Recyclable motorcycle engine transportation bracket

An engine and motorcycle technology, which is applied in the field of recyclable motorcycle engine transport brackets, can solve the problems of high loading and unloading costs, difficult to distinguish engines, and high packaging costs, so as to reduce transportation costs, ensure reliability, and improve reliability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

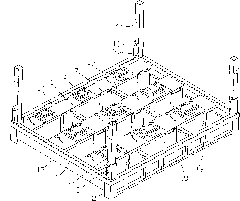

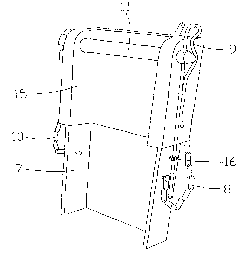

[0035] like figure 1 , image 3 As shown, the frame 1 is a rectangle and is welded by four parallel frame bars. A base column 2 is respectively arranged under the four corners of the frame 1 , the base column 2 is a rectangular tube, the top of the base column 2 is welded to the frame 1 , and the four base columns 2 support the frame 1 together. Below the short frame strips of the frame 1 is provided with a connecting plate 17 parallel to it, the end of the connecting plate 17 is welded and fixed to the corresponding bottom column 2, and the bottom edge of the connecting plate 17 is connected to the bottom surface of the bottom column 2 have a certain distance between them. A connecting beam 18 parallel to it is arranged below the long frame strip of the frame 1 , and the end of the connecting beam 18 is welded and fixed to the corresponding bottom column ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com