Movable loading and unloading machine with deflecting conveying function

A conveyor and loader technology, applied in conveyors, loading/unloading, transportation and packaging, etc., can solve the problem of inability to complete mobile turning transportation, etc., to reduce manual assistance time, improve the working environment, and shorten the working cycle. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

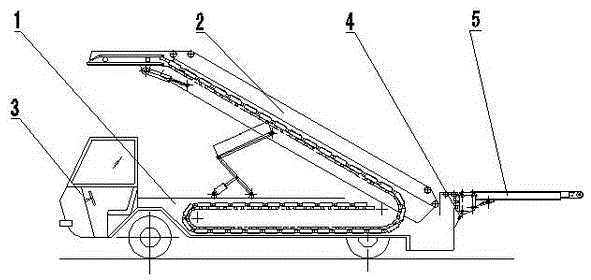

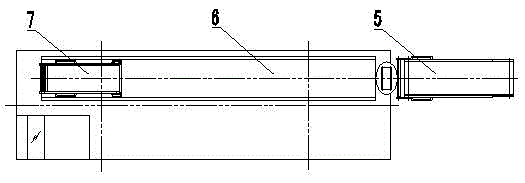

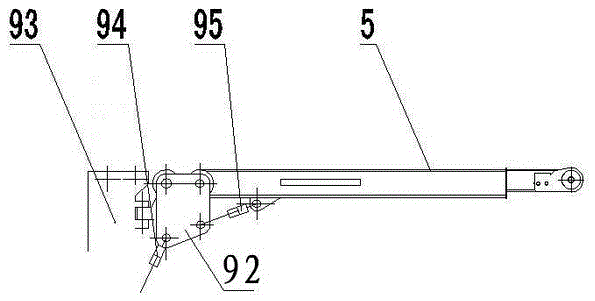

[0031] Such as figure 1 , figure 2As shown, the present invention is made up of vehicle chassis 1, conveying device 2, electric control system 3, hydraulic system 4, conveying device 2 is placed on vehicle chassis 1; The conveyor consists of 7 components. Integrating machinery, electricity, and hydraulic pressure as a whole, using its own diesel engine as power (or external power supply), through mechanical transmission, electrical and hydraulic control technology, it controls the electronic control system 3 and hydraulic system 4 to realize the driving and loading and unloading operations of the whole machine:

[0032] (a) Drive the vehicle chassis 1 to travel, turn, and brake. The vehicle chassis 1 of the present invention must also meet the installation requirements of the components of the conveying device 2 . The vehicle chassis 1 can be a general-purpose vehicle chassis or a self-made vehicle chassis, has the functions of walking, steering and braking, can undertake t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com