Special hanger for loading and unloading steel rails

A technology of steel rails and spreaders, applied in the field of spreaders, which can solve the problems of damaged and scrapped wire ropes, increased loading and unloading costs, and low loading and unloading efficiency, and achieves the effects of low loading and unloading costs, simple operation, and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The invention will be further described below in conjunction with the accompanying drawings and embodiments.

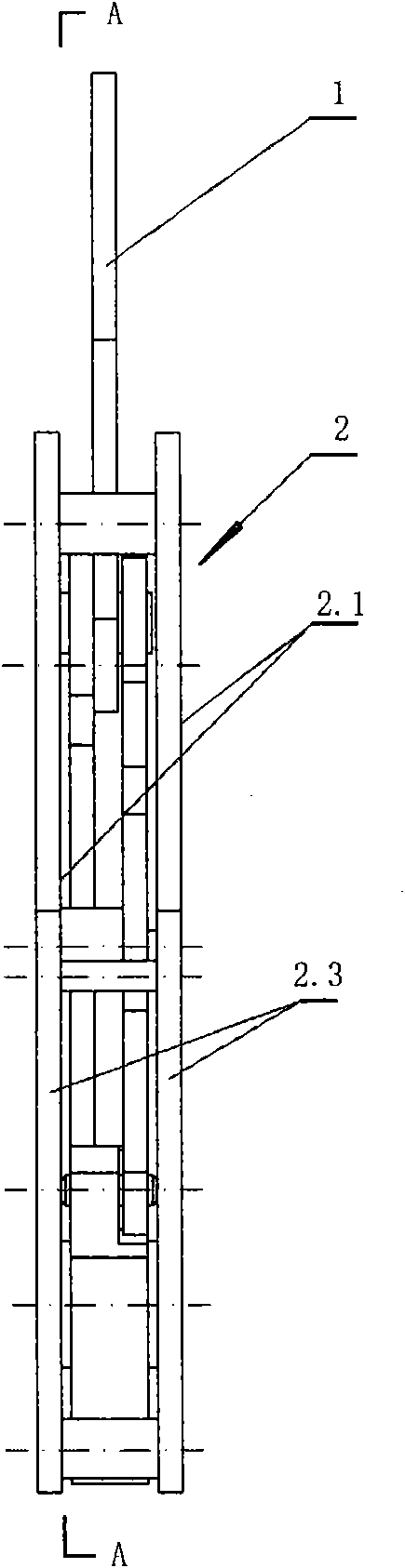

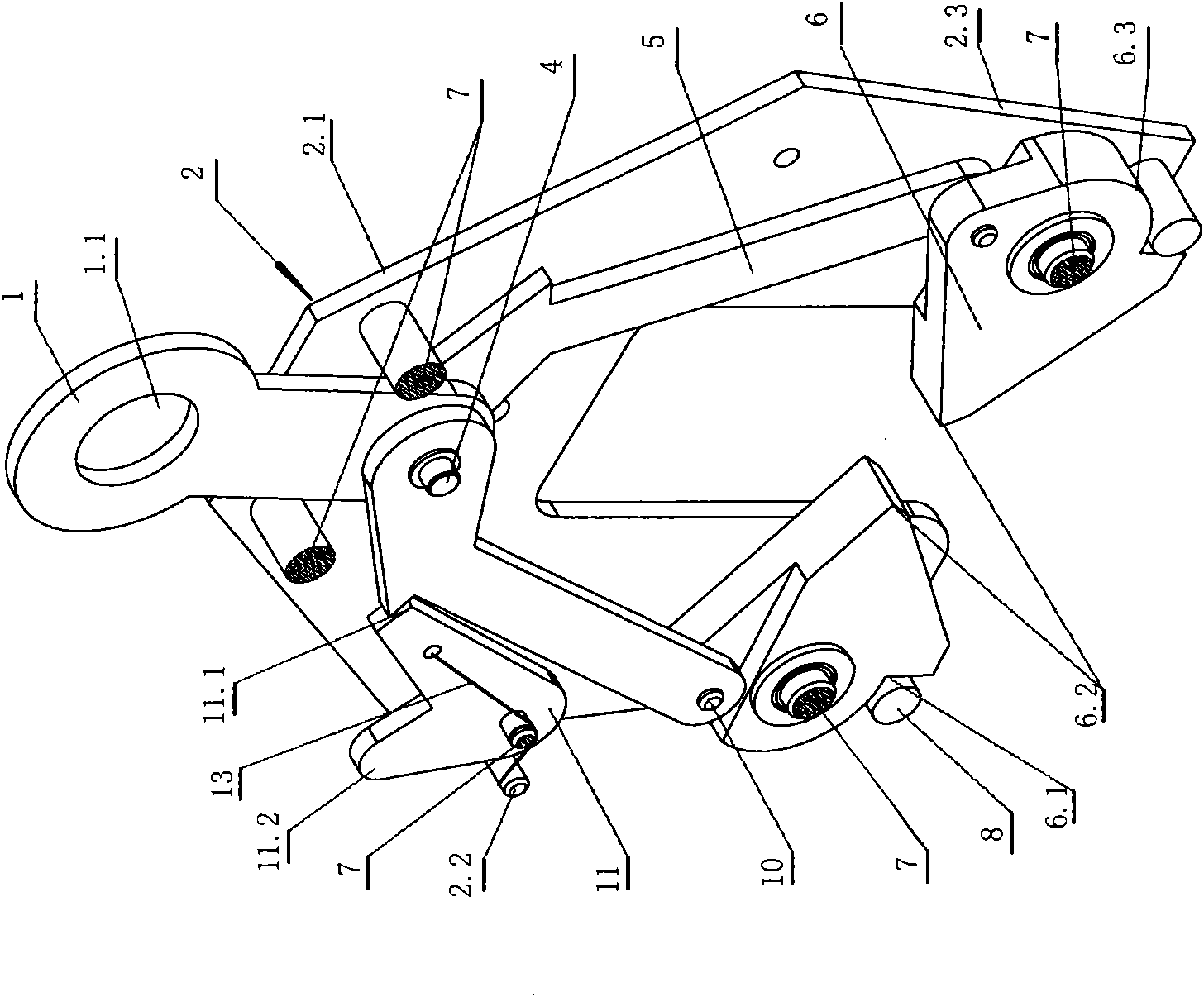

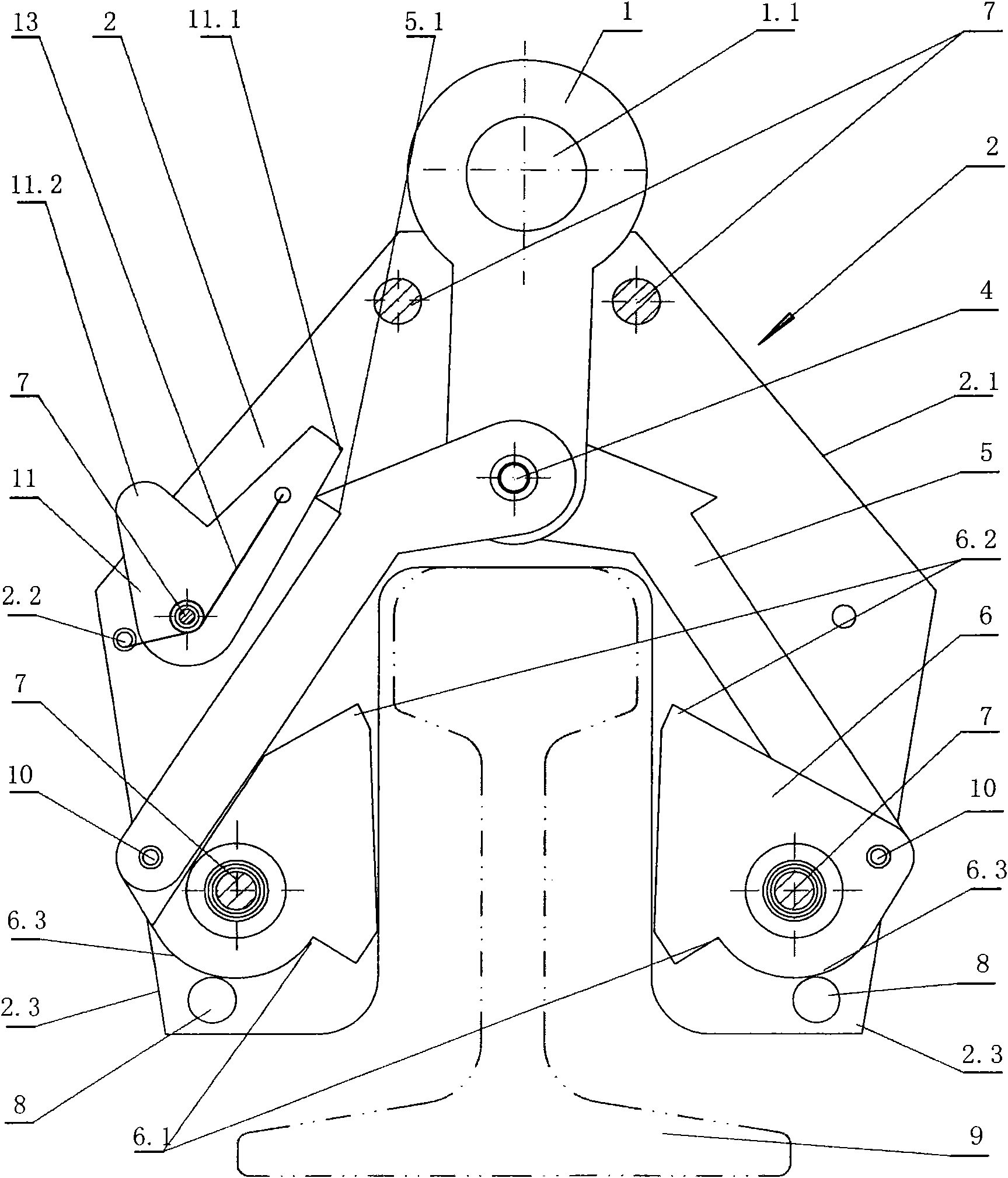

[0017] figure 1 in (see figure 2 , image 3 , Figure 4 ), in the upright saddle-shaped support 2, the floating support has a lifting lug 1 that is movably connected to the upper ends of the left and right symmetrical two outer turn-shaped pull rods 5; The swivel tongue 6 is supported in the bracket 2, and the bracket 2 and the swivel tongue 6 are provided. Lifting the hook tightens the lifting lug 1, so that the two tongue tips 6.2 of the swivel tongue 6 can be relatively locked in a horizontal position, and loosening the lifting lug 1 can make the swivel tongue 6 The two tongue tips 6.2 of the tongue 6 are upwardly locked in a locking device in an upright position.

[0018] Described saddle-shaped support 2 is to be arranged parallel to each other and can straddle the rail surface (see image 3 , Figure 4 ) The two saddle-shaped splints 2.1 on both si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com