Steel coil identifying and positioning method based on laser technology

A technology of identification and positioning, laser technology, applied in the field of image processing, to achieve the effect of convenient remote monitoring, reliable and stable work, and reduced steel coil loading and unloading and transportation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

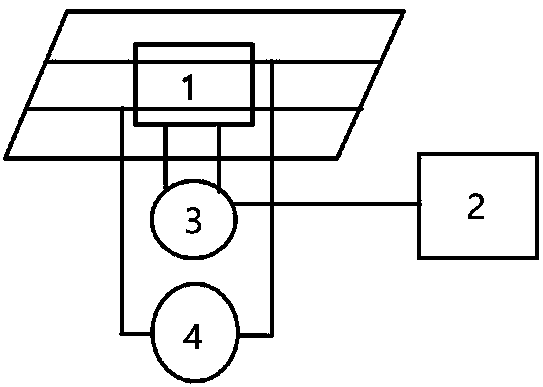

[0021] Embodiment one: see Figure 1 ~ Figure 2 , the steel coil identification and positioning method based on laser technology, the identification and positioning equipment used includes a laser scanner, a laser traction trolley, a calibration device and a computer, and the specific operation steps are as follows:

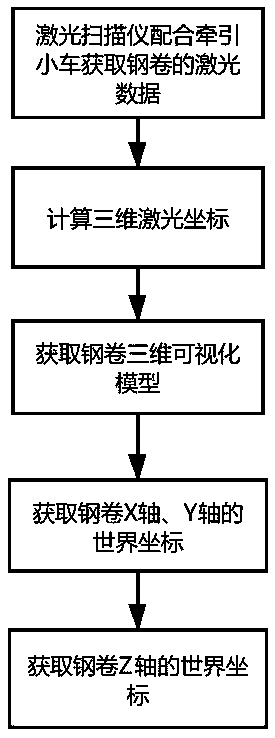

[0022] (1) Use a linear laser scanner to cooperate with the traction trolley to obtain the laser data for steel coil identification and the position value of the trolley;

[0023] (2) Synchronize the laser data and position value, and calculate the three-dimensional space coordinates of the measurement point;

[0024] (3) After using regular grid DEM to process 3D discrete data, use Direct3D to obtain the 3D visualization model of steel coil;

[0025] (4) Obtain the world coordinates of the steel coil on the X-axis and Y-axis by using the contour tracking algorithm and the minimum circumscribed rectangle algorithm;

[0026] (5) Use the projected image to fuse a...

Embodiment 2

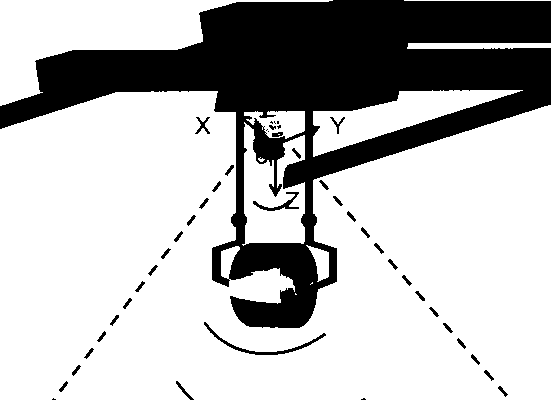

[0027] Embodiment 2: This embodiment is basically the same as Embodiment 1, and the special features are as follows: In the step (1), the linear laser scanner performs regular rotational motion under the traction of the forward motion of the trolley, thereby realizing the scanning of the steel For the complete measurement of the roll surface, the trolley is installed on the I-shaped track of the vehicle, and the laser scanner is installed on the lower end surface of the trolley, where a world coordinate system with the center of the laser scanning surface as the origin is established {O 1}. In described step (2), utilize multi-thread technology to carry out the synchronous analysis and storage of laser scanner and laser dolly position, any point data of laser measurement can use polar coordinates (S i , θ i ) to represent; in {O 1} The vector of any measurement point in the coordinate system can be expressed as:

[0028]

[0029] S in the above formula i is the distance...

Embodiment 3

[0030] Embodiment three: as figure 1 As shown, the steel coil identification and positioning method based on laser technology adopts equipment including laser scanner, laser traction trolley, calibration device and computer;

[0031] The present invention collects the three-dimensional space coordinates of the measuring point through the synchronous movement of the laser scanner and the traction trolley, uses the regular grid DEM to process the three-dimensional discrete data, uses Direct3D to draw and render the three-dimensional model, and further uses the image processing technology to obtain the outer surface of the steel coil. Contour, and then calculate the X, Y axis coordinates of the steel coil, and use the projected image to fuse and superimpose the image to perform circle feature fitting, so as to obtain the coordinates of the steel coil on the Z axis, so as to realize the intelligent identification and positioning of the steel coil , including the following steps: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com