Automatized storing, loading and unloading facility for container

A container and facility technology, applied in loading/unloading, storage devices, transportation and packaging, etc., can solve the problems of reduced container load rate, waste of space, and difficulty in large-scale promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

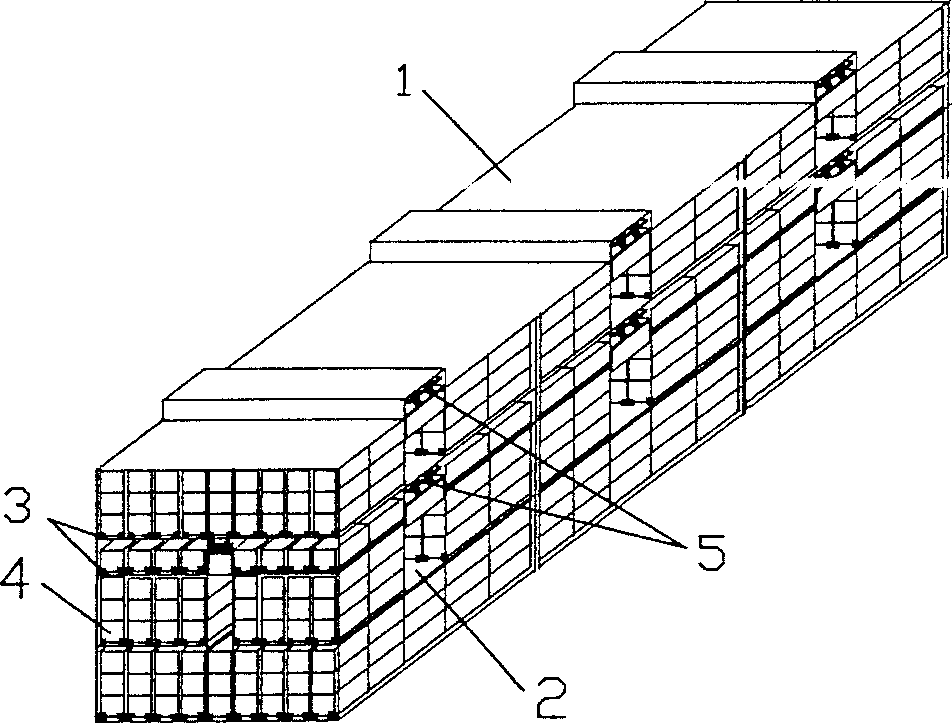

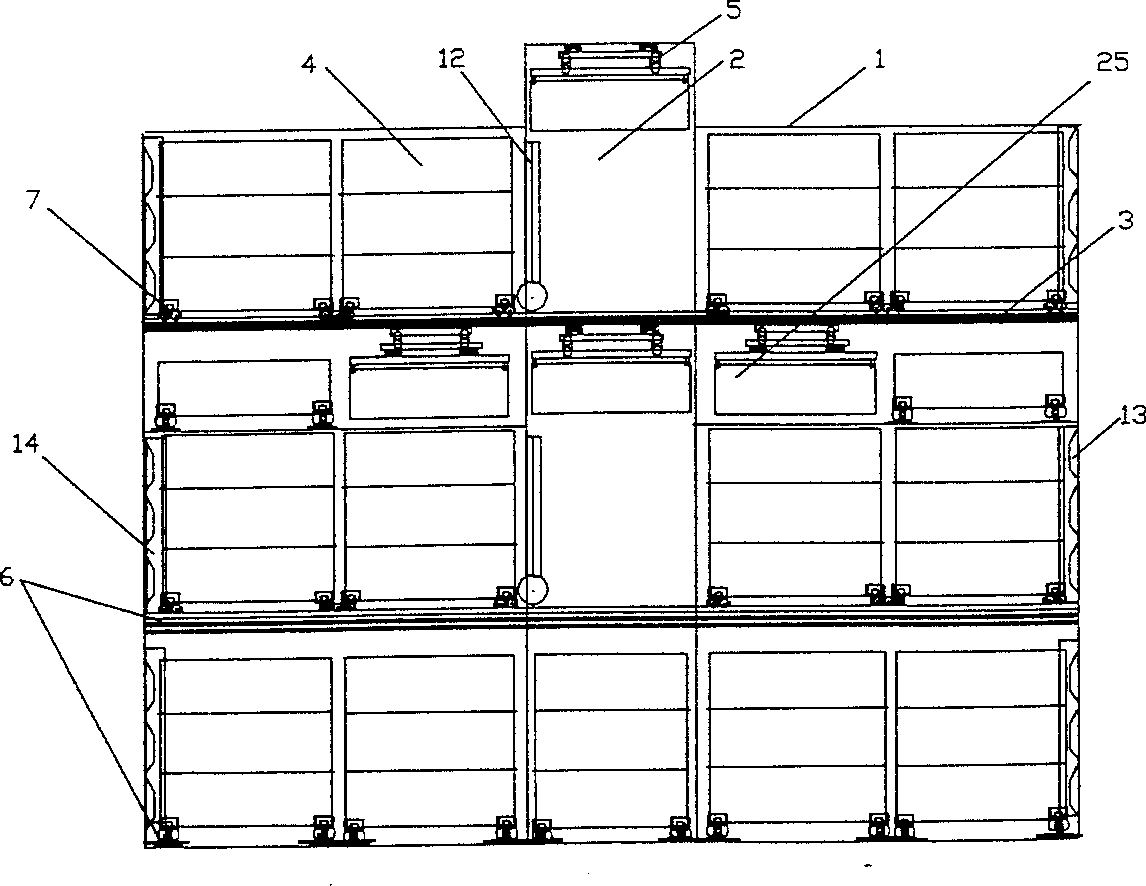

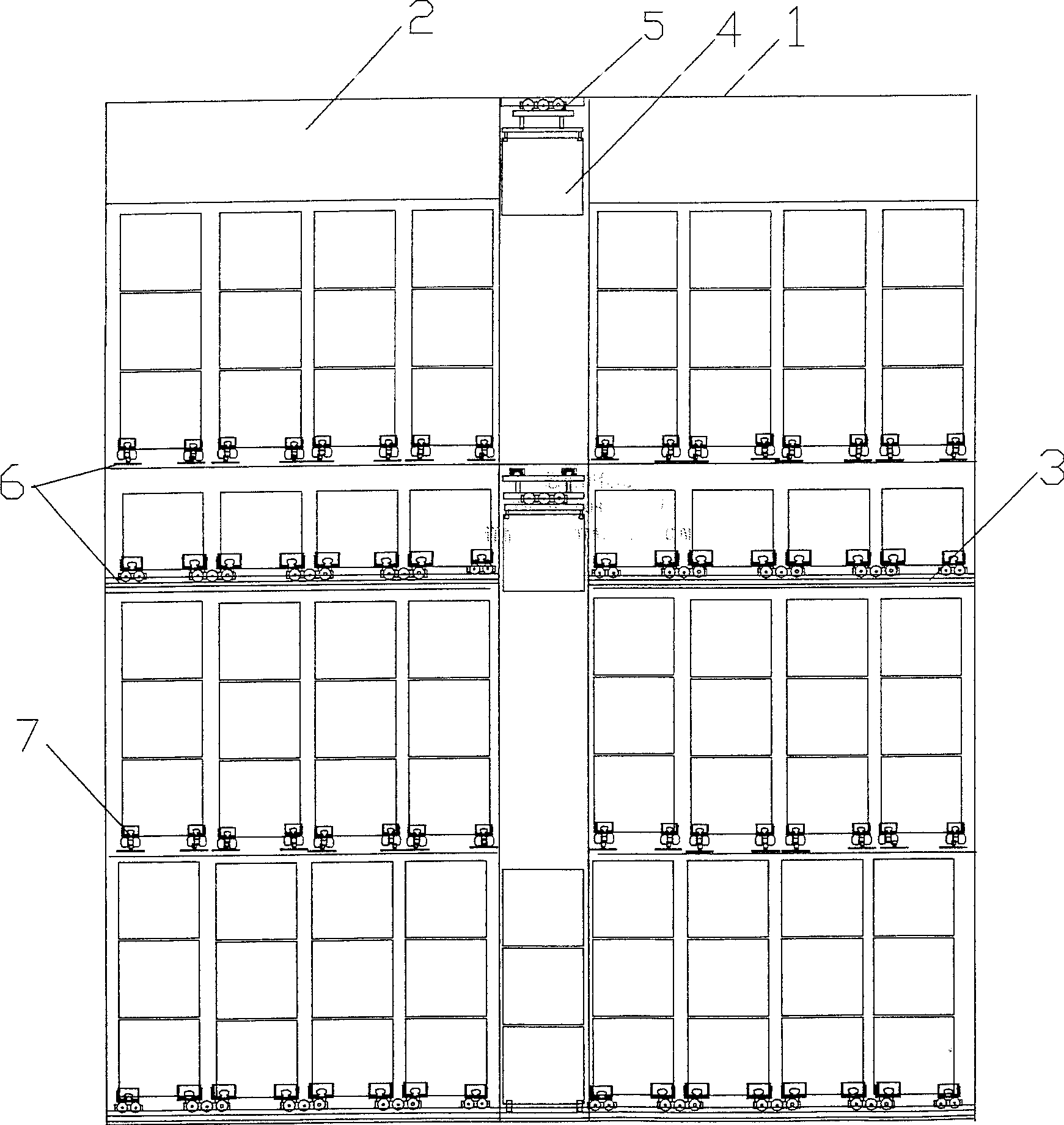

[0111] Example 1: Application of container automatic storage, transportation, and loading and unloading facilities on port terminals

[0112] Container automated storage, transportation, loading and unloading facilities can be applied to port terminals in the following ways:

[0113] 1. Establish container automated storage on top of existing docks

[0114] Compared with the current non-warehousing automated container terminal, the establishment of an automated container storage warehouse on the existing terminal has the advantages of saving land, high efficiency, and low investment. If it is used in conjunction with automatic loading and unloading container ships, its superiority will be greatly improved.

[0115] 2. Build automated container storage and loading and unloading terminals in appropriate waters near the port

[0116] Build an automated container storage and loading and unloading terminal in a suitable water area close to the port. The structural components of t...

Embodiment 2

[0119] Example 2: Application of Container Automated Storage, Transportation, and Loading and Unloading Facilities in Inland Enterprises

[0120] In inland enterprises with very tight land resources and a certain scale of containers, the technology of the present invention can be used to establish automatic storage, loading and unloading container warehouses, and improve efficiency and management level.

Embodiment 3

[0121] Embodiment 3: Application of container automation storage, transportation, loading and unloading facilities in military affairs

[0122] At present, my country's military logistics has built more than 300 automated three-dimensional warehouses, but container automated three-dimensional warehouses are still blank. The present invention will promote the application of container automatic storage, transportation, and loading and unloading facilities in the military, and improve the military logistics support level of our army.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com