Automatic numerical control lathe tailstock control method

A numerical control lathe tailstock and numerically controlled lathe technology are applied in the field of numerically controlled lathes, which can solve the problems that the tailstock of numerically controlled machine tools cannot be automatically fed, the depth of drilling holes cannot be guaranteed, and the processing efficiency is low, so as to improve flexibility and control drilling. Hole depth, the effect of improving the degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

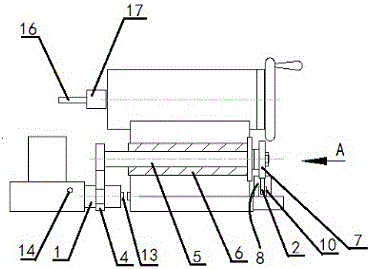

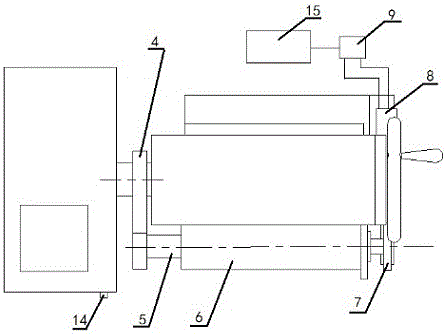

[0020] An automatic control method for a tailstock of a CNC lathe, which uses a cylinder to realize the automatic engagement and disengagement of a saddle and a tailstock of a CNC lathe, and includes a connecting column 1, a rotating arm assembly, a driving assembly and a drill assembly. The middle part of the connecting column 1 is provided with a ring groove 3, the connecting column 1 is fixedly connected with the saddle of the CNC lathe, and a pair of sensors 13 are arranged on the shaft end of the connecting column 1 and the side of the tailstock, and the sensors can be magnetic effect sensors or Hall effect sensors. The sensor can also be a photoelectric sensor.

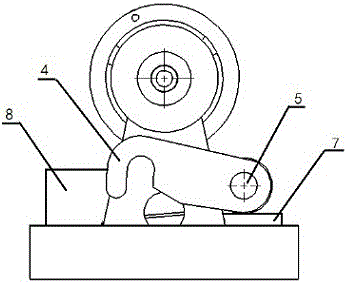

[0021] Described rotating arm assembly comprises rotating arm 4, rotating shaft 5, axle sleeve 6 and bull gear 7, and described axle sleeve 6 is fixed on the front side of CNC lathe tailstock, and described rotating shaft 5 passes through axle sleeve 6, and rotates The front end of the shaft 5 is fixedly connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com