Off land loading and unloading anchoring system and anchoring method for liquid bulk cargo carrier

A mooring system and bulk carrier technology, applied in the field of ship mooring devices, can solve the problems of easy wear and fatigue of mooring cables, insufficient mooring arrangement, troublesome mooring and mooring operations, etc., and achieve the reduction of channel or berth Excavation is beneficial to sustainable development and the effect of saving shoreline resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

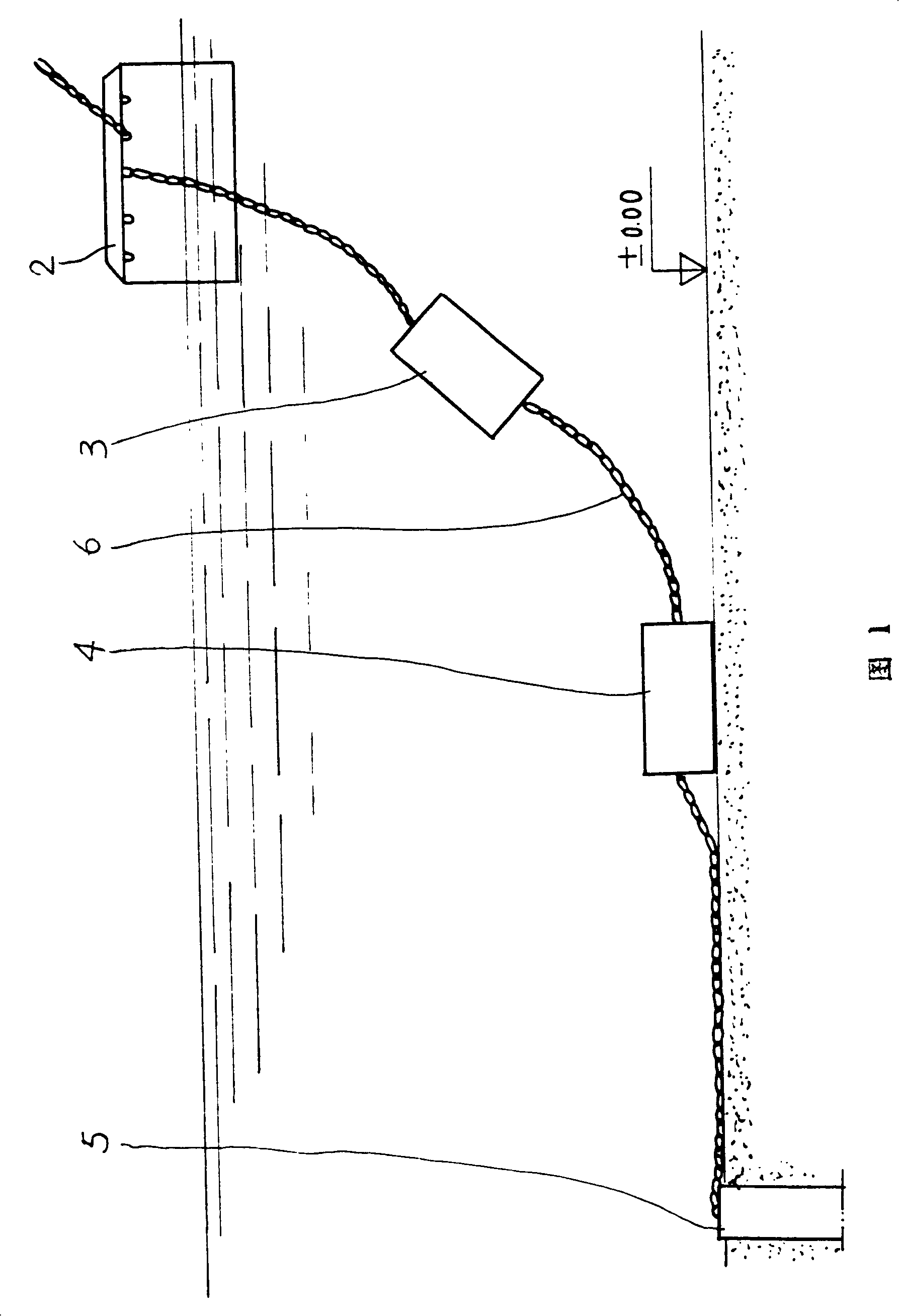

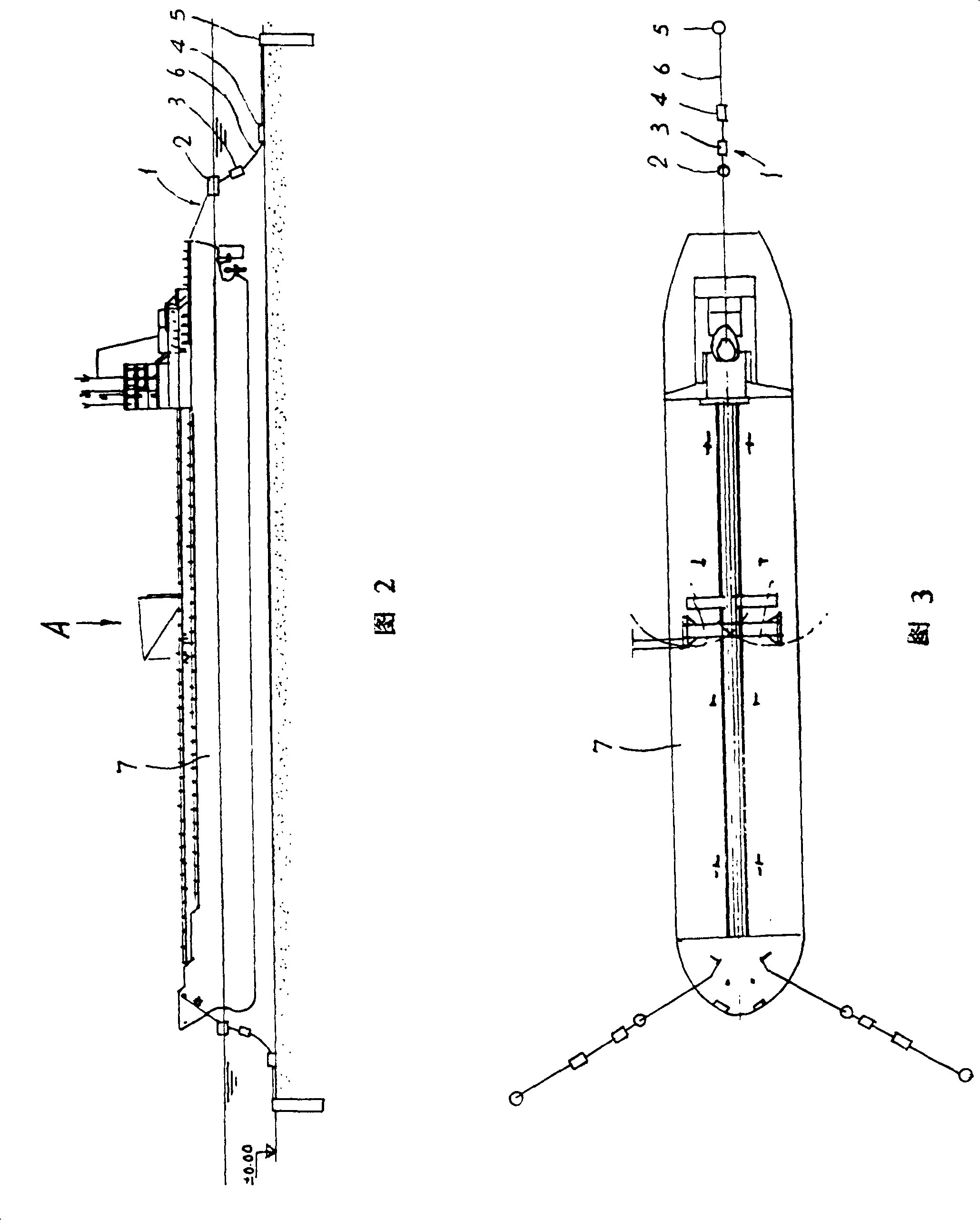

[0028] Referring to Fig. 1, the offshore loading and unloading mooring system of a liquid bulk carrier is composed of three sets of mooring devices 1, and each set of mooring devices 1 is composed of a buoy 2, a suspension counterweight 3, a bottom counterweight 4 and an anchor foundation 5 through a connection. Ties 6 are connected. The buoy 2 of the present embodiment is welded by steel plates to form a hollow floating body. The suspension counterweight 3 and the bottom counterweight 4 are made of reinforced concrete blocks, the anchor foundation 5 is made of piles, and the connecting parts 6 are made of steel chains.

[0029] The mooring method of this mooring system is to connect the buoys 2 in the three sets of mooring devices 1 of the entire mooring system with the liquid bulk carrier 7 through the connecting piece 6, and two sets of mooring devices 1 are tied to the liquid bulk carrier. The bow of the ship 7; another set of mooring devices 1 is connected to the stern o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com