Control system of aeroengine mounting vehicle

An aero-engine and control system technology, applied in aircraft assembly, comprehensive factory control, etc., can solve the problems of poor maneuverability, low degree of automation, and high cost of engine loading and unloading, so as to simplify loading and unloading procedures, improve maneuverability and The effect of degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

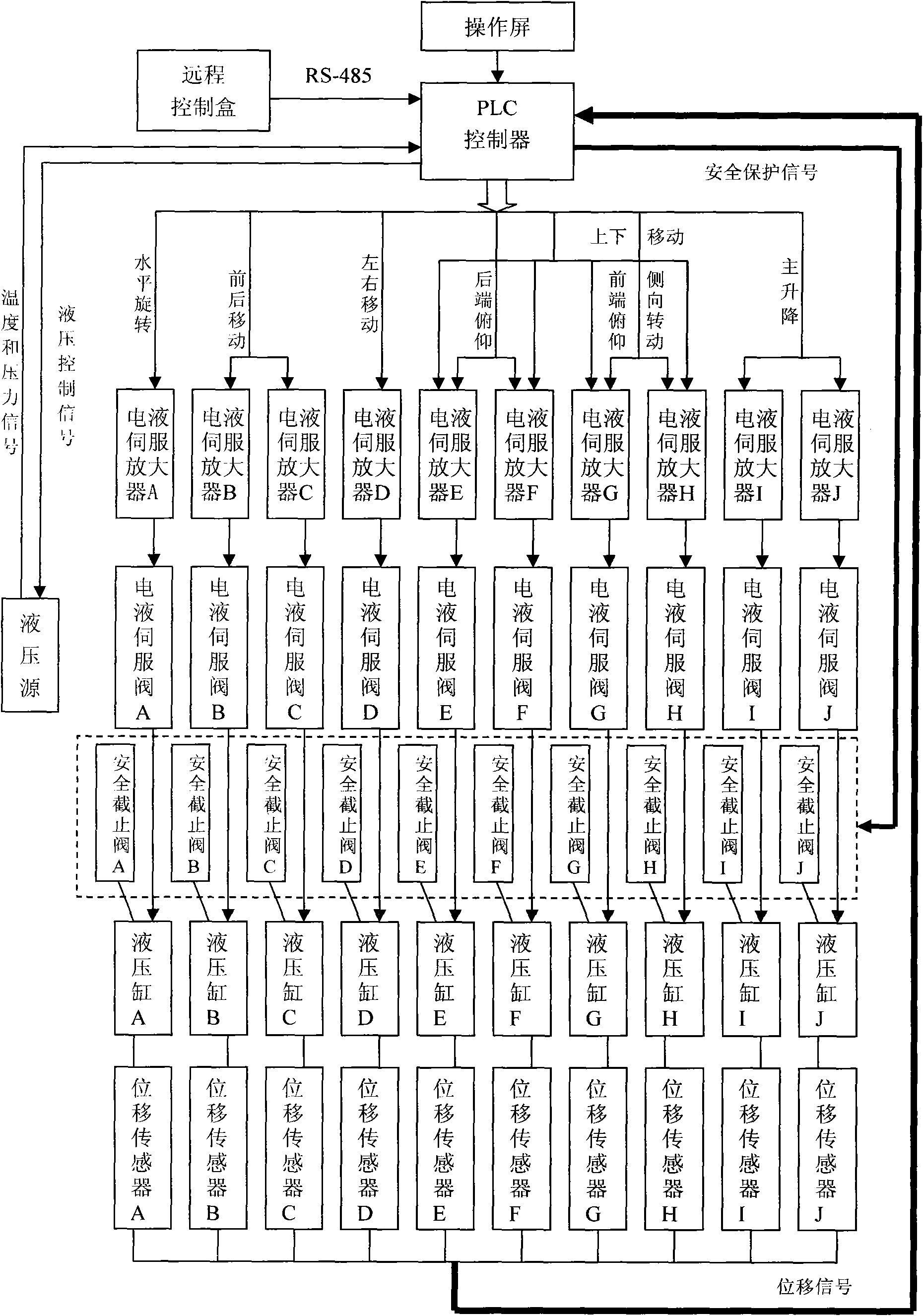

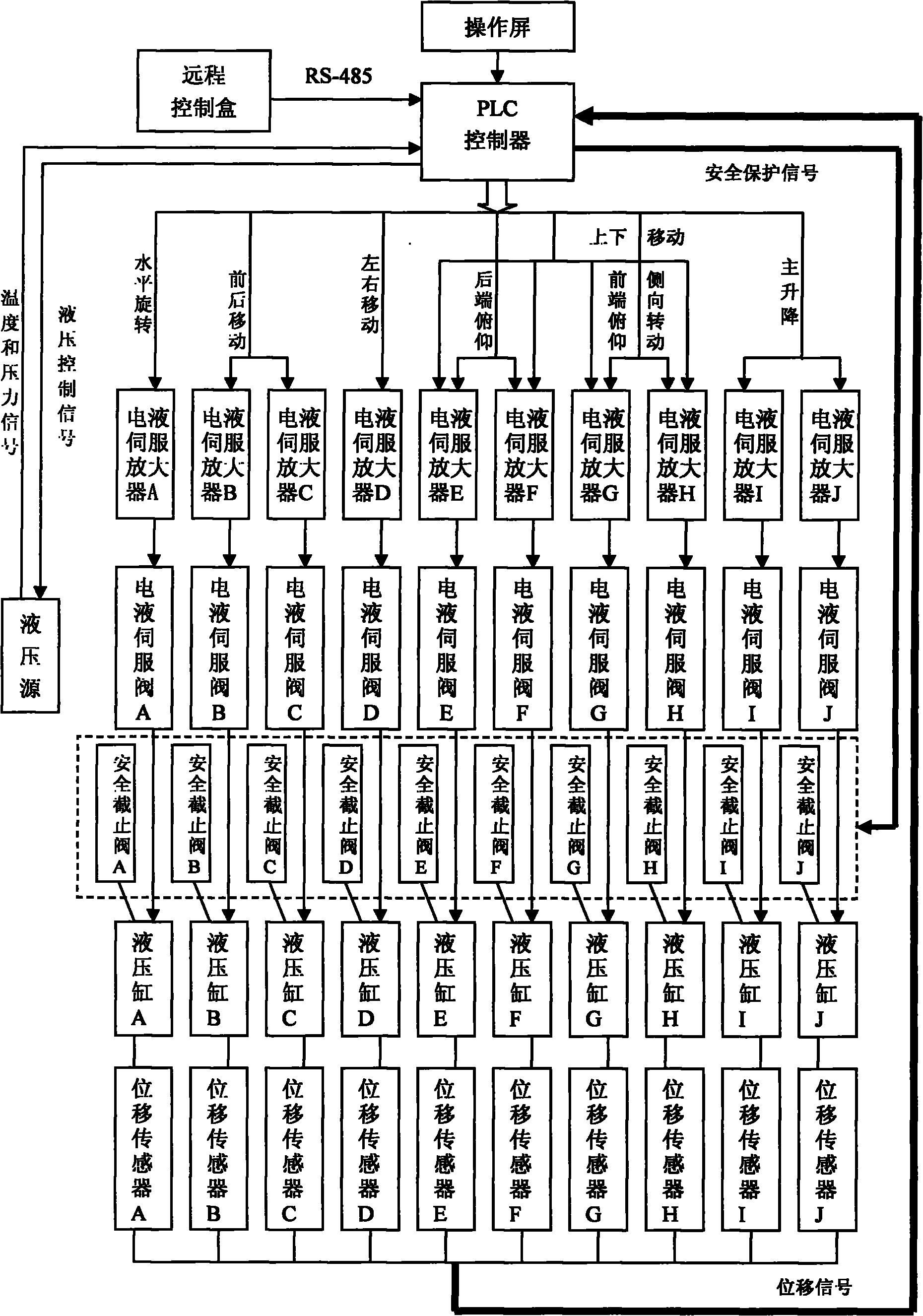

[0017] Below in conjunction with accompanying drawing, technical scheme of the present invention is described further: figure 1 , the control system of the aero-engine installation vehicle, which includes a PLC controller, an operation panel, an electro-hydraulic servo amplifier group, a hydraulic system and a built-in displacement sensor group, wherein the hydraulic system includes an electro-hydraulic servo valve group, a hydraulic source, a pipeline system and The hydraulic cylinder group and the electro-hydraulic servo valve group are set in the pipeline system connecting the hydraulic source and the hydraulic cylinder group. The operation panel is connected to the PLC controller through the bus. The control signal output by the PLC controller is amplified by the electro-hydraulic servo amplifier group and then communicated with the The electro-hydraulic servo valve group is connected, and the output of the built-in displacement sensor group is connected with the PLC contro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com