Radial ultrasonic honing device

A honing processing and ultrasonic technology, applied in the field of radial ultrasonic honing processing devices, can solve the problems of difficulty in obtaining high power and high energy, affecting the oil storage and lubrication performance of the workpiece, and the asynchronous operation of the transducer, so as to avoid the problems of the transducer The effect of asynchronous work, ingenious design and low processing requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

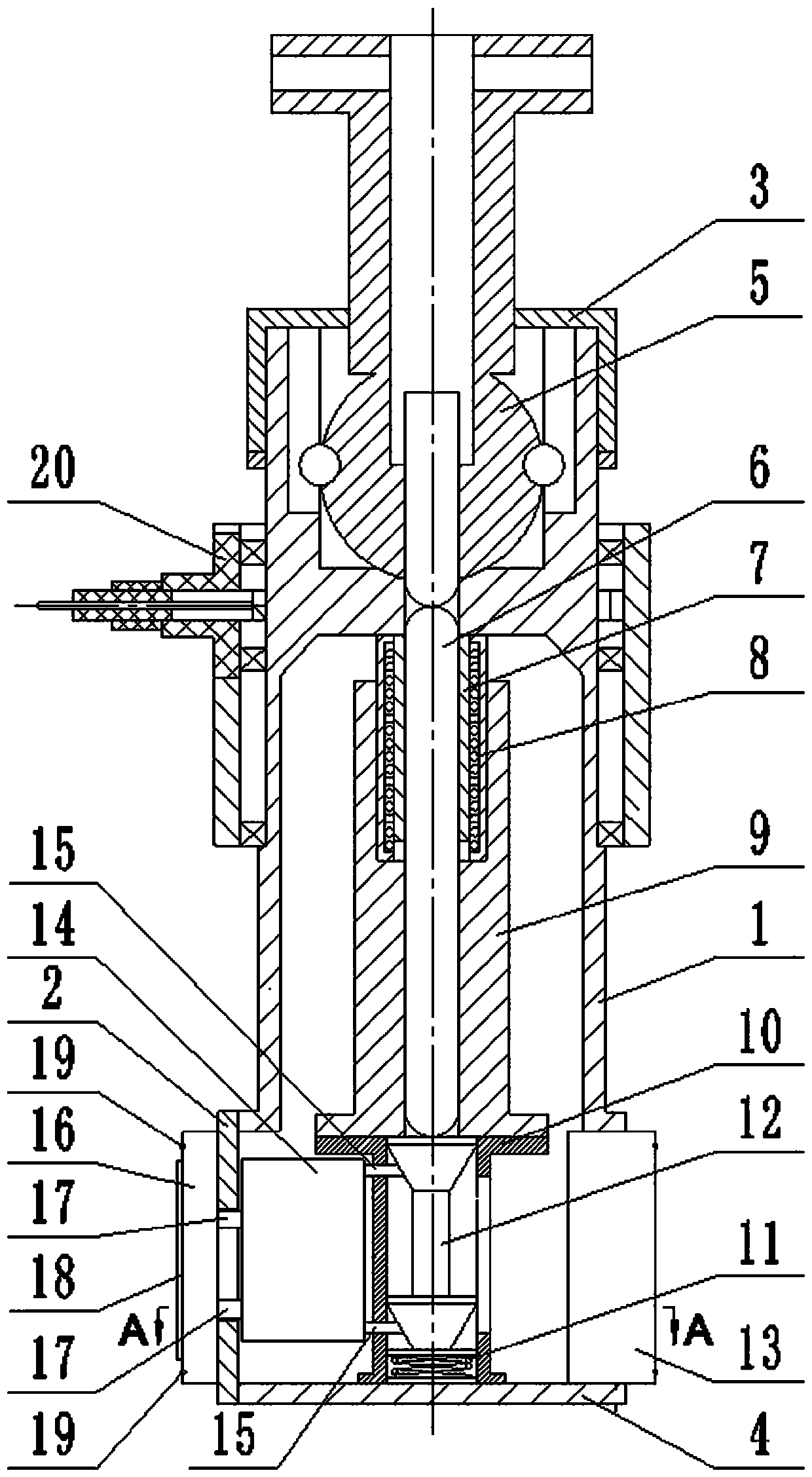

