling is the vacuum adsorption hole extending two horizontal air grooves 4 to the sides of the mobile phone. The lower part of the tooling is the adsorption hole extending an air groove to the bottom of the mobile phone. Three equidistant equidistant air grooves 5 . The upper part of the tooling is a vacuum suction hole extending an air groove to the top of the mobile phone, and the upper middle part is set as a square hollow structure, with square air grooves 6 distributed around it, and the four corners of the square are rounded. Three equidistant air grooves are extended on the top of the square structure, of which the left air groove is connected to the rectangular hollow structure, and square air grooves 7 are distributed arou...

Embodiment 2

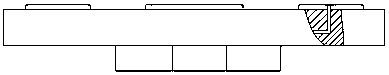

[0034] Embodiment 2: In this embodiment, the bottom surface is disc-shaped, with a diameter of 500mm and a height of 30mm, and a device connected to the polishing machine is provided at the bottom. Six through holes are distributed in the disk, and the vacuum adsorption hole of the machine tool is connected with the six through holes in the disk.

[0035] The vacuum adsorption tooling is a rectangular sheet structure with a length of 150mm, a width of 66mm and a height of 6.5mm. The groove width of the air groove is 4.5mm, the depth is 6.5mm, and the distance between the two grooves is 25mm. The ends of each air groove are rounded, and the radius of the rounded corners is 2mm. Square hollow structure The side length of the square is 12.5mm, and the height is 6.5mm consistent with the vacuum adsorption tooling. The four corners of the square hollow structure are rounded. Remove the tooling material in this area and set it as a hollow structure. Rectangular hollow structure ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com