Soft abrasive flow field testing method based on level set

A test method and level set technology, applied in the field of abrasive flow processing, can solve the problems of low calculation accuracy of the soft abrasive flow field and the inability to accurately obtain the best processing state.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention will be further described below in conjunction with the accompanying drawings.

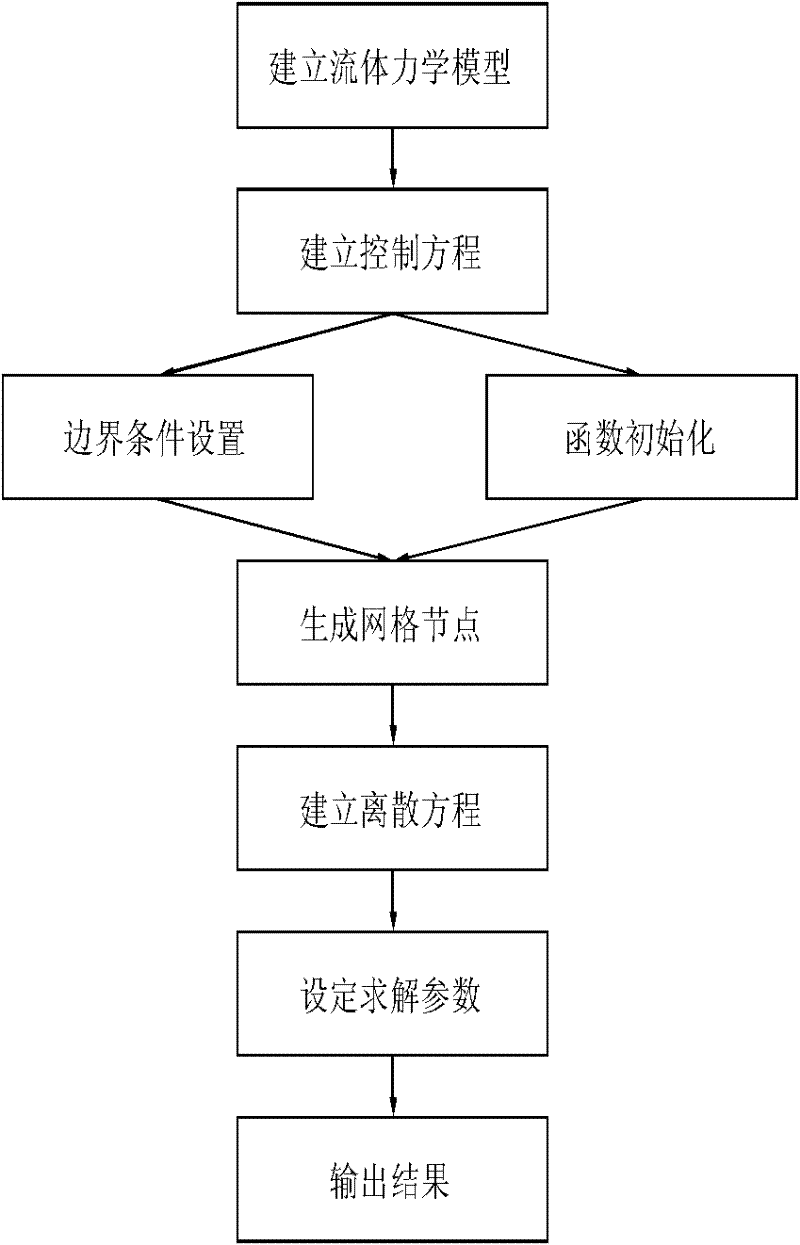

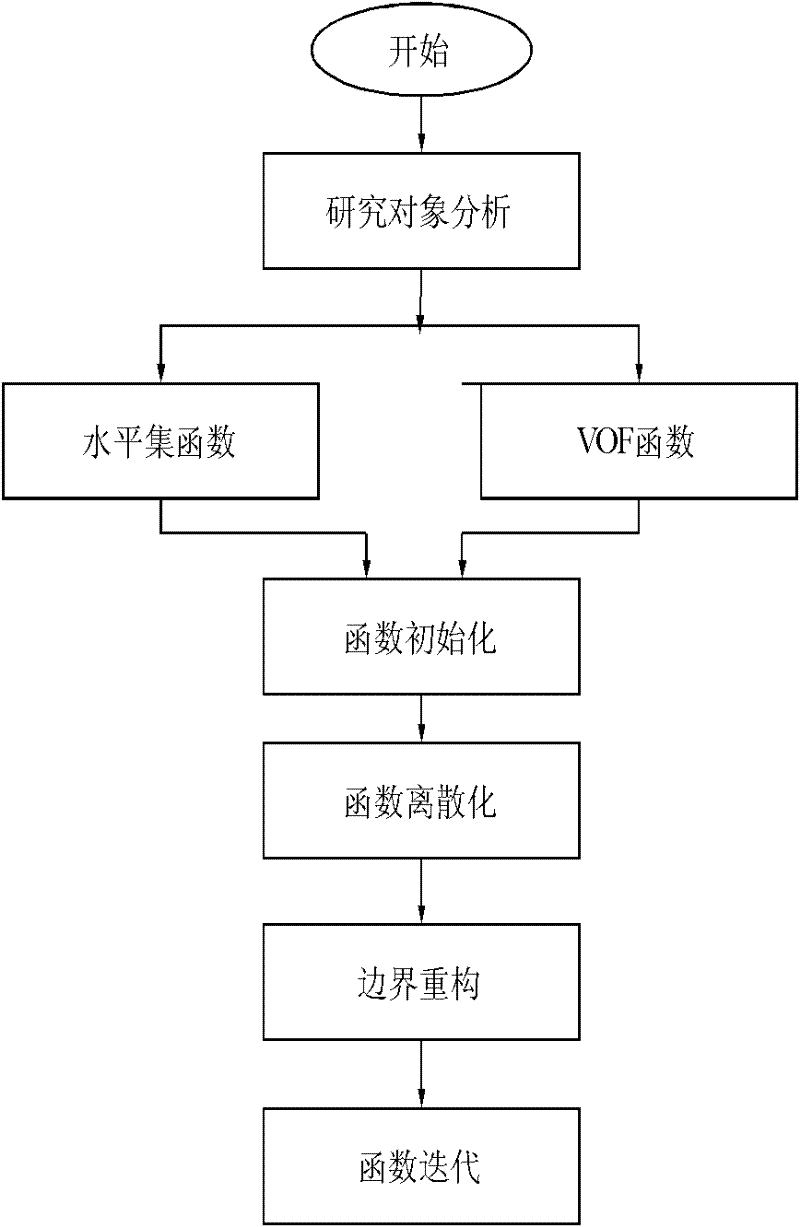

[0048] refer to Figure 1 to Figure 5 , a soft abrasive flow field test method based on level set, the test method comprises the following steps:

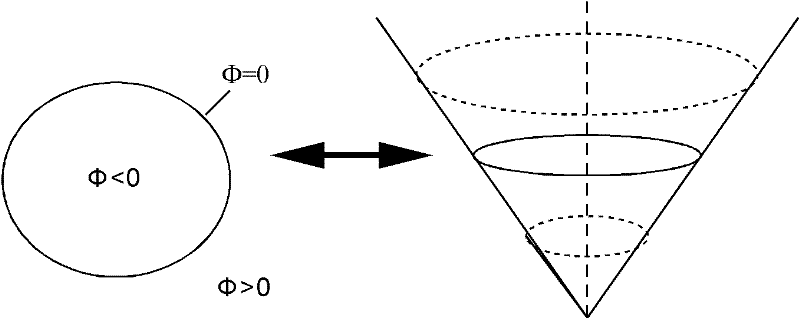

[0049] 1) By combining with the fluid Navier-Stokes equation, the motion equation of the level set function of the soft abrasive flow is established;

[0050] 2) Discretization and projection of the space: replace the original continuous space with a set of finite discrete points, and at the same time convert the divergence into a divergence-free quantity through projection;

[0051] 3) discretize the time;

[0052] 4) The combination of level set function and VOF function is iterated;

[0053] 5) Reconstruction of the distance function: Reconstruction is to construct the distribution of the original function with a certain precision under the condition of known function segment average value. Due to the internal effect ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com