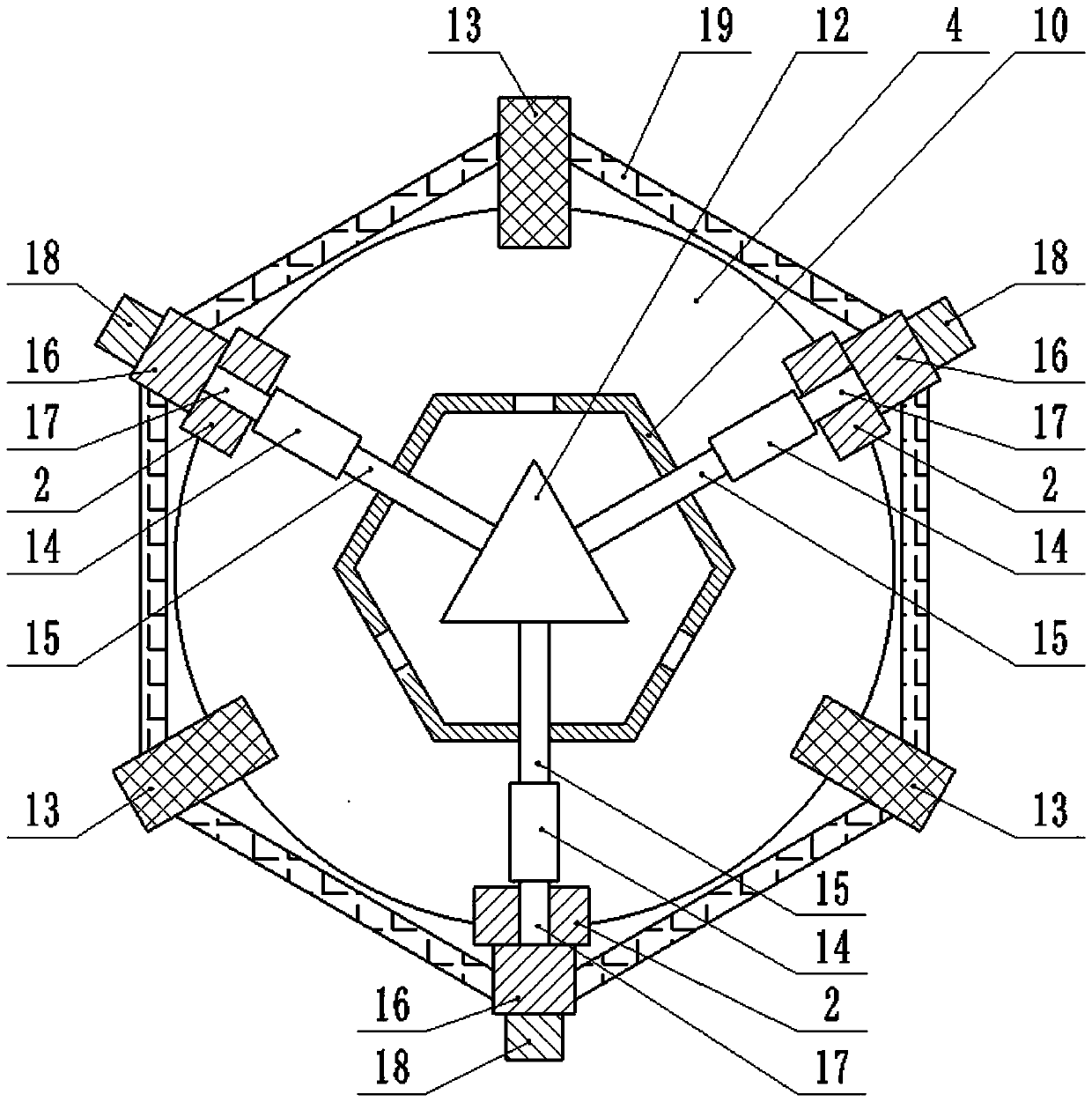

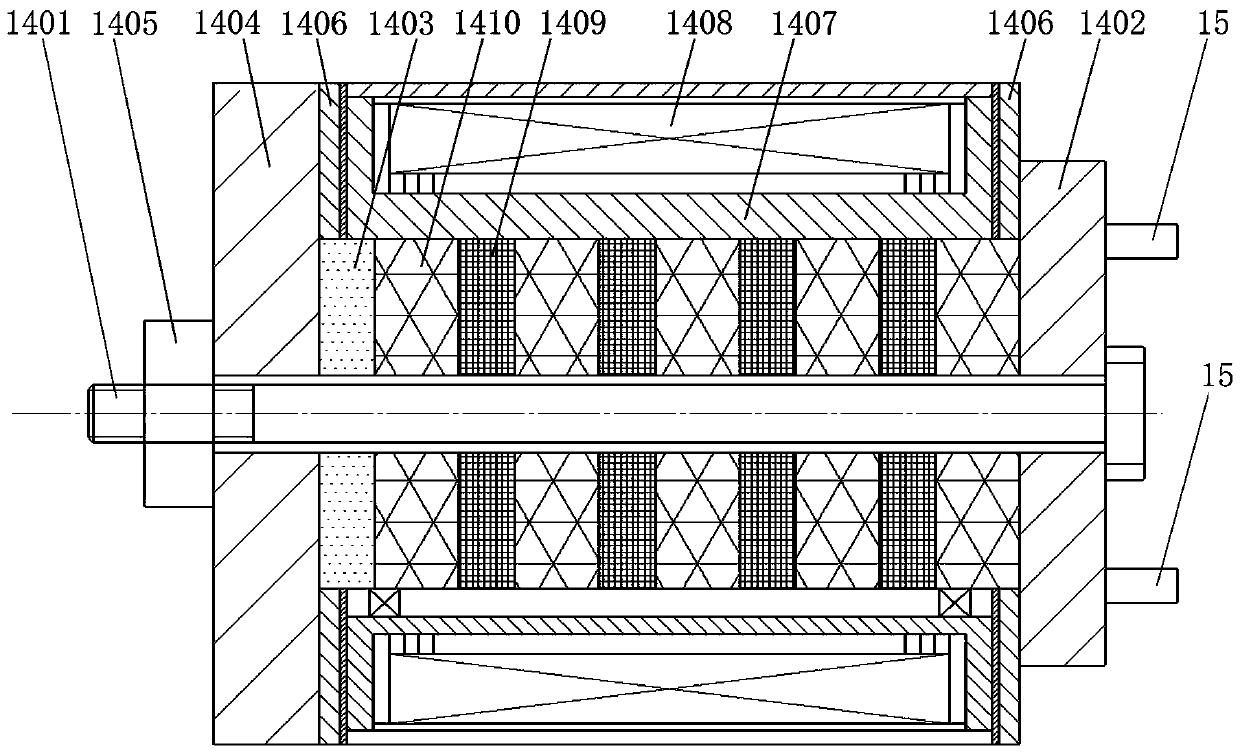

[0034] Radial ultrasonic honing processing device, including outer cylinder 1, support rod 2, upper cover 3, lower cover 4, floating mechanism 5, ejector rod 6, limit cylinder 7, linear bearing 8, inner cylinder 9, support cylinder 10, reset Spring 11, expansion mandrel 12, guide bar 13, rare earth giant magnetostrictive transducer 14, inner pin rod 15, oil stone seat 16, outer pin rod 17, oil stone 18, ring spring 19, collector ring 20;

[0035] Wherein, the inner cavity of the outer cylinder 1 is provided with a partition, and the partition divides the inner cavity of the outer cylinder 1 into an upper chamber and a lower chamber; the center of the partition is provided with a through hole;

[0036] The number of support rods 2 is N; the upper ends of the N support rods 2 are fixed to the open edge of the lower end of the outer cylinder 1, and the N support rods 2 are arranged equidistantly around the axis of the outer cylinder 1; each support rod 2 A pair of pin holes are ope...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com